ISO/FDIS 8655-2

(Main)Piston-operated volumetric apparatus

Piston-operated volumetric apparatus

Appareils volumétriques à piston

General Information

RELATIONS

Standards Content (sample)

FINAL

INTERNATIONAL ISO/FDIS

DRAFT

STANDARD 8655-2

ISO/TC 48

Piston-operated volumetric

Secretariat: DIN

apparatus —

Voting begins on:

2021-11-17

Part 2:

Voting terminates on:

Pipettes

2022-01-12

Appareils volumétriques à piston —

Partie 2: Pipettes

ISO/CEN PARALLEL PROCESSING

RECIPIENTS OF THIS DRAFT ARE INVITED TO

SUBMIT, WITH THEIR COMMENTS, NOTIFICATION

OF ANY RELEVANT PATENT RIGHTS OF WHICH

THEY ARE AWARE AND TO PROVIDE SUPPOR TING

DOCUMENTATION.

IN ADDITION TO THEIR EVALUATION AS

Reference number

BEING ACCEPTABLE FOR INDUSTRIAL, TECHNO-

ISO/FDIS 8655-2:2021(E)

LOGICAL, COMMERCIAL AND USER PURPOSES,

DRAFT INTERNATIONAL STANDARDS MAY ON

OCCASION HAVE TO BE CONSIDERED IN THE

LIGHT OF THEIR POTENTIAL TO BECOME STAN-

DARDS TO WHICH REFERENCE MAY BE MADE IN

NATIONAL REGULATIONS. © ISO 2021

---------------------- Page: 1 ----------------------

ISO/FDIS 8655-2:2021(E)

COPYRIGHT PROTECTED DOCUMENT

© ISO 2021

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting on

the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address below

or ISO’s member body in the country of the requester.ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

© ISO 2021 – All rights reserved

---------------------- Page: 2 ----------------------

ISO/FDIS 8655-2:2021(E)

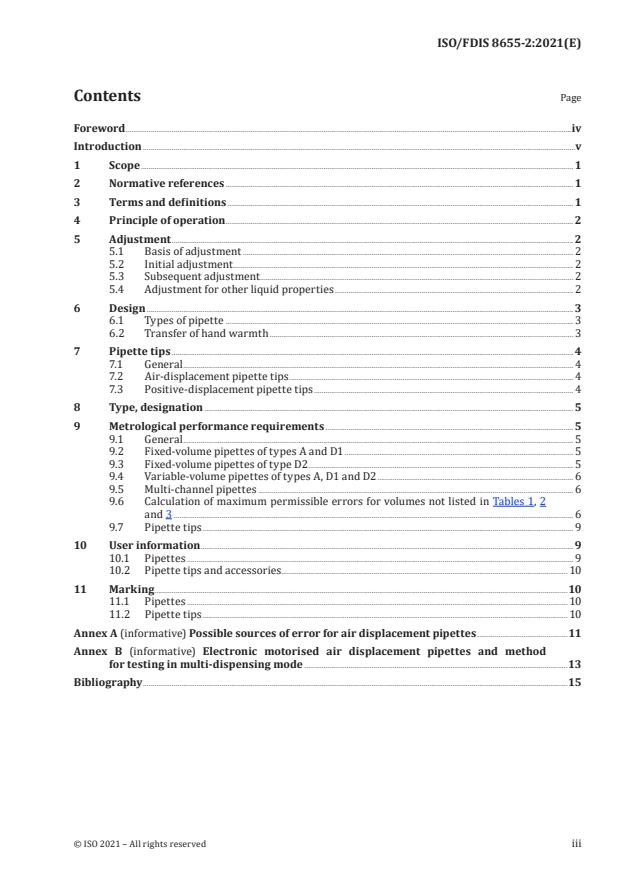

Contents Page

Foreword ........................................................................................................................................................................................................................................iv

Introduction .................................................................................................................................................................................................................................v

1 Scope ................................................................................................................................................................................................................................. 1

2 Normative references ..................................................................................................................................................................................... 1

3 Terms and definitions .................................................................................................................................................................................... 1

4 Principle of operation ..................................................................................................................................................................................... 2

5 Adjustment .................................................................................................................................................................................................................2

5.1 Basis of adjustment ............................................................................................................................................................................ 2

5.2 Initial adjustment ................................................................................................................................................................................. 2

5.3 Subsequent adjustment ................................................................................................................................................................... 2

5.4 Adjustment for other liquid properties ............................................................................................................................ 2

6 Design .............................................................................................................................................................................................................................. 3

6.1 Types of pipette ..................................................................................................................................................................................... 3

6.2 Transfer of hand warmth .............................................................................................................................................................. 3

7 Pipette tips ................................................................................................................................................................................................................. 4

7.1 General ........................................................................................................................................................................................................... 4

7.2 Air-displacement pipette tips .................................................................................................................................................... 4

7.3 Positive-displacement pipette tips ....................................................................................................................................... 4

8 Type, designation ................................................................................................................................................................................................ 5

9 Metrological performance requirements ................................................................................................................................. 5

9.1 General ........................................................................................................................................................................................................... 5

9.2 Fixed-volume pipettes of types A and D1 ....................................................................................................................... 5

9.3 Fixed-volume pipettes of type D2 .......................................................................................................................................... 5

9.4 Variable-volume pipettes of types A, D1 and D2 ...................................................................................................... 6

9.5 Multi-channel pipettes .................................................................................................................................................................... 6

9.6 Calculation of maximum permissible errors for volumes not listed in Tables 1, 2

and 3 ................................................................................................................................................................................................................ 6

9.7 Pipette tips ................................................................................................................................................................................................. 9

10 User information .................................................................................................................................................................................................. 9

10.1 Pipettes ......................................................................................................................................................................................................... 9

10.2 Pipette tips and accessories..................................................................................................................................................... 10

11 Marking ........................................................................................................................................... ............................................................................10

11.1 Pipettes ...................................................................................................................................................................................................... 10

11.2 Pipette tips .............................................................................................................................................................................................. 10

Annex A (informative) Possible sources of error for air displacement pipettes ...............................................11

Annex B (informative) Electronic motorised air displacement pipettes and methodfor testing in multi-dispensing mode .........................................................................................................................................13

Bibliography .............................................................................................................................................................................................................................15

iii© ISO 2021 – All rights reserved

---------------------- Page: 3 ----------------------

ISO/FDIS 8655-2:2021(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www.iso.org/patents).Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to

the World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT), see

www.iso.org/iso/foreword.html.This document was prepared by Technical Committee ISO/TC 48, Laboratory equipment, in collaboration

with the European Committee for Standardization (CEN) Technical Committee CEN/TC 332, Laboratory

equipment, in accordance with the Agreement on technical cooperation between ISO and CEN (Vienna

Agreement).This second edition cancels and replaces the first edition (ISO 8655-2:2002), which has been technically

revised. It also incorporates the Technical Corrigendum ISO 8655-2:2002/Cor.1:2008.

The main changes compared to the previous edition are as follows:— ISO 8655-7 and ISO 8655-8 have been added as normative references;

— metrological performance requirements for pipette tips have been further specified;

— Tables 1 and 2 have been revised;— a new Table 3 has been introduced;

— a new informative Annex B for motorised pipettes has been introduced;

— former Annex A has been added as new Clause 10.

A list of all parts in the ISO 8655 series can be found on the ISO website.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www.iso.org/members.html.© ISO 2021 – All rights reserved

---------------------- Page: 4 ----------------------

ISO/FDIS 8655-2:2021(E)

Introduction

The ISO 8655 series addresses the needs of:

— manufacturers, as a basis for quality control including, where appropriate, the issuance of

manufacturer’s declarations;— calibration laboratories, test houses, users of the equipment and other bodies as a basis for

independent calibration, testing, verification and routine tests.The tests specified in the ISO 8655 series are intended to be carried out by trained personnel.

© ISO 2021 – All rights reserved---------------------- Page: 5 ----------------------

FINAL DRAFT INTERNATIONAL STANDARD ISO/FDIS 8655-2:2021(E)

Piston-operated volumetric apparatus —

Part 2:

Pipettes

1 Scope

This document specifies

— metrological requirements,

— maximum permissible errors,

— requirements for marking and

— information to be provided for users,

for air-displacement (type A) and positive displacement (type D) single-channel and multi-channel

pipettes, complete with their selected tip(s) and any other essential, consumable parts, designed to

deliver the selected volume (Ex).2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 3696:1987, Water for analytical laboratory use — Specification and test methods

ISO 8655-1, Piston-operated volumetric apparatus — Part 1: Terminology, general requirements and user

recommendationsISO 8655-6:— , Piston-operated volumetric apparatus — Part 6: Gravimetric reference measurement

procedure for the determination of volumeISO 8655-7:— , Piston operated volumetric apparatus — Part 7: Alternative measurement procedures for

the determination of volumeISO 8655-8:— , Piston-operated volumetric apparatus — Part 8: Photometric reference measurement

procedure for the determination of volume3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 8655-1 apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https:// www .iso .org/ obp— IEC Electropedia: available at https:// www .electropedia .org/

1) Under preparation. Stage at the time of publication: ISO/FDIS 8655-6:2021.

2) Under preparation. Stage at the time of publication: ISO/FDIS 8655-7:2021.

3) Under preparation. Stage at the time of publication: ISO/FDIS 8655-8:2021.

© ISO 2021 – All rights reserved

---------------------- Page: 6 ----------------------

ISO/FDIS 8655-2:2021(E)

4 Principle of operation

Pipettes are used to accurately handle preselected volumes. A tip is attached to the pipette. Pipettes

are typically operated using forward pipetting. Using forward pipetting, with the piston positioned at

the lower aspiration limit, the tip is dipped into the liquid to be dispensed. When moved to the upper

aspiration limit, the piston aspirates the liquid. The liquid volume to be dispensed is then expelled by

depressing or sliding the piston between the volume-defining limits. Some air-displacement pipettes

(see 6.1, Type A) have an extra air volume which can be used to expel the last drop of liquid.

See also Figure 1.Manufacturers' instruction manuals should contain detailed and specific information about the proper

operation of pipettes.5 Adjustment

5.1 Basis of adjustment

A pipette shall be adjusted for the delivery (Ex) of its nominal volume (or selected volume, in the case of

a variable-volume model).For countries that have adopted the standard reference temperature of 20 °C, the adjustment shall be

for the temperature 20 °C, a relative air humidity of 50 % and a barometric pressure of 101 3 kPa, when

handling grade 3 water as specified in ISO 3696:1987.For those countries that have adopted a standard reference temperature of 27 °C, the adjustment shall

be for the temperature 27 °C, a relative air humidity of 50 % and a barometric pressure of 101 3 kPa,

when handling grade 3 water as specified in ISO 3696:1987.5.2 Initial adjustment

A pipette shall be provided with an initial adjustment.

5.3 Subsequent adjustment

Some pipettes have provision for adjustment when, for example, it is found in a routine check that

the volume delivered is not within specification. Such adjustment shall be made in accordance with

the manufacturer's instructions and by reference to a measurement procedure in accordance with

ISO 8655-6, ISO 8655-7 or ISO 8655-8.Any pipette so adjusted shall have clear, visible evidence that the initial adjustment has been modified.

This information shall also be recorded.5.4 Adjustment for other liquid properties

Some pipettes are designed to have their factory pre-set adjustment altered by the user so that they will

dispense their specified volume when used with liquids with physical properties differing from those

of water (see Annex A for details). In such cases, the design shall prevent unintentional readjustment.

Such adjustment shall be made in accordance with the manufacturer's instructions or by reference to

the selected test procedure from ISO 8655-7 and the modifications made.If the pipette is readjusted, it shall be clearly and unequivocally indicated on the outside of the pipette

that readjustment has been affected. The outside of the pipette shall be marked with the name of the

liquid and the adjusted volume range. This information shall be documented appropriately.

© ISO 2021 – All rights reserved---------------------- Page: 7 ----------------------

ISO/FDIS 8655-2:2021(E)

6 Design

6.1 Types of pipette

A pipette may be designed as follows:

— fixed volume, designed by the manufacturer to dispense only its nominal volume, e.g. 100 μl;

— variable volume, designed by the manufacturer to dispense volumes selectable by the user within

its specified usable volume range, e.g. between 10 μl and 100 μl.The piston may:

— either have a body of air contained between the piston and the surface of the liquid (air displacement

– Type A); or— be in direct contact with the surface of the liquid (positive or direct displacement – Type D).

In the case of the Type D pipette, either the plunger or the capillary, or both may be reusable (Type D1)

or disposable (Type D2). See Figure 1 for details.Type D Type A

Positive (direct) displacement Air displacement

a) Single-channel pipettes b) Multi-channel pipette

Figure 1 — Pipettes

6.2 Transfer of hand warmth

The construction of pipettes and the materials used for their manufacture shall be chosen in such a way

that any heat transmitted from the user's hand to the apparatus during periods of use is minimized.

NOTE Transfer of hand warmth will appear as a systematic drift of results (the delivered volume decreases

over time) during a series of deliveries.© ISO 2021 – All rights reserved

---------------------- Page: 8 ----------------------

ISO/FDIS 8655-2:2021(E)

7 Pipette tips

7.1 General

7.1.1 The dispensing orifice of the tip shall be shaped in such a way that consistent dispensing of the

liquid to be measured is achieved. When the tip is touched against the wall of a vessel in successive

operations, any amount of liquid remaining in or around the dispensing orifice of the tip shall be

consistent.7.1.2 In the case of sterilisable pipette tips the sterilisation procedures indicated as appropriate by

the manufacturer in user information or on packaging (see Clause 10) shall not negatively affect the

metrological characteristics of the tips such as shape, seal and wettability.NOTE This requirement can be assessed by comparing errors of measurement using tips which have and

have not been sterilised.7.2 Air-displacement pipette tips

7.2.1 Air-displacement pipette tips shall be disposable parts, usually made of plastic, which fit on the

tip cone of the pipette and prevent the instrument from contact with the aspirated liquid.

7.2.2 Tips for air-displacement shall be fitted in accordance with the pipette supplier's instructions

to form a good seal between the tip and the tip cone of the pipette.NOTE Variability of amount of externally retained liquid or an incomplete seal will contribute to poor

precision.Pipette tips made of plastic for pipettes with air interface are designed for single use. They shall not be

cleaned for reuse as their metrological characteristics will no longer be reliable.

Single use of a pipette tip means mounting the tip on the pipette only once, and then discarding it after

use. While the tip is mounted on the pipette, it may be used to handle several replicate aspiration and

delivery cycles, as long as a tight seal between the tip and pipette’s tip cone is maintained.

7.2.3 The form of the pipette tips to be used with a multi-channel pipette shall be such that all tips

fitted are positioned with parallel axes in the same plane in order to allow for even liquid dispensing

in the target vessels, e.g. the adjacent well...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.