ASTM E235/E235M-23

(Specification)Standard Specification for Type K and Type N Mineral-Insulated, Metal-Sheathed Thermocouples for Nuclear or for Other High-Reliability Applications

Standard Specification for Type K and Type N Mineral-Insulated, Metal-Sheathed Thermocouples for Nuclear or for Other High-Reliability Applications

ABSTRACT

This specification covers the requirements for sheathed, Type K and N thermocouples for nuclear service. This specification can be used for sheathed thermocouples which are required for laboratory or general commercial applications where the environmental conditions exceed normal service requirements. The measuring junction styles for thermocouples are as follows: Style G2 (grounded) in which measuring junction is electrically connected to conductive sheaths and Style U2 (ungrounded) in which measuring junctions are electrically isolated from conductive sheaths and from reference ground. Different properties of the sheath such as integrity, cracks, voids, inclusions, surface finish, surface defect, and metallurgical structure shall be determined by performing different tests. Insulation resistance between thermoelements and the sheath shall be measured as well.

SCOPE

1.1 This specification covers the requirements for simplex, compacted mineral-insulated, metal-sheathed (MIMS), Type K and N thermocouples for nuclear or other high reliability service. Depending on size, these thermocouples are normally suitable for operating temperatures to 1652 °F [900 °C]; special conditions of environment and life expectancy may permit their use at temperatures in excess of 2012 °F [1100 °C]. This specification was prepared to detail requirements for this type of MIMS thermocouple for use in nuclear environments, but they can also be used for laboratory or general commercial applications where the environmental conditions exceed normal service requirements. The intended use of a MIMS thermocouple in a specific nuclear application will require evaluation of the compatibility of the thermocouple, including the effect of the temperature, atmosphere, and integrated neutron flux on the materials and accuracy of the thermoelements in the proposed application by the purchaser.

1.2 This specification does not attempt to include all possible specifications, standards, etc., for materials that may be used as sheathing, insulation, and thermocouple wires for sheathed-type construction. The requirements of this specification include only the austenitic stainless steels and other alloys as allowed by Specification E585/E585M for sheathing, magnesium oxide or aluminum oxide as insulation, and Type K and N thermocouple wires for thermoelements (see Note 1).

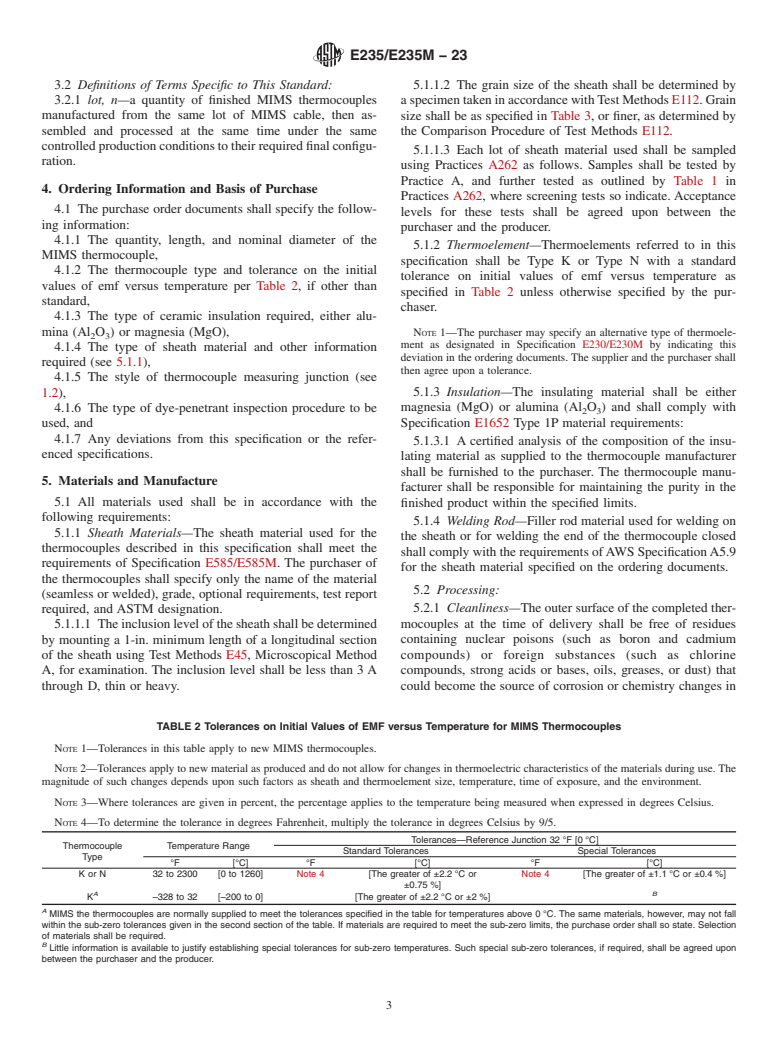

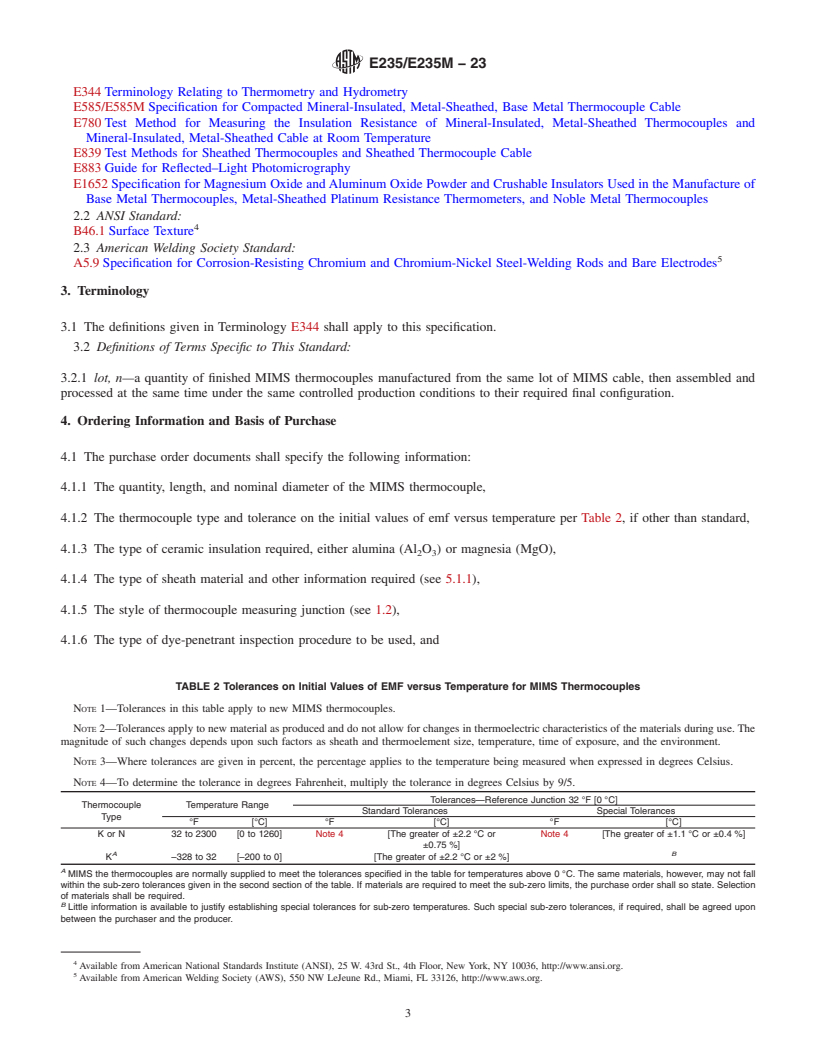

1.3 General Design—Nominal sizes of the finished thermocouples shall be 0.0400 in., 0.0625 in., 0.125 in., 0.1875 in., or 0.250 in. [1.000 mm, 1.500 mm, 3.000 mm, 4.500 mm, or 6.000 mm]. Sheath dimensions and tolerances for each nominal size shall be in accordance with Table 1 and Figs. 1 and 2. The measuring junction styles for thermocouples covered by this specification are as follows:

FIG. 1 Grounded Measuring Junction, Style G

FIG. 2 Ungrounded Measuring Junction, Style U

1.3.1 Style G2 (grounded)—The measuring junction is electrically connected to its conductive sheath, and

1.3.2 Style U2 (ungrounded)—The measuring junction is electrically isolated from its conductive sheath and from reference ground.

1.4 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system are not exact equivalents or conversions; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recomm...

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: E235/E235M − 23 An American National Standard

Standard Specification for

Type K and Type N Mineral-Insulated, Metal-Sheathed

Thermocouples for Nuclear or for Other High-Reliability

1

Applications

This standard is issued under the fixed designation E235/E235M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

2

1. Scope 1.3.1 Style G (grounded)—The measuring junction is elec-

trically connected to its conductive sheath, and

1.1 This specification covers the requirements for simplex,

2

1.3.2 Style U (ungrounded)—The measuring junction is

compacted mineral-insulated, metal-sheathed (MIMS), Type K

electrically isolated from its conductive sheath and from

and N thermocouples for nuclear or other high reliability

reference ground.

service. Depending on size, these thermocouples are normally

1.4 The values stated in either SI units or inch-pound units

suitable for operating temperatures to 1652 °F [900 °C]; spe-

are to be regarded separately as standard. The values stated in

cial conditions of environment and life expectancy may permit

each system are not exact equivalents or conversions;

their use at temperatures in excess of 2012 °F [1100 °C]. This

therefore, each system shall be used independently of the other.

specification was prepared to detail requirements for this type

Combining values from the two systems may result in non-

of MIMS thermocouple for use in nuclear environments, but

conformance with the standard.

they can also be used for laboratory or general commercial

applications where the environmental conditions exceed nor-

1.5 This standard does not purport to address all of the

mal service requirements. The intended use of a MIMS

safety concerns, if any, associated with its use. It is the

thermocouple in a specific nuclear application will require

responsibility of the user of this standard to establish appro-

evaluation of the compatibility of the thermocouple, including

priate safety, health, and environmental practices and deter-

the effect of the temperature, atmosphere, and integrated

mine the applicability of regulatory limitations prior to use.

neutron flux on the materials and accuracy of the thermoele-

1.6 This international standard was developed in accor-

ments in the proposed application by the purchaser.

dance with internationally recognized principles on standard-

ization established in the Decision on Principles for the

1.2 This specification does not attempt to include all

Development of International Standards, Guides and Recom-

possible specifications, standards, etc., for materials that may

mendations issued by the World Trade Organization Technical

be used as sheathing, insulation, and thermocouple wires for

Barriers to Trade (TBT) Committee.

sheathed-type construction. The requirements of this specifi-

cation include only the austenitic stainless steels and other

2. Referenced Documents

alloys as allowed by Specification E585/E585M for sheathing,

3

2.1 ASTM Standards:

magnesium oxide or aluminum oxide as insulation, and Type K

A262 Practices for Detecting Susceptibility to Intergranular

and N thermocouple wires for thermoelements (see Note 1).

Attack in Austenitic Stainless Steels

1.3 General Design—Nominal sizes of the finished thermo-

E3 Guide for Preparation of Metallographic Specimens

couples shall be 0.0400 in., 0.0625 in., 0.125 in., 0.1875 in., or

E45 Test Methods for Determining the Inclusion Content of

0.250 in. [1.000 mm, 1.500 mm, 3.000 mm, 4.500 mm, or

Steel

6.000 mm]. Sheath dimensions and tolerances for each nominal

E112 Test Methods for Determining Average Grain Size

size shall be in accordance with Table 1 and Figs. 1 and 2. The

E165/E165M Practice for Liquid Penetrant Testing for Gen-

measuring junction styles for thermocouples covered by this

eral Industry

specification are as follows:

E220 Test Method for Calibration of Thermocouples By

1 2

This specification is under the jurisdiction of ASTM Committee E20 on Style G and Style U measuring junctions were previously termed Class 1 and

Temperature Measurement and is the direct responsibility of Subcommittee E20.12 Class 2 measuring junctions respectively.

3

on Thermocouples - Specifications. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved July 1, 2023. Published July 2023. Originally approved contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

in 1964. Last previous edition approve

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: E235/E235M − 19 E235/E235M − 23 An American National Standard

Standard Specification for

Type K and Type N Mineral-Insulated, Metal-Sheathed

Thermocouples for Nuclear or for Other High-Reliability

1

Applications

This standard is issued under the fixed designation E235/E235M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification covers the requirements for simplex, compacted mineral-insulated, metal-sheathed (MIMS), Type K and N

thermocouples for nuclear or other high reliability service. Depending on size, these thermocouples are normally suitable for

operating temperatures to 1652 °F [900 °C]; special conditions of environment and life expectancy may permit their use at

temperatures in excess of 2012 °F [1100 °C]. This specification was prepared to detail requirements for this type of MIMS

thermocouple for use in nuclear environments, but they can also be used for laboratory or general commercial applications where

the environmental conditions exceed normal service requirements. The intended use of a MIMS thermocouple in a specific nuclear

application will require evaluation of the compatibility of the thermocouple, including the effect of the temperature, atmosphere,

and integrated neutron flux on the materials and accuracy of the thermoelements in the proposed application by the purchaser.

1.2 This specification does not attempt to include all possible specifications, standards, etc., for materials that may be used as

sheathing, insulation, and thermocouple wires for sheathed-type construction. The requirements of this specification include only

the austenitic stainless steels and other alloys as allowed by Specification E585/E585M for sheathing, magnesium oxide or

aluminum oxide as insulation, and Type K and N thermocouple wires for thermoelements (see Note 1).

1.3 General Design—Nominal sizes of the finished thermocouples shall be 0.0400 in., 0.0625 in., 0.125 in., 0.1875 in., or 0.250

in. [1.000 mm, 1.500 mm, 3.000 mm, 4.500 mm, or 6.000 mm]. Sheath dimensions and tolerances for each nominal size shall be

in accordance with Table 1 and Figs. 1 and 2. The measuring junction styles for thermocouples covered by this specification are

as follows:

2

1.3.1 Style G (grounded)—The measuring junction is electrically connected to its conductive sheath, and

2

1.3.2 Style U (ungrounded)—The measuring junction is electrically isolated from its conductive sheath and from reference

ground.

1.4 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each

system are not exact equivalents or conversions; therefore, each system shall be used independently of the other. Combining values

from the two systems may result in non-conformance with the standard.

1

This specification is under the jurisdiction of ASTM Committee E20 on Temperature Measurement and is the direct responsibility of Subcommittee E20.12 on

Thermocouples - Specifications.

Current edition approved May 1, 2019July 1, 2023. Published May 2019July 2023. Originally approved in 1964. Last previous edition approved in 20182019 as

E235/E235M – 12 (2018).E235/E235M – 19. DOI: 10.1520/E0235_E0235M-19.10.1520/E0235_E0235M-23.

2

Style G and Style U measuring junctions were previously termed Class 1 and Class 2 measuring junctions respectively.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E235/E235M − 23

TABLE 1 Dimensions for Style G and U Measuring Junctions

Minimum Minimum Minimum

Sheath Outside Diameter, A E, Tolerance F, Tolerance

Sheath Insulation Wire

Wall, Thickness, Diameter,

Tolerance

BWall, CThickness, DDiameter,

Nominal min max min max

min max B C D

Inches

0.0400 0.0390 0.0415 0.006 0.004 0.005 0.006 0.020 0.004 0.021

0.0625 0.0615 0.0640 0.009 0.005 0.010 0.009 0.032 0.005 0.032

0.1250 0.1240 0.1265 0.012 0.012 0.020 0.012 0.062 0.012 0.063

0.1875 0.1865 0.1890 0.020 0.022 0.031 0.020 0.093 0.022 0.095

0.2500 0.2480 0.2520 0.030 0.024 0.040 0.030 0.125 0.024 0.125

[Millimetres]

[1.000] [0.975] [1.038] [0.15] [0.10] [0.13] [0.15] [0.51] [0.10] [0.53]

[1.500] [1.475] [1.538] [0.23] [0.13] [0.25] [0.23] [0.81] [0.13] [0.81]

[3.000] [2.975] [3.038] [0.30] [0

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.