ISO/DIS 9809-4

(Main)Gas cylinders -- Refillable seamless steel gas cylinders -- Design, construction and testing

Gas cylinders -- Refillable seamless steel gas cylinders -- Design, construction and testing

Bouteilles à gaz -- Bouteilles à gaz rechargeables en acier sans soudure -- Conception, construction et essais

General Information

RELATIONS

Standards Content (sample)

DRAFT INTERNATIONAL STANDARD

ISO/DIS 9809-4

ISO/TC 58/SC 3 Secretariat: BSI

Voting begins on: Voting terminates on:

2020-09-09 2020-12-02

Gas cylinders — Refillable seamless steel gas cylinders —

Design, construction and testing —

Part 4:

Stainless steel cylinders with an Rm value of less than

1 100 MPa

Bouteilles à gaz — Bouteilles à gaz rechargeables en acier sans soudure — Conception, construction et

essais —Partie 4: Bouteilles en acier inoxydable avec une valeur Rm inférieure à 1 100 MPa

ICS: 23.020.35THIS DOCUMENT IS A DRAFT CIRCULATED

FOR COMMENT AND APPROVAL. IT IS

THEREFORE SUBJECT TO CHANGE AND MAY

NOT BE REFERRED TO AS AN INTERNATIONAL

STANDARD UNTIL PUBLISHED AS SUCH.

IN ADDITION TO THEIR EVALUATION AS

BEING ACCEPTABLE FOR INDUSTRIAL,

This document is circulated as received from the committee secretariat.

TECHNOLOGICAL, COMMERCIAL AND

USER PURPOSES, DRAFT INTERNATIONAL

STANDARDS MAY ON OCCASION HAVE TO

BE CONSIDERED IN THE LIGHT OF THEIR

POTENTIAL TO BECOME STANDARDS TO

WHICH REFERENCE MAY BE MADE IN

Reference number

NATIONAL REGULATIONS.

ISO/DIS 9809-4:2020(E)

RECIPIENTS OF THIS DRAFT ARE INVITED

TO SUBMIT, WITH THEIR COMMENTS,

NOTIFICATION OF ANY RELEVANT PATENT

RIGHTS OF WHICH THEY ARE AWARE AND TO

PROVIDE SUPPORTING DOCUMENTATION. ISO 2020

---------------------- Page: 1 ----------------------

ISO/DIS 9809-4:2020(E)

COPYRIGHT PROTECTED DOCUMENT

© ISO 2020

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting

on the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address

below or ISO’s member body in the country of the requester.ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii © ISO 2020 – All rights reserved

---------------------- Page: 2 ----------------------

ISO/DIS 9809-4:2020(E)

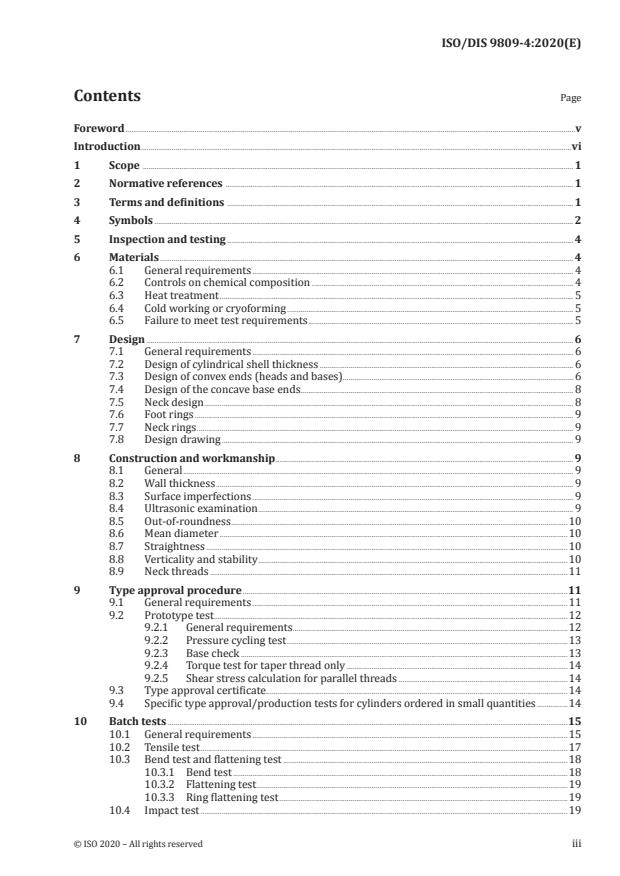

Contents Page

Foreword ..........................................................................................................................................................................................................................................v

Introduction ................................................................................................................................................................................................................................vi

1 Scope ................................................................................................................................................................................................................................ 1

2 Normative references ..................................................................................................................................................................................... 1

3 Terms and definitions .................................................................................................................................................................................... 1

4 Symbols .......................................................................................................................................................................................................................... 2

5 Inspection and testing .................................................................................................................................................................................... 4

6 Materials ....................................................................................................................................................................................................................... 4

6.1 General requirements ....................................................................................................................................................................... 4

6.2 Controls on chemical composition ........................................................................................................................................ 4

6.3 Heat treatment ........................................................................................................................................................................................ 5

6.4 Cold working or cryoforming ..................................................................................................................................................... 5

6.5 Failure to meet test requirements .......................................................................................................................................... 5

7 Design .............................................................................................................................................................................................................................. 6

7.1 General requirements ....................................................................................................................................................................... 6

7.2 Design of cylindrical shell thickness .................................................................................................................................... 6

7.3 Design of convex ends (heads and bases)........................................................................................................................ 6

7.4 Design of the concave base ends.............................................................................................................................................. 8

7.5 Neck design ................................................................................................................................................................................................ 8

7.6 Foot rings ..................................................................................................................................................................................................... 9

7.7 Neck rings .................................................................................................................................................................................................... 9

7.8 Design drawing ....................................................................................................................................................................................... 9

8 Construction and workmanship ........................................................................................................................................................... 9

8.1 General ........................................................................................................................................................................................................... 9

8.2 Wall thickness .......................................................................................................................................................................................... 9

8.3 Surface imperfections ....................................................................................................................................................................... 9

8.4 Ultrasonic examination .................................................................................................................................................................... 9

8.5 Out-of-roundness ...............................................................................................................................................................................10

8.6 Mean diameter .....................................................................................................................................................................................10

8.7 Straightness ............................................................................................................................................................................................10

8.8 Verticality and stability .................................................................................................................................................................10

8.9 Neck threads ..........................................................................................................................................................................................11

9 Type approval procedure .........................................................................................................................................................................11

9.1 General requirements ....................................................................................................................................................................11

9.2 Prototype test ........................................................................................................................................................................................12

9.2.1 General requirements ...............................................................................................................................................12

9.2.2 Pressure cycling test ..................................................................................................................................................13

9.2.3 Base check ..........................................................................................................................................................................13

9.2.4 Torque test for taper thread only ...................................................................................................................14

9.2.5 Shear stress calculation for parallel threads ........................................................................................14

9.3 Type approval certificate.............................................................................................................................................................14

9.4 Specific type approval/production tests for cylinders ordered in small quantities ................14

10 Batch tests ................................................................................................................................................................................................................15

10.1 General requirements ....................................................................................................................................................................15

10.2 Tensile test ...............................................................................................................................................................................................17

10.3 Bend test and flattening test ....................................................................................................................................................18

10.3.1 Bend test ..............................................................................................................................................................................18

10.3.2 Flattening test .................. .................................................... ............................................................................................19

10.3.3 Ring flattening test ......................................................................................................................................................19

10.4 Impact test ...............................................................................................................................................................................................19

© ISO 2020 – All rights reserved iii---------------------- Page: 3 ----------------------

ISO/DIS 9809-4:2020(E)

10.5 Hydraulic burst test .........................................................................................................................................................................21

10.5.1 Test installation ...................................................................... ........................................................................................21

10.5.2 Test conditions................................................................................................................................................................22

10.5.3 Interpretation of test results ..............................................................................................................................23

10.6 Intergranular corrosion test .....................................................................................................................................................24

11 Tests/examinations on every cylinder .......................................................................................................................................24

11.1 General ........................................................................................................................................................................................................24

11.2 Hydraulic test ........................................................................................................................................................................................25

11.2.1 Proof pressure test ......................................................................................................................................................25

11.2.2 Volumetric expansion test ....................................................................................................................................25

11.3 Hardness test .........................................................................................................................................................................................25

11.4 Leak test .....................................................................................................................................................................................................25

11.5 Capacity check ......................................................................................................................................................................................26

12 C ertification ............................................................................................................................................................................................................26

13 Marking .......................................................................................................................................................................................................................26

Annex A (informative) Description and evaluation of manufacturing imperfectionsand conditions for rejection of seamless steel gas cylinders at the time of final

inspection by the manufacturer ........................................................................................................................................................27

Annex B (informative) Ultrasonic examination .....................................................................................................................................42

Annex C (informative) Example of Type approval certificate ..................................................................................................48

Annex D (informative) Example of Acceptance certificate..........................................................................................................49

Annex E (informative) Example of shear strength calculation for parallel threads.........................................52

Bibliography .............................................................................................................................................................................................................................54

iv © ISO 2020 – All rights reserved---------------------- Page: 4 ----------------------

ISO/DIS 9809-4:2020(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www .iso .org/ directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www .iso .org/ patents).Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to the

World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT), see www .iso .org/

iso/ foreword .html.This document was prepared by Technical Committee ISO/TC 58, Gas cylinders, Subcommittee SC 3,

Cylinder design.This second edition replaces the first edition (ISO 9809-4: 2014), which has been technically revised.

The main changes compared to the previous edition are as follows:— Update of Clause 5

— Clarification of Figure 3

— Clarification of 8.9

— Modification of 9.1, 9.2, 9.2.4, Annex A

— New section 9.2.5 for parallel threads

— New section 9.4 for cylinders ordered in small quantitied.

A list of all parts in the ISO 9809-series can be found on the ISO website.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www .iso .org/ members .html.© ISO 2020 – All rights reserved v

---------------------- Page: 5 ----------------------

ISO/DIS 9809-4:2020(E)

Introduction

The purpose of this document is to provide a specification for the design, manufacture, inspection, and

testing of a seamless stainless steel cylinder for worldwide usage. The objective is to balance the design

and economic efficiency against international acceptance and universal utility.ISO 9809 (all parts) aims to eliminate the concern about climate, duplicate inspections, and restrictions

currently existing because of the lack of definitive International Standards.[1]

This document has been written so that it is suitable to be referenced in the UN Model Regulations.

vi © ISO 2020 – All rights reserved---------------------- Page: 6 ----------------------

DRAFT INTERNATIONAL STANDARD ISO/DIS 9809-4:2020(E)

Gas cylinders — Refillable seamless steel gas cylinders —

Design, construction and testing —

Part 4:

Stainless steel cylinders with an Rm value of less than 1

100 MPa

1 Scope

This document specifies the minimum requirements for the material, design, construction and

workmanship, manufacturing processes, examinations, and tests at manufacture for refillable seamless

stainless steel gas cylinders— with water capacities up to and including 150 l

— for compressed, liquefied, and dissolved gases

— with a maximum actual tensile strength, R , of less than 1 100 MPa.

NOTE If so desired, cylinders of water capacity between 150 l and 450 l can be manufactured to be in full

compliance with this document.2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 148-1, Metallic materials — Charpy pendulum impact test — Part 1: Test method

ISO 3651-2, Determination of resistance to intergranular corrosion of stainless steels — Part 2:

Ferritic,austenitic and ferritic-austenitic (duplex) stainless steels — Corrosion test in media containing

sulfuric acidISO 6506-1, Metallic materials — Brinell hardness test — Part 1: Test method

ISO 6508-1, Metallic materials — Rockwell hardness test — Part 1: Test method

ISO 9329-4, Seamless steel tubes for pressure purposes — Technical delivery conditions — Part 4: Austenitic

stainless steelsISO 9712, Non-destructive testing — Qualification and certification of NDT personnel

ISO 10286, Gas cylinders - TerminologyISO 13769, Gas cylinders — Stamp marking

3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 10286 and the following apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https:// www .iso .org/ obp© ISO 2020 – All rights reserved 1

---------------------- Page: 7 ----------------------

ISO/DIS 9809-4:2020(E)

— IEC Electropedia: available at http:// www .electropedia .org/

3.1

batch

quantity of up to 200 cylinders, plus cylinders for destructive testing of the same nominal diameter,

thickness, length, and design made successively on the same equipment, from the same cast of steel,

and subjected to the same heat treatment for the same duration of time3.2

burst pressure

highest pressure reached in a cylinder during a burst test

3.3

cryoforming

process where the cylinder is subjected to a controlled low-temperature deformation treatment that

results in a permanent increase in strength3.4

design stress factor

ratio of the equivalent wall stress at test pressure,p , to guaranteed minimum yield strength,R

h eg3.5

rendered unserviseable

cylinder that has been treated in such a way as to render it impossible for use

3.6

reject

cylinder that has been set aside (Level 2 or Level 3) and not allowed to go into service

3.7repair

action to return a rejected cylinder to a Level 1 condition

3.8

test pressure

required pressure applied during a pressure test

Note 1 to entry: Test pressure is used for the cylinder wall thickness calculation.

3.9yield strength

stress value corresponding to the 0,2 % proof stress or for austenitic steels in the solution-annealed

condition, 1 % proof stress3.10

working pressure

settled pressure of a compressed gas at a uniform reference temperature of 15 °C in a full gas cylinder

4 SymbolsA percentage elongation after the fracture for a gauge length of Lo

a calculated minimum thickness, in millimetres, of the cylindrical shell

a' guaranteed minimum thickness, in millimetres, of the cylindrical shell

2 © ISO 2020 – All rights reserved

---------------------- Page: 8 ----------------------

ISO/DIS 9809-4:2020(E)

a guaranteed minimum thickness, in millimetres, of a concave base at the knuckle (see Figure 2)

a guaranteed minimum thickness, in millimetres, at the centre of a concave base (see Figure 2)

b guaranteed minimum thickness, in millimetres, at the centre of a convex base (see Figure 1)

c maximum permissible deviation, in millimetres, of burst profile for quenched and tempered

cylinders (see Figure 11)c maximum permissible deviation, in millimetres, of the burst profile for cryoformed or solu-

tion-annealed cylinders with less than 7,5 mm wall thickness (see Figure 12)D nominal outside diameter of the cylinder, in millimetres (see Figure 1)

D diameter, in millimetres, of former (see Figure 6)

F design stress factor (variable) (see 3.7)

H outside height, in millimetres, of the domed part (convex head or base end) (see Figure 1)

h outside depth (concave base end), in millimetres (see Figure 2)L original gauge length, in millimetres, as defined in ISO 6892 (see Figure 5)

l overall length of the cylinder, in millimetres (see Figure 3)

n ratio of the diameter of the bend test former to the actual thickness of test piece,t

P measured burst pressure, in bar, above the atmospheric pressureNOTE 1 bar = 10 Pa = 0,1 MPa.

P hydraulic test pressure, in bar, above the atmospheric pressure

P observed pressure when the cylinder starts yielding during the hydraulic burst test, in bar,

above the atmospheric pressurer inside knuckle radius, in millimetres (see Figures 1 and 2)

R actual value of the yield strength, in megapascals, as determined by the tensile test (see 10.2)

R minimum guaranteed value of the yield strength (see 7.1.1), in megapascals, for the finished

cylinderR actual value of the tensile strength, in megapascals, as determined by the tensile test (see 10.2)

R minimum guaranteed value of the tensile strength, in megapascals, for the finished cylinder

S original cross-sectional area of the tensile test piece, in square millimetres, in accordance with

ISO 6892t actual thickness of the test specimen, in millimetres

t average cylinder wall thickness at the position of testing during the flattening test, in millimetres

u ratio of the distance between the knife edges or platens in the flattening test to the average

cylinder wall thickness at the position of the testV water capacity of the cylinder, in litres

w Width, in millimetres, of the tensile test piece (see Figure 5)

© ISO 2020 – All rights reserved 3

---------------------- Page: 9 ----------------------

ISO/DIS 9809-4:2020(E)

5 Inspection and testing

Assessment of conformity to this document shall be carried out in accordance with the applicable

regulations of the countries of use.To ensure that the cylinders conform to this document, they shall be subject to inspection and testing in

accordance with Clauses 9, 10 and 11.Tests and examinations performed to demonstrate compliance with this document shall be conducted

using instruments calibrated before being put into service and thereafter according to an established

programme.6 Materials

6.1 General requirements

6.1.1 Materials for the manufacture of gas cylinders shall fall within one of the following categories:

a) internationally recognized cylinder steels;b) nationally recognized cylinder steels;

c) new cylinder steels resulting from technical progress.

For all categories, the relevant conditions specified in 6.2 and 6.3 shall be satisfied.

6.1.2 There is a risk of sensitization to the intergranular corrosion resulting from the hot processing

of austenitic and duplex stainless steels. Intergranular corrosion testing shall be carried out for such

materials in accordance with 10.6.6.1.3 The cylinder manufacturer shall establish the means to identify the cylinders with the cast of

steel from which they are made.6.1.4 Grades of steel used for the cylinder manufacture shall be compatible with the intended gas

service, e.g. corrosive gases and embrittling gases (see ISO 11114-1).6.1.5 Some grades of stainless steel can be susceptible to environmental stress corrosion cracking.

Special precautions shall be taken in such cases, such as appropriate coating.6.1.6 Some grades of stainless steel can be susceptible to phase transformation at low temperatures

resulting in a brittle alloy. Special precautions shall be taken in such cases, i.e. not using the cylinder

below the minimum acceptable temperature.6.2 Controls on chemical composition

6.2.1 The following are the four broad categories of stainless steels:

— ferritic;

— martensitic;

— austenitic;

— austenitic/ferritic (duplex).

Recognized steels are listed in ISO 15510. Other grades of stainless steel can also be used provided that

they fulfil all the requirements of this document.4 © ISO 2020 – All rights reserved

---------------------- Page: 10 ----------------------

ISO/DIS 9809-4:2020(E)

6.2.2 The cylinder manufacturer shall obtain and make available certificates of cast (heat) analyses of

the steels supplied for the construction of gas cylinders.Should check analyses be required, they shall be carried out either on the specimens taken during the

manufacture from the material in the form as supplied by the steel maker to the cylinder manufacturer,

or from finished cylinders. In any check analysis, the maximum permissible deviation from the limits

specified for the cast analyses shall conform to the values specified in ISO 9329-4.

6.3 Heat treatment6.3.1 The cylinder manufacturer shall certify the heat treatment process applied to the finished

cylinders.6.3.2 The finished cylinders made from the ferritic or martensitic steel categories shall be quenched

and tempered, except if they are cold worked (see 6.4).6.3.3 For the ferritic and martensitic steels, the heat treatment process shall achieve the required

mechanical properties.6.3.4 The actual temperature to which a type of steel is subjected to obtain a given tensile strength

shall not deviate by more than 30 °C from the temperature specifi...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.