ASTM E2871-12

(Test Method)Standard Test Method for Evaluating Disinfectant Efficacy against Pseudomonas aeruginosa Biofilm Grown in CDC Biofilm Reactor using Single Tube Method

Standard Test Method for Evaluating Disinfectant Efficacy against <emph type="bdit">Pseudomonas aeruginosa</emph> Biofilm Grown in CDC Biofilm Reactor using Single Tube Method

SIGNIFICANCE AND USE

Vegetative biofilm bacteria are phenotypically different from suspended planktonic cells of the same genotype. Biofilm growth reactors are engineered to produce biofilms with specific characteristics (2). Altering either the engineered system or operating conditions will modify those characteristics as well as the physicochemical environment. The goal in biofilm research and efficacy testing is to choose the growth reactor and operating conditions that generate the most relevant biofilm for the particular study.

The test method was developed using Pseudomonas aeruginosa ATCC 15442 biofilm grown on borosilicate glass coupons in the CDC Biofilm Reactor and liquid disinfectants. Efficacy data developed using other bacteria, different shear, different coupons, or other standardized biofilm reactor systems, and/or other forms of disinfectants may result in different log10 reduction (LR) values and repeatability and reproducibility standard deviations.

The efficacy test was designed to determine the log10 reduction in bacteria after exposure to a disinfectant in a closed system.

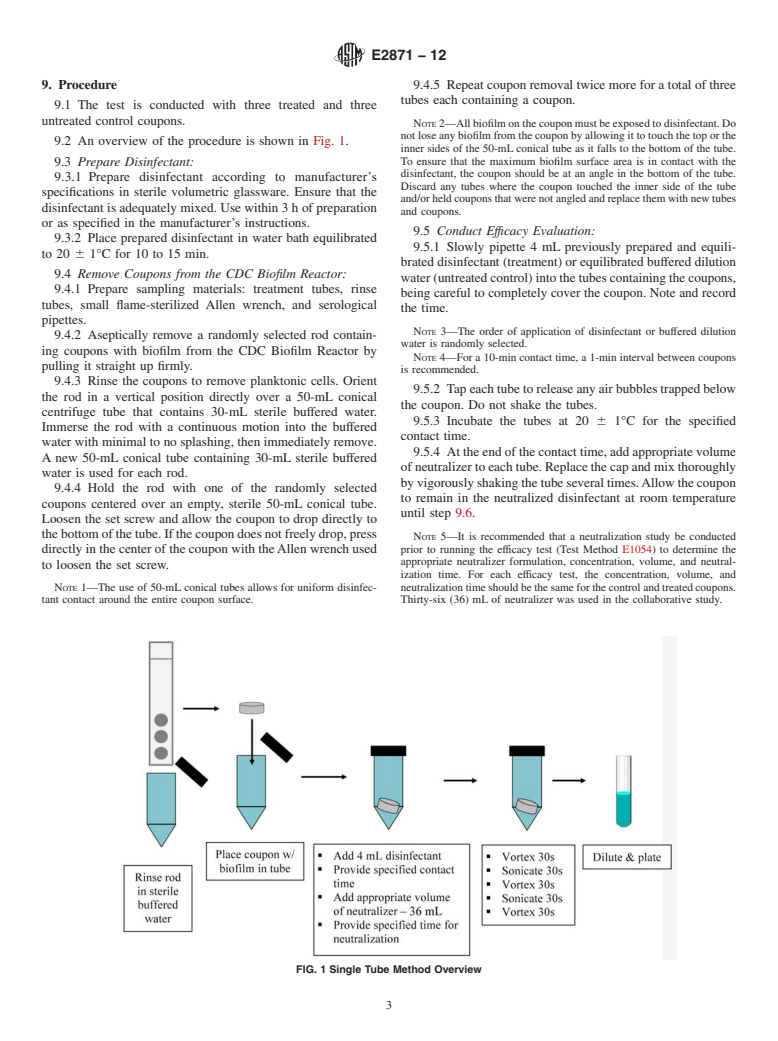

The test method was developed using 50-mL conical tubes. The conical geometry allows for disinfectant exposure to biofilm on all surfaces of the coupon.

Each efficacy test includes a single contact time and temperature for three untreated control coupons (exposed to buffered dilution water) and three treated coupons (per disinfectant/concentration combination).

SCOPE

1.1 This test method specifies the operational parameters required to perform a quantitative liquid disinfectant efficacy test against biofilm bacteria.

1.2 The test method was developed using a Pseudomonas aeruginosa biofilm grown in the CDC Biofilm Reactor (Test Method E2562), modified to include borosilicate glass coupons as a hard nonporous surface and P. aeruginosa ATCC 15442.

1.3 Disinfectant preparation and contact time are used in the assessment according to the manufacturer’s instructions for use.

1.4 The test method uses a closed system to treat biofilm. A coupon is placed in a single tube for the treatment, neutralization, and sampling steps to prevent the loss of cells.

1.5 Verification of disinfectant neutralization is determined prior to conducting the test method.

1.6 This test method describes how to sample and analyze treated and untreated control biofilms for viable cells. Biofilm population density is recorded as log10 colony-forming units per coupon. Efficacy is reported as a log10 reduction of viable cells.

1.7 Basic microbiology training is required to perform this assay.

1.8 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.9 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E2871 −12

StandardTest Method for

Evaluating Disinfectant Efficacy against Pseudomonas

aeruginosa Biofilm Grown in CDC Biofilm Reactor using

Single Tube Method

This standard is issued under the fixed designation E2871; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2.1 ASTM Standards:

1.1 This test method specifies the operational parameters

E1054 Test Methods for Evaluation of Inactivators of Anti-

required to perform a quantitative liquid disinfectant efficacy

microbial Agents

test against biofilm bacteria.

E2562 Test Method for Quantification of Pseudomonas

1.2 The test method was developed using a Pseudomonas

aeruginosa Biofilm Grown with High Shear and Continu-

aeruginosa biofilm grown in the CDC Biofilm Reactor (Test

ous Flow using CDC Biofilm Reactor

MethodE2562),modifiedtoincludeborosilicateglasscoupons

2.2 Other Standards:

as a hard nonporous surface and P. aeruginosa ATCC 15442.

Method 9050 C.1.a Buffered Dilution Water Preparation

1.3 Disinfectantpreparationandcontacttimeareusedinthe

according to Eaton et al (1)

assessment according to the manufacturer’s instructions for

use. 3. Terminology

3.1 Definitions:

1.4 The test method uses a closed system to treat biofilm.A

3.1.1 biofilm, n—microorganisms living in a self-organized

coupon is placed in a single tube for the treatment,

community attached to surfaces, interfaces, or each other,

neutralization, and sampling steps to prevent the loss of cells.

embedded in a matrix of extracellular polymeric substances of

1.5 Verification of disinfectant neutralization is determined

microbial origin, while exhibiting altered phenotypes with

prior to conducting the test method.

respect to growth rate and gene transcription.

1.6 This test method describes how to sample and analyze 3.1.1.1 Discussion—Biofilm may be comprised of bacteria,

treated and untreated control biofilms for viable cells. Biofilm fungi, algae, protozoa, viruses, or infinite combinations of

population density is recorded as log colony-forming units these microorganisms. The qualitative characteristics of a

per coupon. Efficacy is reported as a log reduction of viable biofilm including, but not limited to, population density,

cells. taxonomic diversity, thickness, chemical gradients, chemical

composition,consistency,andothermaterialsinthematrixthat

1.7 Basic microbiology training is required to perform this

are not produced by the biofilm microorganisms, are controlled

assay.

by the physicochemical environment in which it exists.

1.8 The values stated in SI units are to be regarded as

3.1.2 contact time, n—predeterminedtimethatthebiofilmis

standard. No other units of measurement are included in this

exposed to the activity of a disinfectant.

standard.

3.1.3 coupon, n—biofilm growth surface.

1.9 This standard does not purport to address all of the

3.1.4 disinfectant, n—a chemical that destroys vegetative

safety concerns, if any, associated with its use. It is the

forms of microorganisms, but does not ordinarily kill bacterial

responsibility of the user of this standard to establish appro-

spores.

priate safety and health practices and determine the applica-

3.2 Acronyms:

bility of regulatory limitations prior to use.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

This test method is under the jurisdiction of ASTM Committee E35 on contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Pesticides, Antimicrobials, and Alternative Control Agents and is the direct Standards volume information, refer to the standard’s Document Summary page on

responsibility of Subcommittee E35.15 on Antimicrobial Agents. the ASTM website.

Current edition approved April 1, 2012. Published June 2012. DOI: 10.1520/ The boldface numbers in parentheses refer to a list of references at the end of

E2871–12. this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E2871−12

3.2.1 ATCC—American Type Culture Collection. 6.3 Test tube rack, any capable of holding 50-mL conical

centrifuge tubes.

3.2.2 CDC—Centers for Disease Control and Prevention.

6.4 Micropipettes, continuously adjustable pipettes with

3.2.3 CFU—colony-forming unit.

volume capacity of 100 µL and 1000 µL.

4. Summary of Test Method

6.5 Sterile pipette tips, 100-µL and 1000-µL volumes.

4.1 This test method describes the use of the single tube

6.6 Bunsen burner, used to flame-sterilizeAllen wrench and

method to evaluate the efficacy of a liquid disinfectant against

plate spreader.

a Pseudomonas aeruginosa biofilm on a hard nonporous

6.7 95 % Ethanol, used to flame-sterilize Allen wrench and

surface grown in the CDC Biofilm Reactor. The test method

plate spreader.

consists of adding a disinfectant (treated) or a control buffer

(untreated) to individual coupons held in 50-mL conical tubes.

6.8 Small Allen wrench, for loosening set screws and

Three coupons are treated with disinfectant and three coupons pushing coupons out of reactor rods.

receive buffered dilution water. Neutralizer is added to the

6.9 Timer, any that can display time in seconds.

tubes after the appropriate contact time. A combination of

6.10 Vortex mixer, any vortex that will ensure proper agita-

vortexing and sonication are used to remove the biofilm from

tion and mixing of centrifuge tubes.

thecouponanddisaggregatetheclumps.Thecellsuspensionis

serially diluted and plated on agar medium.Viable plate counts

6.11 Serological pipettes, sterile single-use pipettes with

from treated and untreated control coupons are used to calcu- volume capacity of 1, 5, 10, 25, and 50 mL.

late the log reduction of viable cells.

6.12 Plate spreader, for spreading serial dilutions on agar

plates.

5. Significance and Use

6.13 Water bath, any capable of maintaining a constant

5.1 Vegetative biofilm bacteria are phenotypically different

temperature of 20 6 1°C.

from suspended planktonic cells of the same genotype. Biofilm

6.14 Sterilizer, any steam sterilizer capable of producing the

growth reactors are engineered to produce biofilms with

conditions of sterilization.

specific characteristics (2). Altering either the engineered

system or operating conditions will modify those characteris-

6.15 Colony counter, any one of several types may be used.

tics as well as the physicochemical environment. The goal in

A hand tally for recording of the bacterial count is recom-

biofilm research and efficacy testing is to choose the growth

mended if manual counting is done.

reactorandoperatingconditionsthatgeneratethemostrelevant

6.16 Environmental incubator, any capable of maintaining a

biofilm for the particular study.

temperature of 36 6 2°C.

5.2 The test method was developed using Pseudomonas

6.17 Appropriate glassware/plasticware, as required to

aeruginosa ATCC 15442 biofilm grown on borosilicate glass

make media and agar plates.

coupons in the CDC Biofilm Reactor and liquid disinfectants.

Efficacy data developed using other bacteria, different shear, 6.18 Volumetric flasks, used for preparing disinfectants.

different coupons, or other standardized biofilm reactor sys-

6.19 Magnetic stir bars, sterile, for mixing prepared disin-

tems,and/orotherformsofdisinfectantsmayresultindifferent

fectant.

log reduction (LR) values and repeatability and reproducibil-

6.20 Magnetic stir plate, any capable of mixing.

ity standard deviations.

5.3 The efficacy test was designed to determine the log

10 7. Reagents and Materials

reductioninbacteriaafterexposuretoadisinfectantinaclosed

7.1 Purity of Water—all references to water as diluent or

system.

reagent shall mean distilled water or water of equal purity.

5.4 The test method was developed using 50-mL conical

7.2 Bacterial Plating Medium—R2A agar is recommended.

tubes.Theconicalgeometryallowsfordisinfectantexposureto

7.3 Buffered Water—0.0425 g KH PO /L distilled water,

biofilm on all surfaces of the coupon.

2 4

filter-sterilized and 0.405 g MgCl·6H O/L distilled water;

5.5 Each efficacy test includes a single contact time and

filter-sterilized (prepared according to Method 9050 C.1.a

temperature for three untreated control coupons (exposed to

Buffered Dilution Water Preparation (1)).

buffered dilution water) and three treated coupons (per

7.4 Disinfectant—product to be tested.

disinfectant/concentration combination).

7.5 Neutralizer—Dey/Engley Neutralization Broth or one

6. Apparatus

specific to the disinfectant being evaluated as determined for

6.1 Conical centrifuge tubes, sterile, any with 50-mL vol-

effectiveness and toxicity according to Test Method E1054.

ume capacity and secure leakproof lids.

8. Culture/Inoculum Preparation

6.2 Ultrasonic water bath, any capable of maintaining a

homogeneous sound distribution at 45 kHz with a variable 8.1 Borosilicate glass coupons with mature Pseudomonas

power setting and a volume large enough to accommodate aeruginosa ATCC 15442 biofilm grown according to Test

50-mL conical tubes in a wet environment. Method E2562 through step 10.2.4.

E2871−12

9. Procedure 9.4.5 Repeat coupon removal twice more for a total of three

tubes each containing a coupon.

9.1 The test is conducted with three treated and three

untreated control coupons.

NOTE2—Allbiofilmonthecouponmustbeexposedtodisinfectant.Do

not lose any biofilm from the coupon by allowing it to touch the top or the

9.2 An overview of the procedure is shown in Fig. 1.

inner sides of the 50-mL conical tube as it falls to the bottom of the tube.

To ensure that the maximum biofilm surface area is in contact with the

9.3 Prepare Disinfectant:

disinfectant, the coupon should be at an angle in the bottom of the tube.

9.3.1 Prepare disinfectant according to manufacturer’s

Discard any tubes where the coupon touched the inner side of the tube

specifications in sterile volumetric glassware. Ensure that the

and/orheldcouponsthatwerenotangledandreplacethemwithnewtubes

disinfectant is adequately mixed. Use within3hof preparation

and coupons.

or as specified in the manufacturer’s instructions.

9.5 Conduct Effıcacy Evaluation:

9.3.2

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.