ASTM B605-95a(2015)

(Specification)Standard Specification for Electrodeposited Coatings of Tin-Nickel Alloy

Standard Specification for Electrodeposited Coatings of Tin-Nickel Alloy

ABSTRACT

This specification establishes the requirements for electrodeposited tin-nickel alloy coatings from aqueous solutions intended for the corrosion protection of fabricated articles of iron, steel, zinc-base alloys, copper, and copper alloys. This specification does not apply to sheets, strips, or wires in the fabricated form. It also may not be applicable to finely threaded articles, but the decision to use the coating on such components may be made by the purchaser. Coating grades shall be designated by a service condition number, which indicates the severity of exposure for which the coating is intended, and a coating thickness notation. Iron and steel specimens shall undergo pre- and post-coating treatments for reducing the risk of hydrogen embrittlement. Coatings shall be sampled, tested, and conform to specified requirements as to appearance (visible defects), composition, thickness (assessed either by microscopical, magnetic, coulometric, beta backscatter, or X-ray spectrometry), adhesion (determined either by burnishing, or heat-quench test), and integrity (including gross defects, mechanical damage, and porosity).

SCOPE

1.1 This specification covers the requirements for electrodeposited tin-nickel alloy coatings from aqueous solutions intended for the corrosion protection of fabricated articles of iron, steel, zinc-base alloys, copper, and copper alloys. The composition of the alloy remains constant at 65/35 tin-nickel in spite of wide fluctuations in both composition and operating conditions. The composition corresponds quite closely to an equiatomic ratio, and the process favors the co-deposition of tin and nickel atoms at identical rates.

1.2 This specification does not apply to sheet, strip, or wire in the fabricated form. It also may not be applicable to threaded articles having basic major diameters up to and including 19 mm because of the nonuniformity of thickness that can be expected on fine threads. However, a decision to use the coating on such components may be made by the purchaser.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:B605 −95a (Reapproved 2015)

Standard Specification for

1

Electrodeposited Coatings of Tin-Nickel Alloy

This standard is issued under the fixed designation B605; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope B252Guide for Preparation of Zinc Alloy Die Castings for

Electroplating and Conversion Coatings

1.1 Thisspecificationcoverstherequirementsforelectrode-

B281Practice for Preparation of Copper and Copper-Base

posited tin-nickel alloy coatings from aqueous solutions in-

Alloys for Electroplating and Conversion Coatings

tended for the corrosion protection of fabricated articles of

B322Guide for Cleaning Metals Prior to Electroplating

iron, steel, zinc-base alloys, copper, and copper alloys. The

B374Terminology Relating to Electroplating

compositionofthealloyremainsconstantat65/35tin-nickelin

B487Test Method for Measurement of Metal and Oxide

spite of wide fluctuations in both composition and operating

Coating Thickness by Microscopical Examination of

conditions. The composition corresponds quite closely to an

Cross Section

equiatomic ratio, and the process favors the co-deposition of

B499Test Method for Measurement of CoatingThicknesses

tin and nickel atoms at identical rates.

by the Magnetic Method: Nonmagnetic Coatings on

1.2 This specification does not apply to sheet, strip, or wire

Magnetic Basis Metals

inthefabricatedform.Italsomaynotbeapplicabletothreaded

B504Test Method for Measurement of Thickness of Metal-

articles having basic major diameters up to and including 19

lic Coatings by the Coulometric Method

mm because of the nonuniformity of thickness that can be

B507Practice for Design ofArticles to Be Electroplated on

expected on fine threads. However, a decision to use the

Racks

coating on such components may be made by the purchaser.

B567Test Method for Measurement of Coating Thickness

by the Beta Backscatter Method

1.3 The values stated in SI units are to be regarded as

standard. No other units of measurement are included in this B568Test Method for Measurement of Coating Thickness

by X-Ray Spectrometry

standard.

B571Practice for Qualitative Adhesion Testing of Metallic

1.4 This standard does not purport to address all of the

Coatings

safety concerns, if any, associated with its use. It is the

B602Test Method for Attribute Sampling of Metallic and

responsibility of the user of this standard to establish appro-

Inorganic Coatings

priate safety and health practices and determine the applica-

B634Specification for Electrodeposited Coatings of Rho-

bility of regulatory limitations prior to use.

dium for Engineering Use

B697Guide for Selection of Sampling Plans for Inspection

2. Referenced Documents

of Electrodeposited Metallic and Inorganic Coatings

2

2.1 ASTM Standards:

B762Test Method of Variables Sampling of Metallic and

B183Practice for Preparation of Low-Carbon Steel for

Inorganic Coatings

Electroplating

B765GuideforSelectionofPorosityandGrossDefectTests

B242Guide for Preparation of High-Carbon Steel for Elec-

for Electrodeposits and Related Metallic Coatings

troplating

B809Test Method for Porosity in Metallic Coatings by

B246Specification for Tinned Hard-Drawn and Medium-

Humid Sulfur Vapor (“Flowers-of-Sulfur”)

Hard-Drawn Copper Wire for Electrical Purposes

B849Specification for Pre-Treatments of Iron or Steel for

Reducing Risk of Hydrogen Embrittlement

B850GuideforPost-CoatingTreatmentsofSteelforReduc-

1

This specification is under the jurisdiction of ASTM Committee B08 on

Metallic and Inorganic Coatings and is the direct responsibility of Subcommittee ing the Risk of Hydrogen Embrittlement

B08.06 on Soft Metals.

D3951Practice for Commercial Packaging

Current edition approved March 1, 2015. Published April 2015. Originally

approved in 1975. Last previous edition approved in 2009 as B605–95a(2009).

3. Terminology

DOI: 10.1520/B0605-95AR15.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

3.1 Definitions:

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3.1.1 Many terms used in this standard are defined in

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. Terminology B374.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B605−95a (2015)

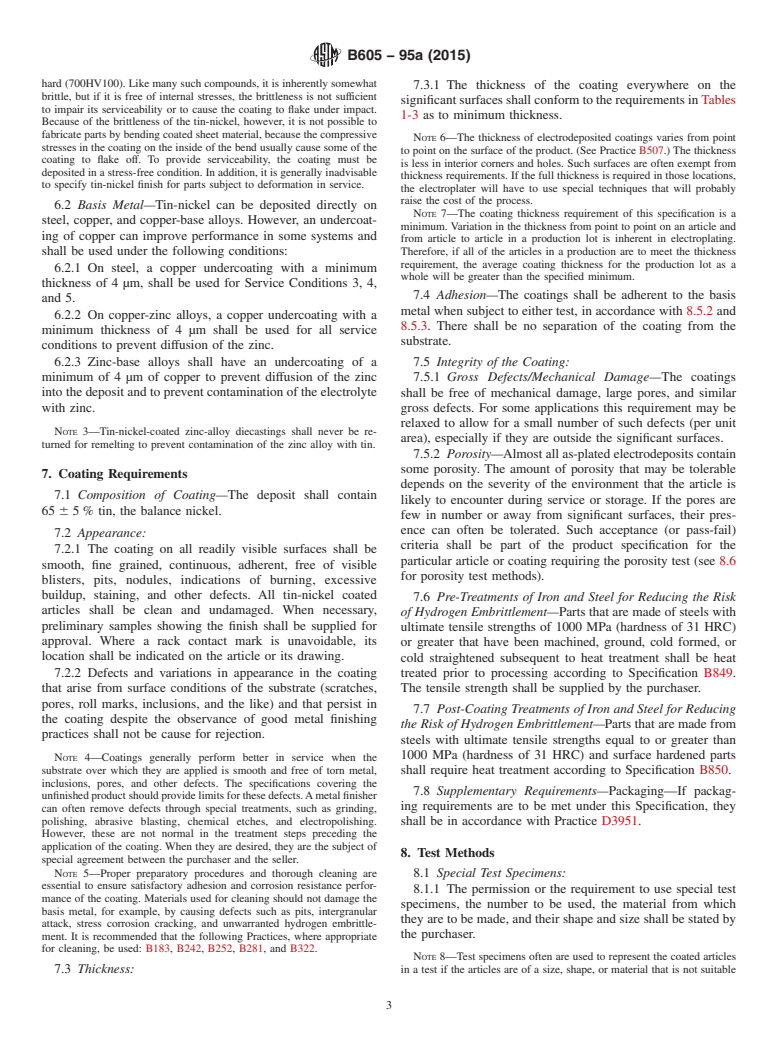

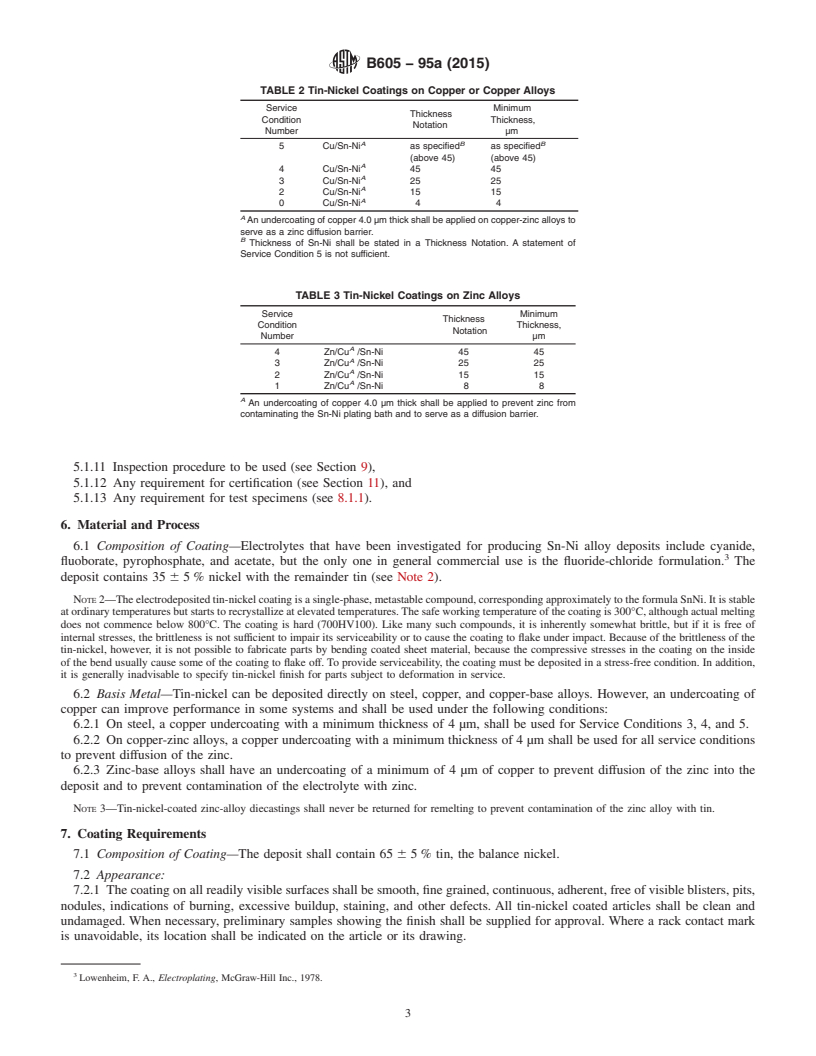

TABLE 2 Tin-Nickel Coatings on Copper or Copper Alloys

3.1.2 significant surface—that portion of a coated article’s

surface where the coating is required to meet all the require- Service Minimum

Thickness

Condition Thickness,

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: B605 − 95a (Reapproved 2009) B605 − 95a (Reapproved 2015)

Standard Specification for

1

Electrodeposited Coatings of Tin-Nickel Alloy

This standard is issued under the fixed designation B605; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification covers the requirements for electrodeposited tin-nickel alloy coatings from aqueous solutions intended for

the corrosion protection of fabricated articles of iron, steel, zinc-base alloys, copper, and copper alloys. The composition of the

alloy remains constant at 65/35 tin-nickel in spite of wide fluctuations in both composition and operating conditions. The

composition corresponds quite closely to an equiatomic ratio, and the process favors the co-deposition of tin and nickel atoms at

identical rates.

1.2 This specification does not apply to sheet, strip, or wire in the fabricated form. It also may not be applicable to threaded

articles having basic major diameters up to and including 19 mm because of the nonuniformity of thickness that can be expected

on fine threads. However, a decision to use the coating on such components may be made by the purchaser.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

B183 Practice for Preparation of Low-Carbon Steel for Electroplating

B242 Guide for Preparation of High-Carbon Steel for Electroplating

B246 Specification for Tinned Hard-Drawn and Medium-Hard-Drawn Copper Wire for Electrical Purposes

B252 Guide for Preparation of Zinc Alloy Die Castings for Electroplating and Conversion Coatings

B281 Practice for Preparation of Copper and Copper-Base Alloys for Electroplating and Conversion Coatings

B322 Guide for Cleaning Metals Prior to Electroplating

B374 Terminology Relating to Electroplating

B487 Test Method for Measurement of Metal and Oxide Coating Thickness by Microscopical Examination of Cross Section

B499 Test Method for Measurement of Coating Thicknesses by the Magnetic Method: Nonmagnetic Coatings on Magnetic Basis

Metals

B504 Test Method for Measurement of Thickness of Metallic Coatings by the Coulometric Method

B507 Practice for Design of Articles to Be Electroplated on Racks

B567 Test Method for Measurement of Coating Thickness by the Beta Backscatter Method

B568 Test Method for Measurement of Coating Thickness by X-Ray Spectrometry

B571 Practice for Qualitative Adhesion Testing of Metallic Coatings

B602 Test Method for Attribute Sampling of Metallic and Inorganic Coatings

B634 Specification for Electrodeposited Coatings of Rhodium for Engineering Use

B697 Guide for Selection of Sampling Plans for Inspection of Electrodeposited Metallic and Inorganic Coatings

B762 Test Method of Variables Sampling of Metallic and Inorganic Coatings

B765 Guide for Selection of Porosity and Gross Defect Tests for Electrodeposits and Related Metallic Coatings

B809 Test Method for Porosity in Metallic Coatings by Humid Sulfur Vapor (“Flowers-of-Sulfur”)

1

This specification is under the jurisdiction of ASTM Committee B08 on Metallic and Inorganic Coatings and is the direct responsibility of Subcommittee B08.06 on Soft

Metals.

Current edition approved Sept. 1, 2009March 1, 2015. Published November 2009April 2015. Originally approved in 1975. Last previous edition approved in 20042009

as B605 – 95a (2004).(2009). DOI: 10.1520/B0605-95AR09.10.1520/B0605-95AR15.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B605 − 95a (2015)

B849 Specification for Pre-Treatments of Iron or Steel for Reducing Risk of Hydrogen Embrittlement

B850 Guide for Post-Coating Treatment

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.