ASTM F2142-01(2019)

(Test Method)Standard Test Method for Performance of Drawer Warmers

Standard Test Method for Performance of Drawer Warmers

SIGNIFICANCE AND USE

5.1 The energy input rate and thermostat calibration tests are used to confirm that the drawer warmer is operating properly prior to further testing.

5.2 Preheat energy and time can be useful to food service operators to manage energy demands and to know how quickly the drawer warmer can be ready for operation.

5.3 Idle energy rate and holding energy rate can be used by the food service operator to estimate energy consumption during operating periods and to consider energy consumption when choosing a drawer warmer.

5.4 The drawer pan temperature and drawer pan temperature uniformity can be used by an operator to choose a drawer warmer which meets their food holding needs.

SCOPE

1.1 This test method evaluates the preheat, idle, and holding energy consumption and temperature uniformity of drawer warmers. The food service operator can use this evaluation to select a drawer warmer and understand its energy performance and temperature uniformity. A drawer warmer is described as a commercial kitchen appliance that consists of one or more heated drawers and which is used to hold hot food (usually no greater than 200°F) that has been cooked in a separate appliance, at a specified temperature.

1.2 This test method is applicable to freestanding and built-in electric drawer warmers equipped for:

1.2.1 Industry-standard 12 × 20 × 6–in. (nominal size) pans, or

1.2.2 Standard-oversized 15 × 20 × 5–in. (nominal size) pans.

1.3 The drawer warmer can be evaluated with respect to the following (where applicable):

1.3.1 Energy input rate (10.2),

1.3.2 Energy consumption rate at maximum setting (10.2),

1.3.3 Temperature calibration (10.3),

1.3.4 Preheat energy consumption and time (10.4),

1.3.5 Idle energy rate (10.5),

1.3.6 Holding energy rate (10.6), and

1.3.7 Temperature uniformity (10.6).

1.4 The values stated in inch-pound units are to be regarded as standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F2142 − 01 (Reapproved 2019) An American National Standard

Standard Test Method for

Performance of Drawer Warmers

This standard is issued under the fixed designation F2142; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

1.1 Thistestmethodevaluatesthepreheat,idle,andholding

energy consumption and temperature uniformity of drawer

2. Referenced Documents

warmers. The food service operator can use this evaluation to

select a drawer warmer and understand its energy performance

2.1 ASHRAE Document:

andtemperatureuniformity.Adrawerwarmerisdescribedasa

ASHRAE Guideline 2—1986 (RA90)Engineering Analysis

commercial kitchen appliance that consists of one or more

of Experimental Data

heated drawers and which is used to hold hot food (usually no

2.2 NSF Standard:

greater than 200°F) that has been cooked in a separate

Standard Number 4—Commercial Cooking,

appliance, at a specified temperature.

Rethermalization, and Powered Hot Food Holding and

Transport Equipment

1.2 This test method is applicable to freestanding and

built-in electric drawer warmers equipped for:

3. Terminology

1.2.1 Industry-standard12×20×6–in.(nominalsize)pans,

or

3.1 Definitions:

1.2.2 Standard-oversized 15 × 20 × 5–in. (nominal size)

3.1.1 drawer pan, n—that portion of the appliance in which

pans.

food products are held. Industry-standard drawer pans are

nominally 12×20×6 in. deep; standard-oversized drawer

1.3 The drawer warmer can be evaluated with respect to the

pans are nominally 15×20×5 in. deep.

following (where applicable):

1.3.1 Energy input rate (10.2), 3.1.2 drawer pan centerpoint temperature, n—the tempera-

1.3.2 Energy consumption rate at maximum setting (10.2), ture as measured at the geometric center of the drawer pan

1.3.3 Temperature calibration (10.3), using a single thermocouple.

1.3.4 Preheat energy consumption and time (10.4),

3.1.3 drawer warmer, n—an appliance that consists of one

1.3.5 Idle energy rate (10.5),

or more heated drawers and that is designed to hold hot food

1.3.6 Holding energy rate (10.6), and

that has been cooked in a separate appliance at a specified

1.3.7 Temperature uniformity (10.6).

temperature.

1.4 The values stated in inch-pound units are to be regarded

3.1.4 energy input rate, n—peak rate at which a drawer

as standard.

warmer consumes energy (kW), typically reflected during

preheat.

1.5 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

3.1.5 holding energy rate, n—the rate of energy consumed

responsibility of the user of this standard to establish appro-

(Btu/h or kW) by the drawer warmer while keeping the heated

priate safety, health, and environmental practices and deter-

food product (dinner rolls) warm.

mine the applicability of regulatory limitations prior to use.

3.1.6 idle energy rate, n—therateofenergyconsumed(kW)

1.6 This international standard was developed in accor-

by the drawer warmer while “idling“ or maintaining the

dance with internationally recognized principles on standard-

drawers at a calibrated 150°F set point.

ization established in the Decision on Principles for the

3.1.7 preheat energy, n—amountofenergyconsumedbythe

Development of International Standards, Guides and Recom-

drawer warmer while preheating the drawer pan(s) from

This test method is under the jurisdiction of ASTM Committee F26 on Food

Service Equipment and is the direct responsibility of Subcommittee F26.06 on Available from American Society of Heating, Refrigerating, and Air-

Productivity and Energy Protocol. Conditioning Engineers, Inc. (ASHRAE), 1791 Tullie Circle, NE, Atlanta, GA

Current edition approved May 1, 2019. Published June 2019. Originally 30329,http://www.ashrae.org.

approved in 2001. Last previous edition approved in 2013 as F2142–01(2013). Available from NSF International, P.O. Box 130140, 789 N. Dixboro Rd.,Ann

DOI: 10.1520/F2142-01R19. Arbor, MI 48113-0140, http://www.nsf.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F2142 − 01 (2019)

ambient room temperature (75 6 2.5°F) to 150°F, with the 6.3 Thermocouple(s), industry standard type T or type K

control(s) set to a calibrated 150°F. thermocouple wire with a range of 0 to 350°F and an

uncertainty of 61°F.

3.1.8 preheat rate, n—average rate (°F/min) at which the

drawerpanisheatedfromambienttemperature(75 62.5°F)to

6.4 Watt-Hour Meter, for measuring the electrical energy

150°F, with the control(s) set to a calibrated 150°F.

consumption of a drawer warmer, shall have a resolution of at

least10W·handamaximumuncertaintynogreaterthan1.5%

3.1.9 preheat time, n—time required for the drawer warmer

of the measured value for any demand greater than 100W. For

to preheat from ambient room temperature (75 6 2.5°F) to

any demand less than 100 W, the meter shall have a resolution

150°F, with the control(s) set to a calibrated 150°F.

of at least 10 W·h and a maximum uncertainty no greater than

3.1.10 uncertainty, n—measure of systematic and precision

10%.

errors in specified instrumentation or measure of repeatability

of a reported test result.

7. Reagents and Materials

7.1 Dinner Roll, shall be a nominal 3 in. square breadroll,

4. Summary of Test Method

approximately 2 in. tall, weighing 5.5 6 1.0 lb per 60 rolls.

4.1 The drawer warmer is connected to the appropriate

metered energy source, and the energy input rate is determined

8. Sampling, Test Units

to confirm that the appliance is operating within 5% of the

8.1 Drawer Warmer—Select a representative production

nameplate energy input rate.

model for performance testing.

4.2 The drawer pan temperature and energy consumption

rate are determined with the drawer warmer controls set to the

9. Preparation of Apparatus

maximum setting.

9.1 Install the drawer warmer according to the manufactur-

4.3 The accuracy of the drawer warmer’s temperature con-

er’s instructions and consistent with industry practices. Sur-

trol is checked at 150°F and adjusted as necessary to within

rounding surfaces cannot add insulating factors, which may

65°F.

influence the test results.All sides of the drawer warmer shall

have a minimum of 3 ft. of clearance from any sidewall, side

4.4 The amount of energy and time required to preheat the

partition or other operating appliance. The associated heating

drawer warmer from ambient (75 6 2.5°F) to 150°F, based on

orcoolingsystemforthespaceshallbecapableofmaintaining

a calibrated 150°F set point, is determined.

an ambient temperature of 75 6 2.5°F within the testing

4.5 The rate of idle energy consumption is determined with

environment.

the drawer warmer set to maintain 150°F and no food load in

9.2 Connect the drawer warmer to a calibrated energy test

the drawer pans.

meter. A voltage regulator may be required during tests if the

4.6 Therateofholdingenergyconsumption,thedrawerpan

voltage supply is not within 62.5% of the manufacturer’s

temperature, and the drawer pan temperature uniformity are

nameplate voltage.

determined with a food load and with the drawer warmer

9.3 Confirm (while the elements are energized) that the

controls set to the calibrated 150°F set point.

supply voltage is within 62.5% of the operating voltage

specified by the manufacturer. Record the test voltage for each

5. Significance and Use

test.

5.1 The energy input rate and thermostat calibration tests

NOTE 1—It is the intent of the testing procedure herein to evaluate the

are used to confirm that the drawer warmer is operating

performance of a drawer warmer at its rated electric voltage. If an electric

properly prior to further testing.

unit is rated dual voltage (that is, designed to operate at either 208 or 240

5.2 Preheat energy and time can be useful to food service

V with no change in components), the voltage selected by the manufac-

turer and/or tester shall be reported. If a drawer warmer is designed to

operatorstomanageenergydemandsandtoknowhowquickly

operate at two voltages without a change in the resistance of the heating

the drawer warmer can be ready for operation.

elements, the performance of the unit (for example, preheat time) may

5.3 Idle energy rate and holding energy rate can be used by differ at the two voltages.

the food service operator to estimate energy consumption

9.4 Assure that the drawer warmer’s vent (if applicable) is

during operating periods and to consider energy consumption

closed for all tests.

when choosing a drawer warmer.

9.5 Place one thermocouple at the geometric center of each

5.4 The drawer pan temperature and drawer pan tempera-

drawer pan in the drawer warmer, centered front to back, side

ture uniformity can be used by an operator to choose a drawer

to side, and top to bottom. This is the drawer pan centerpoint

warmer which meets their food holding needs.

temperature.

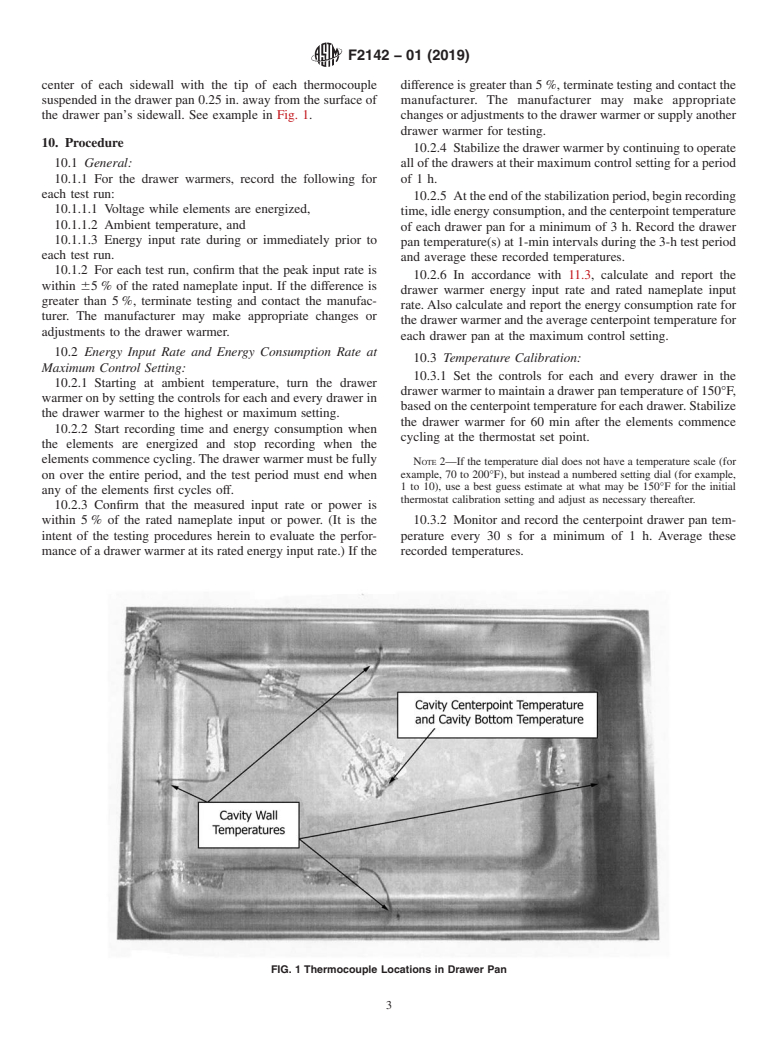

9.6 For the temperature uniformity test, place an additional

6. Apparatus

5 thermocouples in each drawer pan in the drawer warmer as

6.1 Data Acquisition System, for measuring energy and

follows: Place one thermocouple 0.25 in. above the bottom of

temperatures, capable of multiple channel displays updating at

the drawer pan and centered front to back and side to side.

least every 2 s.

Place one thermocouple on each sidewall of the drawer pan

6.2 Stop Watch, with a 1-s resolution. (total of four thermocouples). Locate the thermocouples in the

F2142 − 01 (2019)

center of each sidewall with the tip of each thermocouple differenceisgreaterthan5%,terminatetestingandcontactthe

suspended in the drawer pan 0.25 in. away from the surface of manufacturer. The manufacturer may make appropriate

the drawer pan’s sidewall. See example in Fig. 1. changesoradjustmentstothedrawerwarmerorsupplyanother

drawer warmer for testing.

10. Procedure

10.2.4 Stabilizethedrawerwarmerbycontinuingtooperate

10.1 General: allofthedrawersattheirmaximumcontrolsettingforaperiod

10.1.1 For the drawer warmers, record the following for of1h.

each test run:

10.2.5 Attheendofthestabilizationperiod,beginrecording

10.1.1.1 Voltage while elements are energized,

time,idleenergyconsumption,andthecenterpointtemperature

10.1.1.2 Ambient temperature, and

of each drawer pan for a minimum of 3 h. Record the drawer

10.1.1.3 Energy input rate during or immediately prior to

pantemperature(s)at1-minintervalsduringthe3-htestperiod

each test run.

and average these recorded temperatures.

10.1.2 For each test run, confirm that the peak input rate is

10.2.6 In accordance with 11.3, calculate and report the

within 65% of the rated nameplate input. If the difference is

drawer warmer energy input rate and rated nameplate input

greater than 5%, terminate testing and contact the manufac-

rate.Also calculate and report the energy consumption rate for

turer. The manufacturer may make appropriate changes or

thedrawerwarmerandtheaveragecenterpointtemperaturefor

adjustments to the drawer warmer.

each drawer pan at the maximum control setting.

10.2 Energy Input Rate and Energy Consumption Rate at

10.3 Temperature Calibration:

Maximum Control Setting:

10.3.1 Set the controls for each and every drawer in the

10.2.1 Starting at ambient temperature, turn the drawer

drawerwarmertomaintainadrawerpantemperatureof150°F,

warmeronbysettingthecontrolsforeachandeverydrawerin

basedonthecenterpointtemperatureforeachdrawer.Stabilize

the drawer warmer to the highest or maximum setting.

the drawer warmer for 60 min after the elements commence

10.2.2 Start recording time and energy consumption when

cycling at the thermostat set point.

the elements are energized and stop recording when the

elementscommencecycling.Thedrawerwarmermustbefully

NOTE 2—If the temperature dial does not have a temperature scale (for

example, 70 to 200°F), but instead a numbered setting dial (for example,

on over the entire period, and the test period must end when

1 to 10), use a best guess estimate at what may be 150°F for the initial

any of the elements first cycles off.

thermostat calibration setting and adjust as necessary thereafter.

10.2.3 Confirm that the measured input rate or power is

within 5% of the rated nameplate input or power. (It is the 10.3.2 Monitor and record the centerpoint drawer pan tem-

intent of the testing procedures herein to evaluate the perfor- perature every 30 s for a minimum of 1 h. Average these

mance of a drawer warmer at its rated energy input rate.) If the recorded temperatures.

FIG. 1 Thermocouple Locations in Drawer Pan

F2142 − 01 (2019)

10.3.3 As required (as indicated by the average The dinner rolls shall be heated to an average internal

temperature), adjust the temperature control(s) to attain an temperature of 160 6 2°F as measured with a thermocouple.

actual drawer pan temperature of 150 6 5°F for each drawer. 10.6.3 At the end of the preheat period, place 60 heated

Repeat10.3.2toconfirmthatthepantemperatureis150 65°F. dinner rolls (standard size pans; 80 dinner rolls for oversized

10.3.4 To facilitate further testing, mark on the dial the pans) into each drawer pan. The dinner rolls shall be evenly

exact position of the thermostat control(s) that corresponds to spread throughout the drawer and shall be placed into the

an average drawer pan temperature of 150 6 5°F . Record the drawer in two layers of 30 rolls each (standard size pans; 40

final control setting. rolls per layer for oversized pans). Ensure that the thermo-

couple measuring the center point temperature in each pan

10.4 Preheat Energy Consumption and Time:

continues to measure the air temperature and is not covered by

NOTE 3—The preheat test should be conducted as the first appliance

any of the food product. Open and shut each drawer individu-

operation on the day of the test, starting with the drawer warmer and each

ally as it is loaded. Allow no more than 2 min to load each

drawer pan at room temperature (75 6 2.5°F).

drawer.

10.4.1 Record the drawer pan centerpoint temperature(s)

10.6.4 After every drawer is loaded, allow the drawer

and ambient temperature at the start of the test. The pan

warmer to stabilize for 1 h.

temperature(s) shall be 75 6 2.5°F at the start of the test.

10.6.5 At the end of the 1 h stabilization period, begin

10.4.2 Turntheunito

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.