ASTM F2799-14(2019)

(Practice)Standard Practice for Maintenance of Aircraft Electrical Wiring Systems

Standard Practice for Maintenance of Aircraft Electrical Wiring Systems

SIGNIFICANCE AND USE

4.1 This practice is intended to be used as a standard wiring practice for aircraft when not contrary to standards published by the aircraft original equipment manufacturer (OEM) or regulations. This practice is intended to be used for maintenance and preventive maintenance of electrical wiring interconnection systems (EWIS).

4.2 This practice is not intended to supersede or replace any government specification or specific manufacturer’s instructions regarding EWIS maintenance or repair.

SCOPE

1.1 Definition—This practice defines acceptable practices and processes for the maintenance, preventative maintenance, and repair of electric systems in general aviation aircraft. This practice does not change or create any additional regulatory requirements nor does it authorize changes in or permit deviations from existing regulatory requirements.

1.2 Applicability—The guidance provided in this practice is directed to air carriers, air operators, maintenance providers, repair stations, and anyone performing maintenance or repairs.

1.3 Protections and Warnings—This practice provides guidance to minimize contamination and accidental damage to electrical wiring interconnection systems (EWIS) while working on aircraft.

1.4 “Protect and Clean As You Go” Philosophy—This philosophy is applied to aircraft wiring through inclusion in operators’ maintenance and training programs. This philosophy stresses the importance of protective measures when working on or around wire bundles and connectors. It stresses how important it is to protect EWIS during structural repairs, (STC) installations, or other alterations by ensuring that metal shavings, debris, and contamination resulting from such work are removed.

1.5 Units—The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

Note 1: When SI units are required, refer to Annex 5 of ICAO.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F2799 − 14 (Reapproved 2019)

Standard Practice for

Maintenance of Aircraft Electrical Wiring Systems

This standard is issued under the fixed designation F2799; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Development of International Standards, Guides and Recom-

mendations issued by the World Trade Organization Technical

1.1 Definition—This practice defines acceptable practices

Barriers to Trade (TBT) Committee.

and processes for the maintenance, preventative maintenance,

and repair of electric systems in general aviation aircraft. This

2. Referenced Documents

practice does not change or create any additional regulatory

2.1 ASTM Standards:

requirements nor does it authorize changes in or permit

F2490 Guide for Aircraft Electrical Load and Power Source

deviations from existing regulatory requirements.

Capacity Analysis

1.2 Applicability—The guidance provided in this practice is

F2639 Practice for Design, Alteration, and Certification of

directed to air carriers, air operators, maintenance providers,

Aircraft Electrical Wiring Systems

repair stations, and anyone performing maintenance or repairs.

2.2 ICAO Standard:

1.3 Protections and Warnings—This practice provides guid-

ICAOAnnex 5 Units of Measurement to Be Used inAir and

ance to minimize contamination and accidental damage to

Ground Operations

electrical wiring interconnection systems (EWIS) while work-

2.3 JEDEC Standard:

ing on aircraft.

EIA 471 Symbol and Label for Electrostatic Sensitive De-

vices

1.4 “Protect and Clean As You Go” Philosophy—This

philosophy is applied to aircraft wiring through inclusion in

2.4 NEMA Standard:

operators’maintenanceandtrainingprograms.Thisphilosophy WC 27500 Standards for Aerospace and Industrial Electric

stresses the importance of protective measures when working

Cable

on or around wire bundles and connectors. It stresses how

2.5 RTCA Standard:

important it is to protect EWIS during structural repairs, (STC)

DO-160C Environmental Conditions and Test Procedures

installations, or other alterations by ensuring that metal

for Airborne Equipment

shavings, debris, and contamination resulting from such work

2.6 SAE Standards:

are removed.

AS4372 Performance Requirements for Wire, Electric, Insu-

lated Copper or Copper Alloy

1.5 Units—The values stated in inch-pound units are to be

regarded as standard. The values given in parentheses are AS4373 Test Methods for Insulated Electric Wire

AS21919 Clamp, Loop Type, Cushioned Support

mathematical conversions to SI units that are provided for

information only and are not considered standard. AS22759 Wire, Electrical, Fluoropolymer-Insulated, Copper

NOTE 1—When SI units are required, refer to Annex 5 of ICAO. or Copper Alloy

AS50881 Wiring Aerospace Vehicle

1.6 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

priate safety, health, and environmental practices and deter-

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

mine the applicability of regulatory limitations prior to use.

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

1.7 This international standard was developed in accor-

Available from International Civil Aviation Organization (ICAO), Customer

dance with internationally recognized principles on standard-

Services Unit, 999 Robert-Bourassa Boulevard, Montréal, Québec, H3C 5H7,

ization established in the Decision on Principles for the

Canada, https://www.icao.int.

Available from the JEDEC Solid State Technology Association, 3103 N. 10th

St., Suite 240-S, Arlington, VA 22201-2107, https://www.jedec.org/.

1 5

This practice is under the jurisdiction of ASTM Committee F39 on Aircraft Available from National Electrical Manufacturers Association (NEMA), 1300

Systems and is the direct responsibility of Subcommittee F39.02 on Inspection, N. 17th St., Suite 900, Arlington, VA 22209, http://www.nema.org.

Alteration, Maintenance, and Repair. Available from RTCA, Inc., 1150 18th NW, Suite 910, Washington, DC 20036,

Current edition approved June 1, 2019. Published June 2019. Originally https://www.rtca.org.

approved in 2009. Last previous edition approved in 2014 as F2799–14. DOI: Available from Society of Automotive Engineers (SAE), 400 Commonwealth

10.1520/F2799–14R19. Dr., Warrendale, PA 15096, https://www.sae.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F2799 − 14 (2019)

ARP1870 Aerospace Systems Electrical Bonding and 3.3.17 UV—ultraviolet

Grounding for Electromagnetic Compatibility and Safety

ARP1928 TorqueRecommendationsforAttachingElectrical

4. Significance and Use

Wiring Devices to Terminal Boards or Blocks, Studs,

4.1 This practice is intended to be used as a standard wiring

Posts, etc.

practice for aircraft when not contrary to standards published

2.7 Federal Standards:

by the aircraft original equipment manufacturer (OEM) or

Advisory Circular 20-53A Protection of Aircraft Fuel Sys-

regulations. This practice is intended to be used for mainte-

tems against Fuel Vapor Ignition due to Lightning

nance and preventive maintenance of electrical wiring inter-

MIL-C-22520/2C Crimping Tools, Terminal, Hand, Wire

connection systems (EWIS).

Termination

4.2 This practice is not intended to supersede or replace any

MIL-S-8802 Sealing Compound, Temperature-Resistant, In-

government specification or specific manufacturer’s instruc-

tegral Fuel Tanks and Fuel Cell Cavities, High Adhesion

tions regarding EWIS maintenance or repair.

MIL-T-7928 Terminal, Lug Splices, Conductors, Crimp

Style, Copper

5. Maintenance

MIL-T-43435 Tape, Lacing and Tying

MS17821 Specification for Cable and Marker Color Code

5.1 Electrical Systems:

Numbers

5.1.1 Maintenance:

MS17822 Specification for Cable and Marker Color Code

5.1.1.1 Scheduled and unscheduled maintenance activities,

Numbers

if done improperly, may contribute to long-term problems and

NAVAIR 01-1A-505 Installation Practices—Aircraft Elec-

degradation of wiring. Certain repairs may have limited dura-

tric and Electronic Wiring

bility and shall be evaluated to ascertain if rework is necessary.

Repairs that conform to manufacturers’recommended mainte-

3. Terminology

nance practices are generally considered permanent and should

3.1 Definitions:

not require rework. Care shall be taken to prevent undue

3.1.1 maintenance, n—inspection, overhaul, repair,

collateral damage to EWIS while performing maintenance on

preservation, and the replacement of parts but excludes pre-

other systems. Metal shavings and debris have been discovered

ventive maintenance.

on wire bundles after maintenance, repairs, or modifications

3.2 Definitions of Terms Specific to This Standard:

have been performed. Care shall be taken to protect wire

3.2.1 electrical wiring interconnection system (EWIS),

bundles and connectors during maintenance and repair. Work

n—as used in this practice, any wire, wiring device, or

areas should be cleaned while the work progresses to ensure

combination of these, including termination devices, installed

that all shavings and debris are removed.The work area should

in any area of the aircraft for the purpose of transmitting

be thoroughly cleaned after work is complete, and the area

electrical energy between two or more intended termination

shall be inspected after the final cleaning. Maintenance,

points.

repairs, and alterations should be performed using the most

effective methods available to protect the surrounding EWIS.

3.3 Acronyms:

Since wire splices are more susceptible to degradation, arcing,

3.3.1 AC—alternating current

and overheating, the recommended method of repairing a wire

3.3.2 CFC—carbon fiber composite

is with an environmentally sealed splice. (Warning—For

3.3.3 DC—direct current

personal safety and to avoid the possibility of fire, turn off all

3.3.4 EDS—electronic data system electrical power before starting an inspection of the aircraft

electrical system or performing maintenance.)

3.3.5 EMI—electromagnetic interference

5.1.1.2 Repair of any system component that fails an elec-

3.3.6 ESD—electrostatic discharge

trical measurement test shall conform to manufacturer’s in-

3.3.7 EWIS—electrical wiring interconnection system

structions and, in lieu of manufacturer’s manuals, Practice

3.3.8 ICAO—International Civil Aviation Organization

F2639 or appropriate regulatory guidance materials.

5.1.1.3 Wire bundles should be routed in accessible areas

3.3.9 NiCad—nickel cadmium

that are protected from damage from personnel, cargo, and

3.3.10 OEM—original equipment manufacturer

maintenance activity.They should not be routed in areas where

3.3.11 PC—personal computer

they are likely to be used as handholds or as support for

3.3.12 PTFE—polytetrafluoroethylene

personal equipment or where they could become damaged

during removal of aircraft equipment.

3.3.13 RF—radio frequency

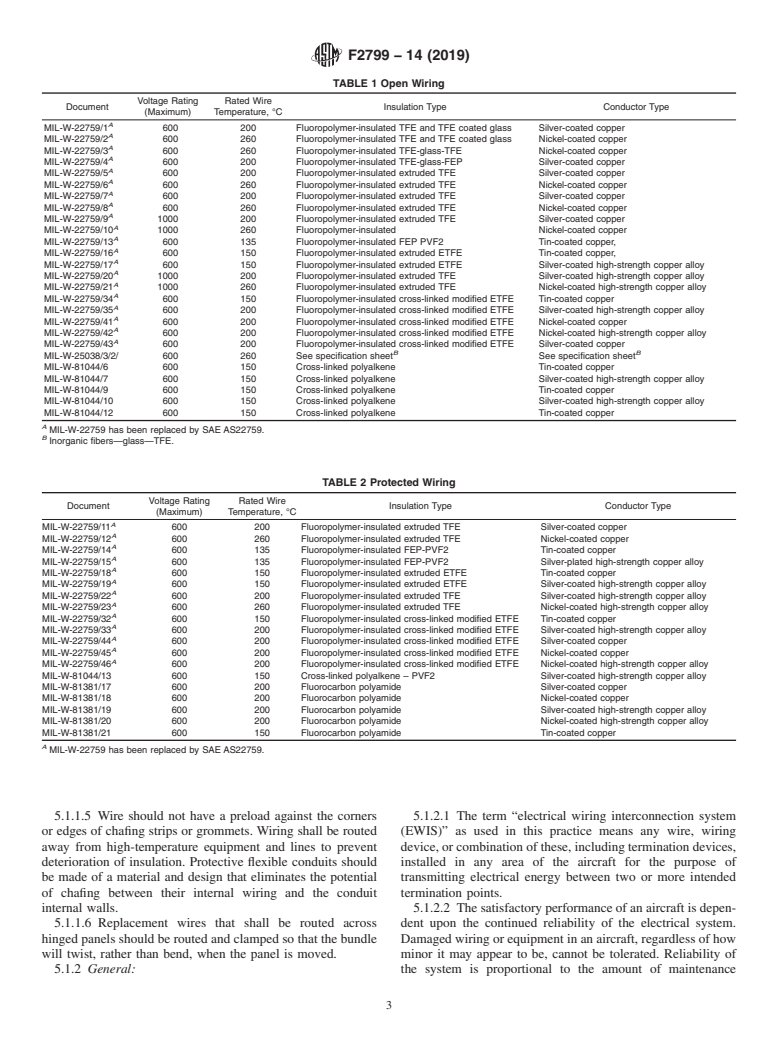

5.1.1.4 Replacement wires (see Tables 1 and 2) should be

3.3.14 SOC—state of charge

clamped so that contact with equipment and structure is

3.3.15 STC—supplemental-type certificate

avoided. Where this cannot be accomplished, extra protection

3.3.16 SWAMP—severe wind and moisture problem

in the form of grommets, chafe strips, and so forth, should be

provided. Protective grommets shall be used wherever wires

cannot be clamped in a way that ensures at least a ⁄8 in. (9.5

Available from U.S. Government Publishing Office, 732 N. Capitol St., NW,

Washington, DC 20401, http://www.gpo.gov. mm) clearance from structure at penetrations.

F2799 − 14 (2019)

TABLE 1 Open Wiring

Voltage Rating Rated Wire

Document Insulation Type Conductor Type

(Maximum) Temperature, °C

A

MIL-W-22759/1 600 200 Fluoropolymer-insulated TFE and TFE coated glass Silver-coated copper

A

MIL-W-22759/2 600 260 Fluoropolymer-insulated TFE and TFE coated glass Nickel-coated copper

A

MIL-W-22759/3 600 260 Fluoropolymer-insulated TFE-glass-TFE Nickel-coated copper

A

MIL-W-22759/4 600 200 Fluoropolymer-insulated TFE-glass-FEP Silver-coated copper

A

MIL-W-22759/5 600 200 Fluoropolymer-insulated extruded TFE Silver-coated copper

A

MIL-W-22759/6 600 260 Fluoropolymer-insulated extruded TFE Nickel-coated copper

A

MIL-W-22759/7 600 200 Fluoropolymer-insulated extruded TFE Silver-coated copper

A

MIL-W-22759/8 600 260 Fluoropolymer-insulated extruded TFE Nickel-coated copper

A

MIL-W-22759/9 1000 200 Fluoropolymer-insulated extruded TFE Silver-coated copper

A

MIL-W-22759/10 1000 260 Fluoropolymer-insulated Nickel-coated copper

A

MIL-W-22759/13 600 135 Fluoropolymer-insulated FEP PVF2 Tin-coated copper,

A

MIL-W-22759/16 600 150 Fluoropolymer-insulated extruded ETFE Tin-coated copper,

A

MIL-W-22759/17 600 150 Fluoropolymer-insulated extruded ETFE Silver-coated high-strength copper alloy

A

MIL-W-22759/20 1000 200 Fluoropolymer-insulated extruded TFE Silver-coated high-strength copper alloy

A

MIL-W-22759/21 1000 260 Fluoropolymer-insulated extruded TFE Nickel-coated high-strength copper alloy

A

MIL-W-22759/34 600 150 Fluoropolymer-insulated cross-linked modified ETFE Tin-coated copper

A

MIL-W-22759/35 600 200 Fluoropolymer-insulated cross-linked modified ETFE Silver-coated high-strength copper alloy

A

MIL-W-22759/41 600 200 Fluoropolymer-insulated cross-linked modified ETFE Nickel-coated copper

A

MIL-W-22759/42 600 200 Fluoropolymer-insulated cross-linked modified ETFE Nickel-coated high-strength copper alloy

A

MIL-W-22759/43 600 200 Fluoropolymer-insulated cross-linked modified ETFE Silver-coated copper

B B

MIL-W-25038/3/2/ 600 260 See specification sheet See specification sheet

MIL-W-81044/6 600 150 Cross-linked polyalkene Tin-coated copper

MIL-W-81044/7 600 150 Cross-linked polyalkene Silver-coated high-strength copper alloy

MIL-W-81044/9 600 150 Cross-linked polyalkene Tin-coated copper

MIL-W-81044/10 600 150 Cross-linked polyalkene Silver-coated high-strength copper alloy

MIL-W-81044/12 600 150 Cross-linked polyalkene Tin-coated copper

A

MIL-W-22759 has been replaced by SAE AS22759.

B

Inorganic fibers—glass—TFE.

TABLE 2 Protected Wiring

Voltage Rating Rated Wire

Document Insulation Type Conductor Type

(Maximum) Temperature, °C

A

MIL-W-22759/11 600 200 Fluoropolymer-insulated extruded TFE Silver-coated copper

A

MIL-W-22759/12 600 260 Fluoropolymer-insulated extruded TFE Nickel-coated copper

A

MIL-W-22759/14 600 135 Fluoropolymer-insulated FEP-PVF2 Tin-coated copper

A

MIL-W-22759/15 600 135 Fluoropolymer-insulated FEP-PVF2 Silver-plated high-strength copper alloy

A

MIL-W-22759/18 600 150 Fluoropolymer-insulated extruded ETFE Tin-coated copper

A

MIL-W-22759/19 600 150 Fluoropolymer-insulated extruded ETFE Silver-coated high-strength copper alloy

A

MIL-W-22759/22 600 200 Fluoropolymer-insulated extruded TFE Silver-coated high-strength copper alloy

A

MIL-W-22759/23 600 260 Fluoropolymer-insulated extruded TFE Nickel-coated high-strength copper alloy

A

MIL-W-22759/32 600 150 Fluoropolymer-insulated cross-linked modified ETFE Tin-coated copper

A

MIL-W-22759/33 600 200 Fluoropolymer-insulated cross-linked modified ETFE Silver-coated high-strength copper alloy

A

MIL-W-22759/44 600 200 Fluoropolymer-insulated cross-linked modified ETFE Silver-coated copper

A

MIL-W-22759/45 600 200 Fluoropolymer-insulated cross-linked modified ETFE Nickel-coated copper

A

MIL-W-22759/46 600 200 Fluoropolymer-insulated cross-linked modified ETFE Nickel-coated high-strength copper alloy

MIL-W-81044/13 600 150 Cross-linked polyalkene – PVF2 Silver-coated high-strength copper alloy

MIL-W-81381/17 600 200 Fluorocarbon polyamide Silver-coated copper

MIL-W-81381/18 600 200 Fluorocarbon polyamide Nickel-coated copper

MIL-W-81381/19 600 200 Fluorocarbon polyamide Silver-coated high-strength copper alloy

MIL-W-81381/20 600 200 Fluorocarbon polyamide Nickel-coated high-strength copper alloy

MIL-W-81381/21 600 150 Fluorocarbon polyamide Tin-coated copper

A

MIL-W-22759 has been replaced by SAE AS22759.

5.1.1.5 Wire should not have a preload against the corners 5.1.2.1 The term “electrical wiring interconnection system

or edges of chafing strips or grommets. Wiring shall be routed (EWIS)” as used in this practice means any wire, wi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.