ASTM B628-98

(Specification)Standard Specification for Silver-Copper Eutectic Electrical Contact Alloy

Standard Specification for Silver-Copper Eutectic Electrical Contact Alloy

SCOPE

1.1 This specification covers 72% silver-28% copper (eutectic) alloy rod, wire, strip, and sheet material for electrical contacts.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B 628 – 98

Standard Specification for

Silver-Copper Eutectic Electrical Contact Alloy

This standard is issued under the fixed designation B 628; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

A

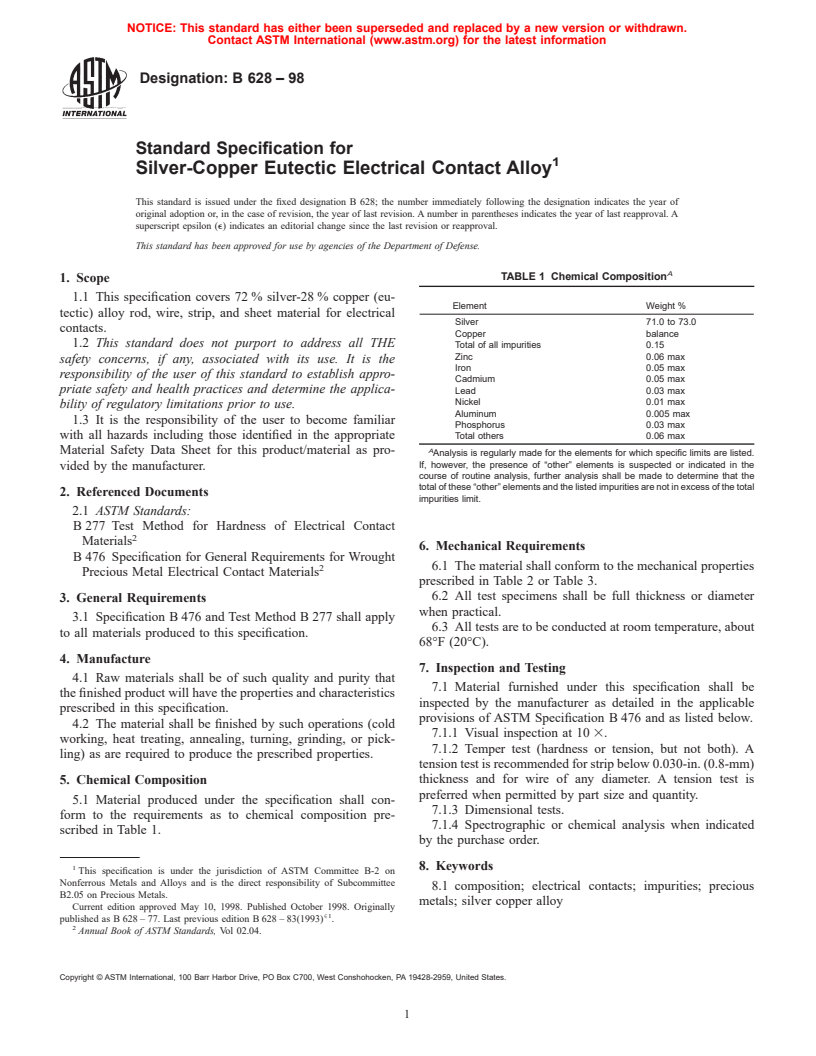

TABLE 1 Chemical Composition

1. Scope

1.1 This specification covers 72 % silver-28 % copper (eu-

Element Weight %

tectic) alloy rod, wire, strip, and sheet material for electrical

Silver 71.0 to 73.0

contacts.

Copper balance

1.2 This standard does not purport to address all THE

Total of all impurities 0.15

Zinc 0.06 max

safety concerns, if any, associated with its use. It is the

Iron 0.05 max

responsibility of the user of this standard to establish appro-

Cadmium 0.05 max

priate safety and health practices and determine the applica-

Lead 0.03 max

Nickel 0.01 max

bility of regulatory limitations prior to use.

Aluminum 0.005 max

1.3 It is the responsibility of the user to become familiar

Phosphorus 0.03 max

with all hazards including those identified in the appropriate Total others 0.06 max

A

Material Safety Data Sheet for this product/material as pro-

Analysis is regularly made for the elements for which specific limits are listed.

If, however, the presence of “other” elements is suspected or indicated in the

vided by the manufacturer.

course of routine analysis, further analysis shall be made to determine that the

total of these “other” elements and the listed impurities are not in excess of the total

2. Referenced Documents

impurities limit.

2.1 ASTM Standards:

B 277 Test Method for Hardness of Electrical Contact

Materials

6. Mechanical Requirements

B 476 Specification for General Requirements for Wrought

6.1 The material shall conform to the mechanical properties

Precious Metal Electrical Contact Materials

prescribed in Table 2 or Table 3.

6.2 All test specimens shall be full thickness or diameter

3. General Requirements

when practical.

3.1 Specification B 476 and Test Method B 277 shall apply

6.3 All tests are to be conducted at room temperature, about

to all materials produced to this specification.

68°F (20°C).

4. Manufacture

7. Inspection and Testing

4.1 Raw materials shall be of such quality and purity that

7.1 Material furnished under this specification shall be

the finished product will have the properties and characteristics

inspected by the manufacturer as detailed in the applicable

prescribed in this specification.

provisions of ASTM Specification B 476 and as listed below.

4.2 The material shall be finished by such operations (cold

7.1.1 Visual inspection at 10 3.

working, heat treating, annealing, turning, grinding, or pick-

7.1.2 Temper test (hardness or tension, but not both). A

ling) as are required to produce the prescribed properties.

tension test is recommended for strip below 0.030-in. (0.8-mm)

thickness and for wire of any diameter. A tension test is

5. Chemical Composition

preferred when permitted by part size and quantity.

5.1 Material produced under the specification shall con-

7.1.3 Dimensional tests.

form to the requirements as to chemical composition pre-

7.1.4 Spectrographic or chemical analysis when indicated

scribed in Table 1.

by the purchase order.

1 8. Keywords

This specification is under the jurisdiction of ASTM Committee B-2 on

Nonferrous Metals and Alloys and is the direct responsibility of Subcommittee

8.1 composition; electrical contacts; impurities; precious

B2.05 on Precious Metals.

metals; silver copper alloy

Current edition approved May 10, 1998. Published October 1998. Originally

{1

published as B 628 – 77. Last previous edition B 628 – 83(1993) .

Annual Book of ASTM Standards, Vol 02.04.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

B 628

TABLE 2 Mechanical Properties of Sheet and Strip

Reduction inB&S Percent Ultimate Tensile Strength, psi (MPa) Minimum

Hardness,

Temper Numbers Reduction Elongation

Rockwell 30 T

Minimum Maximum

(Reference) (Reference) in 2 in., %

A 0 0 45 000 55 000 15 56–64

(310) (380)

1/4H 1 11 56 000 66 000 7 61–69

(390) (460)

1/2H 2 21 60 000 70 000 3

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.