ISO/DIS 26444.2

(Main)Gas cylinders -- Refillable welded aluminium alloy gas cylinders for greater than 60 bar test pressure - Design, construction and testing

Gas cylinders -- Refillable welded aluminium alloy gas cylinders for greater than 60 bar test pressure - Design, construction and testing

Bouteilles à gaz -- Bouteilles à gaz rechargeables en alliage d'aluminium soudées avec une pression d'essai supérieur à 60 bars -- Conception, construction et essais

General Information

Standards Content (sample)

DRAFT INTERNATIONAL STANDARD ISO/DIS 26444.2

ISO/TC 58/SC 3 Secretariat: BSI

Voting begins on: Voting terminates on:

2010-02-19 2010-04-19

INTERNATIONAL ORGANIZATION FOR STANDARDIZATION • МЕЖДУНАРОДНАЯ ОРГАНИЗАЦИЯ ПО СТАНДАРТИЗАЦИИ • ORGANISATION INTERNATIONALE DE NORMALISATION

Gas cylinders — Refillable welded aluminium alloy gas cylindersfor greater than 60 bar test pressure - Design, construction and

testing

Bouteilles à gaz — Bouteilles à gaz rechargeables en alliage d'aluminium soudées avec une pression d'essai

supérieur à 60 bars — Conception, construction et essaisICS 23.020.30

In accordance with the provisions of Council Resolution 15/1993 this document is circulated in

the English language only.Conformément aux dispositions de la Résolution du Conseil 15/1993, ce document est distribué

en version anglaise seulement.To expedite distribution, this document is circulated as received from the committee secretariat.

ISO Central Secretariat work of editing and text composition will be undertaken at publication

stage.Pour accélérer la distribution, le présent document est distribué tel qu'il est parvenu du

secrétariat du comité. Le travail de rédaction et de composition de texte sera effectué au

Secrétariat central de l'ISO au stade de publication.THIS DOCUMENT IS A DRAFT CIRCULATED FOR COMMENT AND APPROVAL. IT IS THEREFORE SUBJECT TO CHANGE AND MAY NOT BE

REFERRED TO AS AN INTERNATIONAL STANDARD UNTIL PUBLISHED AS SUCH.IN ADDITION TO THEIR EVALUATION AS BEING ACCEPTABLE FOR INDUSTRIAL, TECHNOLOGICAL, COMMERCIAL AND USER PURPOSES, DRAFT

INTERNATIONAL STANDARDS MAY ON OCCASION HAVE TO BE CONSIDERED IN THE LIGHT OF THEIR POTENTIAL TO BECOME STANDARDS TO

WHICH REFERENCE MAY BE MADE IN NATIONAL REGULATIONS.RECIPIENTS OF THIS DRAFT ARE INVITED TO SUBMIT, WITH THEIR COMMENTS, NOTIFICATION OF ANY RELEVANT PATENT RIGHTS OF WHICH

THEY ARE AWARE AND TO PROVIDE SUPPORTING DOCUMENTATION.International Organization for Standardization, 2010

---------------------- Page: 1 ----------------------

ISO/DIS 26444.2

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but shall

not be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In

downloading this file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat

accepts no liability in this area.Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation

parameters were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In the

unlikely event that a problem relating to it is found, please inform the Central Secretariat at the address given below.

Copyright noticeThis ISO document is a Draft International Standard and is copyright-protected by ISO. Except as permitted

under the applicable laws of the user's country, neither this ISO draft nor any extract from it may be

reproduced, stored in a retrieval system or transmitted in any form or by any means, electronic, photocopying,

recording or otherwise, without prior written permission being secured.Requests for permission to reproduce should be addressed to either ISO at the address below or ISO's

member body in the country of the requester.ISO copyright office

Case postale 56 CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Reproduction may be subject to royalty payments or a licensing agreement.

Violators may be prosecuted.

ii ISO 2010 – All rights reserved

---------------------- Page: 2 ----------------------

ISO/DIS 26444

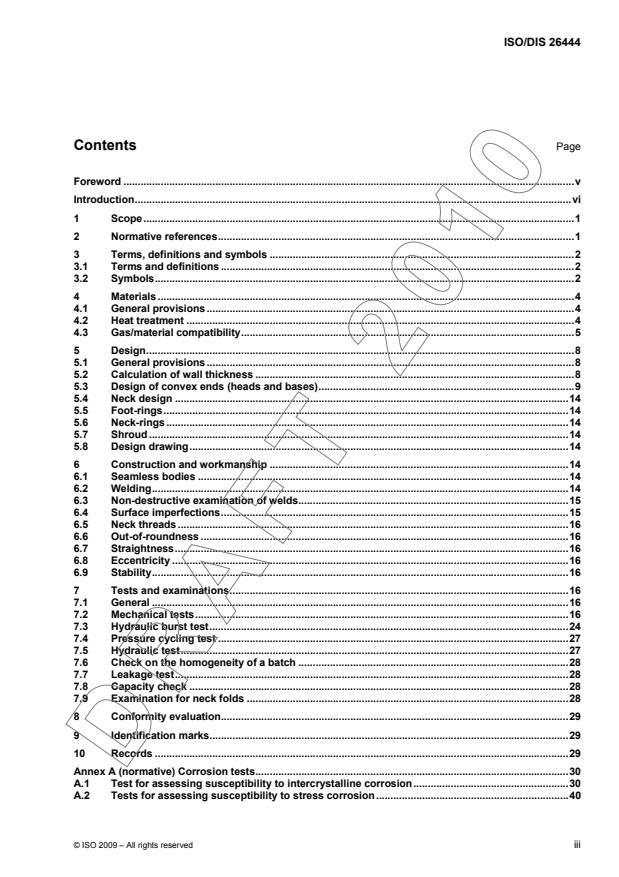

Contents Page

Foreword .............................................................................................................................................................v

Introduction........................................................................................................................................................vi

1 Scope......................................................................................................................................................1

2 Normative references............................................................................................................................1

3 Terms, definitions and symbols ..........................................................................................................2

3.1 Terms and definitions ...........................................................................................................................2

3.2 Symbols..................................................................................................................................................2

4 Materials .................................................................................................................................................4

4.1 General provisions................................................................................................................................4

4.2 Heat treatment .......................................................................................................................................4

4.3 Gas/material compatibility....................................................................................................................5

5 Design.....................................................................................................................................................8

5.1 General provisions................................................................................................................................8

5.2 Calculation of wall thickness ...............................................................................................................8

5.3 Design of convex ends (heads and bases).........................................................................................9

5.4 Neck design .........................................................................................................................................14

5.5 Foot-rings.............................................................................................................................................14

5.6 Neck-rings ............................................................................................................................................14

5.7 Shroud ..................................................................................................................................................14

5.8 Design drawing....................................................................................................................................14

6 Construction and workmanship ........................................................................................................14

6.1 Seamless bodies .................................................................................................................................14

6.2 Welding.................................................................................................................................................14

6.3 Non-destructive examination of welds..............................................................................................15

6.4 Surface imperfections.........................................................................................................................15

6.5 Neck threads ........................................................................................................................................16

6.6 Out-of-roundness ................................................................................................................................16

6.7 Straightness.........................................................................................................................................16

6.8 Eccentricity ..........................................................................................................................................16

6.9 Stability.................................................................................................................................................16

7 Tests and examinations......................................................................................................................16

7.1 General .................................................................................................................................................16

7.2 Mechanical tests..................................................................................................................................16

7.3 Hydraulic burst test.............................................................................................................................24

7.4 Pressure cycling test ..........................................................................................................................27

7.5 Hydraulic test.......................................................................................................................................27

7.6 Check on the homogeneity of a batch ..............................................................................................28

7.7 Leakage test.........................................................................................................................................28

7.8 Capacity check ....................................................................................................................................28

7.9 Examination for neck folds ................................................................................................................28

8 Conformity evaluation.........................................................................................................................29

9 Identification marks.............................................................................................................................29

10 Records ................................................................................................................................................29

Annex A (normative) Corrosion tests.............................................................................................................30

A.1 Test for assessing susceptibility to intercrystalline corrosion......................................................30

A.2 Tests for assessing susceptibility to stress corrosion...................................................................40

© ISO 2009 – All rights reserved iiiDRAFT 2010

---------------------- Page: 3 ----------------------

ISO/DIS 26444

Annex B (normative) Test method to determine sustained-load-cracking resistance of aluminium

alloy cylinders..................................................................................................................................... 45

B.1 Principle............................................................................................................................................... 45

B.2 General................................................................................................................................................. 45

B.3 Definitions and symbols .................................................................................................................... 45

B.4 Specimen configurations and number of tests ............................................................................... 46

B.5 Fatigue precracking............................................................................................................................ 46

B.6 Specimen testing procedure ............................................................................................................. 46

B.7 Crack growth examination................................................................................................................. 48

B.8 Cylinder thickness qualification........................................................................................................ 48

B.9 Report .................................................................................................................................................. 48

Annex C (normative) New design type testing and production testing.................................................... 51

C.1 New design type testing..................................................................................................................... 51

C.2 Production testing .............................................................................................................................. 52

C.3 Failure to meet test requirements..................................................................................................... 53

Annex D (normative) Description, evaluation of manufacturing imperfections and conditions for

rejection of welded aluminium alloy gas cylinders at time of visual inspection ......................... 55

D.1 Introduction......................................................................................................................................... 55

D.2 General................................................................................................................................................. 55

D.3 Manufacturing imperfections ............................................................................................................ 55

Annex E (informative) Examples of new design type approval and production test certificates .......... 61

E.1 Model new design type approval certificate .................................................................................... 61

E.2 Production testing certificate............................................................................................................ 63

Bibliography..................................................................................................................................................... 67

iv © ISO 2009 – All rights reservedDRAFT 2010

---------------------- Page: 4 ----------------------

ISO/DIS 26444

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies

(ISO member bodies). The work of preparing International Standards is normally carried out through ISO

technical committees. Each member body interested in a subject for which a technical committee has been

established has the right to be represented on that committee. International organizations, governmental and

non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the

International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of technical committees is to prepare International Standards. Draft International Standards

adopted by the technical committees are circulated to the member bodies for voting. Publication as an

International Standard requires approval by at least 75 % of the member bodies casting a vote.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. ISO shall not be held responsible for identifying any or all such patent rights.

ISO 26444 was prepared by Technical Committee ISO/TC 58, Gas cylinders, Subcommittee SC 3, Gas

cylinders design.© ISO 2009 – All rights reserved v

DRAFT 2010

---------------------- Page: 5 ----------------------

ISO/DIS 26444

Introduction

The purpose of this International Standard is to provide a specification for the design, manufacture, inspection and

approval of refillable transportable welded aluminium alloy gas cylinders with a test pressure greater than 60 bar.

The specifications given are based on general knowledge of, and experience with, materials, design

requirements, manufacturing processes and control during manufacture, of cylinders.

vi © ISO 2009 – All rights reservedDRAFT 2010

---------------------- Page: 6 ----------------------

ISO/DIS 26444

Gas cylinders — Refillable welded aluminium alloy gas cylinders

for greater than 60 bar test pressure - Design, construction and

testing

1 Scope

This International Standard specifies minimum requirements for the material, design, construction and

workmanship, manufacturing processes and tests at manufacture of refillable transportable welded aluminium alloy

gas cylinders, with a test pressure greater than 60 bar, of water capacities from 0,5 litre up to and including 150 litres

for compressed, liquefied and dissolved gases.This International Standard includes requirements for spherical receptacles and cylinders made from seamless

bodies with welded non-pressure bearing attachments such as shrouds and foot rings etc.

2 Normative referencesThe following referenced documents are indispensable for the application of this document. For dated references,

only the edition cited applies. For undated references, the latest edition of the referenced document (including any

amendments) applies.ISO 2107:1983, Aluminium, magnesium and their alloys – Temper designations

ISO 6892:1998, Metallic materials – Tensile testing at ambient temperature

ISO 7539-6:1995, Corrosion of metals and alloys – Stress corrosion testing – Part 6: Preparation and use of pre-

cracked specimensISO 7866:1999, Gas cylinders – Refillable seamless aluminium alloy gas cylinders – Design, construction and

testingISO 9606-2, Qualification test of welders – Fusion welding – Part 2: Aluminium and aluminium alloys

ISO 9956-4:1995, Specification and approval of welding procedures for metallic materials – Part 4: Welding

procedure tests for the arc welding of aluminium and its alloysISO 10042:2005, Arc-welded joints in aluminium and its weldable alloys; guidance on quality levels for

imperfectionsISO 11114-1, Transportable gas cylinders – Compatibility of cylinders and valve materials with gas contents – Part

1: Metallic materialsISO 11116-1, Gas cylinders – 17E taper thread for connection of valves to gas cylinders – Part 1: Specifications

ISO 11116-2, Gas cylinders – 17E taper thread for connection of valves to gas cylinders – Part 2: Inspection

gauges© ISO 2009 – All rights reserved 1

DRAFT 2010

---------------------- Page: 7 ----------------------

ISO/DIS 26444

ISO 11117:1998, Gas cylinders – Valve protection caps and valve guards for industrial and medical gas cylinders –

Design, construction and testsISO 11191:1997, Gas cylinders – 25E taper thread for connection of valves to gas cylinders – Inspection gauges

ISO 13341, Transportable gas cylinders – Fitting of valves to gas cylindersISO 13769, Gas cylinders – Stamp marking

ISO 17636, Non-destructive testing of welds – Radiographic testing of fusion-welded joints

3 Terms, definitions and symbols3.1 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1.1

yield strength

value corresponding to the 0,2 % proof strength (non proportional elongation), R ,

p0 23.1.2

solution heat treatment

thermal treatment which consists of heating the products to a suitable temperature, holding at that temperature long

enough to allow constituents to enter into solid solution and cooling rapidly enough to hold the constituents in

solution3.1.3

quenching

controlled rapid cooling in a suitable medium to retain the solute phase in solid solution

3.1.4artificial ageing

heat treatment process in which the solute phase is precipitated to give an increased yield stress and tensile

strength3.1.5

batch

quantity of up to 200 cylinders, plus cylinders for destructive testing, of the same nominal diameter, thickness and

design, made successively from the same cast and subjected to the same heat treatment for the same duration of

timeNOTE The lengths of the cylinders in the heat treatment batch may vary by up to ± 12 %.

3.1.6design stress factor (F) (variable)

ratio of equivalent wall stress at test pressure (p ) to guaranteed minimum yield strength (Reg)

3.1.7non-destructive examination

examination or test that does not materially or adversely affect the item being examined

3.2 SymbolsA Percentage elongation after fracture, determined by the tensile test 7.2.3

2 © ISO 2009 – All rights reserved

DRAFT 2010

---------------------- Page: 8 ----------------------

ISO/DIS 26444

a Calculated minimum thickness, in millimetres, of the cylindrical or spherical shell

a' Guaranteed minimum thickness, in millimetres, of the cylindrical or spherical shell

b Guaranteed minimum thickness, in millimetres, at the centre of a convex baseD Nominal outside diameter, in millimetres, of the cylinder, spherical cylinder or domed end (see Figure 2)

D Nominal inside diameter, in millimetres, of the cylinder, spherical cylinder or domed end (see Figure 2)

d Diameter of former, in millimetres (see Figure 4)F Design stress factor (variable) (see 3.1.6)

h Internal height, in millimetres, of semi-ellipsoidal or torispherical domed end (convex head or base end) (see

Figure 2)h Variable used in the determination of shape factor, K (see 5.3.1)

h External height, in millimetres, of a semi-ellipsoidal or torispherical domed end (convex head or base end) (see

Figure 2 and note below)K Shape factor for a semi-ellipsoidal or torispherical domed end, obtained according to the values h /D and

e oa/D , with interpolation where necessary, (see Figure 1)

L Original gauge length, in millimetres, according to ISO 6892

n The ratio of the diameter of the bend test former to actual thickness of test piece (t)

p Measured burst pressure, in bar above atmospheric pressurep Hydraulic test pressure, in bar above atmospheric pressure

p Lower cyclic pressure, in bar above atmospheric pressure

p Observed yield pressure which produces a permanent volumetric expansion of 0,2 %, in bar above

atmospheric pressureR Minimum guaranteed value of the yield strength (see 3.1.1), in MPa, for the finished cylinder

R Actual value of theyield strength, in MPa, as determined by the tensile test specified in 7.2.3 for the finished

cylinderR Minimum guaranteed value of the tensile strength, in MPa, for the finished cylinder

R Actual value of the tensile strength, in MPa, as determined by the tensile test specified in 7.2.3 for the finished

cylinderr Internal knuckle radius, in millimetres, of torispherical end (see Figure 2c))

) 5 5 2

1 bar = 10 Pa = 10 N/m

© ISO 2009 – All rights reserved 3

DRAFT 2010

---------------------- Page: 9 ----------------------

ISO/DIS 26444

r′ Internal radius, in millimetres, of dishing of torispherical end (see Figure 2c))

r External knuckle radius, in millimetres, of torispherical end (see Figure 2c))r′ External radius, in millimetres, of dishing of torispherical end (see Figure 2c))

s Straight flange length, in millimetres, for semi-ellipsoidal and torispherical domed ends (see Figure 2b)) and

2c))S Original cross-sectional area of tensile test piece, in square millimetres, according to ISO 6892

t Actual thickness of test specimen, in millimetrest Calculated minimum thickness, in millimetres, of a domed end

w Width, in millimetres, of tensile test piece

V Volumetric expansion attained at burst, expressed as a percentage of the initial volume (see 7.3)

expZ Stress reduction factor (see 5.2.1)

4 Materials

4.1 General provisions

4.1.1 Aluminium alloys may be used to produce gas cylinders provided that they satisfy the requirements of the

corrosion resistance tests described in Annex A, and meet all other requirements of this International Standard,

including Annex B.4.1.2 Examples of the alloys most commonly used for the fabrication of gas cylinders are those given in Table 1.

4.1.3 After the completion of all welding (including that of the attachments) and before the hydraulic test each

cylinder shall be heat treated if required to meet the design criteria.4.2 Heat treatment

4.2.1 General

Any welding on the pressure bearing part shall take place before any final heat treatment (see 6.2).

4.2.2 Heat treatable alloysThe manufacturer shall specify on the prototype testing documentation, where required, the solution heat treatment

and artificial ageing temperatures and the times for which the cylinders have been held at those temperatures. The

medium used for quenching after solution heat treatment shall be identified.Unless the alloy is subjected to a temperature in excess of 400 °C during the forming process, a stabilizing

treatment shall be carried out and the temperature and the time at temperature, shall be identified by the

manufacturer.However, the stabilizing treatment is not necessary for a cylinder of which the wall thickness in 5.2 is calculated

with the minimum guaranteed yield strength value of the O-tempered alloy (or the alloy annealed for complete re-

crystallization before forming of cylinder, as defined in ISO 2107: 1983).4 © ISO 2009 – All rights reserved

DRAFT 2010

---------------------- Page: 10 ----------------------

ISO/DIS 26444

If the cylinder is intended for dissolved gas service it shall only be used in the fully annealed condition, i.e. the

minimum guaranteed properties used for the material shall consider the heat treatment to be applied, e.g. during

the massing operation.4.2.3 Non-heat treatable alloys

The manufacturer shall specify on the prototype testing documentation, where required, the type of metal forming

operation carried out (extrusion, drawing, ironing, head forming, etc.) Unless the alloy is subjected to a temperature

in excess of 400 °C during the forming process, a stabilizing treatment shall be carried out and the temperature,

and time at temperature, shall be identified by the manufacturer.4.2.4 Control of specified heat treatment

During the heat treatment, the manufacturer shall comply with the specified temperatures and durations, within the

following ranges:a) Temperatures

Solution temperature : maximum range 20 °C

Artificial ageing temperature : maximum range 20 °C

Stabilizing temperature : maximum range 20 °C

b) Durations

Time cylinders actually spend at temperature during treatments:

All treatments : maximum range 20 %

4.3 Gas/material compatibility

Gas/material compatibility shall be verified as specified in ISO 11114-1.

© ISO 2009 – All rights reserved 5

DRAFT 2010

---------------------- Page: 11 ----------------------

DRAFT 2010

ISO/DIS 26444

Table 1 — Chemical composition of aluminium alloys

Type of Type

Chemical composition - weight %

alloy AA

2), 3)

registered

Si Fe Cu Mn Mg Cr Zn Ti Pb Bi Others Aluminium

Each Total

designation

2,2 0,15

min.

- - - - - - Remainder

5052 A - - - -

0,25 0,40 0,10 0,10 2,8 0,35 0,10 - 0,05 0,15

max. - -

3,1 0,15

min. - - - - - - Remainder

5154 A - - - -

0,25 0,40 0,10 0,10 3,9 0,35 0,20 0,20 0,05 0,15

max. - -

0,40 4,0 0,05

min.

- - - - - - Remainder

5083A D - - -

0,40 0,40 0,10 1,0 4,9 0,25 0,25 0,15 0,05 0,15

max. - -

min.

- - - - - - Remainder

6061A D 0,40 - 0,15 - 0,8 0,04

max. 0,0030 0,0030

0,8 0,7 0,40 0,15 1,2 0,35 0,25 0,15 0,05 0,15

1) AA is the Aluminum Association Inc., 900 19th Street N.W., Washington D.C., 20006-2168, USA.

2) Type A and Type B may be used for the body and Type C for the non pressure bearing part.

3) Type D may be used for the body and the non pressure bearing part.© ISO 2009 – All rights reserved 6

---------------------- Page: 12 ----------------------

DRAFT 2010

ISO/DIS 26444

Table 1 — Chemical composition of aluminium alloys (cont.)

Type of Type

Chemica composition - weight %

alloy AA

2), 3)

registered

Si Fe Cu Mn Mg Cr Zn Ti Pb Bi Others Aluminium

Each Total

designation

min

6063 C 0,2 - - - 0,4 - - - - - - - Remainder

max

0,7 0,5 0,1 0,3 0,9 0,1 0,2 0,2 0,0030 - 0,05 0,15

min

6082 D 0,7 - - 0,40 0,60 - - - - - - - Remainder

max

1,3 0,50 0,10 1,0 1,2 0,25 0,20 0,10 0,0030 0,0030 0,05 0,15

min

6082 B 1,2 - - 0,8 1,0 - - - - - - - Remainder

max

1,6 0,5 0,1 1,0 1,4 0,1 0,2 0,2 0,0030 0,0030 0,05 0,15

1) AA is the Aluminum Association Inc., 900 19th Street N.W., Washington D.C., 20006-2168, USA.

2) Type A and Type B may be used for the body and Type C for the non pressure bearing part.

3) Type D may be used for the body and the non pressure bearing part.© ISO 2009 – All rights reserved 7

---------------------- Page: 13 ----------------------

ISO/DIS 26444

5 Design

5.1 General provisions

5.1.1 The calculation of the wall thickness of the pressure-bearing parts shall be related to the yield strength

(R ) of the material to ensure elastic behaviour.5.1.2 For calculation purposes the value of the yield strength (R ) is limited to a maximum of 0,9 R for

eg mgaluminium alloys.

5.1.3 The internal pressure upon which the calculation of wall thickness is based shall be the hydraulic test

pressure (p ).5.1.4 For dissolved gases, the manufacturing process of the porous mass can modify the characteristics of the

aluminium alloy used. This shall be considered when designing the...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.