SIST EN 15079:2015

(Main)Copper and copper alloys - Analysis by spark source optical emission spectrometry (S-OES)

Copper and copper alloys - Analysis by spark source optical emission spectrometry (S-OES)

This European Standard specifies a routine method for the analysis of copper and copper alloys by spark source optical emission spectrometry (S-OES). The method is applicable to all elements except copper commonly present in copper and copper alloys present as impurities or minor or main constituents, and detectable by S-OES.

Kupfer und Kupferlegierungen - Analyse durch optische Emissionsspektrometrie mit Funkenanregung (F-OES)

Diese Europäische Norm legt ein Routineverfahren für die Analyse von Kupfer und Kupferlegierungen mit optischer Emissionsspektrometrie mit Funkenanregung (F OES) fest. Das Verfahren ist anwendbar auf alle Elemente mit Ausnahme von Kupfer, welche als Verunreinigungen oder Neben oder Hauptbestandteile in Kupfer oder Kupferlegierungen vorliegen und die mit F OES bestimmbar sind.

Cuivre et alliages de cuivre - Analyse par spectrométrie d'émission optique à étincelles (SEO-E)

La présente Norme européenne spécifie une méthode de routine pour l’analyse du cuivre et des alliages de cuivre par spectrométrie d’émission optique à étincelles (SEO-E). Cette méthode s'applique à tous les éléments généralement présents dans le cuivre et les alliages de cuivre, à l'exception du cuivre lui-même, tels que les impuretés ou les constituants mineurs ou principaux, pouvant être déterminés par SEO-E.

Baker in bakrove zlitine - Analiza z optično emisijsko spektrometrijo, inducirano z iskrenjem (S-OES)

Ta evropski standard določa rutinsko metodo za analizo bakra in bakrovih zlitin z optično emisijsko spektrometrijo, inducirano z iskrenjem (S-OES). Ta metoda se uporablja za vse elemente, razen za baker, ki je običajno prisoten v bakru in bakrovih zlitinah, ki so prisotni kot nečistoče ali manj ali bolj pomembne sestavine, pri čemer se jih zazna s S-OES.

General Information

- Status

- Published

- Public Enquiry End Date

- 08-Feb-2015

- Publication Date

- 09-Aug-2015

- Technical Committee

- INEK - Nonferrous metals

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 10-Jul-2015

- Due Date

- 14-Sep-2015

- Completion Date

- 10-Aug-2015

Relations

- Effective Date

- 01-Sep-2015

Overview

EN 15079:2015 - "Copper and copper alloys - Analysis by spark optical emission spectrometry (S-OES)" is a CEN European standard that defines a routine analytical method for the chemical analysis of copper and copper alloys using spark source optical emission spectrometry (S-OES). Published in May 2015, it updates and supersedes EN 15079:2007 and provides requirements for reliable, repeatable S-OES testing and reporting for elements commonly found in copper alloys.

Key Topics

- Principle: Measurement of element-specific optical emission produced by a spark discharge; element concentrations derived from calibration curves using reference materials.

- Apparatus: Requirements for an S-OES spectrometer with spark source and suitable sample-surface preparation equipment (turning, milling, grinding).

- Sampling & Surface Preparation: Sampling per ISO 1811 series; prepared surfaces must be flat, clean and free from defects or contamination; consistent preparation methods to avoid bias.

- Calibration & Recalibration:

- Use of certified reference materials (CRMs) or well-characterized reference materials with matching matrix.

- Calibration ranges must cover expected alloy compositions and extend below the minimum reporting limits (≥ 3× detection limit).

- Procedures for drift compensation (selective or global recalibration) and type recalibration for matrix effects.

- Analysis Procedures:

- Minimum number of sparks per calibration sample (≥ four acceptable sparks) and cooling between sparks to avoid heating bias.

- Analytical programs: intensity-based for trace analysis or ratioed/internal-standard approaches (normal and virtual modes) for matrix variance.

- Instrument status checks, drift control, and use of quality-control samples.

- Results & Documentation: Expression of results, precision statements, and required test report elements. Informative annexes provide typical wavelengths, calibration ranges, detection limits and background equivalent concentrations for copper alloys.

Applications

EN 15079:2015 is designed for routine laboratory and production use where fast, accurate elemental analysis of copper alloys is required:

- Incoming material inspection and alloy verification in manufacturing (brass, bronze, etc.)

- Quality control (QA/QC) and process control using statistical process control (SPC)

- Failure analysis, metallurgical testing and research labs

- Calibration and validation of S-OES instruments by instrument manufacturers and accredited testing laboratories

Who Should Use It

- Metallurgical and materials testing laboratories

- Quality managers and production engineers in copper-alloy manufacturing

- Instrument vendors and calibration service providers

- Certification bodies and conformity assessment organizations

Related Standards

- ISO 1811-1 - Sampling of cast unwrought products for chemical analysis

- ISO 1811-2 - Sampling of wrought products and castings for chemical analysis

- EN 15079:2007 - superseded by EN 15079:2015

Keywords: EN 15079:2015, spark optical emission spectrometry, S‑OES, copper alloys analysis, calibration, reference materials, sample preparation, drift control, chemical analysis.

Frequently Asked Questions

SIST EN 15079:2015 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Copper and copper alloys - Analysis by spark source optical emission spectrometry (S-OES)". This standard covers: This European Standard specifies a routine method for the analysis of copper and copper alloys by spark source optical emission spectrometry (S-OES). The method is applicable to all elements except copper commonly present in copper and copper alloys present as impurities or minor or main constituents, and detectable by S-OES.

This European Standard specifies a routine method for the analysis of copper and copper alloys by spark source optical emission spectrometry (S-OES). The method is applicable to all elements except copper commonly present in copper and copper alloys present as impurities or minor or main constituents, and detectable by S-OES.

SIST EN 15079:2015 is classified under the following ICS (International Classification for Standards) categories: 77.040.30 - Chemical analysis of metals; 77.120.30 - Copper and copper alloys. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 15079:2015 has the following relationships with other standards: It is inter standard links to SIST EN 15079:2007. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

You can purchase SIST EN 15079:2015 directly from iTeh Standards. The document is available in PDF format and is delivered instantly after payment. Add the standard to your cart and complete the secure checkout process. iTeh Standards is an authorized distributor of SIST standards.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Kupfer und Kupferlegierungen - Analyse durch optische Emissionsspektrometrie mit Funkenanregung (F-OES)Cuivre et alliages de cuivre - Analyse par spectrométrie d'émission optique à étincelles (SEO-E)Copper and copper alloys - Analysis by spark source optical emission spectrometry (S-OES)77.120.30Baker in bakrove zlitineCopper and copper alloys77.040.30Kemijska analiza kovinChemical analysis of metalsICS:Ta slovenski standard je istoveten z:EN 15079:2015SIST EN 15079:2015en,fr,de01-september-2015SIST EN 15079:2015SLOVENSKI

STANDARDSIST EN 15079:20071DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 15079

May 2015 ICS 77.040.30; 77.120.30 Supersedes EN 15079:2007English Version

Copper and copper alloys - Analysis by spark optical emission spectrometry (S-OES)

Cuivre et alliages de cuivre - Analyse par spectrométrie d'émission optique à étincelles (SEO-E)

Kupfer und Kupferlegierungen - Analyse durch optische Emissionsspektrometrie mit Funkenanregung (F-OES) This European Standard was approved by CEN on 24 April 2015.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2015 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 15079:2015 ESIST EN 15079:2015

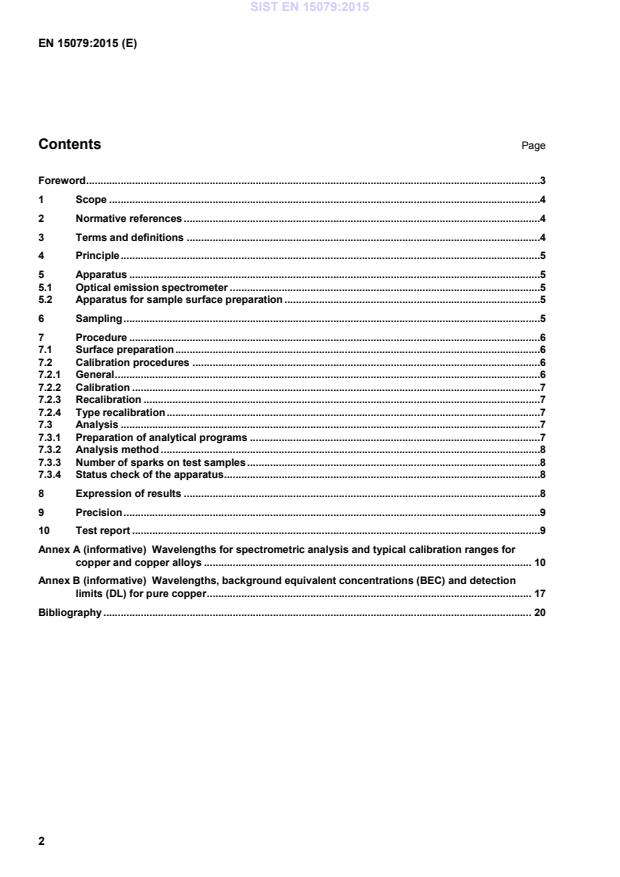

Wavelengths for spectrometric analysis and typical calibration ranges for copper and copper alloys . 10 Annex B (informative)

Wavelengths, background equivalent concentrations (BEC) and detection limits (DL) for pure copper . 17 Bibliography . 20

3 Foreword This document (EN 15079:2015) has been prepared by Technical Committee CEN/TC 133 “Copper and cop-per alloys”, the secretariat of which is held by DIN. This European Standard shall be given the status of a national standard, either by publication of an identical text or by endorsement, at the latest by November 2015, and conflicting national standards shall be withdrawn at the latest by November 2015. Attention is drawn to the possibility that some of the elements of this document may be the subject of patent rights. CEN [and/or CENELEC] shall not be held responsible for identifying any or all such patent rights. This document supersedes EN 15079:2007. Within its programme of work, Technical Committee CEN/TC 133 requested CEN/TC 133/WG 10 "Methods of analysis" to revise this standard: EN 15079:2007, Copper and copper alloys — Analysis by spark source optical emission spectrometry (S-OES). In comparison with EN 15079:2007, the following changes were made: a) Definitions 3.1 to 3.5 have been improved; b) 7.2.2 Calibration has been modified. According to the CEN/CENELEC Internal Regulations, the national standards organisations of the following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the United Kingdom. SIST EN 15079:2015

5 3.5 recalibration samples samples at both low and high points of the calibration ranges used to recalibrate the spectrometer Note 1 to entry: These samples are measured during the calibration procedure and the intensities obtained are stored in the computer according to the manufacturer's instructions. Note 2 to entry: No chemical analyses are necessary, but the homogeneity of these samples should be carefully eval-uated. 3.6 quality control sample sample with known composition which is analysed in the same way as the test sample to check the trueness of the analytical results 4 Principle Measurement of the intensity of the radiation, whose wavelength is characteristic of each element, generated by a spark resulting from the application of an electrical discharge between the sample, as one electrode, and an inert counter-electrode. Concentrations of elements are determined by relating the measured intensities of test samples to calibration curves prepared from reference materials. 5 Apparatus 5.1 Optical emission spectrometer Spectrometer with spark source capable of measuring the intensities of the optical radiation emitted at specific wavelengths by the elements present in the material. The wavelengths generally used are given in Annex A. 5.2 Apparatus for sample surface preparation The most common surface preparation techniques for copper and copper alloys are turning and milling or grinding for copper, provided that the composition of the surface shall not be influenced. The lathe, milling machine or any other machines used for surface preparation shall be able to produce a surface that conforms to the requirements of 7.1. WARNING — The appropriate safety recommendations for the use of mechanical apparatus shall be observed. These operations shall be carried out only by properly trained personnel wearing appropriate personal protective equipment. 6 Sampling Sampling shall be carried out in accordance with ISO 1811-1 or ISO 1811-2, as appropriate. The sample needs to be sufficiently homogeneous with regard to the spark impact. The measuring surface should be free of defects. SIST EN 15079:2015

7 7.2.2 Calibration The calibration of the spectrometer is carried out by using a series of certified reference materials which have the same or at least similar matrix and metallurgical structure as the samples to be analysed, in order to calculate the calibration functions from which the analysis of test samples can be obtained. The content range of the certified reference materials used shall cover that of all the samples to be analysed within each specific analytical program. For each element in ea

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...