ASTM A270-03a(2008)e1

(Specification)Standard Specification for Seamless and Welded Austenitic Stainless Steel Sanitary Tubing

Standard Specification for Seamless and Welded Austenitic Stainless Steel Sanitary Tubing

ABSTRACT

This specification covers grades of seamless, welded, and heavily cold worked austenitic and ferritic/austenitic stainless steel sanitary tubing. Seamless tubes shall be manufactured by a process that does not involve welding at any stage. Welded tubes shall be made using an automated welding process with no addition of filler metal during the welding process. Heavily cold worked tubes shall be made by applying cold working of not less than 35% reduction of thickness of both wall and weld to a welded tube prior to the final anneal. No filler shall be used in making the weld. All material shall be furnished in the heat-treated condition. A chemical analysis of either one length of flat-rolled stock or one tube shall be made for each heat. Each tube shall be subjected to mechanical tests like reverse flattening test, hydrostatic test or nondestructive electric test. The following surface finishes may be specified: mill finish, mechanically polished surface finish, finish No. 80, finish No. 120, finish No. 180, finish No. 240, electropolished finish, and maximum roughness average surface finish. Longitudinally polished finish shall be performed on the inside surface only while a circumferential polished finish shall be done on either the inside surface, outside surface, or both.

SCOPE

1.1 This specification covers grades of seamless, welded, and heavily cold worked welded austenitic and ferritic/austenitic stainless steel sanitary tubing intended for use in the dairy and food industry and having special surface finishes. Pharmaceutical quality may be requested, as a supplementary requirement.

1.2 This specification covers tubes in sizes up to and including 12 in. (304.8 mm) in outside diameter.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.4 Optional supplementary requirements are provided, and when one or more of these are desired, each shall be so stated in the order.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

´1

Designation: A270 – 03a (Reapproved 2008)

Standard Specification for

Seamless and Welded Austenitic and Ferritic/Austenitic

Stainless Steel Sanitary Tubing

This standard is issued under the fixed designation A270; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

´ NOTE—The units statement in 1.3 was corrected editorially in October 2008.

1. Scope E527 Practice for Numbering Metals and Alloys in the

Unified Numbering System (UNS)

1.1 This specification covers grades of seamless, welded,

2.2 ASME Standard:

and heavily cold worked welded austenitic and ferritic/

B46.1 Surface Texture (Surface Roughness, Waviness, and

austenitic stainless steel sanitary tubing intended for use in the

Lay)

dairy and food industry and having special surface finishes.

2.3 ASME Boiler and Pressure Vessel Code:

Pharmaceutical quality may be requested, as a supplementary

Section VIII Pressure Vessels

requirement.

2.4 Other Standard:

1.2 This specification covers tubes in sizes up to and

SAE J1086 Practice for Numbering Metals and Alloys

including 12 in. (304.8 mm) in outside diameter.

(UNS)

1.3 The values stated in inch-pound units are to be regarded

as standard. The values given in parentheses are mathematical

3. Terminology

conversions to SI units that are provided for information only

3.1 Definition:

and are not considered standard.

3.1.1 roughness average, Ra, n—arithmetic average surface

1.4 Optional supplementary requirements are provided, and

roughness normally reported in microinches or microns; a

when one or more of these are desired, each shall be so stated

measurement of surface roughness usually performed by mov-

in the order.

ing a stylus in a straight line along the surface, although other

2. Referenced Documents methods may be used.

2.1 ASTM Standards:

4. Ordering Information

A262 Practices for Detecting Susceptibility to Intergranular

4.1 It is the responsibility of the purchaser to specify all

Attack in Austenitic Stainless Steels

requirements that are necessary for material ordered under this

A480/A480M Specification for General Requirements for

specification. Such requirements may include, but are not

Flat-Rolled Stainless and Heat-Resisting Steel Plate,

limited to, the following:

Sheet, and Strip

4.1.1 Quantity (feet, metres, or number of lengths),

A923 Test Methods for Detecting Detrimental Intermetallic

4.1.2 Name of material (austenitic steel tube),

Phase in Duplex Austenitic/Ferritic Stainless Steels

4.1.3 Process seamless (SML), welded (WLD), or heavily

A967 Specification for Chemical Passivation Treatments

cold worked (HCW),

for Stainless Steel Parts

4.1.4 Size (outside diameter and average wall thickness),

A1016/A1016M Specification for General Requirements

4.1.5 Length (specific or random),

for Ferritic Alloy Steel, Austenitic Alloy Steel, and Stain-

4.1.6 Surface finish (Section 13),

less Steel Tubes

4.1.7 Optional requirements (product analysis, see Section

9; hydrostatic or nondestructive electric test, see Section11).

This specification is under the jurisdiction of ASTM CommitteeA01 on Steel,

4.1.8 Test report required (Certification Section of Specifi-

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee

cation A1016/A1016M),

A01.10 on Stainless and Alloy Steel Tubular Products.

Current edition approved Oct. 1, 2008. Published January 2009. Originally

approved in 1944. Last previous edition approved in 2003 as A270–03a. DOI:

10.1520/A0270-03AR08E01. Available from American Society of Mechanical Engineers (ASME), ASME

For referenced ASTM standards, visit the ASTM website, www.astm.org, or International Headquarters, Three Park Ave., New York, NY 10016-5990, http://

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM www.asme.org.

Standards volume information, refer to the standard’s Document Summary page on Available from Society of Automotive Engineers (SAE), 400 Commonwealth

the ASTM website. Dr., Warrendale, PA 15096-0001, http://www.sae.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

´1

A270 – 03a (2008)

4.1.9 Specification designation, uctanalysistoleranceisnotapplicabletothecarboncontentfor

4.1.10 Special requirements, and material with a specified maximum carbon of 0.04 % or less.

4.2 Any supplementary requirements. 9.2 If the original test for product analysis fails, retests of

two additional lengths of flat-rolled stock or tubes shall be

5. General Requirements

made. Both retests for the elements in question shall meet the

5.1 Material furnished under this specification shall con-

requirements of the specification; otherwise all remaining

form to the applicable requirements of the current edition of material in the heat or lot (Note 1) shall be rejected or, at the

Specification A1016/A1016M, unless otherwise provided

option of the producer, each length of flat-rolled stock or tube

herein. may be individually tested for acceptance. Lengths of flat

rolled stock or tubes that do not meet the requirements of the

6. Manufacture

specification shall be rejected.

6.1 Thetubesshallbemanufacturedbyoneofthefollowing

10. Mechanical Tests Required

processes:

6.1.1 Seamless (SML) tubes shall be made by a process that 10.1 Reverse Flattening Test—For welded tubes, one re-

does not involve welding at any stage. verse flattening test shall be made on a specimen from each

6.1.2 Welded (WLD) tubes shall be made using an auto- 1500 ft (457 m) of finished tubing.

mated welding process with no addition of filler metal during

11. Hydrostatic or Nondestructive Electric Test

the welding process.

6.1.3 Heavily cold worked (HCW) tubes shall be made by 11.1 Each tube shall be subjected to the nondestructive

electric test or the hydrostatic test. The type of test to be used

applying cold working of not less than 35 % reduction of

thickness of both wall and weld to a welded tube prior to the shall be at the option of the manufacturer, unless otherwise

specified in the purchase order.

final anneal. No filler shall be used in making the weld. Prior

to cold working, the weld shall be 100 % radiographically

12. Permissible Variations in Dimensions

inspectedinaccordancewiththerequirementsofASMEBoiler

12.1 The following variations in dimensions shall apply:

and Pressure Vessel Code Section VIII, Division 1, latest

revision, Paragraph UW 51. 12.1.1 For tubes with a specified wall thickness of 0.049 in.

(1.24 mm) and greater, variations in outside diameter from

6.2 At the manufacturer’s option, tubing may be furnished

either hot finished or cold finished. those specified shall not exceed the amount prescribed inTable

2. For tubes with a specified wall thickness less than 0.049 in.

7. Heat Treatment

(1.24 mm), the diameter tolerances shall be a matter for

7.1 All material shall be furnished in the heat-treated agreement by the manufacturer and the purchaser.

condition. The heat treatment procedure, except for S31803, 12.1.2 When tubing >4 in. (101.6 mm) outside diameter is

S32003, S32205, S32750, N08926 and N08367, shall consist ordered, additional ovality may be required for thin wall

of heating the material to a minimum temperature of 1900 °F tubing. Thin wall tubing applies when the specified wall is less

(1040 °C) and quenching in water or rapid cooling by other than0.150in.(3.81mm).Whenthinwalltubingisordered,the

means. maximum and minimum outside diameter at any cross section

7.2 N08926 shall be heat-treated to a minimum temperature shall deviate from the specified outside diameter by no more

of 2010 °F (1100 °C) followed by quenching in water or than twice the permissible variation in outside diameter given

rapidly cooling by other means. UNS N08367 should be in Table 2; however, the mean diameter at that cross section

must still be within the given permissible variation.

solution annealed from 2025 °F (1107 °C) minimum followed

by rapid quenching. 12.1.3 The wall thickness at any point shall not vary more

than 12.5 %, from the specified wall thickness.

7.3 S31803 and S32205 shall be heat-treated in a tempera-

ture range of 1870 °F (1020 °C) to 2010 °F (1100 °C) followed 12.1.4 Variations in length shall meet the requirements in

Table 2 except when the Pharmaceutical Quality Tubing

by quenching in water or rapidly cooling by other means.

7.4 S32750 shall be heat-treated in a temperature range of (Supplementary Requirement S2) is specified.

1880 °F (1025 °C) to 2060 °F (1125 °C) followed by

13. Surface Finishes

quenching in water or rapidly cooling by other means.

7.5 S32003 shall be heat-treated in a temperature range of 13.1 The following surface finishes may be specified:

13.1.1 Mill Finish—Afinishwithoutadditionalpolishingor

1850 °F (1010 °C) to 2010 °F (1100 °C).

operations intended to smooth the surface.

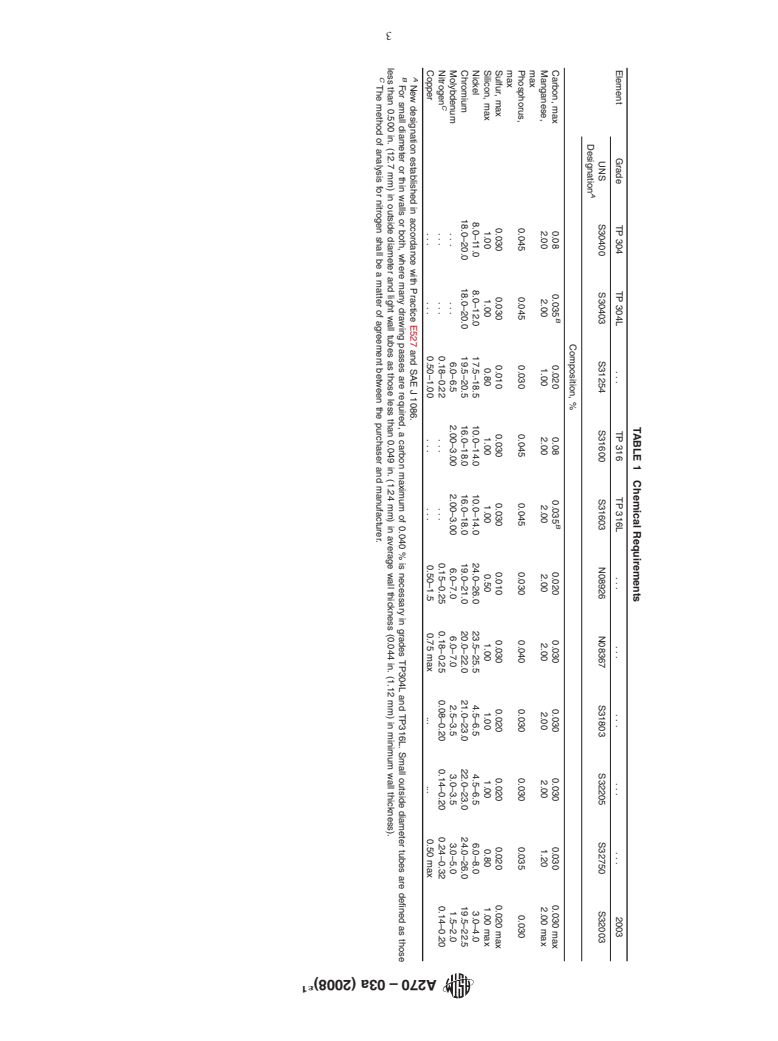

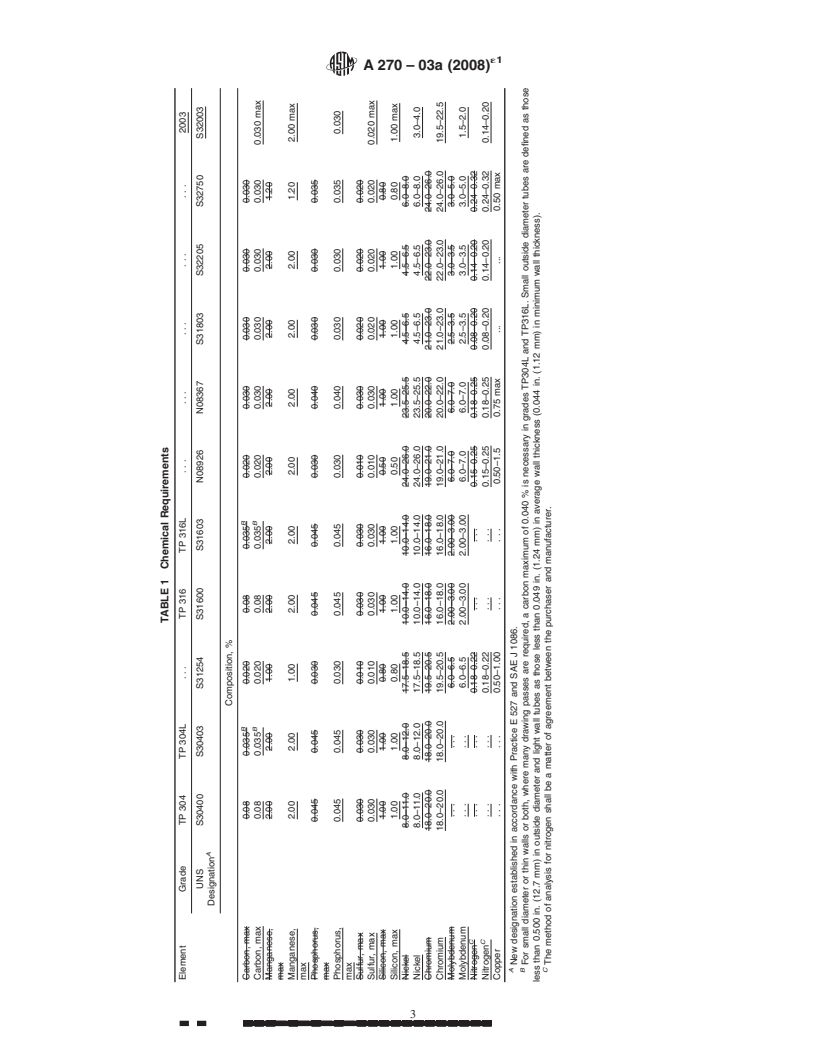

8. Chemical Composition

13.1.2 Mechanically Polished Surface Finish—The pur-

8.1 An analysis of either one length of flat-rolled stock or chaser may specify one of the following finish numbers for a

mechanically polished surface:

one tube shall be made for each heat. The chemical composi-

tionthusdeterminedshallconformtotherequirementsgivenin 13.1.2.1 Finish No. 80—A ground finish produced by pol-

Table 1. ishing a tube with an abrasive media impregnated with No. 80

grit.

9. ProductAnalysis

13.1.2.2 Finish No. 120—A ground finish produced by

9.1 When requested by the purchaser, product analysis polishing a tube with an abrasive media impregnated with No.

tolerance in SpecificationA480/A480M shall apply. The prod- 120 grit.

´1

A270 – 03a (2008)

TABLE 1 Chemical Requirements

Element Grade TP 304 TP 304L . . . TP 316 TP 316L . . . . . . . . . . . . . . . 2003

UNS S30400 S30403 S31254 S31600 S31603 N08926 N08367 S31803 S32205 S32750 S32003

A

Designation

Composition, %

B B

Carbon, max 0.08 0.035 0.020 0.08 0.035 0.020 0.030 0.030 0.030 0.030 0.030 max

Manganese, 2.00 2.00 1.00 2.00 2.00 2.00 2.00 2.00 2.00 1.20 2.00 max

max

Phosphorus, 0.045 0.045 0.030 0.045 0.045 0.030 0.040 0.030 0.030 0.035 0.030

max

Sulfur, max 0.030 0.030 0.010 0.030 0.030 0.010 0.030 0.020 0.020 0.020

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation:A270–03a Designation: A 270 – 03a (Reapproved 2008)

Standard Specification for

Seamless and Welded Austenitic and Ferritic/Austenitic

Stainless Steel Sanitary Tubing

This standard is issued under the fixed designation A 270; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

´ NOTE—The units statement in 1.3 was corrected editorially in October 2008.

1. Scope *

1.1 This specification covers grades of seamless, welded, and heavily cold worked welded austenitic and ferritic/austenitic

stainless steel sanitary tubing intended for use in the dairy and food industry and having special surface finishes. Pharmaceutical

quality may be requested, as a supplementary requirement.

1.2 This specification covers tubes in sizes up to and including 12 in. (304.8 mm) in outside diameter.

1.3The values stated in inch-pound units are to be regarded as the standard.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.4 Optional supplementary requirements are provided, and when one or more of these are desired, each shall be so stated in

the order.

2. Referenced Documents

2.1 ASTM Standards:

A 262 Practices for Detecting Susceptibility to Intergranular Attack in Austenitic Stainless Steels

A 480/A 480M Specification for General Requirements for Flat-Rolled Stainless and Heat-Resisting Steel Plate, Sheet, and

Strip

A 923 Test Methods for Detecting Detrimental Intermetallic Phase in Wrought Duplex Austenitic/Ferritic Stainless Steels

A 967 Specification for Chemical Passivation Treatments for Stainless Steel Parts

A 1016/A 1016M Specification for General Requirements for Ferritic Alloy Steel, Austenitic Alloy Steel, and Stainless Steel

Tubes

E 527 Practice for Numbering Metals andAlloys (UNS) Practice for Numbering Metals andAlloys in the Unified Numbering

System (UNS)

2.2 ASME Standard:

B46.1 Surface Texture (Surface Roughness, Waviness, and Lay)

2.3 ASME Boiler and Pressure Vessel Code:

Section VIII Pressure Vessels

2.4 Other Standard:

SAE J1086 Practice for Numbering Metals and Alloys (UNS)

3. Terminology

3.1 Definition:

3.1.1 roughness average, Ra, n—arithmetic average surface roughness normally reported in microinches or microns; a

This specification is under the jurisdiction ofASTM CommitteeA01 on Steel, Stainless Steel and RelatedAlloys,Alloys and is the direct responsibility of Subcommittee

A01.10 on Stainless and Alloy Steel Tubular Products.

Current edition approved Dec.Oct. 1, 2003.2008. Published January 2004.2009. Originally approved in 1944. Last previous edition approved in 2003 as A 270–03a.

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Available from ASME International, Three Park Avenue, New York, NY 10016–5990.

Available from American Society of Mechanical Engineers (ASME), ASME International Headquarters, Three Park Ave., New York, NY 10016-5990, http://

www.asme.org.

Available from Society of Automotive Engineers (SAE), 400 Commonwealth Dr., Warrendale, PA 15096-0001, http://www.sae.org.

*ASummary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

´1

A 270 – 03a (2008)

measurement of surface roughness usually performed by moving a stylus in a straight line along the surface, although other

methods may be used.

4. Ordering Information

4.1 It is the responsibility of the purchaser to specify all requirements that are necessary for material ordered under this

specification. Such requirements may include, but are not limited to, the following:

4.1.1 Quantity (feet, metres, or number of lengths),

4.1.2 Name of material (austenitic steel tube),

4.1.3 Process seamless (SML), welded (WLD), or heavily cold worked (HCW),

4.1.4 Size (outside diameter and average wall thickness),

4.1.5 Length (specific or random),

4.1.6 Surface finish (Section 13),

4.1.7 Optional requirements (product analysis, see Section 9; hydrostatic or nondestructive electric test, see Section11).

4.1.8 Test report required (Certification Section of Specification A 1016/A 1016M),

4.1.9 Specification designation,

4.1.10 Special requirements, and

4.2 Any supplementary requirements.

5. General Requirements

5.1 Material furnished under this specification shall conform to the applicable requirements of the current edition of

Specification A 1016/A 1016M, unless otherwise provided herein.

6. Manufacture

6.1 The tubes shall be manufactured by one of the following processes:

6.1.1 Seamless (SML) tubes shall be made by a process that does not involve welding at any stage.

6.1.2 Welded (WLD) tubes shall be made using an automated welding process with no addition of filler metal during the

welding process.

6.1.3 Heavily cold worked (HCW) tubes shall be made by applying cold working of not less than 35 % reduction of thickness

of both wall and weld to a welded tube prior to the final anneal. No filler shall be used in making the weld. Prior to cold working,

theweldshallbe100 %radiographicallyinspectedinaccordancewiththerequirementsofASMEBoilerandPressureVesselCode

Section VIII, Division 1, latest revision, Paragraph UW 51.

6.2 At the manufacturer’s option, tubing may be furnished either hot finished or cold finished.

7. Heat Treatment

7.1 All material shall be furnished in the heat-treated condition. The heat treatment procedure, except for S31803, S32003,

S32205, S32750, N08926 and N08367, shall consist of heating the material to a minimum temperature of 1900 °F (1040 °C) and

quenching in water or rapid cooling by other means.

7.2 N08926 shall be heat-treated to a minimum temperature of 2010°F [1100°C] 2010 °F (1100 °C) followed by quenching in

water or rapidly cooling by other means. UNS N08367 should be solution annealed from 2025°F [1107°C] 2025 °F (1107 °C)

minimum followed by rapid quenching.

7.3 S31803 and S32205 shall be heat-treated in a temperature range of 1870°F [1020°C] 1870 °F (1020 °C) to 2010°F [1100°C]

2010 °F (1100 °C) followed by quenching in water or rapidly cooling by other means.

7.4 S32750 shall be heat-treated in a temperature range of 1880°F [1025°C] 1880 °F (1025 °C) to 2060°F [1125°C]2060 °F

(1125 °C) followed by quenching in water or rapidly cooling by other means.

7.5 S32003 shall be heat-treated in a temperature range of 1850 °F (1010 °C) to 2010 °F (1100 °C).

8. Chemical Composition

8.1 An analysis of either one length of flat-rolled stock or one tube shall be made for each heat. The chemical composition thus

determined shall conform to the requirements given in Table 1.

9. ProductAnalysis

9.1 When requested by the purchaser, product analysis tolerance in Specification A 480/A 480M shall apply. The product

analysis tolerance is not applicable to the carbon content for material with a specified maximum carbon of 0.04 % or less.

9.2 Iftheoriginaltestforproductanalysisfails,retestsoftwoadditionallengthsofflat-rolledstockortubesshallbemade.Both

retests for the elements in question shall meet the requirements of the specification; otherwise all remaining material in the heat

or lot (Note 1) shall be rejected or, at the option of the producer, each length of flat-rolled stock or tube may be individually tested

for acceptance. Lengths of flat rolled stock or tubes that do not meet the requirements of the specification shall be rejected.

10. Mechanical Tests Required

10.1 Reverse Flattening Test—Forweldedtubes,onereverseflatteningtestshallbemadeonaspecimenfromeach1500ft(457

m) of finished tubing.

´1

A 270 – 03a (2008)

TABLE 1 Chemical Requirements

Element Grade TP 304 TP 304L . . . TP 316 TP 316L . . . . . . . . . . . . . . . 2003

UNS S30400 S30403 S31254 S31600 S31603 N08926 N08367 S31803 S32205 S32750 S32003

A

Designation

Composition, %

B B

Carbon, max 0.08 0.035 0.020 0.08 0.035 0.020 0.030 0.030 0.030 0.030 0.030 max

Manganese, 2.00 2.00 1.00 2.00 2.00 2.00 2.00 2.00 2.00 1.20 2.00 max

max

Phosphorus, 0.045 0.045 0.030 0.045 0.045 0.030 0.040 0.030 0.030 0.035 0.030

max

Sulfur, max 0.030 0.030 0.010 0.030 0.030 0.010 0.030 0.020 0.020 0.020 0.020 max

Silicon, max 1.00 1.00 0.80 1.00 1.00 0.50 1.00 1.00 1.00 0.80 1.00 max

Nickel 8.0–11.0 8.0–12.0 17.5–18.5 10.0–14.0 10.0–14.0 24.0–26.0 23.5–25.5 4.5–6.5 4.5–6.5 6.0–8.0 3.0–4.0

Chromium 18.0–20.0 18.0–20.0 19.5–20.5 16.0–18.0 16.0–18.0 19.0–21.0 20.0–22.0 21.0–23.0 22.0–23.0 24.0–26.0 19.5–22.5

Molybdenum . . . . . . 6.0–6.5 2.00–3.00 2.00–3.00 6.0–7.0 6.0–7.0 2.5–3.5 3.0–3.5 3.0–5.0 1.5–2.0

C

Nitrogen . . . . . . 0.18–0.22 . . . . . . 0.15–0.25 0.18–0.25 0.08–0.20 0.14–0.20 0.24–0.32 0.14–0.20

Copper . . . . . . 0.50–1.00 . . . . . . 0.50–1.5 0.75 max . . 0.50 max

A

New designation established in accordance with Practice E 527 and SAE J 1086.

B

For small diameter or thin walls or both, where many drawing passes are required, a carbon maximum of 0.040 % is necessary in grades TP304L and TP316L. Small outside diameter tubes are defined as those

less than 0.500 in. (12.7 mm) in outside diameter and light wall tubes as those less than 0.049 in. (1.24 mm) in average wall thickness (0.044 in. (1.12 mm) in minimum wall thickness).

C

The method of analysis for nitrogen shall be a matter of agreement between the purchaser and manufacturer.

´1

A 270 – 03a (2008)

11. Hydrostatic or Nondestructive Electric Test

11.1 Each tube shall be subjected to the nondestructive electric test or the hydrostatic test. The type of test to be used shall be

at the option of the manufacturer, unless otherwise specified in the purchase order.

12. Permissible Variations in Dimensions

12.1 The following variations in dimensions shall apply:

12.1.1 For tubes with a specified wall thickness of 0.049 in. (1.24 mm) and greater, variations in outside diameter from those

specifiedshallnotexceedtheamountprescribedinTable2.Fortubeswithaspecifiedwallthicknesslessthan0.049in.(1.24mm),

the diameter tolerances shall be a matter for agreement by the manufacturer and the purchaser.

12.1.2 Whentubing>4in.(101.6mm)outsidediameterisordered,additionalovalitymayberequiredforthinwalltubing.Thin

wall tubing applies when the specified wall is less than 0.150 in. (3.81 mm). When thin wall tubing is ordered, the maximum and

minimum outside diameter at any cross section shall deviate from the specified outside diameter by no more than twice the

permissible variation in outside diameter given in Table 2; however, the mean diameter at that cross section must still be within

the given permissible variation.

12.1.3 The wall thickness at any point shall not vary more than 12.5 %, from the specified wall thickness.

12.1.4 Variations in length shall meet the requirements in Table 2 except when the Pharmaceutical Quality Tubing

(Supplementary Requirement S2) is specified.

13. Surface Finishes

13.1 The following surface finishes may be specified:

13.1.1 Mill Finish— A finish without additional polishing or operations intended to smooth the surface.

13.1.2 Mechanically Polished Surface Finish—The purchaser may specify one of the following finish numbers for a

mechanically polished surface:

13.1.2.1 Finish No. 80—A ground finish produced by polishing a tube with an abrasive media impregnated with No. 80 grit.

13.1.2.2 Finish No. 120—Aground finish produced by polishing a tube with an abrasive media impregnated with No. 120 grit.

13.1.2.3 Finish No. 180—Aground finish produced by polishing a tube with an abrasive media impregnated with No. 180 grit.

13.1.2.4 Finish No. 240—Aground finish produced by polishing a tube with an abrasive media impregnated with No. 240 grit.

13.1.2.5 Other mechanically polished finishes may be agreed upon between the purchaser and manufacturer.

13.1.3 Electropolished Finish—A bright reflective finish produced by electropolishing. The manufacturer may use other

polishing operations prior to electropolishing.

13.1.4 Maximum Roughness Average (Ra) Surface Finish—The customer may specify a maximum Ra on the inside surface,

outside surface, or both. The measurement of surface roughness shall be in accordance with ASME B46.1.

13.1.4.1 When no agreement is made regarding Ra measurement of longitudinally polished tube, disputes shall be resolved

using measurements made in accordance with ASME B46.1.

13.2 The manufacturer shall select a manufacturing method to produce the specified finish. The operations may or may not

include polishing.

13.2.1 The purchaser may specify the polishing type for either the inside surface, outside surface or both for the final desired

effect.

13.2.1.1 Longitudinally Polished Finish— It is usually performed on the inside surface only.

13.2.1.2 Circumferential (Rotary) Polished Finish—Thiscanbeperformedoneithertheinsidesurface,outsidesurface,orboth.

13.2.1.3 When the surface is finished by circumferential mechanical polishing, the Ra measurement shall be measured in the

longitudinal direction. Roughness measurement of a longitudinal mechanical polished surface shall be a matter of agreement

between the manufacturer and the purchaser.

13.3 Acceptance criteria for minor surface imperfections shall be a matter for agreement by the manufacturer and the purchaser.

13.4 Combinations of the above finishes for internal and external surfaces may be specified. When tubes are polished on one

surface only, the other surface may be the regular mill finish.

TABLE 2 Permissible Variations in Dimensions

Size, Outside Permissible Variations in Outside Permissible Variations in Cut

A

Diameter, Diameter, in. (mm) Length, in. (mm)

in. (mm)

Over Under Over Under

1.000 (25.4) and under 0.005 (0.13) 0.005 (0.13) ⁄8 (3.2) 0

Over 1 (25.4) to 2 (50.8) 0.008 (0.20) 0.008 (0.20) ⁄8 (3.2) 0

Over 2 (50.8) to 3 (76.2) 0.010 (0.25) 0.010 (0.25) ⁄8 (3.2) 0

Over 3 (76.2) to 4 (101.6) 0.015 (0.38) 0.015 (0.38) ⁄8 (3.2) 0

1 3

Over 4 (101.6) to 5 ⁄

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation:A270–03 Designation: A 270 – 03a (Reapproved 2008)

Standard Specification for

Seamless and Welded Austenitic and Ferritic/Austenitic

Stainless Steel Sanitary Tubing

This standard is issued under the fixed designation A 270; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

´ NOTE—The units statement in 1.3 was corrected editorially in October 2008.

1. Scope *

1.1 This specification covers grades of seamless, welded, and heavily cold worked welded austenitic and ferritic/austenitic

stainless steel sanitary tubing intended for use in the dairy and food industry and having special surface finishes. Pharmaceutical

quality may be requested, as a supplementary requirement.

1.2 This specification covers tubes in sizes up to and including 12 in. (304.8 mm) in outside diameter.

1.3The values stated in inch-pound units are to be regarded as the standard.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.4 Optional supplementary requirements are provided, and when one or more of these are desired, each shall be so stated in

the order.

2. Referenced Documents

2.1 ASTM Standards:

A 262 Practices for Detecting Susceptibility to Intergranular Attack in Austenitic Stainless Steels

A 480/A 480M Specification for General Requirements for Flat-Rolled Stainless and Heat-Resisting Steel Plate, Sheet, and

Strip

A 923 Test Methods for Detecting Detrimental Intermetallic Phase in Wrought Duplex Austenitic/Ferritic Stainless Steels

A 967 Specification for Chemical Passivation Treatments for Stainless Steel Parts

A 1016/A 1016M Specification for General Requirements for Ferritic Alloy Steel, Austenitic Alloy Steel, and Stainless Steel

Tubes

E 527 Practice for Numbering Metals andAlloys (UNS) Practice for Numbering Metals andAlloys in the Unified Numbering

System (UNS)

2.2 ASME Standard:

B46.1 Surface Texture (Surface Roughness, Waviness, and Lay)

2.3 ASME Boiler and Pressure Vessel Code:

Section VIII Pressure Vessels

2.4 Other Standard:

SAE J1086 Practice for Numbering Metals and Alloys (UNS)

3. Terminology

3.1 Definition:

3.1.1 roughness average, Ra, n—arithmetic average surface roughness normally reported in microinches or microns; a

This specification is under the jurisdiction ofASTM CommitteeA01 on Steel, Stainless Steel and RelatedAlloys,Alloys and is the direct responsibility of Subcommittee

A01.10 on Stainless and Alloy Steel Tubular Products.

Current edition approved Apr. 10, 2003.Oct. 1, 2008. Published May 2003.January 2009. Originally approved in 1944. Last previous edition approved in 20012003 as

A270–01.A 270–03a.

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

, Vol 01.03.volume information, refer to the standard’s Document Summary page on the ASTM website.

Annual Book of ASTM Standards, Vol 01.01.

Available from American Society of Mechanical Engineers (ASME), ASME International Headquarters, Three Park Ave., New York, NY 10016-5990, http://

www.asme.org.

Available from ASME International, Three Park Avenue, New York, NY 10016–5990.

Available from Society of Automotive Engineers (SAE), 400 Commonwealth Dr., Warrendale, PA 15096-0001, http://www.sae.org.

*ASummary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

´1

A 270 – 03a (2008)

measurement of surface roughness usually performed by moving a stylus in a straight line along the surface, although other

methods may be used.

4. Ordering Information

4.1Orders for material under this specification should include the following, as required, to describe the desired material

adequately:

4.1 It is the responsibility of the purchaser to specify all requirements that are necessary for material ordered under this

specification. Such requirements may include, but are not limited to, the following:

4.1.1 Quantity (feet, metres, or number of lengths),

4.1.2Name of material (seamless or welded tubes),

4.1.3Size (outside diameter and average wall thickness),

4.1.4Length (specific or random),

4.1.5Surface finish (Section

4.1.2 Name of material (austenitic steel tube),

4.1.3 Process seamless (SML), welded (WLD), or heavily cold worked (HCW),

4.1.4 Size (outside diameter and average wall thickness),

4.1.5 Length (specific or random),

4.1.6 Surface finish (Section 13),

4.1.67 Optional requirements (product analysis, see Section 9; hydrostatic or nondestructive electric test, see Section11).

4.1.7Test report required (Certification Section of Specification A1016/A1016M),

4.1.8Specification designation,

4.1.9Special requirements, and

4.1.8 Test report required (Certification Section of Specification A 1016/A 1016M),

4.1.9 Specification designation,

4.1.10 Special requirements, and

4.2 Any supplementary requirements.

5. General Requirements

5.1 Material furnished under this specification shall conform to the applicable requirements of the current edition of

Specification A 1016/A 1016M/A1016M,, unless otherwise provided herein.

6. Manufacture

6.1The tubes shall be made by the seamless or welded process.

6.1 The tubes shall be manufactured by one of the following processes:

6.1.1 Seamless (SML) tubes shall be made by a process that does not involve welding at any stage.

6.1.2 Welded (WLD) tubes shall be made using an automated welding process with no addition of filler metal during the

welding process.

6.1.3 Heavily cold worked (HCW) tubes shall be made by applying cold working of not less than 35 % reduction of thickness

of both wall and weld to a welded tube prior to the final anneal. No filler shall be used in making the weld. Prior to cold working,

theweldshallbe100 %radiographicallyinspectedinaccordancewiththerequirementsofASMEBoilerandPressureVesselCode

Section VIII, Division 1, latest revision, Paragraph UW 51.

6.2 At the manufacturer’s option, tubing may be furnished either hot finished or cold finished.

7. Heat Treatment

7.1 All material shall be furnished in the heat-treated condition. The heat treatment procedure, except for S31803, S32003,

S32205, S32750, N08926 and N08367, shall consist of heating the material to a minimum temperature of 1900 °F (1040 °C) and

quenching in water or rapid cooling by other means.

7.2 N08926 shall be heat-treated to a minimum temperature of 2010°F [1100°C] 2010 °F (1100 °C) followed by quenching in

water or rapidly cooling by other means. UNS N08367 should be solution annealed from 2025°F [1107°C] 2025 °F (1107 °C)

minimum followed by rapid quenching.

7.3 S31803 and S32205 shall be heat-treated in a temperature range of 1870°F [1020°C] 1870 °F (1020 °C) to 2010°F [1100°C]

2010 °F (1100 °C) followed by quenching in water or rapidly cooling by other means.

7.4 S32750 shall be heat-treated in a temperature range of 1880°F [1025°C] 1880 °F (1025 °C) to 2060°F [1125°C] 2060 °F

(1125 °C) followed by quenching in water or rapidly cooling by other means.

7.5 S32003 shall be heat-treated in a temperature range of 1850 °F (1010 °C) to 2010 °F (1100 °C).

8. Chemical Composition

8.1 An analysis of either one length of flat-rolled stock or one tube shall be made for each heat. The chemical composition thus

determined shall conform to the requirements given in Table 1.

´1

A 270 – 03a (2008)

TABLE 1 Chemical Requirements

Element Grade TP 304 TP 304L . . . TP 316 TP 316L . . . . . . . . . . . . . . . 2003

UNS S30400 S30403 S31254 S31600 S31603 N08926 N08367 S31803 S32205 S32750 S32003

A

Designation

Composition, %

B B

Carbon, max 0.08 0.035 0.020 0.08 0.035 0.020 0.030 0.030 0.030 0.030

B B

Carbon, max 0.08 0.035 0.020 0.08 0.035 0.020 0.030 0.030 0.030 0.030 0.030 max

Manganese, 2.00 2.00 1.00 2.00 2.00 2.00 2.00 2.00 2.00 1.20

max

Manganese, 2.00 2.00 1.00 2.00 2.00 2.00 2.00 2.00 2.00 1.20 2.00 max

max

Phosphorus, 0.045 0.045 0.030 0.045 0.045 0.030 0.040 0.030 0.030 0.035

max

Phosphorus, 0.045 0.045 0.030 0.045 0.045 0.030 0.040 0.030 0.030 0.035 0.030

max

Sulfur, max 0.030 0.030 0.010 0.030 0.030 0.010 0.030 0.020 0.020 0.020

Sulfur, max 0.030 0.030 0.010 0.030 0.030 0.010 0.030 0.020 0.020 0.020 0.020 max

Silicon, max 1.00 1.00 0.80 1.00 1.00 0.50 1.00 1.00 1.00 0.80

Silicon, max 1.00 1.00 0.80 1.00 1.00 0.50 1.00 1.00 1.00 0.80 1.00 max

Nickel 8.0–11.0 8.0–12.0 17.5–18.5 10.0–14.0 10.0–14.0 24.0–26.0 23.5–25.5 4.5–6.5 4.5–6.5 6.0–8.0

Nickel 8.0–11.0 8.0–12.0 17.5–18.5 10.0–14.0 10.0–14.0 24.0–26.0 23.5–25.5 4.5–6.5 4.5–6.5 6.0–8.0 3.0–4.0

Chromium 18.0–20.0 18.0–20.0 19.5–20.5 16.0–18.0 16.0–18.0 19.0–21.0 20.0–22.0 21.0–23.0 22.0–23.0 24.0–26.0

Chromium 18.0–20.0 18.0–20.0 19.5–20.5 16.0–18.0 16.0–18.0 19.0–21.0 20.0–22.0 21.0–23.0 22.0–23.0 24.0–26.0 19.5–22.5

Molybdenum . . 6.0–6.5 2.00–3.00 2.00–3.00 6.0–7.0 6.0–7.0 2.5–3.5 3.0–3.5 3.0–5.0

Molybdenum . . 6.0–6.5 2.00–3.00 2.00–3.00 6.0–7.0 6.0–7.0 2.5–3.5 3.0–3.5 3.0–5.0 1.5–2.0

C

Nitrogen . . 0.18–0.22 . . 0.15–0.25 0.18–0.25 0.08–0.20 0.14–0.20 0.24–0.32

C

Nitrogen . . 0.18–0.22 . . 0.15–0.25 0.18–0.25 0.08–0.20 0.14–0.20 0.24–0.32 0.14–0.20

Copper . . . . . . 0.50–1.00 . . . . . . 0.50–1.5 0.75 max . . 0.50 max

A

New designation established in accordance with Practice E 527 and SAE J 1086.

B

For small diameter or thin walls or both, where many drawing passes are required, a carbon maximum of 0.040 % is necessary in grades TP304L and TP316L. Small outside diameter tubes are defined as those

less than 0.500 in. (12.7 mm) in outside diameter and light wall tubes as those less than 0.049 in. (1.24 mm) in average wall thickness (0.044 in. (1.12 mm) in minimum wall thickness).

C

The method of analysis for nitrogen shall be a matter of agreement between the purchaser and manufacturer.

´1

A 270 – 03a (2008)

9. ProductAnalysis

9.1 When requested by the purchaser, product analysis tolerance in Specification A 480/A 480M shall apply. The product

analysis tolerance is not applicable to the carbon content for material with a specified maximum carbon of 0.04 % or less.

9.2 Iftheoriginaltestforproductanalysisfails,retestsoftwoadditionallengthsofflat-rolledstockortubesshallbemade.Both

retests for the elements in question shall meet the requirements of the specification; otherwise all remaining material in the heat

or lot (Note 1) shall be rejected or, at the option of the producer, each length of flat-rolled stock or tube may be individually tested

for acceptance. Lengths of flat rolled stock or tubes that do not meet the requirements of the specification shall be rejected.

10. Mechanical Tests Required

10.1 Reverse Flattening Test—Forweldedtubes,onereverseflatteningtestshallbemadeonaspecimenfromeach1500ft(457

m) of finished tubing.

11. Hydrostatic or Nondestructive Electric Test

11.1 Each tube shall be subjected to the nondestructive electric test or the hydrostatic test. The type of test to be used shall be

at the option of the manufacturer, unless otherwise specified in the purchase order.

12. Permissible Variations in Dimensions

12.1 The following variations in dimensions shall apply:

12.1.1 For tubes with a specified wall thickness of 0.049 in. (1.24 mm) and greater, variations in outside diameter from those

specifiedshallnotexceedtheamountprescribedinTable2.Fortubeswithaspecifiedwallthicknesslessthan0.049in.(1.24mm),

the diameter tolerances shall be a matter for agreement by the manufacturer and the purchaser.

12.1.2 Whentubing>4in.(101.6mm)outsidediameterisordered,additionalovalitymayberequiredforthinwalltubing.Thin

wall tubing applies when the specified wall is less than 0.150 in. (3.81 mm). When thin wall tubing is ordered, the maximum and

minimum outside diameter at any cross section shall deviate from the specified outside diameter by no more than twice the

permissible variation in outside diameter given in Table 2; however, the mean diameter at that cross section must still be within

the given permissible variation.

12.1.3 The wall thickness at any point shall not vary more than 12.5 %, from the specified wall thickness.

12.1.4 Variations in length shall meet the requirements in Table 2 , except when the Pharmaceutical Quality Tubing

(Supplementary Requirement S2) is specified.

13. Surface Finishes

13.1 The following surface finishes may be specified:

13.1.1 Mill Finish— A finish without additional polishing or operations intended to smooth the surface.

13.1.2 Mechanically Polished Surface Finish—The purchaser may specify one of the following finish numbers for a

mechanically polished surface:

13.1.2.1 Finish No. 80—A ground finish produced by polishing a tube with an abrasive media impregnated with No. 80 grit.

13.1.2.2 Finish No. 120—Aground finish produced by polishing a tube with an abrasive media impregnated with No. 120 grit.

13.1.2.3 Finish No. 180—Aground finish produced by polishing a tube with an abrasive media impregnated with No. 180 grit.

13.1.2.4 Finish No. 240—Aground finish produced by polishing a tube with an abrasive media impregnated with No. 240 grit.

13.1.2.5 Other mechanically polished finishes may be agreed upon between the purchaser and manufacturer.

13.1.3 Electropolished Finish—A bright reflective finish produced by electropolishing. The manufacturer may use other

polishing operations prior to electropolishing.

13.1.4 Maximum Roughness Average (Ra) Surface Finish—The customer may specify a maximum Ra on the inside surface,

outside surface, or both. The measurement of surface roughness shall be in accordance with ASME B46.1.

TABLE 2 Permissible Variations in Dimensions

Size, Outside Permissible Variations in Outside Permissible Variations in Cut

A

Diameter, Diameter, in. (mm) Length, in. (mm)

in. (mm)

Over Under Over Under

1.000 (25.4) and under 0.005 (0.13) 0.005 (0.13) ⁄8 (3.2) 0

1 (38.1) to 2 (50.8) 0.008 (0.20) 0.008 (0.20) ⁄8 (3.2) 0

Over 1 (25.4) to 2 (50.8) 0.008 (0.20) 0.008 (0.20) ⁄8 (3.2) 0

2 (63.5) to 3 (76.8) 0.010 (0.25) 0.01

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.