ISO/PRF 9982

(Main)Belt drives -- Pulleys and V-ribbed belts for industrial applications -- PH, PJ, PK, PL and PM profiles: dimensions

Belt drives -- Pulleys and V-ribbed belts for industrial applications -- PH, PJ, PK, PL and PM profiles: dimensions

Transmissions par courroies -- Poulies et courroies striées pour des applications industrielles -- Profils PH, PJ, PK, PL et PM : dimensions

General Information

RELATIONS

Standards Content (sample)

INTERNATIONAL ISO

STANDARD 9982

Third edition

Belt drives — Pulleys and V-ribbed

belts for industrial applications — PH,

PJ, PK, PL and PM profiles: dimensions

Transmissions par courroies — Poulies et courroies striées pour des

applications industrielles — Profils PH, PJ, PK, PL et PM : dimensions

PROOF/ÉPREUVE

Reference number

ISO 9982:2021(E)

ISO 2021

---------------------- Page: 1 ----------------------

ISO 9982:2021(E)

COPYRIGHT PROTECTED DOCUMENT

© ISO 2021

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting

on the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address

below or ISO’s member body in the country of the requester.ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii PROOF/ÉPREUVE © ISO 2021 – All rights reserved

---------------------- Page: 2 ----------------------

ISO 9982:2021(E)

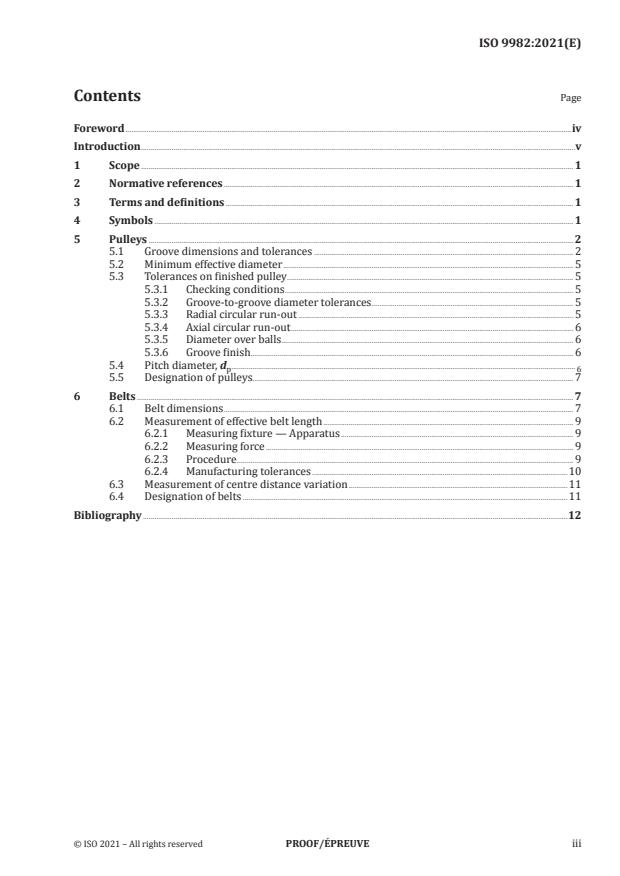

Contents Page

Foreword ........................................................................................................................................................................................................................................iv

Introduction ..................................................................................................................................................................................................................................v

1 Scope ................................................................................................................................................................................................................................. 1

2 Normative references ...................................................................................................................................................................................... 1

3 Terms and definitions ..................................................................................................................................................................................... 1

4 Symbols .......................................................................................................................................................................................................................... 1

5 Pulleys ............................................................................................................................................................................................................................. 2

5.1 Groove dimensions and tolerances ....................................................................................................................................... 2

5.2 Minimum effective diameter ....................................................................................................................................................... 5

5.3 Tolerances on finished pulley ..................................................................................................................................................... 5

5.3.1 Checking conditions ...................................................................................................................................................... 5

5.3.2 Groove-to-groove diameter tolerances ......................................................................................................... 5

5.3.3 Radial circular run-out ............................................................................................................................................... 5

5.3.4 Axial circular run-out ................................................................................................................................................... 6

5.3.5 Diameter over balls........................................................................................................................................................ 6

5.3.6 Groove finish........................................................................................................................................................................ 6

5.4 Pitch diameter, d ...................................................................................................................................................................................

p 65.5 Designation of pulleys....................................................................................................................................................................... 7

6 Belts ................................................................................................................................................................................................................................... 7

6.1 Belt dimensions ...................................................................................................................................................................................... 7

6.2 Measurement of effective belt length .................................................................................................................................. 9

6.2.1 Measuring fixture — Apparatus ......................................................................................................................... 9

6.2.2 Measuring force ................................................................................................................................................................ 9

6.2.3 Procedure ............................................................................................................................................................................... 9

6.2.4 Manufacturing tolerances .....................................................................................................................................10

6.3 Measurement of centre distance variation ..................................................................................................................11

6.4 Designation of belts .........................................................................................................................................................................11

Bibliography .............................................................................................................................................................................................................................12

© ISO 2021 – All rights reserved PROOF/ÉPREUVE iii---------------------- Page: 3 ----------------------

ISO 9982:2021(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www .iso .org/ directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www .iso .org/ patents).Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to the

World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT), see www .iso .org/

iso/ foreword .html.This document was prepared by Technical Committee ISO/TC 41, Pulleys and Belts (including veebelts),

Subcommittee SC 1, Friction.This third edition cancels and replaces the second edition (ISO 9982:1998), which has been technically

revised. The main changes compared to the previous edition are as follows:— updating of the normative reference listing;

— clarification made where the document is not for elastic belts;

— revision of 5.3.6 to reference ISO 254 for pulley roughness;

— removal of the current roughness values;

— specification of the maximum pulley groove radius (Table 2);

— specification of the minimum pulley groove radius of PH and PJ profiles (Table 2);

— specification of the maximum belt groove bottom radius of PH and PJ profiles (Table 8);

— specification of the measuring pulleys and measuring forces of PK, PL and PM profiles (Table 9).

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www .iso .org/ members .html.iv PROOF/ÉPREUVE © ISO 2021 – All rights reserved

---------------------- Page: 4 ----------------------

ISO 9982:2021(E)

Introduction

A V-ribbed belt drive is composed of an endless belt with a longitudinally ribbed traction surface which

engages and grips, by friction, pulley grooves of similar shape. The belt ribbed surface fits the pulley

grooves to make nearly total contact.© ISO 2021 – All rights reserved PROOF/ÉPREUVE v

---------------------- Page: 5 ----------------------

INTERNATIONAL STANDARD ISO 9982:2021(E)

Belt drives — Pulleys and V-ribbed belts for industrial

applications — PH, PJ, PK, PL and PM profiles: dimensions

1 Scope

This document specifies the principal dimensional characteristics of V-ribbed pulley groove profiles,

together with the corresponding endless V-ribbed belts, of PH, PJ, PK, PL and PM profiles which are

used for general industrial applications except elastic belts.The PK belt was originally established for automotive accessory drive applications and ISO 9981 deals

specifically with that particular field.2 Normative references

There are no normative references in this document.

3 Terms and definitions

No terms and definitions are listed in this document.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https:// www .iso .org/ obp— IEC Electropedia: available at https:// www .electropedia .org/

4 Symbols

For the purpose of this document, the symbols given in Table 1 apply.

Table 1 — Symbols

Symbol Designation Unit

b nominal width of the belt mm

b effective line differential mm

d checking ball or rod diameter mm

d effective diameter mm

d outer diameter mm

d pitch diameter mm

E centre distance between the pulleys mm

E maximum centre distance between the pulleys mm

max

E minimum centre distance between the pulleys mm

min

ΔE centre distance variation mm

e groove pitch mm

F measuring force per rib N

f distance between the outside of the rim and the axis of the first groove mm

h belt height mm

K diameter over balls or rods mm

© ISO 2021 – All rights reserved PROOF/ÉPREUVE 1

---------------------- Page: 6 ----------------------

ISO 9982:2021(E)

Table 1 (continued)

Symbol Designation Unit

L effective length mm

N half the difference between the outer diameter and the diameter over balls or rods mm

n number of ribs —p rib pitch mm

r groove bottom radius of pulleys or rib tip radius of belts mm

r groove transitional radius of pulleys or rib bottom radius of belts mm

Ra surface roughness μm

pulley effective circumference mm

x half the difference between the effective diameter and the diameter over balls or mm

rodsα groove or rib angle °

5 Pulleys

5.1 Groove dimensions and tolerances

The groove dimensions of PH, PJ, PK, PL and PM belts are shown i

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.