ISO/DIS 12107

(Main)Metallic materials -- Fatigue testing -- Statistical planning and analysis of data

Metallic materials -- Fatigue testing -- Statistical planning and analysis of data

Matériaux métalliques -- Essais de fatigue -- Plans et analyse statistique de données

General Information

RELATIONS

Buy Standard

Standards Content (sample)

DRAFT INTERNATIONAL STANDARD

ISO/DIS 12107

ISO/TC 164/SC 5 Secretariat: ANSI

Voting begins on: Voting terminates on:

2017-05-10 2017-08-01

Metallic materials — Fatigue testing — Statistical planning

and analysis of data

Matériaux métalliques — Essais de fatigue — Plans et analyse statistique de données

ICS: 77.040.10THIS DOCUMENT IS A DRAFT CIRCULATED

FOR COMMENT AND APPROVAL. IT IS

THEREFORE SUBJECT TO CHANGE AND MAY

NOT BE REFERRED TO AS AN INTERNATIONAL

STANDARD UNTIL PUBLISHED AS SUCH.

IN ADDITION TO THEIR EVALUATION AS

BEING ACCEPTABLE FOR INDUSTRIAL,

This document is circulated as received from the committee secretariat.

TECHNOLOGICAL, COMMERCIAL AND

USER PURPOSES, DRAFT INTERNATIONAL

STANDARDS MAY ON OCCASION HAVE TO

BE CONSIDERED IN THE LIGHT OF THEIR

POTENTIAL TO BECOME STANDARDS TO

WHICH REFERENCE MAY BE MADE IN

Reference number

NATIONAL REGULATIONS.

ISO/DIS 12107:2017(E)

RECIPIENTS OF THIS DRAFT ARE INVITED

TO SUBMIT, WITH THEIR COMMENTS,

NOTIFICATION OF ANY RELEVANT PATENT

RIGHTS OF WHICH THEY ARE AWARE AND TO

PROVIDE SUPPORTING DOCUMENTATION. ISO 2017

---------------------- Page: 1 ----------------------

ISO/DIS 12107:2017(E)

COPYRIGHT PROTECTED DOCUMENT

© ISO 2017, Published in Switzerland

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized otherwise in any form

or by any means, electronic or mechanical, including photocopying, or posting on the internet or an intranet, without prior

written permission. Permission can be requested from either ISO at the address below or ISO’s member body in the country of

the requester.ISO copyright office

Ch. de Blandonnet 8 • CP 401

CH-1214 Vernier, Geneva, Switzerland

Tel. +41 22 749 01 11

Fax +41 22 749 09 47

copyright@iso.org

www.iso.org

ii © ISO 2017 – All rights reserved

---------------------- Page: 2 ----------------------

ISO/DIS 12107:2017(E)

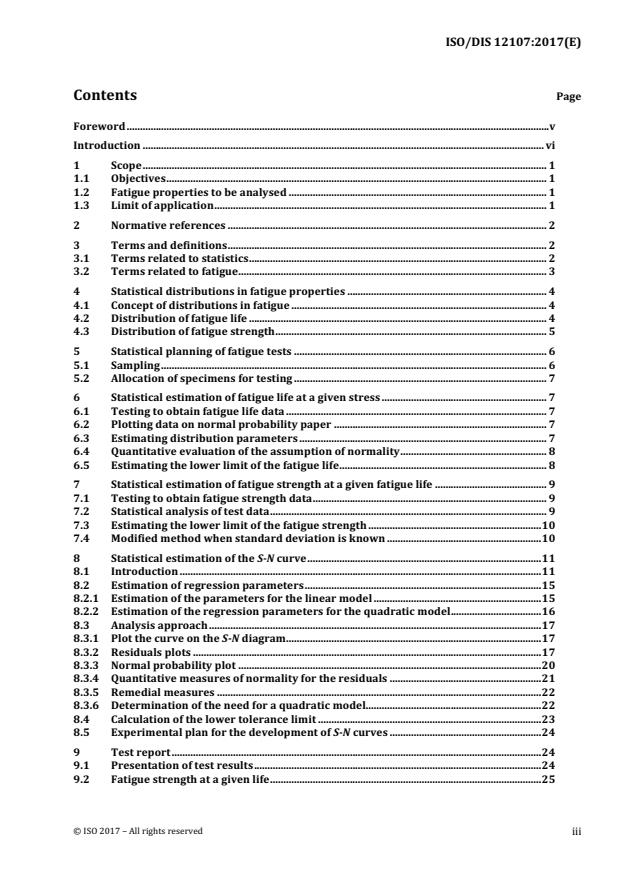

Contents Page

Foreword ............................................................................................................................................................... v

Introduction ....................................................................................................................................................... vi

1 Scope ........................................................................................................................................................ 1

1.1 Objectives ............................................................................................................................................... 1

1.2 Fatigue properties to be analysed ................................................................................................. 1

1.3 Limit of application ............................................................................................................................. 1

2 Normative references ........................................................................................................................ 2

3 Terms and definitions ........................................................................................................................ 2

3.1 Terms related to statistics ................................................................................................................ 2

3.2 Terms related to fatigue .................................................................................................................... 3

4 Statistical distributions in fatigue properties ........................................................................... 4

4.1 Concept of distributions in fatigue ................................................................................................ 4

4.2 Distribution of fatigue life ................................................................................................................ 4

4.3 Distribution of fatigue strength ...................................................................................................... 5

5 Statistical planning of fatigue tests ............................................................................................... 6

5.1 Sampling ................................................................................................................................................. 6

5.2 Allocation of specimens for testing ............................................................................................... 7

6 Statistical estimation of fatigue life at a given stress .............................................................. 7

6.1 Testing to obtain fatigue life data .................................................................................................. 7

6.2 Plotting data on normal probability paper ................................................................................ 7

6.3 Estimating distribution parameters ............................................................................................. 7

6.4 Quantitative evaluation of the assumption of normality ....................................................... 8

6.5 Estimating the lower limit of the fatigue life .............................................................................. 8

7 Statistical estimation of fatigue strength at a given fatigue life .......................................... 9

7.1 Testing to obtain fatigue strength data ........................................................................................ 9

7.2 Statistical analysis of test data ........................................................................................................ 9

7.3 Estimating the lower limit of the fatigue strength ................................................................. 10

7.4 Modified method when standard deviation is known .......................................................... 10

8 Statistical estimation of the S-N curve ........................................................................................ 11

8.1 Introduction ........................................................................................................................................ 11

8.2 Estimation of regression parameters ......................................................................................... 15

8.2.1 Estimation of the parameters for the linear model ............................................................... 15

8.2.2 Estimation of the regression parameters for the quadratic model .................................. 16

8.3 Analysis approach ............................................................................................................................. 17

8.3.1 Plot the curve on the S-N diagram ................................................................................................ 17

8.3.2 Residuals plots ................................................................................................................................... 17

8.3.3 Normal probability plot .................................................................................................................. 20

8.3.4 Quantitative measures of normality for the residuals ......................................................... 21

8.3.5 Remedial measures .......................................................................................................................... 22

8.3.6 Determination of the need for a quadratic model .................................................................. 22

8.4 Calculation of the lower tolerance limit .................................................................................... 23

8.5 Experimental plan for the development of S-N curves ......................................................... 24

9 Test report ........................................................................................................................................... 24

9.1 Presentation of test results ............................................................................................................ 24

9.2 Fatigue strength at a given life ...................................................................................................... 25

© ISO 2017 – All rights reservediii

---------------------- Page: 3 ----------------------

ISO/DIS 12107:2017(E)

9.3 S-N curve ............................................................................................................................................... 25

(informative) Examples of applications ................................................................................ 26

A.1 Example of statistical estimation of fatigue life ...................................................................... 26

A.2 Examples of statistical estimation of fatigue strength .......................................................... 29

A.2.1 Staircase method ............................................................................................................................... 29

A.2.2 Modified staircase method ............................................................................................................. 30

A.3 Examples of statistical estimation of S-N curve ....................................................................... 31

A.3.1 Example of force-contolled fatigue life data ............................................................................. 31

A.3.2 Example of strain–controlled fatigue life data ........................................................................ 33

A.4 Example of an experimental plan to develop S-N fatigue data ........................................... 38

(informative) Statistical tables ................................................................................................. 39

Bibliography ...................................................................................................................................................... 41

© ISO 2017 – All rights reserved---------------------- Page: 4 ----------------------

ISO/DIS 12107:2017(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work. ISO

collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of any

patent rights identified during the development of the document will be in the Introduction and/or on

the ISO list of patent declarations received (see www.iso.org/patents).Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.For an explanation on the meaning of ISO specific terms and expressions related to conformity

assessment, as well as information about ISO's adherence to the World Trade Organization (WTO)

principles in the Technical Barriers to Trade (TBT) see the following URL:

www.iso.org/iso/foreword.html.The committee responsible for this document is ISO/ TC 164, Mechanical testing of metals, Subcommittee

SC 5, Fatigue testing.This second edition cancels and replaces the first edition (ISO 12107:2003), which has been technically

revised.© ISO 2017 – All rights reserved

---------------------- Page: 5 ----------------------

ISO/DIS 12107:2017(E)

Introduction

It is known that the results of fatigue tests display significant variations even when the test is controlled

very accurately. In part, these variations are attributable to non-uniformity of test specimens. Examples

of such non-uniformity include slight differences in chemical composition, heat treatment, surface finish,

etc. The remaining part is related to the stochastic process of fatigue failure itself that is intrinsic to

metallic engineering materials.Adequate quantification of this inherent variation is necessary to evaluate the fatigue property of a

material for the design of machines and structures. It is also necessary for test laboratories to compare

materials in fatigue behaviour, including its variation. Statistical methods are necessary to perform these

tasks. They include both the experimental planning and procedure to develop fatigue data and the

analysis of the results.© ISO 2017 – All rights reserved

---------------------- Page: 6 ----------------------

DRAFT INTERNATIONAL STANDARD ISO/DIS 12107:2017(E)

Metallic materials — Fatigue testing — Statistical planning

and analysis of data

1 Scope

1.1 Objectives

This International Standard presents methods for the experimental planning of fatigue testing and the

statistical analysis of the resulting data. The purpose is to determine the fatigue properties of metallic

materials with both a high degree of confidence and a practical number of specimens.

1.2 Fatigue properties to be analysedThis International Standard provides a method for the analysis of fatigue life properties at a variety of

stress levels using a relationship that can linearly approximate the material's response in appropriate

coordinates.Specifically, it addresses

a) the fatigue life for a given stress, and

b) the fatigue strength for a given fatigue life.

The term “stress” in this International Standard can be replaced by “strain”, as the methods described are

also valid for the analysis of life properties as a function of strain. Fatigue strength in the case of strain-

controlled tests is considered in terms of strain, as it is ordinarily understood in terms of stress in stress-

controlled tests.1.3 Limit of application

This International Standard is limited to the analysis of fatigue data for materials exhibiting

homogeneous behaviour due to a single mechanism of fatigue failure. This refers to the statistical

properties of test results that are closely related to material behaviour under the test conditions.

In fact, specimens of a given material tested under different conditions may reveal variations in failure

mechanisms. For ordinary cases, the statistical property of resulting data represents one failure

mechanism and may permit direct analysis. Conversely, situations are encountered where the statistical

behaviour is not homogeneous. It is necessary for all such cases to be modelled by two or more individual

distributions.An example of such behaviour is often observed when failure can initiate from either a surface or internal

site at the same level of stress. Under these conditions, the data will have mixed statistical characteristics

corresponding to the different mechanisms of failure. These types of results are not considered in this

International Standard because a much higher complexity of analysis is required.Finally, for the S-N case (discussed in Clause 8), this International Standard addresses only complete data.

Runouts (censored data) are not addressed.© ISO 2017 – All rights reserved

---------------------- Page: 7 ----------------------

ISO/DIS 12107:2017(E)

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are

indispensable for its application. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any amendments) applies.

ISO 3534 (all parts), Statistics — Vocabulary and symbols3 Terms and definitions

For the purposes of this document, the terms and definitions given in 3534 and the following apply.

3.1 Terms related to statistics3.1.1

confidence level

value 1 - a of the probability associated with an interval of statistical tolerance

3.1.2degrees of freedom

number calculated by subtracting from the total number of observations the number of parameters

estimated from the data3.1.3

distribution function

function giving, for every value x, the probability that the random variable X is less than or equal to x

3.1.4estimation

operation made for the purpose of assigning, from the values observed in a sample, numerical values to

the parameters of a distribution from which this sample has been taken3.1.5

population

totality of individual materials or items under consideration

3.1.6

random variable

variable that may take any value of a specified set of values

3.1.7

sample

one or more items taken from a population and intended to provide information on the population

3.1.8size

number of items in a population, lot, sample, etc.

© ISO 2017 – All rights reserved

---------------------- Page: 8 ----------------------

ISO/DIS 12107:2017(E)

3.1.9

mean

sum of all the data in a population divided by the number of observations

3.1.10

sample mean

sum of all the data in a sample divided by the number of observations

3.1.11

standard deviation

positive square root of the mean squared standard deviation from the mean from a population.

3.1.12estimated standard deviation

positive square root of the mean squared standard deviation from the mean of a sample.

3.1.13estimated stress or strain

at a given N

3.1.14

one-sided tolerance limit for a normal distribution

number dependent on the failure probability, the confidence level and the degrees of freedom.

3.2 Terms related to fatigue3.2.1

fatigue life

number of cycles observed in the test to achieve the intended failure criterion.

Note The dependent variable in a fatigue test conducted under force or strain control.

3.2.2fatigue strength

value of stress level S at which a specimen would fail at a given fatigue life

Note 1 to entry: This is expressed in megapascals.

3.2.3

specimen

portion or piece of material to be used for a single test determination and normally prepared in a

predetermined shape and in predetermined dimensions© ISO 2017 – All rights reserved

---------------------- Page: 9 ----------------------

ISO/DIS 12107:2017(E)

3.2.4

stress or strain level

Intensity of the applied test stimulus

Note 1 to entry: The independent variable in a fatigue test conducted under stress or strain control. The stress or

strain level can be expressed as amplitude, maximum or range3.2.5

stress step

difference between neighbouring stress levels when conducting the test by the staircase method

Note 1 to entry: This is expressed in megapascals.4 Statistical distributions in fatigue properties

4.1 Concept of distributions in fatigue

The fatigue properties of metallic engineering materials are determined by testing a set of specimens at

various stress levels to generate a fatigue life relationship as a function of stress. The results are usually

expressed as an S-N curve that fits the experimental data plotted in appropriate coordinates. These are

generally either log-log or semi-log plots, with the life values always plotted on the abscissa on a

logarithmic scale.Fatigue test results usually display significant scatter even when the tests are carefully conducted to

minimize experimental error. A component of this variation is due to inequalities, related to chemical

composition or heat treatment, among the specimens, but another component is related to the fatigue

process, an example being the initiation and growth of small cracks under test environments.

The variation in fatigue data are expressed in two ways: the distribution of fatigue life at a given stress

and the distribution of strength at a given fatigue life (see References [1] to [5]).

4.2 Distribution of fatigue lifeFatigue life, N, at a given test stress, S, is considered as a random variable. It is frequently observed the

distribution of fatigue life values at any stress is normal in the logarithmic metric. That is, the logarithms

of the life values follow a normal distribution (See 6.4). This relationship is:x æö

x - µ

Px= exp- dx (1)

( ) ç÷

êú2 s

s 2p

èøx

where x = log N and µ and s are, respectively, the mean and the standard deviation of x.

x xEquation (1) gives the cumulative probability of failure for x. This is the proportion of the population

failing at lives less than or equal to x.Equation (1) does not relate to the probability of failure for specimens at or near the fatigue limit. In this

region, some specimens may fail, while others may not. The shape of the distribution is often skewed,

displaying even greater scatter on the longer-life side. It also may be truncated to represent the longest

failure life observed in the data set.© ISO 2017 – All rights reserved

---------------------- Page: 10 ----------------------

ISO/DIS 12107:2017(E)

This International Standard does not address situations in which a certain number of specimens may fail,

but the remaining ones do not.Other statistical distributions can also be used to express variations in fatigue life. The Weibull [4]

distribution is one of the statistical models often used to represent skewed distributions. On occasion,

this distribution may apply to lives at low stresses, but this special case is not addressed in this

International Standard.Figure 1 shows an example of data from a fatigue test conducted with a statistically based experimental

plan using a large number of specimens (see Reference [5]). The shape of the fatigue life distributions is

demonstrated for explanatory purposes.Key

X cycles to failure

Y stress amplitude, in MPa

Figure 1 — Concept of variation in a fatigue property — Distribution of fatigue life at given

stresses for a 0,25 % C carbon steel tested in the rotating-bending mode4.3 Distribution of fatigue strength

Fatigue strength at a given fatigue life, N, is considered as a random variable. It is expressed as the normal

distribution:y y - µ

Py= exp- dy

( ) (2)

êúç÷

2 s

s 2p

where y = S (at a given N), and µ and s are, respectively, the mean and the standard deviation of y.

y yEquation (2) gives the cumulative probability of failure for y. It defines the proportion of the population

presenting fatigue strengths less than or equal to y.© ISO 2017 – All rights reserved

---------------------- Page: 11 ----------------------

ISO/DIS 12107:2017(E)

Other statistical distributions can also be used to express variations in fatigue strength.

Figure 2 is based on the same experimental data as Figure 1. The variation in the fatigue property is

expressed here in terms of strength at typical fatigue lives (see Reference [5]).

KeyX cycles to failure

Y stress amplitude, in MPa

Figure 2 — Concept of variation in a fatigue property — Distribution of fatigue strength at

typical fatigue lives for a 0,25 % C carbon steel tested in the rotating-bending mode

5 Statistical planning of fatigue tests5.1 Sampling

It is necessary to define clearly the population of the material for which the statistical distribution of

fatigue properties is to be estimated. Specimen selection from the population shall be randomized. It is

also important that the specimens be selected so that they accurately represent the population they are

intended to describe. A complete plan would include additional considerations.If the population consists of several lots or batches of material, the test specimens shall be selected

randomly from each group in a number proportional to the size of each lot or batch. The total number of

specimens taken shall be equal to the required sample size, n.If the population displays any serial nature, e.g. if the properties are related to the date of fabrication, the

population shall be divided into groups related to time. Random samples shall be selected from each

group in numbers proportional to the group size.The specimens taken from a particular batch of material will reveal variability specific to the batch. This

within-batch variation can sometimes be of the same order of importance as the between-batch variation.

When the relative importance of different kinds of variation is known from experience, sampling shall be

performed taking this into consideration.© ISO 2017 – All rights reserved

---------------------- Page: 12 ----------------------

ISO/DIS 12107:2017(E)

Hardness measurement is recommended for some materials, when possible, to divide the population of

the material into distinct groups for sampling. The groups should be of as equal size as possible.

Specimens may be extracted randomly in equal numbers from each group to compose a test sample of

size n. This procedure will generate samples uniformly representing the population, based upon

hardness.5.2 Allocation of specimens for testing

Specimens taken from the test materials shall be allocated to individual fatigue tests in principle in a

random way, in order to minimize unexpected statistical bias. The order of testing of the specimens shall

also be randomized in a series of fatigue tests.When several test machines are used in parallel, specimens shall be tested on each machine in equal or

nearly equal numbers and in a random order. The equivalence of the machines in terms of their

performance shall be verified prior to testing.When the test programme includes several independent test series, e.g. tests at different stress levels or

on different materials for comparison purposes, each test series should be carried out at equal or nearly

equal rates of progress, so that all testing can be completed at approximately the same time.

6 Statistical estimation of fatigue life at a given stress6.1 Testing to obtain fatigue life data

Conduct the fatigue tests at a given stress, S, on a set of carefully prepared specimens to determine the

fatigue life values for each. The number selected will be dependent upon the purpose of the test and the

availability of test material. A set of seven specimens is recommended in this International Standard for

exploratory tests. For reliability purposes, however, at least 28 specimens are recommended.

6.2 Plotting data on normal probability paperPlot the fatigue lives on log-normal probability coordinates. The results should plot as a straight line.

Should one or two data points (really a very low proportion of the data set) deviate from the curve, this

is usually the result of invalid data. Examining test records and failed specimens is useful when there is

non-conforming behaviour. The purpose is to identify a cause for such deviant behaviour to learn if these

results can be discounted. Other statistical distributions e.g. Weibull may be evaluated. However, since

the vast majority of unimodal fatigue results have proven to be distributed log-normally, the standard

does not consider Weibull statistics. Subclause 8.3.3 gives some examples of normal probability plots

constructed from data used to generate an S-N curve. Refer to these plots to understand how they will

appear when the data conform well to the assumption and in other cases when there might be some

issues. Please note that for the present case, the y-axis will just be the property in question as opposed to

the standardized residuals given the y-axis on the presented plots in 8.3.3.One other issue is that if the data appear to support two distinct failure distributions, the data should be

segregated by the root cause. For example, results for both surface and internal initiation sites should be

separated into two groups and evaluated uniquely.6.3 Estimating distribution parameters

Calculation of the sample mean is performed as follows:

© ISO 2017 – All rights reserved

---------------------- Page: 13 ----------------------

ISO/DIS 12107:2017(E)

i=1

(3)

where

is the sample mean;

x is the i th observed value, where x = log (N) and where N is the i th observed fatigue value;

i i 10 i in is the number of data points.

Note that the symbol “^” means an estimation based upon a sample.

The sample standard deviation is calculated using the following relationship:

⎛ ⎞

x−µ

⎜ ⎟

⎝ ⎠

i=1

σ =

n−1

(4)

6.4 Quantitative evaluation of the assumption of normality

A number of statistical tests have been developed attempting to quantitatively consider the assumption

of normality. These tests can sometimes generate conflicting results. However, one that seems quite

useful is the Anderson-Darling Test. The details for performing this evaluation as well as others can be

found in Reference [9]. Also, there are commercially available statistical software packages that perform

quantitative evaluations of normality.6.5 Estimating the lower limit of the fatigue life

Estimate the logarithm of the lower limit of the fatigue life at a given probability of failure, assuming a

log-normal distribution, at the confidence level 1 - a from the equation:∧ ∧ ∧

x =µ −k σ

P,1−

...

© ISO 2017 – All rights reserved

ISO/TC 164/SC 5

Date: 2017-01-20

ISO/DIS 12107:2017(E)

ISO/TC 164/SC 5/WG 4

Secretariat: ANSI

Metallic materials — Fatigue testing — Statistical planning and

analysis of data

Matériaux métalliques — Essais de fatigue — Programmation et analyse statistique de données

WarningThis document is not an ISO International Standard. It is distributed for review and comment. It is

subject to change without notice and may not be referred to as an International Standard.

Recipients of this draft are invited to submit, with their comments, notification of any relevant patent

rights of which they are aware and to provide supporting documentation.Document type: International Standard

Document subtype:

Document stage: (40) Enquiry

Document language: E

/Users/mmitchell/Desktop/ISO DIS 12107 FRANZ KLUBBERG- 2016 After Tokyo/ISO_DIS_12107-

2017(E)_All Dokuments/ISO_DIS_12107_(E).docx STD Version 2.8f---------------------- Page: 1 ----------------------

ISO/DIS 12107:2017(E)

COPYRIGHT PROTECTED DOCUMENT

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or

utilized otherwise in any form or by any means, electronic or mechanical, including photocopying,

or posting on the internet or an intranet, without prior written permission. Permission can be

requested from either ISO at the address below or ISO’s member body in the country of the

requester.ISO copyright office

Ch. de Blandonnet 8 • CP 401

CH-1214 Vernier, Geneva, Switzerland

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

copyright@iso.org

www.iso.org

© ISO 2017 – All rights reserved

---------------------- Page: 2 ----------------------

ISO/DIS 12107:2017(E)

Contents Page

Foreword ............................................................................................................................................................... v

Introduction ....................................................................................................................................................... vi

1 Scope ........................................................................................................................................................ 1

1.1 Objectives ............................................................................................................................................... 1

1.2 Fatigue properties to be analysed ................................................................................................. 1

1.3 Limit of application ............................................................................................................................. 1

2 Normative references ........................................................................................................................ 2

3 Terms and definitions ........................................................................................................................ 2

3.1 Terms related to statistics ................................................................................................................ 2

3.2 Terms related to fatigue .................................................................................................................... 3

4 Statistical distributions in fatigue properties ........................................................................... 4

4.1 Concept of distributions in fatigue ................................................................................................ 4

4.2 Distribution of fatigue life ................................................................................................................ 4

4.3 Distribution of fatigue strength ...................................................................................................... 5

5 Statistical planning of fatigue tests ............................................................................................... 6

5.1 Sampling ................................................................................................................................................. 6

5.2 Allocation of specimens for testing ............................................................................................... 7

6 Statistical estimation of fatigue life at a given stress .............................................................. 7

6.1 Testing to obtain fatigue life data .................................................................................................. 7

6.2 Plotting data on normal probability paper ................................................................................ 7

6.3 Estimating distribution parameters ............................................................................................. 7

6.4 Quantitative evaluation of the assumption of normality ....................................................... 8

6.5 Estimating the lower limit of the fatigue life .............................................................................. 8

7 Statistical estimation of fatigue strength at a given fatigue life .......................................... 9

7.1 Testing to obtain fatigue strength data ........................................................................................ 9

7.2 Statistical analysis of test data ........................................................................................................ 9

7.3 Estimating the lower limit of the fatigue strength ................................................................. 10

7.4 Modified method when standard deviation is known .......................................................... 10

8 Statistical estimation of the S-N curve ........................................................................................ 11

8.1 Introduction ........................................................................................................................................ 11

8.2 Estimation of regression parameters ......................................................................................... 15

8.2.1 Estimation of the parameters for the linear model ............................................................... 15

8.2.2 Estimation of the regression parameters for the quadratic model .................................. 16

8.3 Analysis approach ............................................................................................................................. 17

8.3.1 Plot the curve on the S-N diagram ................................................................................................ 17

8.3.2 Residuals plots ................................................................................................................................... 17

8.3.3 Normal probability plot .................................................................................................................. 19

8.3.4 Quantitative measures of normality for the residuals ......................................................... 21

8.3.5 Remedial measures .......................................................................................................................... 22

8.3.6 Determination of the need for a quadratic model .................................................................. 22

8.4 Calculation of the lower tolerance limit .................................................................................... 23

8.5 Experimental plan for the development of S-N curves ......................................................... 24

9 Test report ........................................................................................................................................... 24

9.1 Presentation of test results ............................................................................................................ 24

9.2 Fatigue strength at a given life ...................................................................................................... 24

© ISO 2017 – All rights reservediii

---------------------- Page: 3 ----------------------

ISO/DIS 12107:2017(E)

9.3 S-N curve ............................................................................................................................................... 25

(informative) Examples of applications ................................................................................ 26

A.1 Example of statistical estimation of fatigue life ...................................................................... 26

A.2 Examples of statistical estimation of fatigue strength .......................................................... 28

A.2.1 Staircase method ............................................................................................................................... 28

A.2.2 Modified staircase method ............................................................................................................. 29

A.3 Examples of statistical estimation of S-N curve ....................................................................... 30

A.3.1 Example of force-contolled fatigue life data ............................................................................. 30

A.3.2 Example of strain–controlled fatigue life data ........................................................................ 32

A.4 Example of an experimental plan to develop S-N fatigue data ........................................... 37

(informative) Statistical tables ................................................................................................. 38

Bibliography ...................................................................................................................................................... 40

© ISO 2017 – All rights reserved---------------------- Page: 4 ----------------------

ISO/DIS 12107:2017(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work. ISO

collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of any

patent rights identified during the development of the document will be in the Introduction and/or on

the ISO list of patent declarations received (see www.iso.org/patents).Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.For an explanation on the meaning of ISO specific terms and expressions related to conformity

assessment, as well as information about ISO's adherence to the World Trade Organization (WTO)

principles in the Technical Barriers to Trade (TBT) see the following URL:

www.iso.org/iso/foreword.html.The committee responsible for this document is ISO/ TC 164, Mechanical testing of metals, Subcommittee

SC 5, Fatigue testing.This second edition cancels and replaces the first edition (ISO 12107:2003), which has been technically

revised.It shall be noted that his ISO standard does not address safety or health concerns, should such issues exist,

that may be associated with its use or application. The user of this standard has the sole responsibility to

establish any appropriate safety and health concerns as well as to determine the applicability of any

national or local regulatory limitations regarding the use of this standard.© ISO 2017 – All rights reserved

---------------------- Page: 5 ----------------------

ISO/DIS 12107:2017(E)

Introduction

It is known that the results of fatigue tests display significant variations even when the test is controlled

very accurately. In part, these variations are attributable to non-uniformity of test specimens. Examples

of such non-uniformity include slight differences in chemical composition, heat treatment, surface finish,

etc. The remaining part is related to the stochastic process of fatigue failure itself that is intrinsic to

metallic engineering materials.Adequate quantification of this inherent variation is necessary to evaluate the fatigue property of a

material for the design of machines and structures. It is also necessary for test laboratories to compare

materials in fatigue behaviour, including its variation. Statistical methods are necessary to perform these

tasks. They include both the experimental planning and procedure to develop fatigue data and the

analysis of the results.© ISO 2017 – All rights reserved

---------------------- Page: 6 ----------------------

DRAFT INTERNATIONAL STANDARD ISO/DIS 12107:2017(E)

Metallic materials — Fatigue testing — Statistical planning

and analysis of data

1 Scope

1.1 Objectives

This International Standard presents methods for the experimental planning of fatigue testing and the

statistical analysis of the resulting data. The purpose is to determine the fatigue properties of metallic

materials with both a high degree of confidence and a practical number of specimens.

1.2 Fatigue properties to be analysedThis International Standard provides a method for the analysis of fatigue life properties at a variety of

stress levels using a relationship that can linearly approximate the material's response in appropriate

coordinates.Specifically, it addresses

a) the fatigue life for a given stress, and

b) the fatigue strength for a given fatigue life.

The term “stress” in this International Standard can be replaced by “strain”, as the methods described are

also valid for the analysis of life properties as a function of strain. Fatigue strength in the case of strain-

controlled tests is considered in terms of strain, as it is ordinarily understood in terms of stress in stress-

controlled tests.1.3 Limit of application

This International Standard is limited to the analysis of fatigue data for materials exhibiting

homogeneous behaviour due to a single mechanism of fatigue failure. This refers to the statistical

properties of test results that are closely related to material behaviour under the test conditions.

In fact, specimens of a given material tested under different conditions may reveal variations in failure

mechanisms. For ordinary cases, the statistical property of resulting data represents one failure

mechanism and may permit direct analysis. Conversely, situations are encountered where the statistical

behaviour is not homogeneous. It is necessary for all such cases to be modelled by two or more individual

distributions.An example of such behaviour is often observed when failure can initiate from either a surface or internal

site at the same level of stress. Under these conditions, the data will have mixed statistical characteristics

corresponding to the different mechanisms of failure. These types of results are not considered in this

International Standard because a much higher complexity of analysis is required.Finally, for the S-N case (discussed in Clause 8), this International Standard addresses only complete data.

Runouts (censored data) are not addressed.© ISO 2017 – All rights reserved

---------------------- Page: 7 ----------------------

ISO/DIS 12107:2017(E)

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are

indispensable for its application. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any amendments) applies.

ISO 3534 (all parts), Statistics — Vocabulary and symbols3 Terms and definitions

For the purposes of this document, the terms and definitions given in 3534 and the following apply.

3.1 Terms related to statistics3.1.1

confidence level

value 1 - a of the probability associated with an interval of statistical tolerance

3.1.2degrees of freedom

number calculated by subtracting from the total number of observations the number of parameters

estimated from the data3.1.3

distribution function

function giving, for every value x, the probability that the random variable X is less than or equal to x

3.1.4estimation

operation made for the purpose of assigning, from the values observed in a sample, numerical values to

the parameters of a distribution from which this sample has been taken3.1.5

population

totality of individual materials or items under consideration

3.1.6

random variable

variable that may take any value of a specified set of values

3.1.7

sample

one or more items taken from a population and intended to provide information on the population

3.1.8size

number of items in a population, lot, sample, etc.

© ISO 2017 – All rights reserved

---------------------- Page: 8 ----------------------

ISO/DIS 12107:2017(E)

3.1.9

mean

sum of all the data in a population divided by the number of observations

3.1.10

sample mean

sum of all the data in a sample divided by the number of observations

3.1.11

standard deviation

positive square root of the mean squared standard deviation from the mean from a population.

3.1.12estimated standard deviation

positive square root of the mean squared standard deviation from the mean of a sample.

3.1.13estimated stress or strain

at a given N

3.1.14

one-sided tolerance limit for a normal distribution

number dependent on the failure probability, the confidence level and the degrees of freedom.

3.2 Terms related to fatigue3.2.1

fatigue life

number of cycles observed in the test to achieve the intended failure criterion.

Note The dependent variable in a fatigue test conducted under force or strain control.

3.2.2fatigue strength

value of stress level S at which a specimen would fail at a given fatigue life

Note 1 to entry: This is expressed in megapascals.

3.2.3

specimen

portion or piece of material to be used for a single test determination and normally prepared in a

predetermined shape and in predetermined dimensions© ISO 2017 – All rights reserved

---------------------- Page: 9 ----------------------

ISO/DIS 12107:2017(E)

3.2.4

stress or strain level

Intensity of the applied test stimulus

Note 1 to entry: The independent variable in a fatigue test conducted under stress or strain control. The stress or

strain level can be expressed as amplitude, maximum or range3.2.5

stress step

difference between neighbouring stress levels when conducting the test by the staircase method

Note 1 to entry: This is expressed in megapascals.4 Statistical distributions in fatigue properties

4.1 Concept of distributions in fatigue

The fatigue properties of metallic engineering materials are determined by testing a set of specimens at

various stress levels to generate a fatigue life relationship as a function of stress. The results are usually

expressed as an S-N curve that fits the experimental data plotted in appropriate coordinates. These are

generally either log-log or semi-log plots, with the life values always plotted on the abscissa on a

logarithmic scale.Fatigue test results usually display significant scatter even when the tests are carefully conducted to

minimize experimental error. A component of this variation is due to inequalities, related to chemical

composition or heat treatment, among the specimens, but another component is related to the fatigue

process, an example being the initiation and growth of small cracks under test environments.

The variation in fatigue data are expressed in two ways: the distribution of fatigue life at a given stress

and the distribution of strength at a given fatigue life (see References [1] to [5]).

4.2 Distribution of fatigue lifeFatigue life, N, at a given test stress, S, is considered as a random variable. It is frequently observed the

distribution of fatigue life values at any stress is normal in the logarithmic metric. That is, the logarithms

of the life values follow a normal distribution (See 6.4). This relationship is:æöx - µ

Px= exp- dx (1)

( )

êú2 s

s 2p

èøx

where x = log N and µ and s are, respectively, the mean and the standard deviation of x.

x xEquation (1) gives the cumulative probability of failure for x. This is the proportion of the population

failing at lives less than or equal to x.Equation (1) does not relate to the probability of failure for specimens at or near the fatigue limit. In this

region, some specimens may fail, while others may not. The shape of the distribution is often skewed,

displaying even greater scatter on the longer-life side. It also may be truncated to represent the longest

failure life observed in the data set.© ISO 2017 – All rights reserved

---------------------- Page: 10 ----------------------

ISO/DIS 12107:2017(E)

This International Standard does not address situations in which a certain number of specimens may fail,

but the remaining ones do not.Other statistical distributions can also be used to express variations in fatigue life. The Weibull [4]

distribution is one of the statistical models often used to represent skewed distributions. On occasion,

this distribution may apply to lives at low stresses, but this special case is not addressed in this

International Standard.Figure 1 shows an example of data from a fatigue test conducted with a statistically based experimental

plan using a large number of specimens (see Reference [5]). The shape of the fatigue life distributions is

demonstrated for explanatory purposes.Key

X cycles to failure

Y stress amplitude, in MPa

Figure 1 — Concept of variation in a fatigue property — Distribution of fatigue life at given

stresses for a 0,25 % C carbon steel tested in the rotating-bending mode4.3 Distribution of fatigue strength

Fatigue strength at a given fatigue life, N, is considered as a random variable. It is expressed as the normal

distribution:y y - µ

Py= exp-ç÷ dy (2)

( )

-¥êúç÷

2 s

s 2p

where y = S (at a given N), and µ and s are, respectively, the mean and the standard deviation of y.

y yEquation (2) gives the cumulative probability of failure for y. It defines the proportion of the population

presenting fatigue strengths less than or equal to y.© ISO 2017 – All rights reserved

---------------------- Page: 11 ----------------------

ISO/DIS 12107:2017(E)

Other statistical distributions can also be used to express variations in fatigue strength.

Figure 2 is based on the same experimental data as Figure 1. The variation in the fatigue property is

expressed here in terms of strength at typical fatigue lives (see Reference [5]).

KeyX cycles to failure

Y stress amplitude, in MPa

Figure 2 — Concept of variation in a fatigue property — Distribution of fatigue strength at

typical fatigue lives for a 0,25 % C carbon steel tested in the rotating-bending mode

5 Statistical planning of fatigue tests5.1 Sampling

It is necessary to define clearly the population of the material for which the statistical distribution of

fatigue properties is to be estimated. Specimen selection from the population shall be randomized. It is

also important that the specimens be selected so that they accurately represent the population they are

intended to describe. A complete plan would include additional considerations.If the population consists of several lots or batches of material, the test specimens shall be selected

randomly from each group in a number proportional to the size of each lot or batch. The total number of

specimens taken shall be equal to the required sample size, n.If the population displays any serial nature, e.g. if the properties are related to the date of fabrication, the

population shall be divided into groups related to time. Random samples shall be selected from each

group in numbers proportional to the group size.The specimens taken from a particular batch of material will reveal variability specific to the batch. This

within-batch variation can sometimes be of the same order of importance as the between-batch variation.

When the relative importance of different kinds of variation is known from experience, sampling shall be

performed taking this into consideration.© ISO 2017 – All rights reserved

---------------------- Page: 12 ----------------------

ISO/DIS 12107:2017(E)

Hardness measurement is recommended for some materials, when possible, to divide the population of

the material into distinct groups for sampling. The groups should be of as equal size as possible.

Specimens may be extracted randomly in equal numbers from each group to compose a test sample of

size n. This procedure will generate samples uniformly representing the population, based upon

hardness.5.2 Allocation of specimens for testing

Specimens taken from the test materials shall be allocated to individual fatigue tests in principle in a

random way, in order to minimize unexpected statistical bias. The order of testing of the specimens shall

also be randomized in a series of fatigue tests.When several test machines are used in parallel, specimens shall be tested on each machine in equal or

nearly equal numbers and in a random order. The equivalence of the machines in terms of their

performance shall be verified prior to testing.When the test programme includes several independent test series, e.g. tests at different stress levels or

on different materials for comparison purposes, each test series should be carried out at equal or nearly

equal rates of progress, so that all testing can be completed at approximately the same time.

6 Statistical estimation of fatigue life at a given stress6.1 Testing to obtain fatigue life data

Conduct the fatigue tests at a given stress, S, on a set of carefully prepared specimens to determine the

fatigue life values for each. The number selected will be dependent upon the purpose of the test and the

availability of test material. A set of seven specimens is recommended in this International Standard for

exploratory tests. For reliability purposes, however, at least 28 specimens are recommended.

6.2 Plotting data on normal probability paperPlot the fatigue lives on log-normal probability coordinates. The results should plot as a straight line.

Should one or two data points (really a very low proportion of the data set) deviate from the curve, this

is usually the result of invalid data. Examining test records and failed specimens is useful when there is

non-conforming behaviour. The purpose is to identify a cause for such deviant behaviour to learn if these

results can be discounted. Other statistical distributions e.g. Weibull may be evaluated. However, since

the vast majority of unimodal fatigue results have proven to be distributed log-normally, the standard

does not consider Weibull statistics. Subclause 8.3.3 gives some examples of normal probability plots

constructed from data used to generate an S-N curve. Refer to these plots to understand how they will

appear when the data conform well to the assumption and in other cases when there might be some

issues. Please note that for the present case, the y-axis will just be the property in question as opposed to

the standardized residuals given the y-axis on the presented plots in 8.3.3.One other issue is that if the data appear to support two distinct failure distributions, the data should be

segregated by the root cause. For example, results for both surface and internal initiation sites should be

separated into two groups and evaluated uniquely.6.3 Estimating distribution parameters

Calculation of the sample mean is performed as follows:

© ISO 2017 – All rights reserved

---------------------- Page: 13 ----------------------

ISO/DIS 12107:2017(E)

i=1

µà = (3)

where

à is the sample mean;

x is the i th observed value, where x = log (N) and where N is the i th observed fatigue value;

i i 10 i in is the number of data points.

Note that the symbol “^” means an estimation based upon a sample.

The sample standard deviation is calculated using the following relationship:

x - µà

( )

i=1

sà = (4)

n- 1

6.4 Quantitative evaluation of the assumption of normality

A number of statistical tests have been developed attempting to quantitatively consider the assumption

of normality. These tests can sometimes generate conflicting results. However, one that seems quite

useful is the Anderson-Darling Test. The details for performing this evaluation as well as others can be

found in Reference [9]. Also, there are commercially available statistical software packages that perform

quantitative evaluations of normality.6.5

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.