ASTM D6265-98

(Practice)Standard Practice for Separation of Contaminants in Polymers Using an Extruder Filter Test

Standard Practice for Separation of Contaminants in Polymers Using an Extruder Filter Test

SCOPE

1.1 This practice covers a means to separate the unmolten particles, gels, and impurities contaminating a polymer sample. The procedure may be used to remove gels and incompatible materials that may cause imperfections in the final extruded product. Under pressure, most gels will break up or deform and pass through a wire mesh filter, however high molecular weight gels may not break up or deform.

1.2 If desired, materials isolated on a wire mesh filter can subsequently be identified by spectroscopic or other analytical means.

Note 1-Although not presented as a quantitative method, the procedure presented in this practice may be used to provide quantitative results at the discretion of the user. The user assumes the responsibility to verify the reproducibility of quantitative results. Detection limit depends on the mesh size of the filter screen, but the procedure is generally applicable to the separation of immiscible contaminants present at concentrations greater than 0.1%.

1.3 The values stated in SI units are to be regarded as the standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazards statements, see Section 8.

Note 2-There is no equivalent ISO standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 6265 – 98

Standard Practice for

Separation of Contaminants in Polymers Using an Extruder

Filter Test

This standard is issued under the fixed designation D 6265; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope (SI) (the Modernized Metric System)

1.1 This practice covers a means to separate the unmolten

3. Terminology

particles, gels, and impurities contaminating a polymer sample.

3.1 The terminology used in this practice is in accordance

The procedure may be used to remove gels and incompatible

with Terminology D 1600 and Guide D 5033. Units and

materials that may cause imperfections in the final extruded

symbols are in accordance with Practice E 380.

product. Under pressure, most gels will break up or deform and

pass through a wire mesh filter, however high molecular weight

4. Summary of Practice

gels may not break up or deform.

4.1 As polymer passes through a wire mesh filter of known

1.2 If desired, materials isolated on a wire mesh filter can

2 2

area and porosity (for example, 0.00032 m (0.049 in. )ofa

subsequently be identified by spectroscopic or other analytical

325 mesh screen) positioned in line at the end of an extruder

means.

barrel, the filter becomes blocked by impurities and gels. This

NOTE 1—Although not presented as a quantitative method, the proce-

procedure is used to remove gels and contaminants that may

dure presented in this practice may be used to provide quantitative results

result in undesirable imperfections in the extruded product.

at the discretion of the user. The user assumes the responsibility to verify

This blockage results in a proportional rise in the pressure

the reproducibility of quantitative results. Detection limit depends on the

behind the filter. Although this Practice is not designed to

mesh size of the filter screen, but the procedure is generally applicable to

provide any quantitative estimate of the level of contamination,

the separation of immiscible contaminants present at concentrations

greater than 0.1 %. the rate of this pressure rise may be correlated to the level of

contamination through appropriate experiments.

1.3 The values stated in SI units are to be regarded as the

standard.

5. Significance and Use

1.4 This standard does not purport to address the safety

5.1 Presence of paper, metal, gels, incompatible polymer, or

concerns, if any, associated with its use. It is the responsibility

other extraneous contamination in polymers, including re-

of the user of this standard to establish appropriate safety and

cycled polymers, may cause problems with extrusion and

health practices and determine the applicability of regulatory

subsequent processing of the material. This procedure is useful

limitations prior to use. For specific hazards statements, see

for separating gross contaminants from polymers. For example,

Section 8.

the procedure is useful for determining the quality of resins to

NOTE 2—There is no equivalent ISO standard.

be used in fiber applications. If desired, the isolated contami-

nants may be subsequently identified by the appropriate visual

2. Referenced Documents

or instrumental procedures.

2.1 ASTM Standards:

D 1238 Test Method for Flow Rates of Thermoplastics by 6. Apparatus

Extrusion Plastometer

6.1 Extruder, designed to deliver a continuous supply of

D 1600 Terminology for Abbreviated Terms Relating to

molten resin to a filter at a uniform rate with good temperature

Plastics

control. An extruder with 25 to 64-mm barrel has been found

D 5033 Guide for the Development of Standards Relating to

to be useful.

the Proper Use of Recycled Plastics

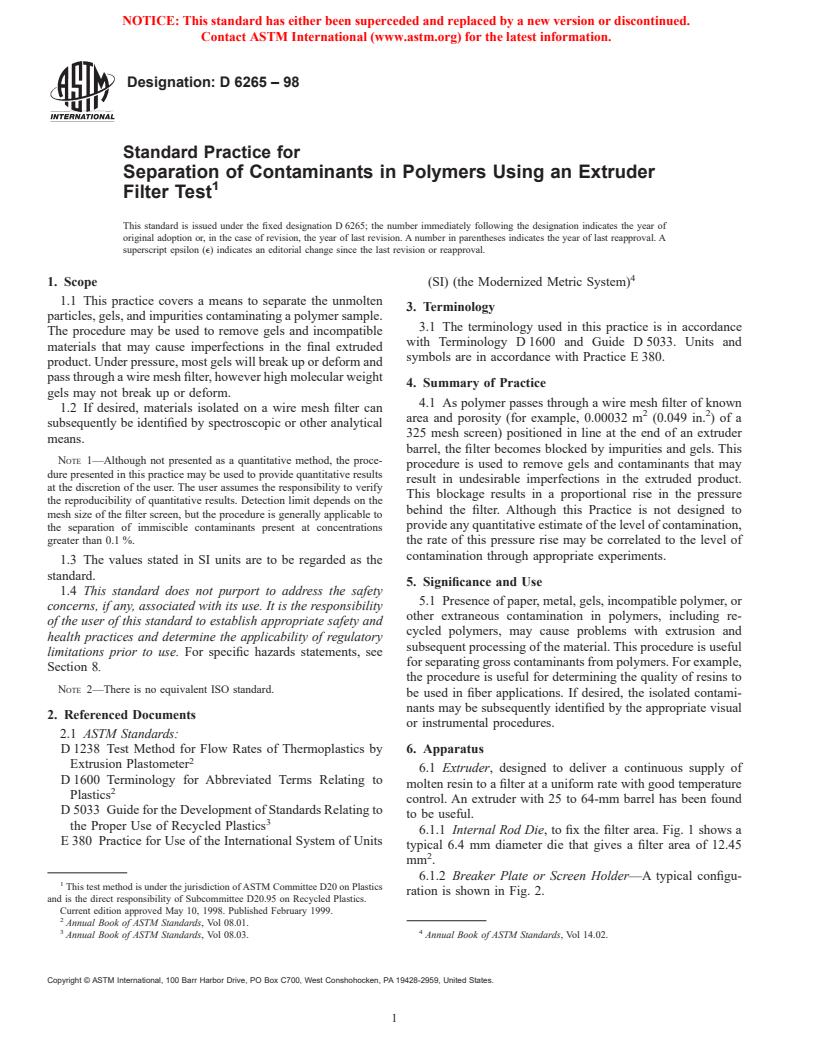

6.1.1 Internal Rod Die, to fix the filter area. Fig. 1 shows a

E 380 Practice for Use of the International System of Units

typical 6.4 mm diameter die that gives a filter area of 12.45

mm .

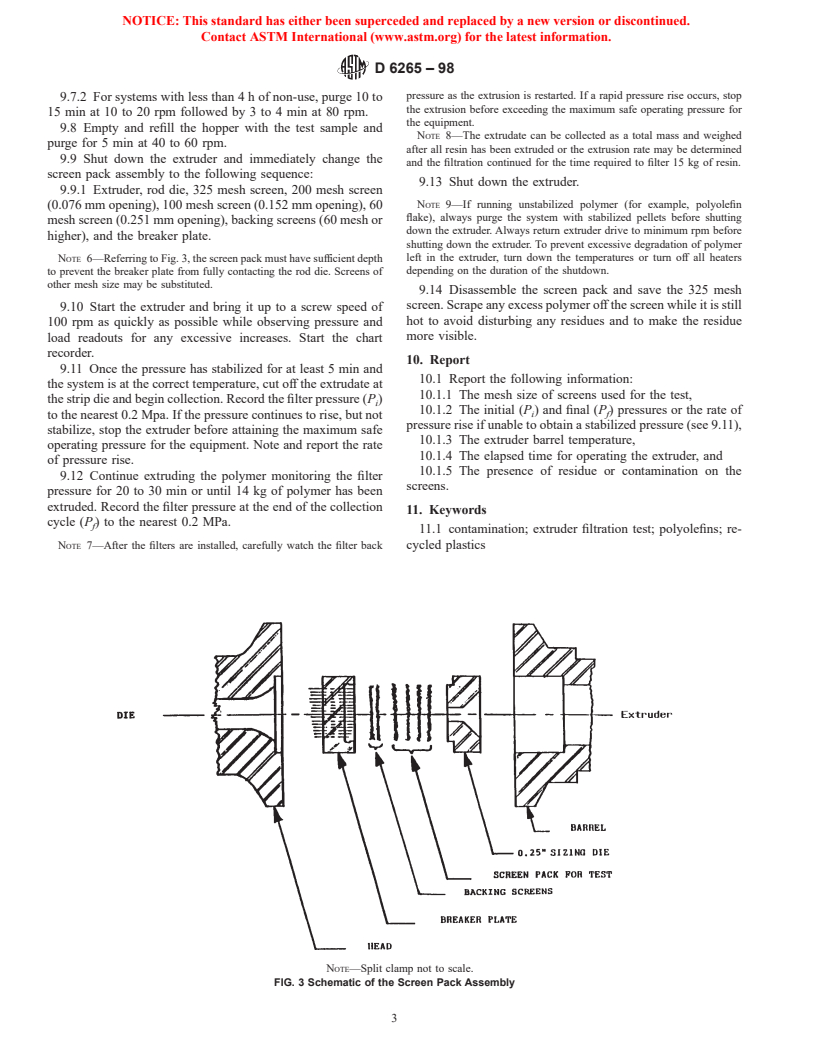

6.1.2 Breaker Plate or Screen Holder—A typical configu-

This test method is under the jurisdiction of ASTM Committee D20 on Plastics

ration is shown in Fig. 2.

and is the direct responsibility of Subcommittee D20.95 on Recycled Plastics.

Current edition approved May 10, 1998. Published February 1999.

Annual Book of ASTM Standards, Vol 08.01.

3 4

Annual Book of ASTM Standards, Vol 08.03. Annual Book of ASTM Standards, Vol 14.02.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D6265–98

6.5 Torque Wrench, with ratchet drive attachment.

6.6 Thermally Insulated Gloves.

6.7 Spatulas and Scrapers, brass, assorted sizes for remov-

ing molten polymer from equipment.

7. Materials

7.1 Virgin Polymer, free of gels and contaminants, for

purging the extruder equipment.

8. Hazards

8.1 Hot polymer can cause serious burns. Do not stand in

front of the extruder because air bubbles, excessive tempera-

ture or pressure can cause hot polymer to be expelled from the

extruder die.

NOTE—A = 0.250 in.,

8.2 Always wear thermally insulated gloves when handling

B = 0.0625 in.,

hot polymer or working directly with the heated areas of the

C = same diameter as extruder barrel, and

D = dimension that when added to the total thickness of the screen pack

extruder.

shall exceed the depth of the screen-retaining recess of

the breaker plate to permit compression of the screens.

9. Procedure

FIG. 1 Schematic Showing the Internal Sizing of the (Rod) Die

9.1 Turn on the power to the extruder and turn on the feed

throat cooling water.

9.2 Set extruder temperature controllers to maintain the

barrel at the appropriate temperature for the polymer (see Table

1).

9.3 Wait at least 30 min after achieving melt temperature

before starting the extruder.

9.4 Insert a new screen pack using 60 (0.251 mm opening)-

100 (0.152 mm opening) -60 mesh screens plus the backing

screens for the extruder purge.

NOTE 4—The screen pack must have sufficient depth to prevent the

breaker plate from fully contacting the rod die. This helps keep the screens

firmly in place, insures the correct surface area of filter screw is actually

used during the test, and simplifies disassembly.

9.5 Close the split clamp and

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.