ASTM A192/A192M-02(2012)

(Specification)Standard Specification for Seamless Carbon Steel Boiler Tubes for High-Pressure Service

Standard Specification for Seamless Carbon Steel Boiler Tubes for High-Pressure Service

ABSTRACT

This guide covers standard specifications for minimum-wall-thickness, seamless carbon steel boiler and superheater tubes for high-pressure service. The steel shall conform to the required chemical composition for carbon, manganese, phosphorus, sulfur, and silicon. The tubes shall have a hardness number not exceeding a specific value. The following mechanical tests shall be conducted, namely: flattening test; flaring test; hardness test; and hydrostatic test.

SCOPE

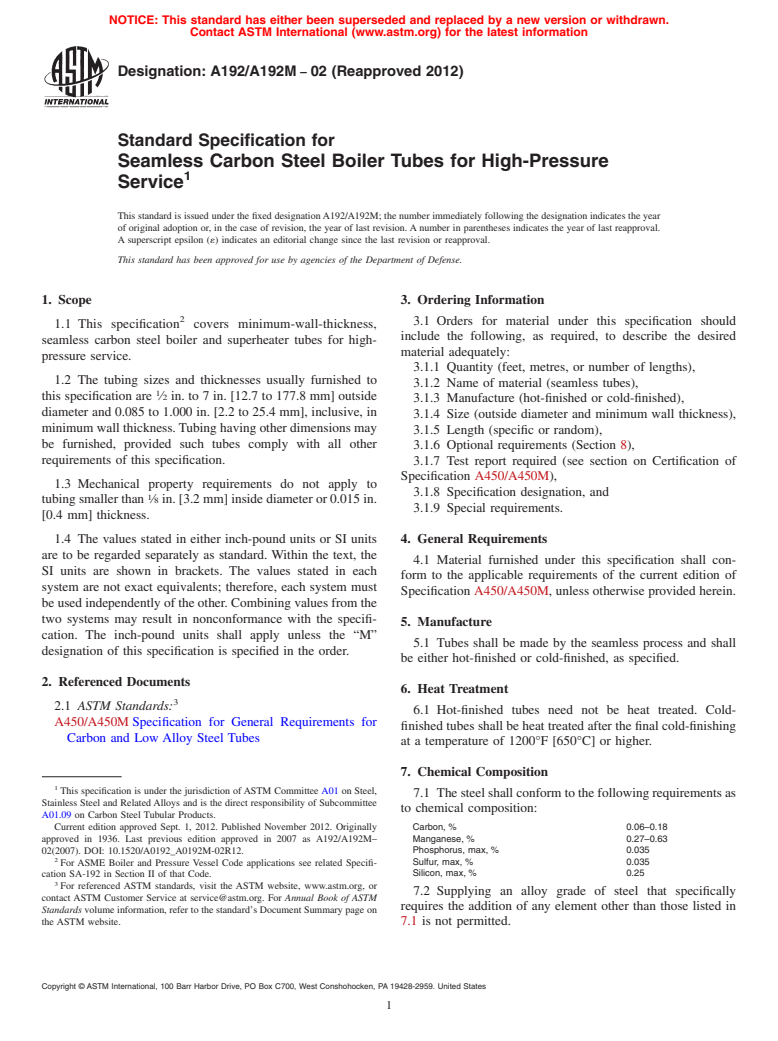

1.1 This specification2 covers minimum-wall-thickness, seamless carbon steel boiler and superheater tubes for high-pressure service.

1.2 The tubing sizes and thicknesses usually furnished to this specification are 1/2 in. to 7 in. [12.7 to 177.8 mm] outside diameter and 0.085 to 1.000 in. [2.2 to 25.4 mm], inclusive, in minimum wall thickness. Tubing having other dimensions may be furnished, provided such tubes comply with all other requirements of this specification.

1.3 Mechanical property requirements do not apply to tubing smaller than 1/8 in. [3.2 mm] inside diameter or 0.015 in. [0.4 mm] thickness.

1.4 The values stated in either inch-pound units or SI units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other. Combining values from the two systems may result in nonconformance with the specification. The inch-pound units shall apply unless the “M” designation of this specification is specified in the order.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A192/A192M −02 (Reapproved 2012)

Standard Specification for

Seamless Carbon Steel Boiler Tubes for High-Pressure

Service

This standard is issued under the fixed designationA192/A192M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 3. Ordering Information

3.1 Orders for material under this specification should

1.1 This specification covers minimum-wall-thickness,

include the following, as required, to describe the desired

seamless carbon steel boiler and superheater tubes for high-

material adequately:

pressure service.

3.1.1 Quantity (feet, metres, or number of lengths),

1.2 The tubing sizes and thicknesses usually furnished to

3.1.2 Name of material (seamless tubes),

this specification are ⁄2 in. to 7 in. [12.7 to 177.8 mm] outside

3.1.3 Manufacture (hot-finished or cold-finished),

diameter and 0.085 to 1.000 in. [2.2 to 25.4 mm], inclusive, in

3.1.4 Size (outside diameter and minimum wall thickness),

minimum wall thickness.Tubing having other dimensions may

3.1.5 Length (specific or random),

be furnished, provided such tubes comply with all other

3.1.6 Optional requirements (Section 8),

requirements of this specification.

3.1.7 Test report required (see section on Certification of

Specification A450/A450M),

1.3 Mechanical property requirements do not apply to

3.1.8 Specification designation, and

tubing smaller than ⁄8 in. [3.2 mm] inside diameter or 0.015 in.

3.1.9 Special requirements.

[0.4 mm] thickness.

4. General Requirements

1.4 The values stated in either inch-pound units or SI units

are to be regarded separately as standard. Within the text, the

4.1 Material furnished under this specification shall con-

SI units are shown in brackets. The values stated in each

form to the applicable requirements of the current edition of

system are not exact equivalents; therefore, each system must

Specification A450/A450M, unless otherwise provided herein.

be used independently of the other. Combining values from the

two systems may result in nonconformance with the specifi-

5. Manufacture

cation. The inch-pound units shall apply unless the “M”

5.1 Tubes shall be made by the seamless process and shall

designation of this specification is specified in the order.

be either hot-finished or cold-finished, as specified.

2. Referenced Documents

6. Heat Treatment

2.1 ASTM Standards:

6.1 Hot-finished tubes need not be heat treated. Cold-

A450/A450M Specification for General Requirements for

finished tubes shall be heat treated after the final cold-finishing

Carbon and Low Alloy Steel Tubes

at a temperature of 1200°F [650°C] or higher.

7. Chemical Composition

This specification is under the jurisdiction of ASTM Committee A01 on Steel,

7.1 The steel shall conform to the following requirements as

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee

to chemical composition:

A01.09 on Carbon Steel Tubular Products.

Current edition approved Sept. 1, 2012. Published November 2012. Originally

Carbon, % 0.06–0.18

approved in 1936. Last previous edition approved in 2007 as A192/A192M– Manganese, % 0.27–0.63

02(2007). DOI: 10.1520/A0192_A0192M-02R12. Phosphorus, max, % 0.035

For ASME Boiler and Pressure Vessel Code applications see related Specifi- Sulfur, max, % 0.035

Silicon, max, % 0.25

cation SA-192 in Section II of that Code.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

7.2 Supplying an alloy grade of steel that specifically

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

requires the addition of any element other than those listed in

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. 7.1 is not permitted.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

A192/A192M − 02 (2012)

8. Product Analysis 10.2 Flaring Test—One flaring test shall be made on speci-

mens from each end of two tubes selected from each lot (see

8.1 When requested o

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.