ISO/DIS 18669-1

(Main)Internal combustion engines -- Piston pins

Internal combustion engines -- Piston pins

Moteurs à combustion interne -- Axes de pistons

General Information

RELATIONS

Standards Content (sample)

DRAFT INTERNATIONAL STANDARD

ISO/DIS 18669-1

ISO/TC 22/SC 34 Secretariat: ANSI

Voting begins on: Voting terminates on:

2020-06-01 2020-08-24

Internal combustion engines — Piston pins —

Part 1:

General specifications

Moteurs à combustion interne — Axes de pistons —

Partie 1: Spécifications générales

ICS: 43.060.10

THIS DOCUMENT IS A DRAFT CIRCULATED

FOR COMMENT AND APPROVAL. IT IS

THEREFORE SUBJECT TO CHANGE AND MAY

NOT BE REFERRED TO AS AN INTERNATIONAL

STANDARD UNTIL PUBLISHED AS SUCH.

IN ADDITION TO THEIR EVALUATION AS

BEING ACCEPTABLE FOR INDUSTRIAL,

This document is circulated as received from the committee secretariat.

TECHNOLOGICAL, COMMERCIAL AND

USER PURPOSES, DRAFT INTERNATIONAL

STANDARDS MAY ON OCCASION HAVE TO

BE CONSIDERED IN THE LIGHT OF THEIR

POTENTIAL TO BECOME STANDARDS TO

WHICH REFERENCE MAY BE MADE IN

Reference number

NATIONAL REGULATIONS.

ISO/DIS 18669-1:2020(E)

RECIPIENTS OF THIS DRAFT ARE INVITED

TO SUBMIT, WITH THEIR COMMENTS,

NOTIFICATION OF ANY RELEVANT PATENT

RIGHTS OF WHICH THEY ARE AWARE AND TO

PROVIDE SUPPORTING DOCUMENTATION. ISO 2020

---------------------- Page: 1 ----------------------

ISO/DIS 18669-1:2020(E)

COPYRIGHT PROTECTED DOCUMENT

© ISO 2020

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting

on the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address

below or ISO’s member body in the country of the requester.ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Fax: +41 22 749 09 47

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii © ISO 2020 – All rights reserved

---------------------- Page: 2 ----------------------

ISO/DIS 18669-1:2020(E)

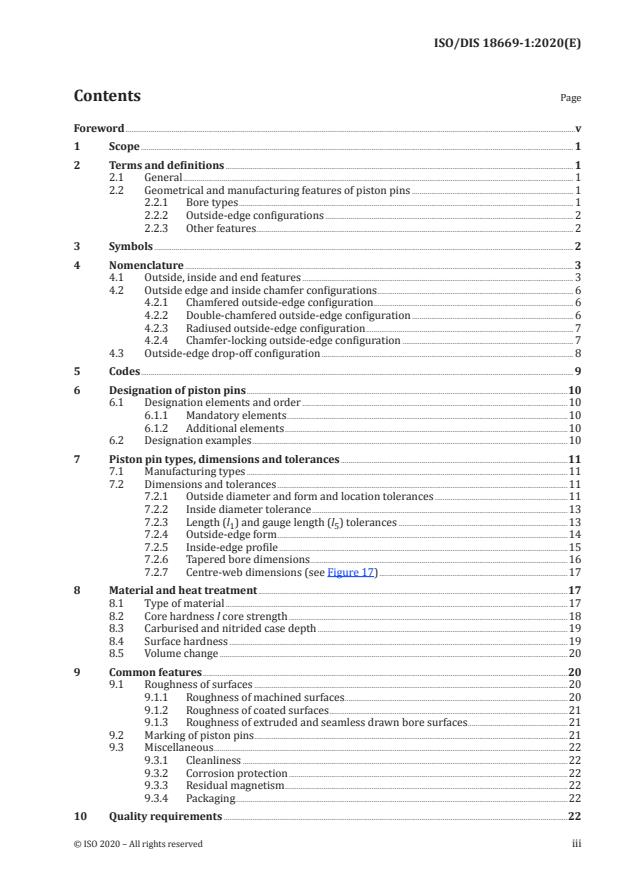

Contents Page

Foreword ..........................................................................................................................................................................................................................................v

1 Scope ................................................................................................................................................................................................................................. 1

2 Terms and definitions ..................................................................................................................................................................................... 1

2.1 General ........................................................................................................................................................................................................... 1

2.2 Geometrical and manufacturing features of piston pins .................................................................................... 1

2.2.1 Bore types .............................................................................................................................................................................. 1

2.2.2 Outside-edge configurations ................................................................................................................................. 2

2.2.3 Other features ..................................................................................................................................................................... 2

3 Symbols .......................................................................................................................................................................................................................... 2

4 Nomenclature .......................................................................................................................................................................................................... 3

4.1 Outside, inside and end features ............................................................................................................................................. 3

4.2 Outside edge and inside chamfer configurations ...................................................................................................... 6

4.2.1 Chamfered outside-edge configuration ........................................................................................................ 6

4.2.2 Double-chamfered outside-edge configuration .................................................................................... 6

4.2.3 Radiused outside-edge configuration ............................................................................................................ 7

4.2.4 Chamfer-locking outside-edge configuration ......................................................................................... 7

4.3 Outside-edge drop-off configuration ................................................................................................................................... 8

5 Codes ................................................................................................................................................................................................................................. 9

6 Designation of piston pins .......................................................................................................................................................................10

6.1 Designation elements and order ..........................................................................................................................................10

6.1.1 Mandatory elements ..................................................................................................................................................10

6.1.2 Additional elements ...................................................................................................................................................10

6.2 Designation examples ....................................................................................................................................................................10

7 Piston pin types, dimensions and tolerances ......................................................................................................................11

7.1 Manufacturing types .......................................................................................................................................................................11

7.2 Dimensions and tolerances .......................................................................................................................................................11

7.2.1 Outside diameter and form and location tolerances .....................................................................11

7.2.2 Inside diameter tolerance .....................................................................................................................................13

7.2.3 Length (l ) and gauge length (l ) tolerances ........................................................................................13

1 57.2.4 Outside-edge form .......................................................................................................................................................14

7.2.5 Inside-edge profile ......................................................................................................................................................15

7.2.6 Tapered bore dimensions ......................................................................................................................................16

7.2.7 Centre-web dimensions (see Figure 17) ..................................................................................................17

8 Material and heat treatment .................................................................................................................................................................17

8.1 Type of material ..................................................................................................................................................................................17

8.2 Core hardness l core strength .................................................................................................................................................18

8.3 Carburised and nitrided case depth ..................................................................................................................................19

8.4 Surface hardness ................................................................................................................................................................................19

8.5 Volume change .....................................................................................................................................................................................20

9 Common features ..............................................................................................................................................................................................20

9.1 Roughness of surfaces ...................................................................................................................................................................20

9.1.1 Roughness of machined surfaces ....................................................................................................................20

9.1.2 Roughness of coated surfaces ............................................................................................................................21

9.1.3 Roughness of extruded and seamless drawn bore surfaces ....................................................21

9.2 Marking of piston pins ...................................................................................................................................................................21

9.3 Miscellaneous ........................................................................................................................................................................................22

9.3.1 Cleanliness .........................................................................................................................................................................22

9.3.2 Corrosion protection .................................................................................................................................................22

9.3.3 Residual magnetism ...................................................................................................................................................22

9.3.4 Packaging.............................................................................................................................................................................22

10 Quality requirements ...................................................................................................................................................................................22

© ISO 2020 – All rights reserved iii---------------------- Page: 3 ----------------------

ISO/DIS 18669-1:2020(E)

10.1 Material characteristics ................................................................................................................................................................22

10.1.1 Decarburisation .............................................................................................................................................................22

10.1.2 Cementite network .....................................................................................................................................................22

10.1.3 Nitride coating ................................................................................................................................................................22

10.1.4 Grinder burn .....................................................................................................................................................................22

10.2 Material defects ...................................................................................................................................................................................22

10.2.1 Cracks .....................................................................................................................................................................................23

10.2.2 Forming streaks .............................................................................................................................................................23

10.3 Visual defects .........................................................................................................................................................................................23

Bibliography .............................................................................................................................................................................................................................25

iv © ISO 2020 – All rights reserved---------------------- Page: 4 ----------------------

ISO/DIS 18669-1:2020(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2. www .iso .org/ directivesAttention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received. www .iso .org/ patentsAny trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.The committee responsible for this document is ISO/TC 22, Road vehicles.

This second edition cancels and replaces the first edition (ISO 18669-1:2004), which has been

technically revised.ISO 18669 consists of the following parts, under the general title Internal combustion engines —

Piston pins:— Part 1: General specifications

— Part 2: Inspection measuring principles

© ISO 2020 – All rights reserved v

---------------------- Page: 5 ----------------------

DRAFT INTERNATIONAL STANDARD ISO/DIS 18669-1:2020(E)

Internal combustion engines — Piston pins —

Part 1:

General specifications

1 Scope

This part of ISO 18669 specifies the essential dimensional characteristics of piston pins with a nominal

outer diameter from 8 mm up to and including 100 mm, for reciprocating internal combustion engines

for road vehicles and other applications. In certain applications, except road vehicles, and provided that

mutual agreement is made between the customer and the manufacturer, this part of ISO 18669 may be

used with suitable modifications.In addition, it establishes a vocabulary, a pin-type classification, material description based on

mechanical properties, common features and quality requirements.The use of this part of ISO 18669 may require a manufacturer and customer statistical process control

agreement.2 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

2.1 General

2.1.1

piston pin

precision cylindrical component that connects the piston to the connecting rod and has a smooth hard

peripheral surface2.2 Geometrical and manufacturing features of piston pins

2.2.1 Bore types

2.2.1.1

cylindrical

pin having a straight cylindrical bore

2.2.1.2

centre web

pin inside diameter formed symmetrically from each end leaving a web in the pin centre

Note 1 to entry: The web is subsequently removed leaving a step as shown in Figure 3.

2.2.1.3tapered

pin with conical-shaped inside diameter near the ends that reduces the weight of the piston pin

2.2.1.4machined

pin with inside diameter produced solely by machining

© ISO 2020 – All rights reserved 1

---------------------- Page: 6 ----------------------

ISO/DIS 18669-1:2020(E)

2.2.1.5

seamless drawn tube

hollow steel product which does not contain any line junctures resulting from the method of

manufacture2.2.1.6

end web

pin inner diameter formed from one end leaving a web near the opposite end

Note 1 to entry: The web is punched out. The pin is then drawn over a mandrel and a forming line may result as

shown in Figure 4.2.2.2 Outside-edge configurations

2.2.2.1

chamfer

outside-edge bevelled feature that is sometimes used to mate with a round retainer ring

Note 1 to entry: Referred to as “locking chamfer” when a round wire retainer ring is located on the chamfer angle

and used to secure the pin in the piston.2.2.2.2

form angle δ

region of outside-edge form that provides a smooth transition to the peripheral surface to facilitate

ease of assembly2.2.2.3

form angle γ

region of outside-edge form that provides a smooth transition to the end face

2.2.2.4

drop-off

non-functional machining feature that creates a transition between the outside edge and the

peripheral surfaceNote 1 to entry: See Figure 12.

2.2.2.5

inside-edge chamfer

bevelled edge between the bore surface and the end faces of the piston pin

2.2.2.6

gauge point

locating point on the pin outside-edge chamfer from where the gauge diameter (d ) and gauge length

(l ) are measured2.2.3 Other features

2.2.3.1

volume change

change detected as a permanent outside-diameter dimensional deviation at reference temperature

after being heated to a test temperature for a specified period of time2.2.3.2

slag lines

linear flaws of non-metallic inclusions

3 Symbols

For the purposes of this part of ISO 18669, the symbols in Table 1 apply.

2 © ISO 2020 – All rights reserved

---------------------- Page: 7 ----------------------

ISO/DIS 18669-1:2020(E)

Table 1 — Symbols

Symbol

Description

abbreviation

a Wall thickness

b Outside-edge drop-off length

c Outside-edge drop-off height

d Outside diameter

d Inside diameter

d Tapered bore diameter

d Centre-web diameter

d Gauge diameter

d End face diameter

e Tapered bore runout

f Outside-edge length

g Outside-edge chamfer length

H Limit hardness

h End face concavity

h End face step

k Tapered bore relief

l Length

l Tapered bore length

l Centre-web length

l Gauge length

r Outside-edge radius

R Core strength

s End face runout

t Inside-edge chamfer length

t Outside-edge form length

α Tapered bore angle

β Outside-edge chamfer angle

γ Outside-edge form angle end face

δ Outside-edge form angle

4 Nomenclature

4.1 Outside, inside and end features

Terms commonly used to describe pins with a cylindrical bore are shown in Figure 1.

© ISO 2020 – All rights reserved 3---------------------- Page: 8 ----------------------

ISO/DIS 18669-1:2020(E)

Key

1 end face

2 bore surface

3 peripheral surface

d outside diameter

d inside diameter

l Length

a wall thickness

See Figure 2.

Figure 1 — Pin with cylindrical bore

Terms commonly used to describe end face concavity are shown in Figure 2a).

Terms commonly used to describe end face step are shown in Figure 2b).

a) End face concavity b) End face step

Key

h end face concavity

h end face step

d end face diameter

NOTE End face concavity and end face step not recommended for end face locking.

Figure 2 — Detail W of Figure 1

Terms commonly used to describe pins with a centre web are shown in Figure 3.

4 © ISO 2020 – All rights reserved

---------------------- Page: 9 ----------------------

ISO/DIS 18669-1:2020(E)

Key

1 centre-web radius

l centre-web length

d centre-web diameter

Figure 3 — Pin with cold-formed centre web

Terms commonly used to describe pins with a cold-formed end-web are shown in Figure 4.

Key1 end-web forming line

Figure 4 — Pin with cold-formed end web

Terms commonly used to describe pins with a tapered bore are shown in Figure 5.

Key

1 tapered bore surface

α tapered bore angle

d tapered bore diameter

l tapered bore length

Figure 5 — Pin with tapered bore

© ISO 2020 – All rights reserved 5

---------------------- Page: 10 ----------------------

ISO/DIS 18669-1:2020(E)

4.2 Outside edge and inside chamfer configurations

Terms commonly used to describe the outside edge and inside chamfer configurations are shown in

Figure 6.Key

1 outside-edge chamfer or radius

2 inside-edge chamfer

t inside-edge chamfer length

See Figures 7 and 8.

See Figure 9.

NOTE This may be used with either a round or rectangular retainer ring.

Figure 6 — Outside-edge configuration (detail X: chamfered; detail Y: radiused)

4.2.1 Chamfered outside-edge configuration

Terms commonly used to describe the chamfered outside-edge configuration are shown in Figure 7.

Keyf outside-edge length

β outside-edge chamfer angle

Figure 7 — Chamfered configuration (detail X of Figure 6)

4.2.2 Double-chamfered outside-edge configuration

Terms commonly used to describe double-chamfered outside-edge configurations are shown in

Figure 8. The double chamfer is for assembly improvements of the piston pin.6 © ISO 2020 – All rights reserved

---------------------- Page: 11 ----------------------

ISO/DIS 18669-1:2020(E)

Key

F outside-edge length

G outside-edge chamfer length

Δ outside-edge form angle

Β outside-edge chamfer angle

Figure 8 — Double-chamfered configuration (detail X of Figure 6)

4.2.3 Radiused outside-edge configuration

Terms commonly used to describe radiused outside-edge configurations are shown in Figure 9.

KeyR outside-edge radius

F outside-edge length

Δ outside-edge form angle

Figure 9 — Radiused configuration (detail Y of Figure 6)

4.2.4 Chamfer-locking outside-edge configuration

Terms commonly used to describe chamfer-locking outside-edge configurations are shown in

Figures 10 and 11.© ISO 2020 – All rights reserved 7

---------------------- Page: 12 ----------------------

ISO/DIS 18669-1:2020(E)

Key

1 gauge points

l gauge length

d gauge diameter

Figure 10 — Chamfer-locking outside-edge for round retainer ring

Key

1 gauge point

g outside-edge chamfer length

f outside-edge length

l gauge length

d gauge diameter

Figure 11 — Detail Z of Figure 10

4.3 Outside-edge drop-off configuration

Terms commonly used to describe outside-edge drop-off configurations are shown in Figure 12a), 12b)

and 12c).The outside-edge drop-off is for manufacturing purposes and is therefore a chamfer that is very small

in height but long in length.8 © ISO 2020 – All rights reserved

---------------------- Page: 13 ----------------------

ISO/DIS 18669-1:2020(E)

a) Chamfered edge and drop-off b) Double-chamfered edge and c) Radiused edge and

drop-off drop-off

Key

B outside-edge drop-off length

C outside-edge drop-off height

G outside-edge chamfer length

F outside-edge length

Δ outside-edge form angle

Β outside-edge chamfer angle

Figure 12 — Drop-off configurations (detail X and Y of Figure 6)

5 Codes

Codes used for piston pins shall be as given in Table 2 with their explanatory descriptions.

Table 2 — Codes and descriptionsRelevant

subclause of

Code Description

this part of

ISO 18669

P1…P6 Pin-type classification according to manufacturing method of the pin centre hole 7.1

X Piston pins in combination with needle bearing 8.3F1, F2, F3 Outside-edge configuration tolerance class 7.2.4

K Carburising steel class K 8.1 / 8.2

S Carburising steel class S 8.1 / 8.2

L Carburising steel class L 8.1 / 8.2

M Carburising steel class M 8.1 / 8.2

N Nitriding steel class N 8.1 / 8.2

V Piston pins with limited volume change 8.3 / 8.4 / 8.5

H1, H2 Surface hardness class 8.4

R1, R2 Peripheral surface roughness class 9.1.1

G Chamfer-locking outside-edge configuration (gauge point) 6.2 / 7.2.4

R Outside-edge radiused 7.2.4 / 6.1.2

C1 Outside-edge chamfered 7.2.4

C2 Outside-edge double chamfered 7.2.4

© ISO 2020 – All rights reserved 9

---------------------- Page: 14 ----------------------

ISO/DIS 18669-1:2020(E)

Table 2 (continued)

Relevant

subclause of

Code Description

this part of

ISO 18669

LA, LB Length tolerance class 7.2.3

MM Manufacturer’s mark 9.2

TC Piston pins with bore surface cold formed 7.2.6

6 Designation of piston pins

6.1 Designation elements and order

To designate piston pins, the following details shall be given, in the order shown below. The codes given

in Table 2 shall be used.6.1.1 Mandatory elements

The following mandatory elements shall constitute the designation of a piston pin:

— designation, i.e. piston pin;— number of International Standard: ISO 18669;

— type of piston pin, e.g. P1;

— hyphen;

— size of piston pin, d × d × l or d / d − α × d × l for a pin with tapered bore;

1 2 1 1 3 2 1— hyphen;

— material code, e.g. L.

6.1.2 Additional elements

The following optional elements may be added to the designation of a piston pin; in this case they shall

be separated from the mandatory elements by a slash (/):— code for outside-edge configuration, e.g. R, C1, C2, G;

— size of chamfer-locking gauge dimensions, d × l × β when code G is specified;

5 5

— code for limited volume change, V;

— code for surface hardness, H1, H2;

— code for surface roughness, R1, R2.

6.2 Designation examples

The following are examples of piston pin designation in accordance with this part of ISO 18669.

EXAMPLE 1 Designation of a piston pin complying with the requirements of ISO 18669-1, manufacturing

type P5 (P5) of outside diameter d = 20 mm (20), inside diameter d = 11 mm (11) and length l = 50 mm (50)

1 2 1made of carburising steel, class L (L) with double chamfered outside-edge configuration (C2), selected chamfer-

locking outside-edge configuration (G) of gauge diameter d = 18,9 mm (18,9), gauge length l = 49 mm (49) and

5 5outside-edge chamfer angle β = 45° (45), limited volume change (V), class 2 surface hardness (H2) and class 1

roughness on peripheral surface (R1). Parameters in parenthesis are used in the ISO piston pin designation:

10 © ISO 2020 – All rights reserved---------------------- Page: 15 ----------------------

ISO/DIS 18669-1:2020(E)

Piston pin ISO 18669-P5, 20 × 11 × 50-L / C2 G-18,9 × 49 × 45 V H2 R1

EXAMPLE 2 Designation of a piston pin complying with the requirements of ISO 18669-1, manufacturing

type P2 (P2) of outside diameter d = 22 mm (22), tapered bore diameter d = 18 mm (18), tapered bore angle

1 3α = 20 (20), inside diameter d = 12 mm (12) and length l = 60 mm (60) made of nitriding steel, class (N).

2 1Parameters in parenthesis are used in the ISO piston pin designation:

Piston pin ISO 18669-P2, 22/18-20 × 12 × 60-N

7 Piston pin types, dimensions and tolerances

7.1 Manufacturing types

Table 3 — Piston pin manufacturing types

Permissible manufacturing methods

Manufacturing

cold-formed seamless

code

machined cold-formed

centre web drawn tube

P1 x x x X

P2 x x x No

P3 no x x No

P4 x x no No

P5 no x no No

P6 x no no No

7.2 Dimensions and tolerances

7.2.1 Outside diameter and form and location tolerances

© ISO 2020 – All rights reserved 11

---------------------- Page: 16 ----------------------

ISO/DIS 18669-1:2020(E)

a) Chamfered edge and drop-off b) Double-chamfered edge and c) Radiused edge and

drop-off drop-off

Key

B outside-edge drop-off length

C outside-edge drop-off height

F outside-edge length

G outside-edge chamfer length

Δ outside-edge form angle

Β outside-edge chamfer angle

See Figure 14.

Figure 13 — Drop-off configurations (detail X and Y of Figure 6)

Table 4 shows the outside diameter tolerances and the permissible cylindricity, circularity and edge

drop-off.Table 4 — Outside diameter (d ) and form and location tolerances

Dimensions in millimetres

Outside diameter Edge drop-off

Cylindricity Circularity

b c

d tolerance max. max.

max. max.

8 to ≤ 16 0 to − 0,004 0,0015 0,001

> 16 to ≤ 30 0 to − 0,005 0,002 0,0015 0,12 × d 0,001

> 30 to ≤ 60 0 to − 0,006 0,0025 0,002

> 60 to ≤ 100 0 to − 0,008 0,003 0,0025 0,08 × d 0,0015

Table 5 — Waviness

Dimensions in millimetres

Sector roundness Filtered bandwidth

Dominant roundness waviness

Outside

15° 30°

diameter

(UPR 1 –50) (UPR 1 –50) (UPR 10 – 50) (UPR 10 – 50)

d max max max max

c c

8 to ≤ 16 0.0006 0.0007 0.0006 0.0006

> 16 to ≤ 30 0.0009 0.0011 0.0009 0.0009

> 30 to ≤ 60 0,0012 0.0014 0,0012 0.0012

a Other values to be agreed between customer and manufacturer

12 © ISO 2020 – All rights reserved

---------------------- Page: 17 ----------------------

ISO/DIS 18669-1:2020(E)

Table 5 (continued)

Sector roundness Filtered bandwidth

Dominant roundness waviness

Outside

15° 30°

diameter

(UPR 1 –50) (UPR 1 –50) (UPR 10 – 50) (UPR 10 – 50)

d max max max

max

> 60 to ≤ 100 0,0015 0,0018 0,0015 0.0015

a Other values to be agreed between customer and manufacturer

7.2.2 Inside diameter tolerance

The tolerances of inside diameter (d ) and concentricity (permissible wall difference) are shown in

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.