ISO/DIS 19426-7

(Main)Standard Details

Structures for mine shafts

Structures de puits de mine

General Information

Standards Content (sample)

DRAFT INTERNATIONAL STANDARD

ISO/DIS 19426-7

ISO/TC 82 Secretariat: DIN

Voting begins on: Voting terminates on:

2020-05-19 2020-08-11

Structures for mine shafts —

Part 7:

Rope guides

ICS: 73.020

THIS DOCUMENT IS A DRAFT CIRCULATED

FOR COMMENT AND APPROVAL. IT IS

THEREFORE SUBJECT TO CHANGE AND MAY

NOT BE REFERRED TO AS AN INTERNATIONAL

STANDARD UNTIL PUBLISHED AS SUCH.

IN ADDITION TO THEIR EVALUATION AS

BEING ACCEPTABLE FOR INDUSTRIAL,

This document is circulated as received from the committee secretariat.

TECHNOLOGICAL, COMMERCIAL AND

USER PURPOSES, DRAFT INTERNATIONAL

STANDARDS MAY ON OCCASION HAVE TO

BE CONSIDERED IN THE LIGHT OF THEIR

POTENTIAL TO BECOME STANDARDS TO

WHICH REFERENCE MAY BE MADE IN

Reference number

NATIONAL REGULATIONS.

ISO/DIS 19426-7:2020(E)

RECIPIENTS OF THIS DRAFT ARE INVITED

TO SUBMIT, WITH THEIR COMMENTS,

NOTIFICATION OF ANY RELEVANT PATENT

RIGHTS OF WHICH THEY ARE AWARE AND TO

PROVIDE SUPPORTING DOCUMENTATION. ISO 2020

---------------------- Page: 1 ----------------------

ISO/DIS 19426-7:2020(E)

COPYRIGHT PROTECTED DOCUMENT

© ISO 2020

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting

on the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address

below or ISO’s member body in the country of the requester.ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Fax: +41 22 749 09 47

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii © ISO 2020 – All rights reserved

---------------------- Page: 2 ----------------------

ISO/DIS 19426-7:2020(E)

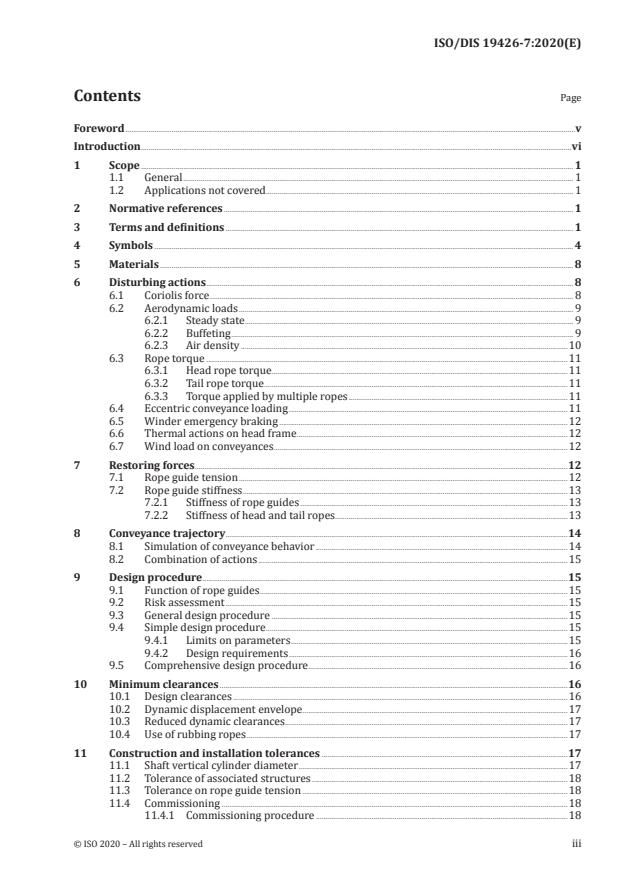

Contents Page

Foreword ..........................................................................................................................................................................................................................................v

Introduction ................................................................................................................................................................................................................................vi

1 Scope ................................................................................................................................................................................................................................. 1

1.1 General ........................................................................................................................................................................................................... 1

1.2 Applications not covered ................................................................................................................................................................ 1

2 Normative references ...................................................................................................................................................................................... 1

3 Terms and definitions ..................................................................................................................................................................................... 1

4 Symbols .......................................................................................................................................................................................................................... 4

5 Materials ....................................................................................................................................................................................................................... 8

6 Disturbing actions ............................................................................................................................................................................................... 8

6.1 Coriolis force ............................................................................................................................................................................................. 8

6.2 Aerodynamic loads .............................................................................................................................................................................. 9

6.2.1 Steady state ...................................................................... ..................................................................................................... 9

6.2.2 Buffeting .................................................................................................................................................................................. 9

6.2.3 Air density ..........................................................................................................................................................................10

6.3 Rope torque ............................................................................................................................................................................................11

6.3.1 Head rope torque ..........................................................................................................................................................11

6.3.2 Tail rope torque ...................................................................... ........................................................................................11

6.3.3 Torque applied by multiple ropes ..................................................................................................................11

6.4 Eccentric conveyance loading .................................................................................................................................................11

6.5 Winder emergency braking ......................................................................................................................................................12

6.6 Thermal actions on head frame .............................................................................................................................................12

6.7 Wind load on conveyances.........................................................................................................................................................12

7 Restoring forces ..................................................................................................................................................................................................12

7.1 Rope guide tension ...........................................................................................................................................................................12

7.2 Rope guide stiffness .........................................................................................................................................................................13

7.2.1 Stiffness of rope guides ...........................................................................................................................................13

7.2.2 Stiffness of head and tail ropes .........................................................................................................................13

8 Conveyance trajectory ..................................................................................................................................................................................14

8.1 Simulation of conveyance behavior ...................................................................................................................................14

8.2 Combination of actions .................................................................................................................................................................15

9 Design procedure ..............................................................................................................................................................................................15

9.1 Function of rope guides ................................................................................................................................................................15

9.2 Risk assessment ..................................................................................................................................................................................15

9.3 General design procedure ..........................................................................................................................................................15

9.4 Simple design procedure .............................................................................................................................................................15

9.4.1 Limits on parameters ................................................................................................................................................15

9.4.2 Design requirements .................................................................................................................................................16

9.5 Comprehensive design procedure .......................................................................................................................................16

10 Minimum clearances .....................................................................................................................................................................................16

10.1 Design clearances ..............................................................................................................................................................................16

10.2 Dynamic displacement envelope ..........................................................................................................................................17

10.3 Reduced dynamic clearances ...................................................................................................................................................17

10.4 Use of rubbing ropes .......................................................................................................................................................................17

11 Construction and installation tolerances ................................................................................................................................17

11.1 Shaft vertical cylinder diameter ............................................................................................................................................17

11.2 Tolerance of associated structures .....................................................................................................................................18

11.3 Tolerance on rope guide tension ..........................................................................................................................................18

11.4 Commissioning ....................................................................................................................................................................................18

11.4.1 Commissioning procedure ...................................................................................................................................18

© ISO 2020 – All rights reserved iii---------------------- Page: 3 ----------------------

ISO/DIS 19426-7:2020(E)

11.4.2 Components of commissioning procedure ............................................................................................18

12 Other design considerations .................................................................................................................................................................18

12.1 Loading and unloading of conveyances ..........................................................................................................................19

12.2 Accessing intermediate levels .................................................................................................................................................19

12.3 Number of rope guides .................................................................................................................................................................19

12.4 Rope guide positions .......................................................................................................................................................................19

12.5 Rope guide construction ..............................................................................................................................................................19

12.6 Rope guide tension and factor of safety .........................................................................................................................19

12.7 Rope guide attachments ..............................................................................................................................................................19

12.8 Shafts with more than one winder .....................................................................................................................................20

12.9 Design life .................................................................................................................................................................................................20

12.10 Rope guide tensioning ...................................................................................................................................................................20

12.10.1 Gravity tensioning devices ...................................................................................................................................20

12.10.2 Hydraulic tensioning devices .............................................................................................................................20

13 Assessment of existing installations .............................................................................................................................................20

13.1 General ........................................................................................................................................................................................................20

13.2 Application of measurements .................................................................................................................................................21

13.3 Upgrades or modifications ........................................................................................................................................................21

14 Inspection and maintenance .................................................................................................................................................................21

14.1 Deterioration mechanisms ........................................................................................................................................................21

14.1.1 Wear .........................................................................................................................................................................................21

14.1.2 Corrosion .............................................................................................................................................................................21

14.1.3 Mechanical damage ....................................................................................................................................................21

14.1.4 Broken wires ....................................................................................................................................................................21

14.2 Inspections ..............................................................................................................................................................................................22

14.2.1 Inspection intervals ....................................................................................................................................................22

14.2.2 Visual Inspection ..........................................................................................................................................................22

14.2.3 Non-destructive inspection .................................................................................................................................22

14.3 Maintenance actions .......................................................................................................................................................................22

14.3.1 Maintenance intervals ..............................................................................................................................................22

14.3.2 Lubrication .........................................................................................................................................................................22

14.3.3 Rope turning and rope lifting .............................................................................................................................22

14.3.4 Equalisation of hoist rope tensions ..............................................................................................................22

14.4 Rope guide discard criteria .......................................................................................................................................................23

14.5 Rope guide attachments ..............................................................................................................................................................23

Annex A (informative) Load combinations and displacement multipliers ...............................................................24

Annex B (informative) Scope of applicability of information in Annexes B to F ..................................................26

Annex C (informative) Preliminary aerodynamic coefficients ...............................................................................................35

Annex D (informative) Rope torque factors ...............................................................................................................................................45

Annex E (informative) Rope guide stiffness and tension ..............................................................................................................47

Annex F (informative) Approximate calculation of conveyance displacement .....................................................51

Bibliography .............................................................................................................................................................................................................................54

iv © ISO 2020 – All rights reserved---------------------- Page: 4 ----------------------

ISO/DIS 19426-7:2020(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www .iso .org/ directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www .iso .org/ patents).Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.For an explanation on the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to the

World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT) see the following

URL: www .iso .org/ iso/ foreword .html.This document was prepared by Technical Committee ISO/TC 82, Mining.

A list of all parts in the ISO 19426 series can be found on the ISO website.

© ISO 2020 – All rights reserved v

---------------------- Page: 5 ----------------------

ISO/DIS 19426-7:2020(E)

Introduction

Many mining companies, and many of the engineering companies which provide designs for mines,

operate globally so ISO 19426 was developed in response to a desire for a unified global approach to

the safe and robust design of structures for mine shafts. The characteristics of ore bodies, such as

their depth and shape, vary in different areas so different design approaches have been developed and

proven with use over time in different countries. Bringing these approaches together in ISO 19426 will

facilitate improved safety and operational reliability.The majority of the material in ISO 19426 deals with the loads to be applied in the design of structures

for mine shafts. Some principles for structural design are given, but for the most part it is assumed that

local standards will be used for the structural design.vi © ISO 2020 – All rights reserved

---------------------- Page: 6 ----------------------

DRAFT INTERNATIONAL STANDARD ISO/DIS 19426-7:2020(E)

Structures for mine shafts —

Part 7:

Rope guides

1 Scope

1.1 General

This document specifies the design loads and the design procedures for the design of rope guides

and rubbing ropes used for guiding conveyances and preventing collisions in vertical mine shafts for

permanent operations. This standard covers personnel and material hoisting, as well as rock hoisting

installations. There are no fundamental limitations placed on the size of conveyances, the hoisting

speeds, shaft layout configurations, or the shaft depth.This standard may be applicable under certain conditions to shaft sinking operations.

There are many reasons, based on technical, timing, and cost factors why rope guides may, or may

not be selected for a particular application, and these require careful assessment at feasibility stage

of any project where rope guides are considered. This standard provides some comments regarding

the advantages and disadvantages of using rope guides compared to rigid guides, and specific design

aspects to be considered when using rope guides. However, this standard is primarily intended to

provide the technical information required to ensure good engineering of shafts where rope guided

hoisting is the chosen solution.1.2 Applications not covered

This document does not cover matters of operational safety.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 12385-6, Steel wire ropes. Safety. Part 6: Stranded ropes for mine shaftsEN 12385-7, Steel wire ropes. Safety. Part 7: Locked coil ropes for mine shafts

ISO 19426-1, Structures for mine shafts — Part 1: Vocabulary

SANS 10293, Condition assessment of steel wire ropes on mine winders

ISO 19426-2, Structures for mine shafts — Part 2: Headframe structures

ISO 19426-5, Structures for mine shafts — Part 5: Shaft system structures

3 Terms and definitions

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at http:// www .iso .org/ obp© ISO 2020 – All rights reserved 1

---------------------- Page: 7 ----------------------

ISO/DIS 19426-7:2020(E)

— IEC Electropedia: available at http:// www .electropedia .org

For the purposes of this document, the terms and definitions given in ISO 19426-1 and the following apply.

3.1cheese weight

a stack of weights, usually steel castings, suspended from the bottom of a rope guide forming a dead

weight tensioning system3.2

collision

direct collision

A direct collision is an event in which a conveyance strikes another conveyance, or some other surface

which is essentially transverse to the direction of travel of the conveyance, as shown in Figure 1 a).

3.3oblique collision

An oblique collision is an event in which a conveyance strikes a shaft side wall, or some other surface

which is oriented essentially parallel with the direction of travel of the conveyance, as shown in

Figure 1 a) and Figure 1 b).a) Direct Collision

b) Oblique Collision

Figure 1 — Schematic of Possible Collision Types

3.4

design clearance

(static clearance)

the nominal distance between different conveyances, or between conveyances and fixed objects, in the

shaft, as shown on the design drawings3.5

design location

the intended location of elements of the rope guided hoisting installation, as shown on the design

drawings.2 © ISO 2020 – All rights reserved

---------------------- Page: 8 ----------------------

ISO/DIS 19426-7:2020(E)

3.6

displacement multiplier

a factor by which the predicted conveyance lateral displacement is multiplied to make statistical

allowance for inaccuracies in simulation and aerodynamic coefficients and construction tolerances

3.7dynamic clearance

the minimum distance between different conveyances, or between conveyances and fixed objects, in

the shaft during hoisting in the shaft, which is equal to the design clearance less the maximum dynamic

displacement3.8

dynamic displacement

the lateral dynamic displacement of conveyances while travelling in the shaft

3.9

design dynamic displacement

the lateral dynamic displacement of conveyances while travelling in the shaft multiplied by the

displacement multiplier, which makes provision for simulation uncertainties and construction

inaccuracies3.10

reduced dynamic clearance

the minimum distance between different conveyances, or between conveyances and fixed objects, in

the shaft during hoisting in the shaft, which is equal to the design clearance less the design dynamic

displacement3.11

entry point

position at which a conveyance enters fixed guides at the top and bottom ends of the hoisting cycle, and

at any intermediate stations3.12

entry speed

the speed at which conveyances enter the fixed guides at the top and bottom ends of the hoisting cycle,

and at any intermediate stations3.13

guide block

(guide bush)

(guide slipper)

the attachment of a conveyance to the rope guides. The guide block is usually made in two halves to bolt

around the rope guide, and it has a guide block liner forming the rubbing surface on the rope guide

3.14intermediate loading stations

any loading stations between bank level or a tipping station at the top of the shaft and a loading station

at the bottom of the shaft, or any loading stations located more than 100 m below the top anchor point

of the rope guides or more than 100 m above the bottom anchor point of the rope guides

3.15operating clearance

the distance between different conveyances, or between conveyances and fixed objects, in the shaft

during operation of the installation, which is equivalent to the design clearance reduced by the lateral

displacement of conveyances while travelling in the shaft, and reduced by anticipated misalignments

and tolerances3.16

rope guide shoe

the mounting to secure the guide block through which the rope guide passes

© ISO 2020 – All rights reserved 3

---------------------- Page: 9 ----------------------

ISO/DIS 19426-7:2020(E)

3.17

rubbing block

(fixed guide slippers)

the contact point between a conveyance and the fixed guides at top and bottom of wind, which can run

within or outside the fixed guide, and where the fixed guides are located close to the rope guides can

also serve the purpose of the rope guide shoe3.18

rubbing plate

a plate, or surface, mounted on the conveyances to provide a surface to rub against the rubbing ropes,

which shall be provided when rubbing ropes are used3.19

rubbing ropes

ropes located between conveyances running on rope guides, intended to deflect conveyances away

from each other, thereby reducing the severity of a possible collision3.20

vertical shaft cylinder

the maximum circular cylinder, clear of any obstructions, that will fit within the excavated mine shaft

and constructed infrastructure3.21

winder emergency braking

(winder trip-out)

braking of the winder under emergency conditions, such as loss of electrical power, detection of over-

tension or under-tension on the hoist ropes, or accident to shaft signal4 Symbols

For the purposes of this document, the following symbols apply.

a Conveyance acceleration, m/s

A Area of side of conveyance, m

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.