ASTM D4641-94(2006)

(Practice)Standard Practice for Calculation of Pore Size Distributions of Catalysts from Nitrogen Desorption Isotherms

Standard Practice for Calculation of Pore Size Distributions of Catalysts from Nitrogen Desorption Isotherms

SIGNIFICANCE AND USE

Pore volume distribution curves obtained from nitrogen sorption isotherms provide one of the best means of characterizing the pore structure in porous catalysts, provided that the limitations of the method are kept in mind. Used in conjunction with the BET treatment for surface area determination (4), these methods provide an indispensable means for studying the structure associated with pores usually important in catalysts. This practice is particularly useful in studying changes in a series of closely related samples caused by treatments, such as heat, compression, or extrusion often used in catalyst manufacturing. Pore volume distribution curves can often provide valuable information during mechanistic studies dealing with catalyst deactivation.

SCOPE

1.1 This practice covers the calculation of pore size distributions for catalysts and catalyst carriers from nitrogen desorption isotherms. The computational procedure is particularly useful for determining how the pore volume is distributed in catalyst samples containing pores whose sizes range from approximately 1.5 to 100 nm (15 to 1000 ) in radius. It should be used with caution when applied to isotherms for samples containing pores both within this size range and pores larger than 100 nm (1000 ) in radius. In such instances the isotherms rise steeply near P/Po = 1 and the total pore volume cannot be well defined. The calculations should be begun at a point on the isotherm near saturation preferably in a region near P/Po = 0.99, establishing an upper limit on the pore size distribution range to be studied. Simplifications are necessary regarding pore shape. A cylindrical pore model is assumed, and the method treats the pores as non-intersecting, open-ended capillaries which are assumed to function independently of each other during the adsorption or desorption of nitrogen. Note 1 - This practice is designed primarily for manual computation and a few simplifications have been made for this purpose. For computer computation, the simplified expressions may be replaced by exact expressions.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D4641–94 (Reapproved 2006)

Standard Practice for

Calculation of Pore Size Distributions of Catalysts from

Nitrogen Desorption Isotherms

This standard is issued under the fixed designation D4641; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D4222 Test Method for Determination of NitrogenAdsorp-

tion and Desorption Isotherms of Catalysts and Catalyst

1.1 This practice covers the calculation of pore size distri-

Carriers by Static Volumetric Measurements

butions for catalysts and catalyst carriers from nitrogen des-

orption isotherms. The computational procedure is particularly

3. Terminology

useful for determining how the pore volume is distributed in

3.1 Definitions—Consult Terminology D3766.

catalyst samples containing pores whose sizes range from

3.2 Symbols:

approximately1.5to100nm(15to1000Å)inradius.Itshould

be used with caution when applied to isotherms for samples

containing pores both within this size range and pores larger

P (i) = pressure after equilibration during desorption,

than 100 nm (1000 Å) in radius. In such instances the

torr.

isotherms rise steeply near P/P = 1 and the total pore volume

o

P (i) = liquid nitrogen vapor pressure, torr.

cannot be well defined. The calculations should be begun at a

V = see 12.4.10 and 12.5 in Test Method D4222.

de

point on the isotherm near saturation preferably in a region

r (i) = radius of inner core calculated from Kelvin

k

near P/P = 0.99, establishing an upper limit on the pore size

o equation, Å.

distribution range to be studied. Simplifications are necessary T = boiling point of nitrogen, K.

regardingporeshape.Acylindricalporemodelisassumed,and V = liquid nitrogen molar volume at T,cm /mole.

L

g = liquid nitrogen surface tension at T, mN/m.

the method treats the pores as non-intersecting, open-ended

T(i) = average thickness of the nitrogen film adsorbed

capillaries which are assumed to function independently of

on the pore walls, Å .

each other during the adsorption or desorption of nitrogen.

r (i) = radius of cylindrical pore given by r (i)+ t (i),

p k

NOTE 1—This practice is designed primarily for manual computation

Å.

and a few simplifications have been made for this purpose. For computer

Q = volume correction factor defined as ( r¯/r¯ ) .

p k

computation, the simplified expressions may be replaced by exact expres-

DV (i) = decrease in the amount of nitrogen adsorbed

T

sions.

caused by a lowering in relative pressure,

1.2 This standard does not purport to address all of the

mm /g.

safety concerns, if any, associated with its use. It is the

DV (i) = volume of liquid nitrogen desorbed from pore

f

responsibility of the user of this standard to establish appro-

walls during thinning of the film, mm /g.

priate safety and health practices and determine the applica-

DV (i) = liquid volume of the inner core in which capil-

k

bility of regulatory limitations prior to use.

larycondensationofthenitrogenoccurs,mm /g.

DV (i) = liquid volume contained in a group of pores

p

2. Referenced Documents

having mean radius r¯,mm /g.

p

2.1 ASTM Standards:

(Dv = cumulative pore volume, mm /g.

p

D3766 Terminology Relating to Catalysts and Catalysis

DS (i ) = area of the pore walls of a cylinder having

p

volume DV,m /g.

p

This practice is under the jurisdiction of ASTM Committee D32 on Catalysts

4. Summary of Practice

and is the direct responsibility of Subcommittee D32.01 on Physical-Chemical

Properties.

4.1 The pore size distribution is determined by analyzing

Current edition approved Oct. 1, 2006. Published October 2006. Originally

the desorption data of the nitrogen isotherm. The nitrogen

´1

approved in 1987. Last previous edition approved in 1999 as D4641–94(1999) .

uptake is caused by the multilayer adsorption of a film of

DOI: 10.1520/D4641-94R06.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

nitrogen on the pore walls and by capillary condensation of the

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

nitrogen in the “inner core” regions of the pores. The relative

Standards volume information, refer to the standard’s Document Summary page on

pressureatwhichfillingofthecoreoccursforagivenporesize

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D4641–94 (2006)

by capillary condensation is predicted from the Kelvin equa- the computational procedure is then made more difficult. In

tion (1). During desorption, thinning of the multilayer film most cases a starting relative pressure of 0.99 will be suitable,

adsorbed on the pore walls occurs in pores which have

which corresponds to an upper limit on pore size of 100 nm

previously lost their capillary condensate. Corrections for film (1000 Å) in radius. If necessary, interpolate the values of V

de

thinning are determined by a procedure involving the surface

to determine the quantity of nitrogen gas adsorbed at the

area and radius of the film which becomes exposed as

chosen starting relative pressure.

desorption proceeds. In principle, the computational procedure

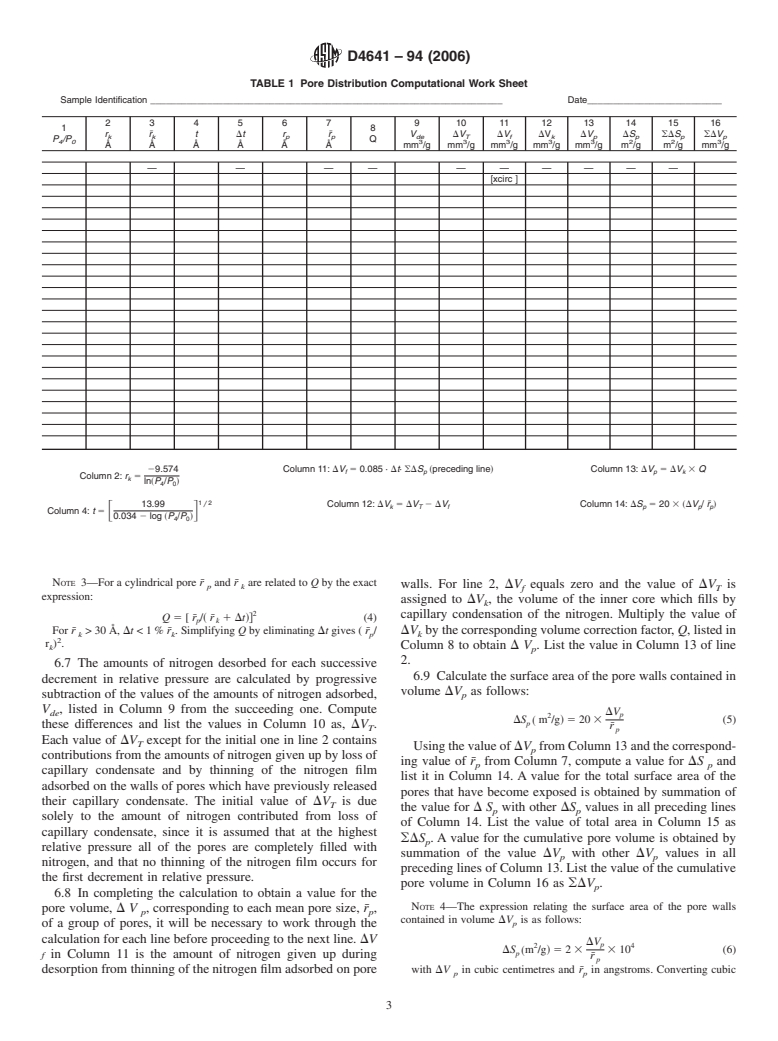

6.2 The procedure requires numerous arithmetical steps

can be applied to either the adsorption branch or desorption

which can best be carried out with the aid of a work sheet.An

branch of the nitrogen isotherm. Unless the presence of

example (4) of a form found useful in the calculations is

ink-bottleshapedporesissuggestedbyanabruptclosureofthe

provided in Table 1. List in descending order the experimen-

desorption branch on the adsorption branch, the distribution

tally determined relative pressures [P (i)/P ( i)] in Column 1,

4 0

curve derived from the desorption data is preferred, and is

beginning with the value chosen as the starting relative

described in this procedure. The computational method is

pressure. Generally, values below a relative pressure of 0.25

essentially the procedure developed by Barrett, Joyner, and

will not be required in the calculations. Convert the uptake

Halenda (2) except for the incorporation of a few simplifica- 3

values into a liquid volume (mm /g) by multiplying the value

tions. 3

of V in cm STP/g with the conversion factor 1.5468 derived

de

from V = 34.67 cm /mole. List in Column 9 the correspond-

NOTE 2—In cases where it has been established that the adsorption

L

branch of the nitrogen isotherm is to be analyzed, the procedure proposed ing quantities of nitrogen adsorbed.

by Cranston and Inkley (3) is recommended.

6.3 For each relative pressure, calculate a value for the

radius of the core, r , by means of the Kelvin equation,

k

5. Significance and Use

2gV

L

5.1 Pore volume distribution curves obtained from nitrogen

RT ln ~P /P !52 (1)

4 0

r

k

sorption isotherms provide one of the best means of character-

izing the pore structure in porous catalysts, provided that the

given in the form

limitationsofthemethodarekeptinmind.Usedinconjunction

9.574

˚

with the BET treatment for surface area determination (4), r ~A!52 (2)

k

ln ~P /P !

4 0

thesemethodsprovideanindispensablemeansforstudyingthe

with T = 77.35 K; g = 8.88 mN/m; and V = 34.67 cm /

structure associated with pores usually important in catalysts.

L

mole. List the values in Column 2. For each successive

This practice is particularly useful in studying changes in a

decrement in relative pressure, calculate r¯ , the mean of the

series of closely related samples caused by treatments, such as

k

values of r for the present and previous pressures, and list

heat, compression, or extrusion often used in catalyst manu-

k

these mean values in Column 3.

facturing. Pore volume distribution curves can often provide

valuable information during mechanistic studies dealing with

6.4 The average thickness, t, of the multilayer film of

catalyst deactivation.

nitrogen adsorbed on the walls of the pores at each relative

pressure is used to calculate the amount of nitrogen desorbed

6. Computational Procedure

from the film in pores which have lost their capillary conden-

6.1 This procedure requires the use of a series of experi-

sate. For each relative pressure, calculate a value for the film

mentally measured relative pressures [P (i)/P (i)] and the thickness from the expression (5)

4 0

corresponding quantities of nitrogen gas adsorbed [V ] ex-

de

13.99

pressed in units of cm STP/g. The experimental data required

˚

t ~A! 5 (3)

F G

0.034 2 log ~P /P !

4 0

in the use of this procedure can be measured by following the

steps outlined in Test Method D4222. Inspect the nitrogen

and list the values in Column 4. For each successive

sorption isotherm in the region above P/P = 0.95. If the solid

o decrement in relative pressure, calculate the differences in the

contains no pores larger than 100 nm (1000 Å) radius, the

values of t, and list these differences as Dt in Column 5.

isotherm remains nearly horizontal over a range of P/P

o

6.5 Since a cylindrical pore model is assumed, the radius of

approaching unity and it is a simple matter to select a starting

the pore, r , is given by addition of the core radius, r , and the

p k

relative pressure within this region, establishing an upper limit

film thickness value, t. Add the values in Column 2 to the

ontheporesizerangetobestudied.Ifporeslargerthan100nm

corresponding values in Column 4 and record the results in

(1000 Å) are present however, the isotherm rises rapidly near

Column 6 as r . For each successive decrement in relative

p

P/P = 1 and the total pore volume cannot be well defined.

O

pressure, calculate r¯ , the mean of the pore radii, r , for the

p p

This limiting adsorption can then be identified reliably only if

present and previous pressures, and record these values in

the temperature is very carefully controlled and there are no

Column 7.

“cold spots” in the apparatus (which lead to bulk condensation

6.6 Compute the quantity (r¯ /r¯ ) from the values listed in

p k

of the gas and a false measure of the adsorption in the

Columns 7 and 3.This quantity will be used later to correct the

volumetric method). Selecting the starting relative pressure for

core volume to the volume for each group of pores. The core

volume is the region within the pore that fills by capillary

3 condensation of the nitrogen. List the computed values in

The boldface numbers in parentheses refer to a list of references at the end of

this standard. Column 8 as the volume correction factor, Q.

D4641–94 (2006)

TABLE 1 Pore Distribution Computational Work Sheet

Sample Identification ____________________________________________________________________ Date__________________________

2 3 4 5 6 7 9 10 11 12 13 14 15 16

1 8

r r¯ t Dt r r¯ V DV DV DV DV DS (DS (DV

k k p p de T f k p p p p

P /P Q

4 0 3 3 3 3 3 2 2 3

Å Å Å Å Å Å mm /g mm /g mm /g mm /g mm /g m /g m /g mm /g

— — — — — —————

[xcirc ]

29.574 Column 11: DV 5 0.085 · Dt· (DS ~preceding line! Column 13: DV 5DV 3 Q

f p p k

Column 2: r 5

k

ln~P /P !

4 0

1 2

13.99 / Column 12: DV 5DV 2DV Column 14: DS 5 20 3 ~DV / r¯ !

k T f p p p

Column 4: t 5

F G

0.034 2 log ~P /P !

4 0

NOTE 3—For a cylindrical pore r¯ and r¯ are related to Q by the exact

walls. For line 2, DV equals zero and the value of DV is

p k

f T

expression:

assigned to DV , the volume of the inner core which fills by

k

capillary condensation of the nitrogen. Multiply the value of

Q 5 [ r¯ /~ r¯ 1Dt!# (4)

p k

DV bythecorrespondingvolumecorrectionfactor, Q,listedin

For r¯ >30Å, Dt<1% r¯ . Simplifying Q by eliminating Dt gives ( r¯ /

k

k k p

r ) .

Column 8 to obtain D V . List the value in Column 13 of line

k

p

2.

6.7 The amounts of nitrogen desorbed for each successive

6.9 Calculate the surface area of the pore walls contained in

decrement in relative pressure are calculated by progressive

volume DV as follows:

subtraction of the values of the amounts of nitrogen adsorbed, p

V , listed in Column 9 from the succeeding one. Compute

DV

de

p

DS ~ m /g! 5 20 3 (5)

p

these differences and list the values in Column 10 as, DV .

r¯

T p

Each value of DV except for the initial one in line 2 contains

T

Usingthevalueof DV fromColumn13andthecorrespond-

p

contributions from the amounts of nitrogen given up by loss of

ing value of r¯ from Column 7, compute a value for DS and

p p

capillary condensate and by thinning of the nitrogen film

list it in Column 14. A value for the total surface area of the

adsorbed on the walls of pores which have previously released

pores that have become exposed is obtained by summation of

their capillary condensate. The initial value of DV is due

T

the value for D S with other DS values in all preceding lines

p p

solely to the amount of nitrogen contributed from loss of

of Column 14. List the value of total area in Column 15 as

capillary condensate, since it is assumed that at the highest

(DS . A value for the cumulative pore volume is obtained by

p

relative pressure all of the pores are completely filled with

summation of the value DV with other DV values in all

p p

nitrogen, and that no thinning of the nitrogen film occurs for

preceding lines of Column 13. List the value of the cumulative

the first decrement in relative pressure.

pore volume in Column 16 as (DV .

p

6.8 In completing the calculation to obtain a value for the

NOTE 4—The expression relating the surface area of the pore walls

pore volume, D V , corresponding to each mean pore size, r¯ ,

p p

contained in volume DV is as follows:

p

of a group of pores, it will be necessary to work through the

calculation for each line before proceeding to the next line. DV

DV

2 p 4

DS ~m /g! 5 2 3 3 10 (6)

p

f in Column 11 is the amount of nitrogen given up during r¯

p

desorption from thinning of the nitrogen film adsorbed on pore with DV in cubic centimetres and r¯ in angstroms. Converting cubic

p p

D4641–94 (2006)

centimetres to cubic millimetres gives rise to the conversion factor of 20

6.12 The last value of (D S computed in Column 15 is

p

in the preceding equation.

assigned to the total cumulative surface area. The last value of

(D V computed in Column 16 is assigned to the total

6.10 An essential feature of this test method is that the

p

cumulative pore volume.

volume of nitrogen lost from the adsorbed multilayer film can

be calculated from the total area of the pores exposed, (DS ,

p

NOTE 7—A comparison of the value for the total cumulative surface

and the decrease in the thickness of the film, Dt. Using the

area with that for the BET surface area determined fr

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.