ISO/TS 22318:2015

(Main)Societal security — Business continuity management systems — Guidelines for supply chain continuity

Societal security — Business continuity management systems — Guidelines for supply chain continuity

ISO/TS 22318:2015 gives guidance on methods for understanding and extending the principles of BCM embodied in ISO 22301 and ISO 22313 to the management of supplier relationships. This Technical Specification is generic and applicable to all organizations (or parts thereof), regardless of type, size and nature of business. It is applicable to the supply of products and services, both internally and externally. The extent of application of this Technical Specification depends on the organization's operating environment and complexity. Supply chain management considers the full range of activities concerned with the provision of supplies or services to an organization as a part of business-as-usual. The scope of this Technical Specification is less broad in that it specifically considers the issues faced by an organization which needs continuity of supply of products and services to protect its business activities or processes, and the continuity strategies for current suppliers within supply chains, which can be used to mitigate the impact of disruption; this is SCCM. Guidance on developing a business continuity plan or business continuity management system is set out in ISO 22301 and ISO 22313.

Sécurité sociétale — Systèmes de management de la continuité en affaires — Lignes directrices pour la continuité de la chaîne d'approvisionnement

General Information

Relations

Standards Content (Sample)

TECHNICAL ISO/TS

SPECIFICATION 22318

First edition

2015-09-01

Societal security — Business

continuity management systems —

Guidelines for supply chain continuity

Sécurité sociétale — Systèmes de management de la continuité

en affaires — Lignes directrices pour la continuité de la chaîne

d’approvisionnement

Reference number

ISO/TS 22318:2015(E)

©

ISO 2015

---------------------- Page: 1 ----------------------

ISO/TS 22318:2015(E)

COPYRIGHT PROTECTED DOCUMENT

© ISO 2015, Published in Switzerland

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized otherwise in any form

or by any means, electronic or mechanical, including photocopying, or posting on the internet or an intranet, without prior

written permission. Permission can be requested from either ISO at the address below or ISO’s member body in the country of

the requester.

ISO copyright office

Ch. de Blandonnet 8 • CP 401

CH-1214 Vernier, Geneva, Switzerland

Tel. +41 22 749 01 11

Fax +41 22 749 09 47

copyright@iso.org

www.iso.org

ii © ISO 2015 – All rights reserved

---------------------- Page: 2 ----------------------

ISO/TS 22318:2015(E)

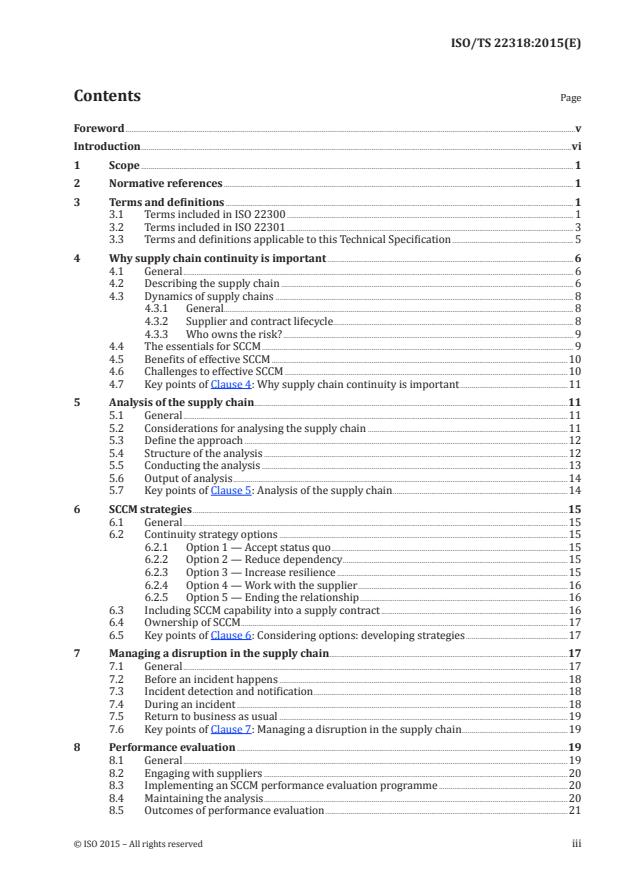

Contents Page

Foreword .v

Introduction .vi

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

3.1 Terms included in ISO 22300 . 1

3.2 Terms included in ISO 22301 . 3

3.3 Terms and definitions applicable to this Technical Specification . 5

4 Why supply chain continuity is important . 6

4.1 General . 6

4.2 Describing the supply chain . 6

4.3 Dynamics of supply chains . 8

4.3.1 General. 8

4.3.2 Supplier and contract lifecycle . . 8

4.3.3 Who owns the risk? . 9

4.4 The essentials for SCCM . 9

4.5 Benefits of effective SCCM .10

4.6 Challenges to effective SCCM .10

4.7 Key points of Clause 4: Why supply chain continuity is important .11

5 Analysis of the supply chain .11

5.1 General .11

5.2 Considerations for analysing the supply chain .11

5.3 Define the approach .12

5.4 Structure of the analysis .12

5.5 Conducting the analysis .13

5.6 Output of analysis .14

5.7 Key points of Clause 5: Analysis of the supply chain .14

6 SCCM strategies .15

6.1 General .15

6.2 Continuity strategy options .15

6.2.1 Option 1 — Accept status quo .15

6.2.2 Option 2 — Reduce dependency .15

6.2.3 Option 3 — Increase resilience .15

6.2.4 Option 4 — Work with the supplier .16

6.2.5 Option 5 — Ending the relationship .16

6.3 Including SCCM capability into a supply contract .16

6.4 Ownership of SCCM .17

6.5 Key points of Clause 6: Considering options: developing strategies .17

7 Managing a disruption in the supply chain .17

7.1 General .17

7.2 Before an incident happens .18

7.3 Incident detection and notification .18

7.4 During an incident .18

7.5 Return to business as usual .19

7.6 Key points of Clause 7: Managing a disruption in the supply chain .19

8 Performance evaluation .19

8.1 General .19

8.2 Engaging with suppliers .20

8.3 Implementing an SCCM performance evaluation programme .20

8.4 Maintaining the analysis .20

8.5 Outcomes of performance evaluation .21

© ISO 2015 – All rights reserved iii

---------------------- Page: 3 ----------------------

ISO/TS 22318:2015(E)

8.6 Key points of Clause 8: Performance management .21

Bibliography .22

iv © ISO 2015 – All rights reserved

---------------------- Page: 4 ----------------------

ISO/TS 22318:2015(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www.iso.org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the meaning of ISO specific terms and expressions related to conformity

assessment, as well as information about ISO’s adherence to the WTO principles in the Technical

Barriers to Trade (TBT) see the following URL: Foreword - Supplementary information

The committee responsible for this document is ISO/TC 292, Security and resilience.

© ISO 2015 – All rights reserved v

---------------------- Page: 5 ----------------------

ISO/TS 22318:2015(E)

Introduction

This Technical Specification expands the business continuity guidance on establishing appropriate

levels of continuity management within an organization’s supply chain given in ISO 22301 and

ISO 22313. It assumes that the organization seeking to establish supply chain continuity management

(SCCM) is aware of the principles of business continuity management and has established, or intends

to implement, a business continuity management system (BCMS) broadly aligned to the established

standards. It also considers the implications to the organization of suppliers of products or services

that do not have adequate continuity arrangements in place.

This Technical Specification will be useful to those who buy, manage or are responsible for a product

or service that is necessary for the organization to produce its own products or services and will assist

them to apply good BCM practice in line with established standards.

Organizations rely on suppliers to deliver products or services on time and to agreed quality or

standards. It is important for an organization, as part of its wider approach to business continuity

management, to recognize the potential impact to its activities of disruption within its supply chain.

Failure by a supplier to deliver on time to an agreed quality and cost, a product or service may trigger

a business disruption event. Conflicting objectives must be managed between reducing supply chain

cost, for example, by reducing cycle times and buffer stock, and managing the supply chain continuity

risk arising from single source and just-in-time supply approaches.

This Technical Specification is relevant to both the supply of products and services from external

suppliers and internal relationships within divisions of the same organization, under any type of

continuing supplier relationship. It also has applicability to single one time sourcing arrangements

where failure to deliver could impact the future of the organization.

Suppliers are classified according to their criticality considering the impact on the organization of a

disruption to the supplied products or services and the “supplier tier”, which defines that supplier’s

relationship with the organization. A Tier 1 supplier has a direct contractual relationship with the

organization, while a Tier 2 supplier provides products and services to a Tier 1 supplier. The same

supply chain continuity considerations apply to relationships between tiers. Tier 1 suppliers would be

responsible for assuring their own supply chain relationships, recognizing that the customer may need

visibility of these relationships both to ensure there is adequate resilience in the supply chain beyond

Tier 1 and to take account of factors such as corporate social responsibility which may require visibility

of further tiers.

The guidance given in this Technical Specification also has relevance to the supplier both so that it

can prepare to meet the business continuity expectations of its customers and also to consider

vulnerabilities which might arise from dependence on a single customer.

This Technical Specification recognizes that suppliers may also comply with the requirements of the

ISO 28000 series of standards for security management within the supply chain. Conformance with

these standards will give organizations further confidence in the resilience of their supply chain and

potentially reduces the risk of disruption when buying goods or services.

The text is aligned with the elements of business continuity management (see Figure 1).

vi © ISO 2015 – All rights reserved

---------------------- Page: 6 ----------------------

ISO/TS 22318:2015(E)

Figure 1 — Elements of business continuity management (BCM) (Source: ISO 22313:2012,

Figure 5)

Table 1 — Elements of business continuity management and relevant Clause in this Technical

Specification

BCMS element ISO/TS 22318 Clause

Operational planning and control Clause 4

Business impact analysis and risk assessment Clause 5

Business continuity strategy Clause 6

Establish and implement business continuity

Clause 7

procedures

Exercising and testing Clause 8

© ISO 2015 – All rights reserved vii

---------------------- Page: 7 ----------------------

TECHNICAL SPECIFICATION ISO/TS 22318:2015(E)

Societal security — Business continuity management

systems — Guidelines for supply chain continuity

1 Scope

This Technical Specification gives guidance on methods for understanding and extending the principles

of BCM embodied in ISO 22301 and ISO 22313 to the management of supplier relationships. This

Technical Specification is generic and applicable to all organizations (or parts thereof), regardless of

type, size and nature of business. It is applicable to the supply of products and services, both internally

and externally. The extent of application of this Technical Specification depends on the organization’s

operating environment and complexity.

Supply chain management considers the full range of activities concerned with the provision of supplies

or services to an organization as a part of business-as-usual. The scope of this Technical Specification

is less broad in that it specifically considers the issues faced by an organization which needs continuity

of supply of products and services to protect its business activities or processes, and the continuity

strategies for current suppliers within supply chains, which can be used to mitigate the impact of

disruption; this is SCCM.

Guidance on developing a business continuity plan or business continuity management system is set

out in ISO 22301 and ISO 22313.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are

indispensable for its application. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any amendments) applies.

ISO 22300, Societal security — Terminology

ISO 22301, Societal security — Business continuity management systems — Requirements

3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 22300, ISO 22301, and the

following apply.

NOTE All terms and definitions contained in ISO 22300 are available on the ISO Online Browsing Platform:

www.iso.org/obp.

3.1 Terms included in ISO 22300

3.1.1

business continuity

capability of the organization to continue delivery of products or services at acceptable predefined

levels following disruptive incident

[SOURCE: ISO 22300:2012, 2.1.10]

3.1.2

business impact analysis

process of analysing activities and the effect that the business disruption might have upon them

[SOURCE: ISO 22300:2012, 2.2.6]

© ISO 2015 – All rights reserved 1

---------------------- Page: 8 ----------------------

ISO/TS 22318:2015(E)

3.1.3

event

occurrence or change of a particular set of circumstances

Note 1 to entry: An event can be one or more occurrences and can have several causes.

Note 2 to entry: An event can consist of something not happening.

Note 3 to entry: An event can sometimes be referred to as an “incident” or “accident”.

Note 4 to entry: An event without consequences can also be referred to as a “near miss”, “incident”, “near hit” or

“close call”.

[SOURCE: ISO 22300:2012, 2.1.8]

3.1.4

exercise

process to train for, assess, practice, and improve performance in an organization

Note 1 to entry: Exercises can be used for validating policies, plans, procedures, training, equipment, and

interorganizational agreements, clarifying and training personnel in roles and responsibilities, improving

interorganizational coordination and communications, identifying gaps in resources, improving individual

performance and identifying opportunities for improvement, and a controlled opportunity to practice

improvisation.

Note 2 to entry: A test is a unique and particular type of exercise, which incorporates an expectation of a pass or

fail element within the goal or objectives of the exercise being planned.

[SOURCE: ISO 22300:2012, 2.4.8]

3.1.5

incident

situation that might be, or could lead to, a disruption, loss, emergency or crisis

[SOURCE: ISO 22300:2012, 2.1.15]

3.1.6

mutual aid agreement

pre-arranged understanding between two or more entities to render assistance to each other

[SOURCE: ISO 22300:2012, 2.2.13]

3.1.7

prioritized activities

activities to which priority must be given following an incident in order to mitigate impacts

Note 1 to entry: Terms in common used to describe activities within this group include critical, essential, vital,

urgent and key.

[SOURCE: ISO 22300:2012, 2.3.5]

3.1.8

risk

effect of uncertainty on objectives

Note 1 to entry: An effect is a deviation from the expected: positive and/or negative.

Note 2 to entry: Objectives can have different aspects (such as financial, health and safety, and environmental

goals) and can apply at different levels (such as strategic, organization-wide, project, product and process).

Note 3 to entry: Risk is often characterized by reference to potential events, and consequences, or a

combination of these.

2 © ISO 2015 – All rights reserved

---------------------- Page: 9 ----------------------

ISO/TS 22318:2015(E)

Note 4 to entry: Risk is often expressed in terms of a combination of the consequences of an event (including

changes in circumstances) and the associated likelihood of occurrence.

Note 5 to entry: Uncertainty is the state, even partial, of deficiency of information related to, understanding or

knowledge of, an event, its consequence, or likelihood.

[SOURCE: ISO 22300:2012, 2.1.5]

3.1.9

top management

person or group of people that directs and controls an organization at the highest level

Note 1 to entry: Top management has the power to delegate authority and provide resources within the

organization.

Note 2 to entry: An organization can, for this purpose, be identified by reference to the scope of the implementation

of a management system.

[SOURCE: ISO 22300:2012, 2.2.4]

3.2 Terms included in ISO 22301

3.2.1

activity

process or set of processes undertaken by an organization (or on its behalf) that produces or supports

one or more products and services

EXAMPLE Such processes include accounts, call centre, IT, manufacture, distribution.

[SOURCE: ISO 22301:2012, 3.1]

3.2.2

business continuity management

holistic management process that identifies potential threats to an organization and the impacts to

business operations those threats, if realized, might cause, and which provides a framework for building

organizational resilience with the capability of an effective response that safeguards the interests of its

key stakeholders, reputation, brand and value-creating activities

[SOURCE: ISO 22301:2012, 3.4]

3.2.3

business continuity management system

BCMS

part of the overall management system that establishes, implements, operates, monitors, reviews,

maintains and improves business continuity

Note 1 to entry: The management system includes organizational structure, policies, planning activities,

responsibilities, procedures, processes and resources.

[SOURCE: ISO 22301:2012, 3.5]

3.2.4

business continuity plan

documented procedures that guide organizations to respond, recover, resume, and restore to a pre-

defined level of operation following disruption

Note 1 to entry: Typically, this covers resources, services and activities required to ensure the continuity of

critical business functions.

[SOURCE: ISO 22301:2012, 3.6]

© ISO 2015 – All rights reserved 3

---------------------- Page: 10 ----------------------

ISO/TS 22318:2015(E)

3.2.5

business continuity programme

ongoing management and governance process supported by top management and appropriately

resourced to implement and maintain business continuity management

[SOURCE: ISO 22301:2012, 3.7]

3.2.6

interested party

stakeholder

person or organization that can affect, be affected by, or perceive themselves to be affected by a

decision or activity

Note 1 to entry: This can be an individual or group that has an interest in any decision or activity of an

organization.

[SOURCE: ISO 22301:2012, 3.21]

3.2.7

minimum business continuity objective

MBCO

minimum level of services and/or products that is acceptable to the organization to achieve its business

objectives during a disruption

[SOURCE: ISO 22301:2012, 3.28]

3.2.8

organization

person or group of people that has its own functions with responsibilities, authorities and relationships

to achieve its objectives

Note 1 to entry: The concept of organization includes, but is not limited to, sole-trader, company, corporation, firm,

enterprise, authority, partnership, charity or institution, or part or combination thereof, whether incorporated

or not, public or private.

Note 2 to entry: For organizations with more than one operating unit, a single operating unit can be defined as an

organization.

[SOURCE: ISO 22301:2012, 3.33]

3.2.9

outsource

make an arrangement where an external organization performs part of an organization’s function or

process

Note 1 to entry: An external organization is outside the scope of the management system, although the outsourced

function or process is within the scope.

[SOURCE: ISO 22301:2012, 3.34]

3.2.10

products and services

beneficial outcomes provided by an organization to its customers, recipients and interested parties, e.g.

manufactured items, car insurance and community nursing

[SOURCE: ISO 22301:2012, 3.41]

3.2.11

recovery time objective

RTO

period of time following an incident within which

— product or service must be resumed,

4 © ISO 2015 – All rights reserved

---------------------- Page: 11 ----------------------

ISO/TS 22318:2015(E)

— activity must be resumed, or

— resources must be recovered

Note 1 to entry: For products, services and activities, the recovery time objective must be less than the time it

would take for the adverse impacts that would arise as a result of not providing a product/service or performing

an activity to become unacceptable.

[SOURCE: ISO 22301:2012, 3.45]

3.2.12

resources

all assets, people, skills, information, technology (including plant and equipment), premises, and

supplies and information (whether electronic or not) that an organization has to have available to use,

when needed, in order to operate and meet its objective

[SOURCE: ISO 22301:2012, 3.47]

3.3 Terms and definitions applicable to this Technical Specification

3.3.1

critical customer

individual or entity, the loss of whose business would threaten the survival of the organization

3.3.2

critical supplier

provider of critical products or services

Note 1 to entry: This includes an “internal supplier”, who is part of the same organization as its customer.

3.3.3

critical products or services

resources obtained from a supplier which, if unavailable, would disrupt the organization’s critical

activities and threaten the survival of the organization

Note 1 to entry: Critical products or services are essential resources to support an organization’s high priority

activities and processes identified in its BIA.

3.3.4

disruption

event, whether anticipated (e.g. a labour strike or hurricane) or unanticipated (e.g. a blackout or

earthquake), which causes an unplanned, negative deviation from the expected delivery of products or

services according to the organization’s objectives

3.3.5

supply chain

network of organizations that are involved, through upstream and downstream linkages, in the

processes and activities that produce value in the form of products and services in the hands of the

ultimate consumer

3.3.6

supply chain continuity management

SCCM

application of business continuity management to a supply chain

Note 1 to entry: BCM should be applied to all the tiers of an organization’s supply chain.

Note 2 to entry: In practice, an organization usually would only apply it to the first tier of their suppliers and

influence critical suppliers to apply SCCM to their suppliers.

© ISO 2015 – All rights reserved 5

---------------------- Page: 12 ----------------------

Outbound logistics

ISO/TS 22318:2015(E)

3.3.7

Tier 1 supplier

directly supplies products or services to the organization usually through a contractual arrangement

3.3.8

Tier 2 supplier

provides products or services to an organization indirectly and through a Tier 1 supplier

4 Why supply chain continuity is important

4.1 General

This Clause considers the factors which provide the structure within which SCCM is conducted. Supply

chains are becoming increasingly complex, extended (often extending internationally) and frequently

changing, exposing the organization to additional risk of supply chain interruption. As a supply chain is

always subject to potential d

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.