ASTM B697-88(2016)

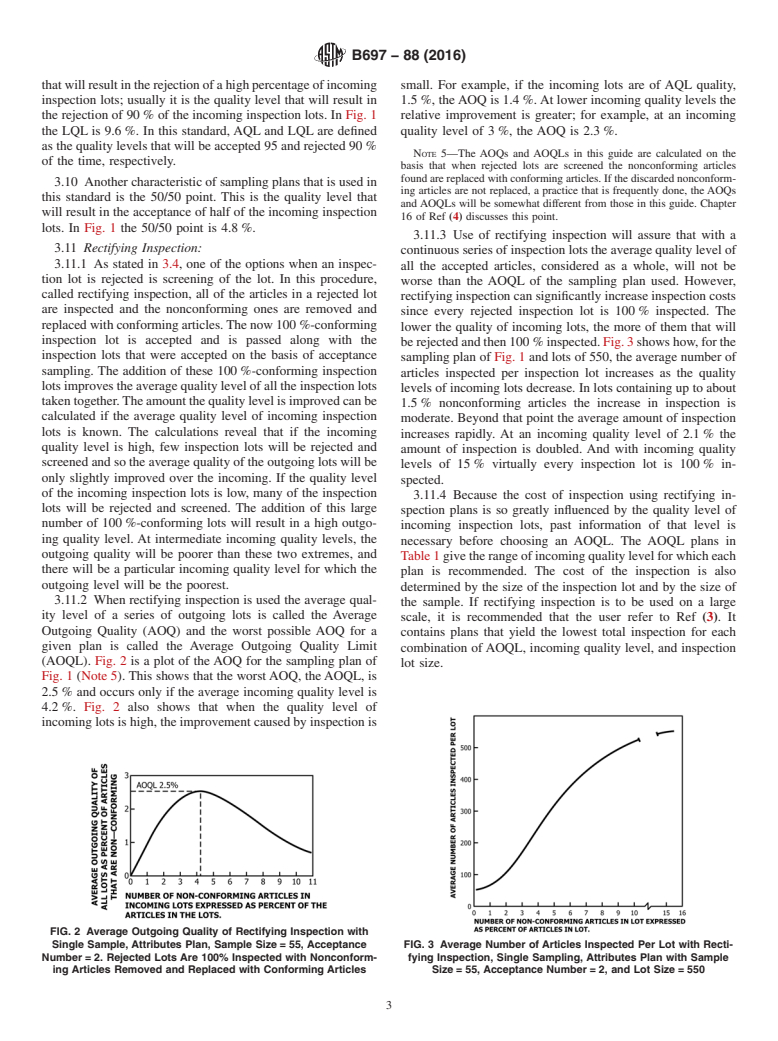

(Guide)Standard Guide for Selection of Sampling Plans for Inspection of Electrodeposited Metallic and Inorganic Coatings

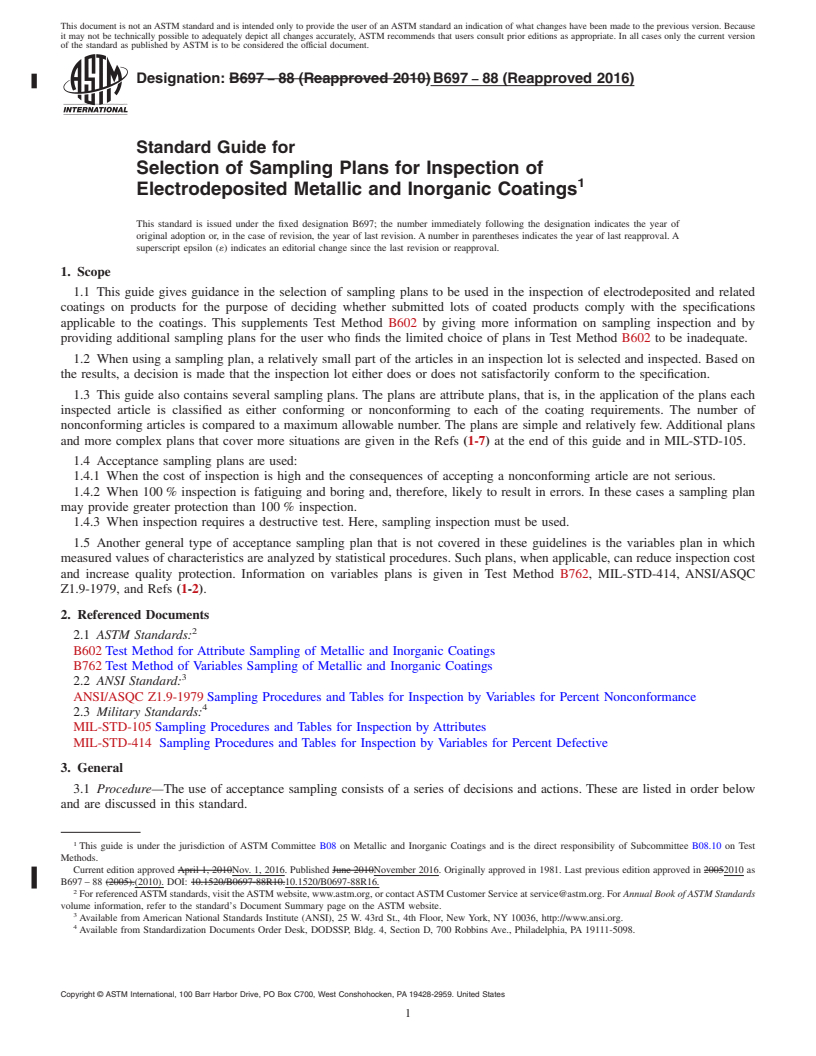

Standard Guide for Selection of Sampling Plans for Inspection of Electrodeposited Metallic and Inorganic Coatings

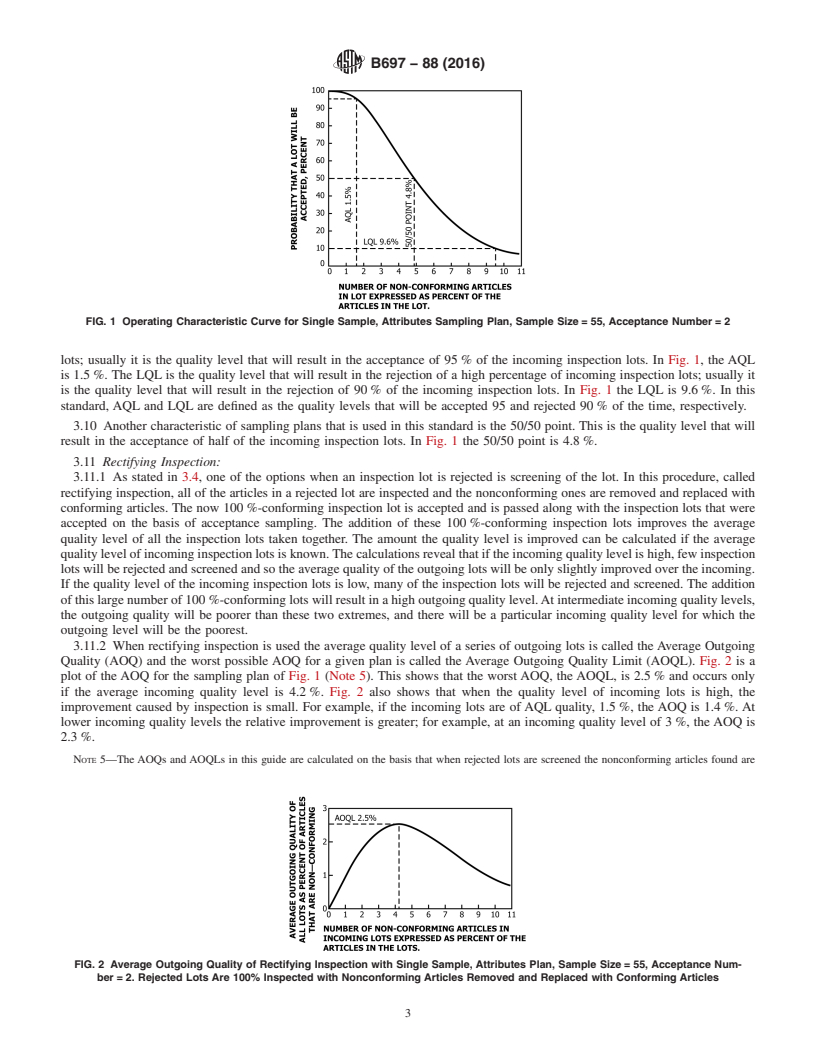

ABSTRACT

This guide covers the standard method for selecting sampling plans to be used in the inspection of electrodeposited metallic and inorganic coatings on products for the purpose of deciding whether submitted lots comply with the specifications applicable to the coatings. The characteristics of the sampling plan are expressed in terms of the Acceptable Quality Level (AQL), Limiting Quality Level (LQL), Average Outgoing Quality (AOQ), and Average Outgoing Quality Limit (AOQL). General procedures and criteria for the construction and selection of the type of sampling plan, selection of a specific plan, selection of the inspection lot, sampling and inspection of samples, and the disposition of lots are discussed fully.

SCOPE

1.1 This guide gives guidance in the selection of sampling plans to be used in the inspection of electrodeposited and related coatings on products for the purpose of deciding whether submitted lots of coated products comply with the specifications applicable to the coatings. This supplements Test Method B602 by giving more information on sampling inspection and by providing additional sampling plans for the user who finds the limited choice of plans in Test Method B602 to be inadequate.

1.2 When using a sampling plan, a relatively small part of the articles in an inspection lot is selected and inspected. Based on the results, a decision is made that the inspection lot either does or does not satisfactorily conform to the specification.

1.3 This guide also contains several sampling plans. The plans are attribute plans, that is, in the application of the plans each inspected article is classified as either conforming or nonconforming to each of the coating requirements. The number of nonconforming articles is compared to a maximum allowable number. The plans are simple and relatively few. Additional plans and more complex plans that cover more situations are given in the Refs (1-7) at the end of this guide and in MIL-STD-105.

1.4 Acceptance sampling plans are used:

1.4.1 When the cost of inspection is high and the consequences of accepting a nonconforming article are not serious.

1.4.2 When 100 % inspection is fatiguing and boring and, therefore, likely to result in errors. In these cases a sampling plan may provide greater protection than 100 % inspection.

1.4.3 When inspection requires a destructive test. Here, sampling inspection must be used.

1.5 Another general type of acceptance sampling plan that is not covered in these guidelines is the variables plan in which measured values of characteristics are analyzed by statistical procedures. Such plans, when applicable, can reduce inspection cost and increase quality protection. Information on variables plans is given in Test Method B762, MIL-STD-414, ANSI/ASQC Z1.9-1979, and Refs (1-2).

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B697 − 88 (Reapproved 2016)

Standard Guide for

Selection of Sampling Plans for Inspection of

1

Electrodeposited Metallic and Inorganic Coatings

This standard is issued under the fixed designation B697; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope procedures. Such plans, when applicable, can reduce inspec-

tion cost and increase quality protection. Information on

1.1 This guide gives guidance in the selection of sampling

variables plans is given in Test Method B762, MIL-STD-414,

plans to be used in the inspection of electrodeposited and

ANSI/ASQC Z1.9-1979, and Refs (1-2).

related coatings on products for the purpose of deciding

whether submitted lots of coated products comply with the

2. Referenced Documents

specificationsapplicabletothecoatings.ThissupplementsTest

2

2.1 ASTM Standards:

Method B602 by giving more information on sampling inspec-

B602 Test Method for Attribute Sampling of Metallic and

tion and by providing additional sampling plans for the user

Inorganic Coatings

who finds the limited choice of plans in Test Method B602 to

B762 Test Method of Variables Sampling of Metallic and

be inadequate.

Inorganic Coatings

1.2 When using a sampling plan, a relatively small part of

3

2.2 ANSI Standard:

thearticlesinaninspectionlotisselectedandinspected.Based

ANSI/ASQC Z1.9-1979 Sampling Procedures and Tables

on the results, a decision is made that the inspection lot either

for Inspection by Variables for Percent Nonconformance

does or does not satisfactorily conform to the specification.

4

2.3 Military Standards:

1.3 This guide also contains several sampling plans. The

MIL-STD-105 Sampling Procedures and Tables for Inspec-

plans are attribute plans, that is, in the application of the plans

tion by Attributes

each inspected article is classified as either conforming or

MIL-STD-414 Sampling Procedures and Tables for Inspec-

nonconforming to each of the coating requirements. The

tion by Variables for Percent Defective

number of nonconforming articles is compared to a maximum

allowable number. The plans are simple and relatively few.

3. General

Additional plans and more complex plans that cover more

3.1 Procedure—The use of acceptance sampling consists of

situations are given in the Refs (1-7) at the end of this guide

a series of decisions and actions. These are listed in order

and in MIL-STD-105.

below and are discussed in this standard.

1.4 Acceptance sampling plans are used:

3.1.1 Select characteristics to be inspected,

1.4.1 When the cost of inspection is high and the conse-

3.1.2 Select type of sampling plan,

quences of accepting a nonconforming article are not serious.

3.1.3 Select quality level,

1.4.2 When 100 % inspection is fatiguing and boring and,

3.1.4 Define inspection lot,

therefore, likely to result in errors. In these cases a sampling

3.1.5 Select sample,

plan may provide greater protection than 100 % inspection.

3.1.6 Inspect sample,

1.4.3 When inspection requires a destructive test. Here,

3.1.7 Classify inspection lot, and

sampling inspection must be used.

3.1.8 Dispose of inspection lot.

1.5 Anothergeneraltypeofacceptancesamplingplanthatis

3.2 The need for acceptance sampling arises when a deci-

not covered in these guidelines is the variables plan in which

sion must be made about what to do with a quantity of articles.

measured values of characteristics are analyzed by statistical

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

1

This guide is under the jurisdiction of ASTM Committee B08 on Metallic and Standards volume information, refer to the standard’s Document Summary page on

Inorganic Coatings and is the direct responsibility of Subcommittee B08.10 on Test the ASTM website.

3

Methods. Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

Current edition approved Nov. 1, 2016. Published November 2016. Originally 4th Floor, New York, NY 10036, http://www.ansi.org.

4

approved in 1981. Last previous edition approved in 2010 as B697 – 88 (2010). Available from Standardization Documents Order Desk, DODSSP, Bldg. 4,

DOI: 10.1520/B0697-88R16. Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B697 − 88 (2016)

This quantity (called the inspection lot in this guide) may be a 3.7 Because acceptance sampling plans permit the accep-

shipment from a supplier, may be art

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: B697 − 88 (Reapproved 2010) B697 − 88 (Reapproved 2016)

Standard Guide for

Selection of Sampling Plans for Inspection of

1

Electrodeposited Metallic and Inorganic Coatings

This standard is issued under the fixed designation B697; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This guide gives guidance in the selection of sampling plans to be used in the inspection of electrodeposited and related

coatings on products for the purpose of deciding whether submitted lots of coated products comply with the specifications

applicable to the coatings. This supplements Test Method B602 by giving more information on sampling inspection and by

providing additional sampling plans for the user who finds the limited choice of plans in Test Method B602 to be inadequate.

1.2 When using a sampling plan, a relatively small part of the articles in an inspection lot is selected and inspected. Based on

the results, a decision is made that the inspection lot either does or does not satisfactorily conform to the specification.

1.3 This guide also contains several sampling plans. The plans are attribute plans, that is, in the application of the plans each

inspected article is classified as either conforming or nonconforming to each of the coating requirements. The number of

nonconforming articles is compared to a maximum allowable number. The plans are simple and relatively few. Additional plans

and more complex plans that cover more situations are given in the Refs (1-7) at the end of this guide and in MIL-STD-105.

1.4 Acceptance sampling plans are used:

1.4.1 When the cost of inspection is high and the consequences of accepting a nonconforming article are not serious.

1.4.2 When 100 % inspection is fatiguing and boring and, therefore, likely to result in errors. In these cases a sampling plan

may provide greater protection than 100 % inspection.

1.4.3 When inspection requires a destructive test. Here, sampling inspection must be used.

1.5 Another general type of acceptance sampling plan that is not covered in these guidelines is the variables plan in which

measured values of characteristics are analyzed by statistical procedures. Such plans, when applicable, can reduce inspection cost

and increase quality protection. Information on variables plans is given in Test Method B762, MIL-STD-414, ANSI/ASQC

Z1.9-1979, and Refs (1-2).

2. Referenced Documents

2

2.1 ASTM Standards:

B602 Test Method for Attribute Sampling of Metallic and Inorganic Coatings

B762 Test Method of Variables Sampling of Metallic and Inorganic Coatings

3

2.2 ANSI Standard:

ANSI/ASQC Z1.9-1979 Sampling Procedures and Tables for Inspection by Variables for Percent Nonconformance

4

2.3 Military Standards:

MIL-STD-105 Sampling Procedures and Tables for Inspection by Attributes

MIL-STD-414 Sampling Procedures and Tables for Inspection by Variables for Percent Defective

3. General

3.1 Procedure—The use of acceptance sampling consists of a series of decisions and actions. These are listed in order below

and are discussed in this standard.

1

This guide is under the jurisdiction of ASTM Committee B08 on Metallic and Inorganic Coatings and is the direct responsibility of Subcommittee B08.10 on Test

Methods.

Current edition approved April 1, 2010Nov. 1, 2016. Published June 2010November 2016. Originally approved in 1981. Last previous edition approved in 20052010 as

B697 – 88 (2005).(2010). DOI: 10.1520/B0697-88R10.10.1520/B0697-88R16.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036, http://www.ansi.org.

4

Available from Standardization Documents Order Desk, DODSSP, Bldg. 4, Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B697 − 88 (2016)

3.1.1 Select characteristics to be inspected,

3.1.2 Select type of sampling plan,

3.1.3 Select quality level,

3.1.4 Define inspection lot,

3.1.5 Select

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.