ISO/DIS 17431

(Main)Fire test -- Reduced-scale model box test

Fire test -- Reduced-scale model box test

Essais au feu -- Essai à échelle réduite utilisant une boîte

General Information

Standards Content (sample)

DRAFT INTERNATIONAL STANDARD ISO/DIS 17431

ISO/TC 92/SC 1 Secretariat: BSI

Voting begins on: Voting terminates on:

2003-09-04 2004-02-04

INTERNATIONAL ORGANIZATION FOR STANDARDIZATION • МЕЖДУНАРОДНАЯ ОРГАНИЗАЦИЯ ПО СТАНДАРТИЗАЦИИ • ORGANISATION INTERNATIONALE DE NORMALISATION

Fire test — Reduced-scale model box testEssais au feu — Essai à échelle réduite utilisant une boîte

ICS 13.220.40; 13.220.50

In accordance with the provisions of Council Resolution 15/1993 this document is circulated in

the English language only.Conformément aux dispositions de la Résolution du Conseil 15/1993, ce document est distribué

en version anglaise seulement.To expedite distribution, this document is circulated as received from the committee secretariat.

ISO Central Secretariat work of editing and text composition will be undertaken at publication

stage.Pour accélérer la distribution, le présent document est distribué tel qu'il est parvenu du

secrétariat du comité. Le travail de rédaction et de composition de texte sera effectué au

Secrétariat central de l'ISO au stade de publication.THIS DOCUMENT IS A DRAFT CIRCULATED FOR COMMENT AND APPROVAL. IT IS THEREFORE SUBJECT TO CHANGE AND MAY NOT BE

REFERRED TO AS AN INTERNATIONAL STANDARD UNTIL PUBLISHED AS SUCH.IN ADDITION TO THEIR EVALUATION AS BEING ACCEPTABLE FOR INDUSTRIAL, TECHNOLOGICAL, COMMERCIAL AND USER PURPOSES, DRAFT

INTERNATIONAL STANDARDS MAY ON OCCASION HAVE TO BE CONSIDERED IN THE LIGHT OF THEIR POTENTIAL TO BECOME STANDARDS TO

WHICH REFERENCE MAY BE MADE IN NATIONAL REGULATIONS.© International Organization for Standardization, 2003

---------------------- Page: 1 ----------------------

ISO/DIS 17431

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but shall

not be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In

downloading this file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat

accepts no liability in this area.Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation

parameters were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In the

unlikely event that a problem relating to it is found, please inform the Central Secretariat at the address given below.

Copyright noticeThis ISO document is a Draft International Standard and is copyright-protected by ISO. Except as permitted

under the applicable laws of the user's country, neither this ISO draft nor any extract from it may be

reproduced, stored in a retrieval system or transmitted in any form or by any means, electronic, photocopying,

recording or otherwise, without prior written permission being secured.Requests for permission to reproduce should be addressed to either ISO at the address below or ISO's

member body in the country of the requester.ISO copyright office

Case postale 56 CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Reproduction may be subject to royalty payments or a licensing agreement.

Violators may be prosecuted.

ii ISO 2003 – All rights reserved

---------------------- Page: 2 ----------------------

ISO/DIS 17431

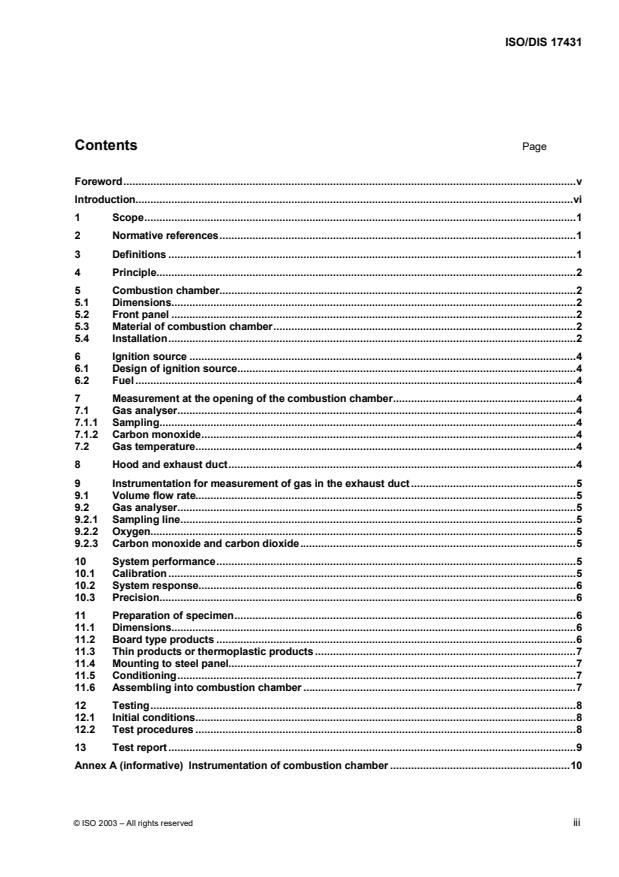

Contents Page

Foreword.......................................................................................................................................................v

Introduction..................................................................................................................................................vi

1 Scope................................................................................................................................................1

2 Normative references.......................................................................................................................1

3 Definitions ........................................................................................................................................1

4 Principle............................................................................................................................................2

5 Combustion chamber.......................................................................................................................2

5.1 Dimensions.......................................................................................................................................2

5.2 Front panel .......................................................................................................................................2

5.3 Material of combustion chamber.....................................................................................................2

5.4 Installation........................................................................................................................................2

6 Ignition source .................................................................................................................................4

6.1 Design of ignition source.................................................................................................................4

6.2 Fuel ...................................................................................................................................................4

7 Measurement at the opening of the combustion chamber.............................................................4

7.1 Gas analyser.....................................................................................................................................4

7.1.1 Sampling...........................................................................................................................................4

7.1.2 Carbon monoxide.............................................................................................................................4

7.2 Gas temperature...............................................................................................................................4

8 Hood and exhaust duct....................................................................................................................4

9 Instrumentation for measurement of gas in the exhaust duct .......................................................5

9.1 Volume flow rate...............................................................................................................................5

9.2 Gas analyser.....................................................................................................................................5

9.2.1 Sampling line....................................................................................................................................5

9.2.2 Oxygen..............................................................................................................................................5

9.2.3 Carbon monoxide and carbon dioxide............................................................................................5

10 System performance........................................................................................................................5

10.1 Calibration ........................................................................................................................................5

10.2 System response..............................................................................................................................6

10.3 Precision...........................................................................................................................................6

11 Preparation of specimen..................................................................................................................6

11.1 Dimensions.......................................................................................................................................6

11.2 Board type products ........................................................................................................................6

11.3 Thin products or thermoplastic products .......................................................................................7

11.4 Mounting to steel panel....................................................................................................................7

11.5 Conditioning.....................................................................................................................................7

11.6 Assembling into combustion chamber ...........................................................................................7

12 Testing..............................................................................................................................................8

12.1 Initial conditions...............................................................................................................................8

12.2 Test procedures ...............................................................................................................................8

13 Test report ........................................................................................................................................9

Annex A (informative) Instrumentation of combustion chamber ............................................................10

© ISO 2003 – All rights reserved iii---------------------- Page: 3 ----------------------

ISO/DIS 17431

Annex B (informative) Recommended ignition source ............................................................................16

Annex C (informative) Preparation of specimen ......................................................................................18

iv © ISO 2003 – All rights reserved---------------------- Page: 4 ----------------------

ISO/DIS 17431

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national

standards bodies (ISO member bodies). The work of preparing International Standards is normally

carried out through ISO technical committees. Each member body interested in a subject for which a

technical committee has been established has the right to be represented on that committee.

International organizations, governmental and non-governmental, in liaison with ISO, also take part in

the work. ISO collaborates closely with the International Electrotechnical Commission (IEC) on all

matters of electrotechnical standardization.International Standards are drafted in accordance with the rules given in the ISO/IEC Directives,

Part 2.The main task of technical committees is to prepare International Standards. Draft International

Standards adopted by the technical committees are circulated to the member bodies for voting.

Publication as an International Standard requires approval by at least 75 % of the member bodies

casting a vote.Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights.

ISO 17431 was prepared by Technical Committee ISO/TC 92, Fire safety, Subcommittee SC 1, Fire

initiation and growth.Annexes A, B and C of this standard are for information only.

© ISO 2003 – All rights reserved v

---------------------- Page: 5 ----------------------

ISO/DIS 17431

Introduction

This test method is intended to describe the fire behaviour of a product under controlled laboratory

conditions.The test method may be used as part of a fire hazard assessment which takes into account all of the

factors which are pertinent to an assessment of the fire hazard of a particular and use.

WARNING — So that suitable precautions can be taken to safeguard health, the attention of all

concerned in fire tests is drawn to the possibility that toxic or harmful gases can be evolved

during combustion of test specimens.The test procedures involve high temperatures and combustion processes from ignition to a

fully developed fire. Therefore, hazards can exist for burns, ignition of extraneous objects or

clothing. The operators should use protective clothing, e.g. helmet, face-shield and equipment

for avoiding exposure to toxic gases.Means for extinguishing a fully developed fire should be available.

vi © ISO 2003 – All rights reserved

---------------------- Page: 6 ----------------------

DRAFT INTERNATIONAL STANDARD ISO/DIS 17431

Fire test — Reduced-scale model box test

1 Scope

This International Standard specifies an intermediate-scale test method that simulates a fire that

under well-ventilated conditions starts in a corner of a small room with a single doorway until the room

is fully involved with fire.The method is primarily intended to evaluate the contribution to toxic hazard in, and potential for fire

spread to, evacuation routes connected to the room of origin in which surface products are installed.

The method is especially suitable for products with which a full-scale room test has to be terminated

before the full involvement of the room with fire because of the occurrence of flashover or any other

safety reasons.2 Normative references

The following referenced documents are indispensable for the application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendments) applies.ISO 554:1976, Standard atmospheres for conditioning and/or testing — Specifications

ISO TR 3814: 1989, Test for measuring "reaction to fire" of building materials — Their development

and applicationISO 9705:1993, Fire tests — Full-scale room test for surface products

ISO 13943:2000, Fire safety — Vocabulary

ISO TR 14697:1996, Guide on the use of substrates

ISO 14934-1:2002, Fire tests — Calibration and use of heat flux meter — Part 1: General principle

3 DefinitionsFor the purpose of this international standard, the definitions given in ISO 13943 and the following

definitions shall apply.3.1

exposed surface

the surface of the product subjected to the heating conditions of the test

© ISO 2003 – All rights reserved 1

---------------------- Page: 7 ----------------------

ISO/DIS 17431

3.2

surface product

any part of a compartment that constitutes an exposed surface on the interior wall, ceiling and/or floor

such as panels, tiles, boards, wall papers or coatings4 Principle

An indication of the toxic hazard in an evacuation route connected to the room of fire origin is

provided by the measurement of certain toxic gas at the doorway of the model box.

The potential for fire spread to objects outside the room of fire origin is evaluated by the heat release

rate and total heat release from the model box.5 Combustion chamber

5.1 Dimensions

The combustion chamber (see Figure 1) shall consist of three walls, a ceiling and a floor connected at

right angles. The inside dimension of the combustion chamber shall have the following dimensions:

a) Length: (1,8 m ± 0,01) mb) Width: (1,1 m ± 0,01) m

c) Height: (1,0 m ± 0,01) m

5.2 Front panel

A front wall panel with an opening of the following dimensions (see Figure 1) shall be attached to the

opening of the combustion chamber in prior to each test. The opening shall be at the centre of the

front wall panel and touch the floor.a) Width of the front panel: (1,1 m ± 0,01) m

b) Height of the front panel: (1,0 m ± 0,01) m

c) Width of the opening: (0,3 m ± 0,01) m

d) Height of the opening: (0,67 m ± 0,01) m

5.3 Material of combustion chamber

The combustion chamber shall be constructed of non-combustible material with a density of

(400-900) kg m . The thickness of the construction shall be (20 ± 2) mm.5.4 Installation

The combustion chamber shall be placed in an essentially draught free space, large enough to ensure

that there is no influence on the test fire. Hanging the combustion chamber can help measurement of

mass loss and accurate collection of combustion products. An example of a design for hanging

combustion chamber is given in Annex A.2 © ISO 2003 – All rights reserved

---------------------- Page: 8 ----------------------

ISO/DIS 17431

6 6

7 7

2 99

8 8

840

1 680

1 800 1 100

B-B A-A

9 300

10 2

1 680

1 110

1 800

11 12

1 Top panel 6 Combustion chamber 11 Horizontal section

2 Inner wall 7 Steel sheet (0,27) 12 Front wall panel

3 Floor 8 Specimen

4 Opening 9 Side wall

5 Fire source 10 Opening

Figure 1 — Combustion chamber with specimen panels, front wall panel and ignition source

© ISO 2003 – All rights reserved 31 100

1 000

840

840

300

670

1 000

840

1 000

670

---------------------- Page: 9 ----------------------

ISO/DIS 17431

6 Ignition source

6.1 Design of ignition source

The ignition source shall be a propane gas burner having a 0,17 m × 0,17 m square top surface layer

of a porous, inert material, e.g. sand. The construction shall be such that an even gas flow is achieved

over the entire opening area. It is recommended to use the gas burner specified in Annex B.

WARNING — All parts and equipment of the burner system such as tubes, couplings, flow

meters, etc. shall be of approved type for propane. The installation shall be performed in

accordance with existing safety regulations.The burner should, for reasons of safety, be equipped with a remote control ignition device,

for example a pilot flame, electric spark or a glow wire. There should be a warning system for

leakage of gas in case of extinction for the flame.6.2 Fuel

The fuel for the burner shall be of industrial grade propane (95 % purity). The net heat of combustion

of the fuel shall be 40 kW during test period. The fuel gas flow rate to the burner shall be measured

with an accuracy of at least ± 3 % and shall be controlled within ± 5 % of the prescribed value of heat

output.7 Measurement at the opening of the combustion chamber

This clause specifies minimum requirement for the instrumentation attached to the opening of the

combustion chamber. Additional information and designs can be found in Annex A.7.1 Gas analyser

7.1.1 Sampling

The gas shall be sampled at the opening of the combustion chamber at a position where the

combustion products flow out and any ambient air coming into the chamber shall not be sampled. The

sampling line shall be made of an inert material that will not influence the concentration of the gas

species to be analysed.7.1.2 Carbon monoxide

The gas concentration shall be measured using an analyser having an accuracy of at least ± 0,02 %

by volume for carbon monoxide. The analyser shall have a time constant not exceeding 3 s.

(See Annex A).7.2 Gas temperature

Gas temperature in the immediate vicinity of the gas-sampling probe shall be measured by a

thermocouple with a maximum diameter of 0,25 mm.8 Hood and exhaust duct

The system for collecting the combustion products shall have a capacity and be designed in such a

way that all of the combustion products leaving the combustion chamber through the opening during a

test are collected. The system shall not disturb the fire-induced flow in the opening. The exhaust

4 © ISO 2003 – All rights reserved---------------------- Page: 10 ----------------------

ISO/DIS 17431

3 -1

capacity shall be at least 2,0 (m s ) at normal pressure and temperature of 25 °C. An example of the

design of hood and exhaust duct is given in Annex C.9 Instrumentation for measurement of gas in the exhaust duct

This clause specifies minimum requirements for the instrumentation for the measurement of the gas in

the exhaust duct. Additional information and designs can be found in ISO 9705 Annex D and Annex E.

9.1 Volume flow rateThe volume flow rate in the exhaust duct shall be measured to an accuracy of at least ± 5 %. The

response time to a stepwise change of the duct flow rate shall be a maximum of 1 s at 90 % of the

final value.9.2 Gas analyser

9.2.1 Sampling line

The gas in the duct shall be sampled at a position where the combustion products are uniformly mixed.

The sampling line shall be made of an inert material which does not influence the concentration of the

gas species to be analysed.9.2.2 Oxygen

The oxygen consumption shall be measured with an accuracy of at least ± 0,01 % by volume. The

oxygen analyser shall have a time constant not exceeding 3 s. (See ISO 9705 Annex D)

9.2.3 Carbon monoxide and carbon dioxideThe gas species shall be measured using analysers having an accuracy of at least + 0,1 % by volume

for carbon dioxide and 0,02 % by volume for carbon monoxide. The analyser shall have a time

constant not exceeding 3 s. (See ISO 9705 Annex D)10 System performance

10.1 Calibration

A calibration test shall be performed prior to each test or one set of tests conducted continually.

The calibration shall be performed with the burner heat output given in Table 1, with the burner

positioned centrally 1 m below the lower edge...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.