ISO/PRF 8210

(Main)Equipment for harvesting -- Combine harvesters -- Test procedure and performance assessment

Equipment for harvesting -- Combine harvesters -- Test procedure and performance assessment

Matériel de récolte -- Moissonneuses-batteuses -- Mode opératoire d'essai et évaluation des performances

General Information

RELATIONS

Standards Content (sample)

INTERNATIONAL ISO

STANDARD 8210

Second edition

Equipment for harvesting — Combine

harvesters — Test procedure and

performance assessment

Matériel de récolte — Moissonneuses-batteuses — Mode opératoire

d'essai et évaluation des performances

PROOF/ÉPREUVE

Reference number

ISO 8210:2021(E)

ISO 2021

---------------------- Page: 1 ----------------------

ISO 8210:2021(E)

COPYRIGHT PROTECTED DOCUMENT

© ISO 2021

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting

on the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address

below or ISO’s member body in the country of the requester.ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii PROOF/ÉPREUVE © ISO 2021 – All rights reserved

---------------------- Page: 2 ----------------------

ISO 8210:2021(E)

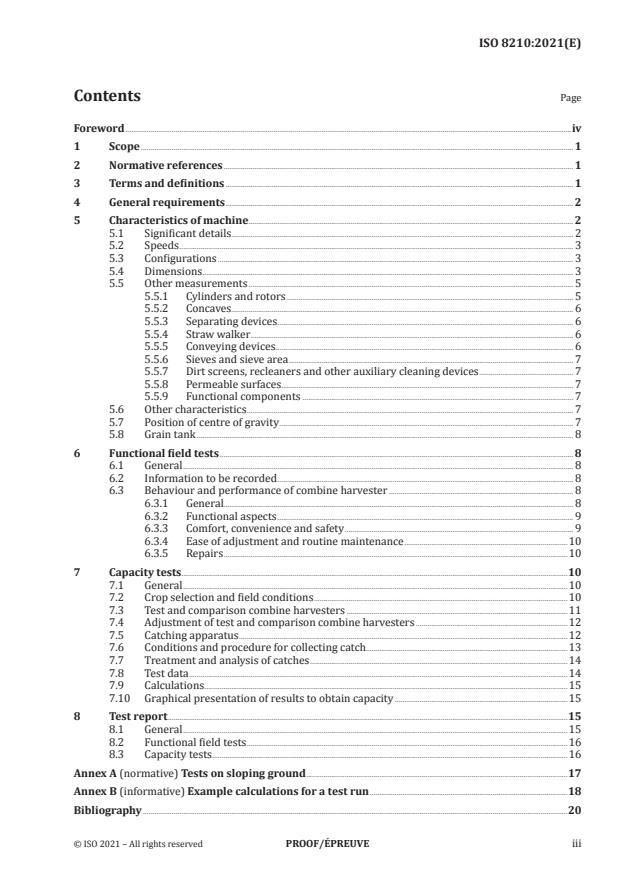

Contents Page

Foreword ........................................................................................................................................................................................................................................iv

1 Scope ................................................................................................................................................................................................................................. 1

2 Normative references ...................................................................................................................................................................................... 1

3 Terms and definitions ..................................................................................................................................................................................... 1

4 General requirements ..................................................................................................................................................................................... 2

5 Characteristics of machine ......................................................................................................................................................................... 2

5.1 Significant details.................................................................................................................................................................................. 2

5.2 Speeds ............................................................................................................................................................................................................. 3

5.3 Configurations ......................................................................................................................................................................................... 3

5.4 Dimensions ................................................................................................................................................................................................. 3

5.5 Other measurements ......................................................................................................................................................................... 5

5.5.1 Cylinders and rotors ..................................................................................................................................................... 5

5.5.2 Concaves ...................................................................... ............................................................................................................ 6

5.5.3 Separating devices .......................................................................................................................................................... 6

5.5.4 Straw walker ........................................................................................................................................................................ 6

5.5.5 Conveying devices ...................................................................... ..................................................................................... 6

5.5.6 Sieves and sieve area .................................................................................................................................................... 7

5.5.7 Dirt screens, recleaners and other auxiliary cleaning devices ................................................. 7

5.5.8 Permeable surfaces ........................................................................................................................................... ............. 7

5.5.9 Functional components ............................................................................................................................................. 7

5.6 Other characteristics .......................................................................................................................................................................... 7

5.7 Position of centre of gravity ......................................................................................................................................................... 7

5.8 Grain tank .................................................................................................................................................................................................... 8

6 Functional field tests ........................................................................................................................................................................................ 8

6.1 General ........................................................................................................................................................................................................... 8

6.2 Information to be recorded .......................................................................................................................................................... 8

6.3 Behaviour and performance of combine harvester ................................................................................................ 8

6.3.1 General...................................................................................................................................................................................... 8

6.3.2 Functional aspects .......................................................................................................................................................... 9

6.3.3 Comfort, convenience and safety ....................................................................................................................... 9

6.3.4 Ease of adjustment and routine maintenance .....................................................................................10

6.3.5 Repairs ...................................................................................................................................................................................10

7 Capacity tests.........................................................................................................................................................................................................10

7.1 General ........................................................................................................................................................................................................10

7.2 Crop selection and field conditions ....................................................................................................................................10

7.3 Test and comparison combine harvesters ...................................................................................................................11

7.4 Adjustment of test and comparison combine harvesters ...............................................................................12

7.5 Catching apparatus ...........................................................................................................................................................................12

7.6 Conditions and procedure for collecting catch.........................................................................................................13

7.7 Treatment and analysis of catches ......................................................................................................................................14

7.8 Test data .....................................................................................................................................................................................................14

7.9 Calculations .............................................................................................................................................................................................15

7.10 Graphical presentation of results to obtain capacity ..........................................................................................15

8 Test report ................................................................................................................................................................................................................15

8.1 General ........................................................................................................................................................................................................15

8.2 Functional field tests .......................................................................................................................................................................16

8.3 Capacity tests .........................................................................................................................................................................................16

Annex A (normative) Tests on sloping ground ........................................................................................................................................17

Annex B (informative) Example calculations for a test run .......................................................................................................18

Bibliography .............................................................................................................................................................................................................................20

© ISO 2021 – All rights reserved PROOF/ÉPREUVE iii---------------------- Page: 3 ----------------------

ISO 8210:2021(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www .iso .org/ directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www .iso .org/ patents).Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to the

World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT), see www .iso .org/

iso/ foreword .html.This document was prepared by Technical Committee ISO/TC 23, Tractors and machinery for agriculture

and forestry, Subcommittee SC 7, Equipment for harvesting and conservation.This second edition of ISO 8210 cancels and replaces ISO 8210:1989 and ISO 6689-2:1997, which have

been technically revised.The main changes compared to the previous edition are as follows.

— Test and performance requirements formerly found in ISO 6689-2 have been added.

— Keys have been added to Figures 1 and 2.— Clarifications have been made in Clause 7.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www .iso .org/ members .html.iv PROOF/ÉPREUVE © ISO 2021 – All rights reserved

---------------------- Page: 4 ----------------------

INTERNATIONAL STANDARD ISO 8210:2021(E)

Equipment for harvesting — Combine harvesters — Test

procedure and performance assessment

1 Scope

This document specifies a test procedure for the measurement and testing of combine harvesters. It

applies to either self-propelled or trailed type, either directly cutting the crop or picking it up from a

windrow, for use in several crops.This document specifies the terminology and methods to be used for measuring important

characteristics of combine harvesters. It includes both functional and capacity tests, in other words,

those conducted over an extended period when ease of operation, ease of adjustment, rate of work and

general operating characteristics can be assessed, and those carried out on specific occasions for the

determination of grain loss and capacity characteristics.It applies to all types of combine harvesters.

2 Normative references

The following documents are referred in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 789-3, Agricultural tractors — Test procedures — Part 3: Turning and clearance diameters

ISO 4254-7, Agricultural machinery — Safety — Part 7: Combine harvesters, forage harvesters, cotton

harvesters and sugar cane harvestersISO 5007, Agricultural wheeled tractors — Operator's seat — Laboratory measurement of transmitted

vibrationISO 5131, Tractors for agriculture and forestry — Measurement of noise at the operator's position —

Survey methodISO 5687, Equipment for harvesting — Combine harvesters — Determination and designation of grain tank

capacity and unloading device performanceISO 5702, Equipment for harvesting — Combine harvester component parts — Equivalent terms

ISO 6689:— , Equipment for harvesting — Combine harvesters and functional components — Vocabulary

ISO 14396, Reciprocating internal combustion engines — Determination and method for the measurement

of engine power — Additional requirements for exhaust emission tests in accordance with ISO 8178

3 Terms and definitionsFor the purposes of the documents, the terms and definitions given in ISO 5702, ISO 6689, ISO 4254-7

and the following apply.ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https:// www .iso .org/ obp1) Under preparation. Stage at the date of publication: ISO/FDIS 6689:2021.

© ISO 2021 – All rights reserved PROOF/ÉPREUVE 1

---------------------- Page: 5 ----------------------

ISO 8210:2021(E)

— IEC Electropedia: available at http:// www.electropedia . org/

3.1

test combine harvester

subject combine harvester or combine harvester configuration to be tested

3.2

comparison combine harvester

other combine harvester or combine harvester configuration to which the test machine is compared, if

applicable3.3

test series

all events and data comprising several test runs (3.4)

3.4

test run

events necessary to record a single set of measurements

3.5

catch

mass of any material collected during the test run (3.4)

3.5.1

grain catch

material collected through the primary clean grain discharge point for the purpose of sample analysis

3.5.2separator catch

material collected from the machine’s normal point of discharge from the separator

3.5.3cleaning catch

material collected from the machine’s normal point of discharge from the cleaning system

4 General requirements4.1 The way in which the combine was selected or obtained for testing and the approximate duration

of any running prior to test shall be stated in the test report.4.2 The combine harvester shall normally be operated in accordance with the manufacturer’s

instructions. The test report shall record and give reasons for any significant departure from them.

4.3 Commercially available accessories as necessary or desirable for the various crops in which the

combine is to be used shall be reported.4.4 Setting and adjustments of the machine shall be generally in accordance with the manufacturer’s

operator's manual. The actual settings shall be recorded and reported.5 Characteristics of machine

5.1 Significant details

All significant details of the combine harvester shall be established and verified in accordance with

the definitions, characteristics and performance criteria laid down in ISO 6689. All dimensions and

performance relating to combine harvesters and their functional components, shall be assessed in

accordance with ISO 6689 and any requirements in this document.2 PROOF/ÉPREUVE © ISO 2021 – All rights reserved

---------------------- Page: 6 ----------------------

ISO 8210:2021(E)

5.2 Speeds

5.2.1 For self-propelled combine harvesters, measurements of the speed of any component shall be

made under “no-load” conditions with the governor control lever set in the normal working position

corresponding to the required working combine harvester regime.5.2.2 For power take-off (PTO) driven machines, these speeds shall be measured at standard PTO

-1 -1 -1 -1rotational frequency (540 min ± 10 min or 1 000 min ± 25 min ). (See ISO 500-1).

5.2.3 Ground speeds shall be measured on a hard, horizontal surface (see ISO 3965), with the governor

control lever in the normal working position and the crop processing mechanism disengaged.

5.2.4 If the combine harvester is fitted with stepless speed change mechanism, the maximum

and minimum speeds obtained for each gear shall be measured. Otherwise, speeds obtained for all

combinations of the gears shall be measured.5.3 Configurations

Component modes for each configuration shall be in accordance with the manufacturer's

recommendations. Refer to the combine harvester’s operator’s manual for applicable configuration for

each operating environment.NOTE Table 1 is presented for reference.

Table 1 — Component modes for each configuration

Position of component

Item # Component Transport Field

1 Front axle Transport mode Operational

2 Rear axle Transport mode Operational

3 Auxiliary axle Down Up

4 Operator access ladders Narrowest Safest position

5 Covers/shielding/cosmetic panels Narrowest Operational

6 Unload device Cradle Outermost limit

7 Unload device auxiliary Collapsed Operational

8 Feederhouse Recommended Operational

9 Straw and/or chaff spreader Transport mode Operational

10 Grain tank extension Transport mode Operational

11 Lighting and marking Transport mode Operational

12 Mirrors Transport mode Operational

13 Antennas Transport mode Operational

5.4 Dimensions

Dimensions of combine harvesters shall be measured according to either field operation or transport

operation as indicated in Table 2 and as defined in 5.4.1 to 5.4.8.© ISO 2021 – All rights reserved PROOF/ÉPREUVE 3

---------------------- Page: 7 ----------------------

ISO 8210:2021(E)

Table 2 — Summary of machine configurations for each measurement

Configuration

Subclause Measurement Transport Field

reference

5.4.1 Combine harvester length X X

5.4.2 Combine harvester height X X

5.4.3 Combine harvester width X X

5.4.4 Turning diameter X X

5.4.5 Clearance diameter X X

5.4.6 Head working widths X

5.4.7 Head working widths - Maize X

5.4.8 Ground clearance X

5.4.8 Maximum discharge height X

5.4.8 Maximum clearance height X

5.4.8 Maximum reach X

5.4.8 Height of cutterbar X

5.4.1 Combine harvester length shall be measured, both in transport configuration and equipped for

field configuration. In the field conditions, the head shall be fully raised and the reel fully forward; the

longest available divider shall be fitted. If other equipment, options or attachments affect the length,

such equipment shall be specified.5.4.2 Combine harvester height shall be measured with all components in position for transport

configuration. The height with all components in position for field configuration shall be measured. It

shall be stated whether or not the combine harvester is fitted with a cab.5.4.3 Combine harvester width shall be measured both in the transport configuration and equipped

for field configuration. In the field condition, the head fitted shall be the same as that fitted when

determining head working width and effective cutterbar width as specified in ISO 6689.

5.4.4 The turning diameter shall be measured in accordance with ISO 789-3 without applying the

brakes.If the left-hand and right-hand turning radius are not equal, both should be stated.

5.4.5 The clearance diameter shall be measured in accordance with ISO 789-3.If the left-hand and right-hand turning radius are not equal, both should be stated.

5.4.6 Where adjustable dividers are used, the minimum and maximum head working widths shall be

indicated.5.4.7 Where the header width is adjustable, the minimum and maximum effective working widths of

maize head cutters shall be indicated, including the number of picking units.5.4.8 The ground clearance, the maximum discharge height, the maximum clearance height, the

maximum reach, length of unloader, and the height of the cutterbar shall be determined under the

following conditions.a) Tyre and wheel or track equipment shall be stated, and tyres shall be inflated to the field operating

pressures recommended by the combine harvester manufacturer.b) The plane on which the combine harvester is standing shall be substantially level.

4 PROOF/ÉPREUVE © ISO 2021 – All rights reserved---------------------- Page: 8 ----------------------

ISO 8210:2021(E)

c) The size and type of head and reel installed at the time of measuring shall be stated.

d) All optional equipment mounted on the combine harvester shall be specified.5.4.9 Furthermore, the height of the cutterbar shall be stated as the highest point and the lowest point

to which the cutterbar can be raised or lowered, measured from the ground plane to the tip of the knife

section.5.5 Other measurements

5.5.1 Cylinders and rotors

Single or multiple cylinders or rotors may be disposed laterally (see Figure 1) or longitudinally (see

Figure 2) within the combine harvester. If multiple cylinders or rotors are used, the number shall be

stated, and the dimensions given as in Figures 1 and 2.Key

1 concave grate

2 concave grate extension

3 direction of combine harvester travel

α concave arc

α concave arc

ϕD threshing cylinder diameter

ϕD separating cylinder diameter

Figure 1 — Laterally disposed cylinders or rotors

© ISO 2021 – All rights reserved PROOF/ÉPREUVE 5

---------------------- Page: 9 ----------------------

ISO 8210:2021(E)

Key

1 concave grate

2 concave grate extension

α concave arc #1

α concave arc #2

ϕD rotor diameter #1

ϕD rotor diameter #2

Figure 2 — Longitudinally disposed cylinders or rotors (viewed from rear)

5.5.2 Concaves

5.5.2.1 If more than one concave is used, the dimensions and surfaces of each of them shall be indicated

separately. The concave grate surfaces are cumulative.5.5.2.2 If the combine harvester has more than one rotor, with its related concave and separating

grates, the quantity shall be indicated with the length and the area of the separating grate.

5.5.2.3 When using concave arc to describe the concave, the diameter of the associated cylinder, or

rotor, shall also be noted (see Figures 1 and 2). If the concave arc varies with concave adjustment, then

the ranges of arc should be noted.5.5.3 Separating devices

5.5.3.1 5.5.2.2 also applies for separating grates and secondary separating grates.

5.5.3.2 The surface of auxiliary separating devices shall not be added to that of separating devices.

5.5.4 Straw walkerIf there are adjustable sections at the rear of the straw walker, they shall be fully extended when

determining the length of the walkers.5.5.5 Conveying devices

Devices that only convey material within the combine harvester (for example, grain pans, augers,

paddles and other non-permeable conveyors) while they can contribute to good separation by stratifying

6 PROOF/ÉPREUVE © ISO 2021 – All rights reserved---------------------- Page: 10 ----------------------

ISO 8210:2021(E)

the material advantageously, do no actual separation of grain from material other than grain (MOG),

and their areas may not be classified as separating areas, or added to the other separating areas.

5.5.6 Sieves and sieve areaTo determine the sieve area where sieve extensions are used in the standard specifications of the

combine harvester, their surfaces shall be measured by the same means and these conditions shall be

stated. The component sieves and sieve extensions may be totalled and represented as total sieve area.

If a grain pan extension comb (grate or fingers) is used to achieve suspension of the grain mat, its area

should not be included when establishing the cleaning area.5.5.7 Dirt screens, recleaners and other auxiliary cleaning devices

These surface areas of these devices shall be specified.

5.5.8 Permeable surfaces

Sieve area and pneumatic cleaning areas shall be calculated and expressed.

5.5.9 Functional components

For the purposes of reporting combine harvester specifications, the functional component areas

defined in ISO 6689:—, 3.6 and covered in 5.5 shall be listed separately and individually. Areas shall not

be used singly or in combination as a measure of a combine harvester's capacity, performance or value.

5.6 Other characteristics5.6.1 The engine net power shall be determined in accordance with ISO 14396.

5.6.2 The throughputs defined in ISO 6689:—, 4.1 and measured in 7.2.5, shall be indicated with the

corresponding MOG:G ratio value.5.6.3 When indicating the combine harvester mass equipped for operation in the field, the accessories

fitted to the combine harvester shall be listed and their mass indicated.5.7 Position of centre of gravity

5.7.1 It shall be specified, for the machine tested, whether it is equipped with powered rear-wheel

drive or not and if it has a chopper attachment. This is a supplementary measurement applicable to self-

propelled combine harvesters only.5.7.2 The position of the centre of gravity shall be determined under the conditions outlined in Table 3.

See also ISO 16231-2.© ISO 2021 – All rights reserved PROOF/ÉPREUVE 7

---------------------- Page: 11 ----------------------

ISO 8210:2021(E)

Table 3 — Machine configuration for determining centre of gravity

Component or entity Condition

Machine Empty of crop

Header Fully raised

Reel Most forward position

Fuel tank(s) Full

Grain tank(s) Full

Driver Simulated by the mass of 75 kg placed on the driver's seat

Sacks placed to represent most unstable condition

Bagger platform

of normal field operation

5.8 Grain tank

The grain tank capacity and unloading time shall be measured in accordance with ISO 5687.

6 Functional field tests6.1 General

Functional field tests shall be carried out over an extended period, for example, several months or a

complete harvesting season in a particular area and shall include as wide a range as practicable of

crops, crop varieties and/or crop conditions which are important to that area.6.2 Information to be recorded

In each field worked, the following information shall be recorded:

a) atmospheric conditions;

b) slope and state of ground;

c) shape of field;

d) height of crop and stubble;

e) crop: variety, condition, weed content, grain moisture, residue moisture, and approximate yield;

f) machine hours of operation (for example, engine, separator, header);g) approximate area harvested;

h) approximate volume of fuel used.

6.3 Behaviour and performance of combine harvester

6.3.1 General

Throughout the test period, the general behaviour and performance of the combine harvester shall

be kept under observation, and shall subsequently be reported on, with particular reference to the

information outlined in 6.3.2 to 6.3.5.8 PROOF/ÉPREUVE © ISO 2021 – All rights reserved

---------------------- Page: 12 ----------------------

ISO 8210:2021(E)

6.3.2 Functional aspects

The operator shall observe and report on the following aspects of the behaviour and performance of

the combine harvester:a) the effectiveness of cutting, gathering and/or picking up of the crop;

b) the occurrence of blockages;

c) the adequacy of engine power, governor con

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.