ASTM B635-00(2015)

(Specification)Standard Specification for Coatings of Cadmium-Tin Mechanically Deposited

Standard Specification for Coatings of Cadmium-Tin Mechanically Deposited

ABSTRACT

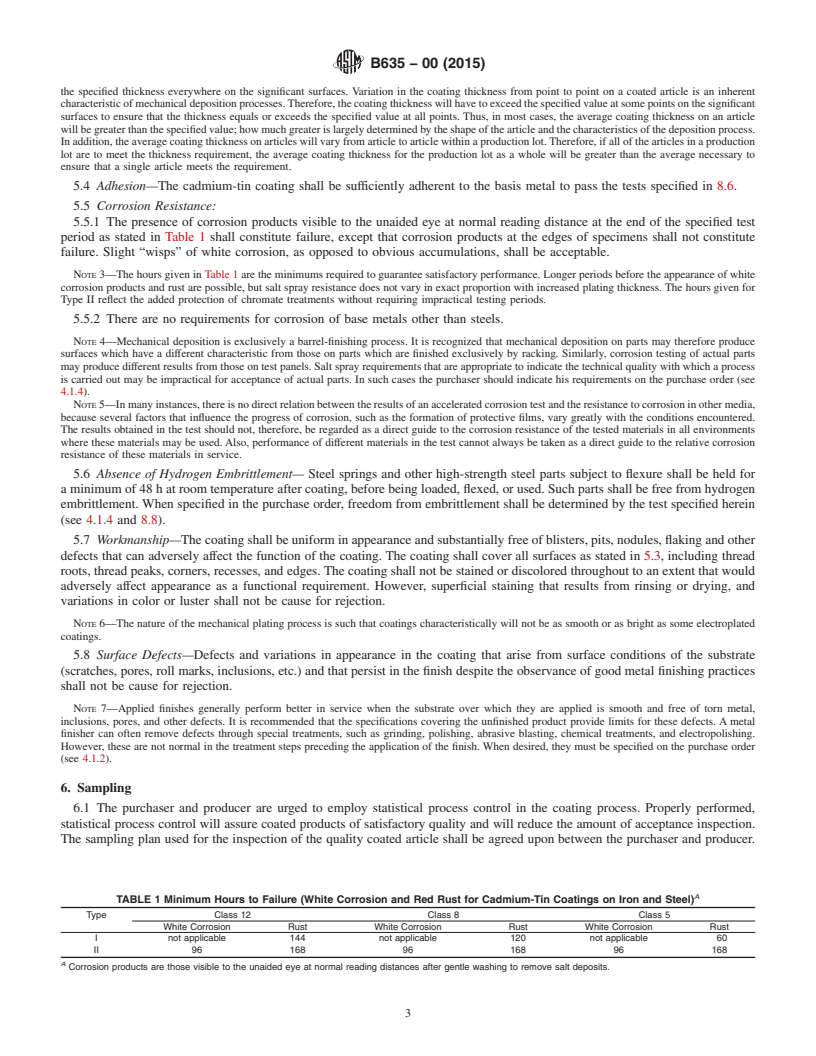

This specification covers the requirements for a coating that is a mixture of cadmium and tin mechanically deposited on metal products. The coating shall be 45 to 75 mass % cadmium, the remainder tin. All steel parts that have ultimate tensile strength of 1000 MPa and above and that contain tensile stresses caused by machining, grinding, straightening, or cold forming operation shall be given a stress relief heat treatment prior to cleaning and metal deposition. High-strength steels that have heavy oxide or scale shall be cleaned before application of the coating in accordance with guide B 242. Chromate treatment for Type II shall be done in a solution containing hexavalent chromium. The cadmium-tin coating shall be sufficiently adherent to the basis metal to pass the prescribed testing. Steel springs and other high-strength steel parts shall be free from hydrogen embrittlement. The coating shall be uniform in appearance and substantially free of blisters, pits, nodules, flaking and other defects that can adversely affect the function of the coating. Chemical composition of the cadmium-tin coating shall be determined when required on the purchase order by procedures given in methods E 87 or test methods E 396. The thickness of the coating shall be determined by the microscopical method, the magnetic method, or the beta backscatter method as applicable. Chromate conversion coatings of cadmium-tin both have an essentially silvery-white appearance. Adhesion of the cadmium-tin deposit to the basis metal shall be tested in a manner that is consistent with the service requirements of the coated article. Coated parts to be tested for the absence of embrittlement from cleaning shall be tested for brittle failure in accordance with a suitable method.

SCOPE

1.1 This specification covers the requirements for a coating that is a mixture of cadmium and tin mechanically deposited on metal products. The coating is provided in various thicknesses up to and including 12 μm.

1.2 Mechanical deposition greatly reduces the risk of hydrogen embrittlement and is suitable for coating bores and recesses in many parts that cannot be conveniently plated electrolytically. (See Appendix X1.)

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazards statements, see Section 7.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B635 − 00 (Reapproved 2015)

Standard Specification for

1

Coatings of Cadmium-Tin Mechanically Deposited

This standard is issued under the fixed designation B635; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope by the Magnetic Method: Nonmagnetic Coatings on

Magnetic Basis Metals

1.1 This specification covers the requirements for a coating

B567 Test Method for Measurement of Coating Thickness

that is a mixture of cadmium and tin mechanically deposited on

by the Beta Backscatter Method

metal products. The coating is provided in various thicknesses

B571 Practice for Qualitative Adhesion Testing of Metallic

up to and including 12 µm.

Coatings

1.2 Mechanical deposition greatly reduces the risk of hy-

B602 Test Method for Attribute Sampling of Metallic and

drogen embrittlement and is suitable for coating bores and

Inorganic Coatings

recesses in many parts that cannot be conveniently plated

B697 Guide for Selection of Sampling Plans for Inspection

electrolytically. (See Appendix X1.)

of Electrodeposited Metallic and Inorganic Coatings

B762 Test Method of Variables Sampling of Metallic and

1.3 The values stated in SI units are to be regarded as

standard. No other units of measurement are included in this Inorganic Coatings

E87 Methods for Chemical Analysis of Lead, Tin, Antimony,

standard.

and Their Alloys (Photometric Methods) (Withdrawn

1.4 This standard does not purport to address all of the

3

1983)

safety concerns, if any, associated with its use. It is the

E396 Test Methods for Chemical Analysis of Cadmium

responsibility of the user of this standard to establish appro-

F1470 Practice for Fastener Sampling for Specified Me-

priate safety and health practices and determine the applica-

chanical Properties and Performance Inspection

bility of regulatory limitations prior to use. For specific hazards

statements, see Section 7. 2.2 U.S. Federal Standard:

FED-STD-141 Paint, Varnish, Lacquer, and Related Mate-

4

2. Referenced Documents

rials; Methods of Inspection, Sampling and Testing

2

2.1 ASTM Standards:

2.3 U.S. Military Standard:

B117 Practice for Operating Salt Spray (Fog) Apparatus

MIL-L-7808J Lubricating Oil, Aircraft Turbine Engine, Syn-

4

B183 Practice for Preparation of Low-Carbon Steel for

thetic Base

Electroplating

B201 Practice for Testing Chromate Coatings on Zinc and

3. Classification

Cadmium Surfaces

3.1 Classes—Cadmium-tin coatings are classified on the

B242 Guide for Preparation of High-Carbon Steel for Elec-

basis of thickness, as follows:

troplating

Class Minimum Thickness, µm

B322 Guide for Cleaning Metals Prior to Electroplating

12 12

B487 Test Method for Measurement of Metal and Oxide

8 8

5 5

Coating Thickness by Microscopical Examination of

Cross Section

3.2 Types—Cadmium-tin coatings are identified by types on

B499 Test Method for Measurement of Coating Thicknesses

the basis of supplementary treatment required, as follows:

3.2.1 Type I—As coated, without supplementary chromate

treatment (see X1.1).

1

This specification is under the jurisdiction of ASTM Committee B08 on

3.2.2 Type II—With supplementary chromate treatment (see

Metallic and Inorganic Coatings and is the direct responsibility of Subcommittee

X1.2).

B08.06 on Soft Metals.

Current edition approved March 1, 2015. Published April 2015. Originally

approved in 1978. Last previous edition approved in 2009 as B635 – 00(2009). DOI:

10.1520/B0635-00R15.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or The last approved version of this historical standard is referenced on

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM www.astm.org.

4

Standards volume information, refer to the standard’s Document Summary page on Available from Standardization Documents Order Desk, Bldg. 4 Section D, 700

the ASTM website. Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B635 − 00 (2015)

4. Ordering Information used to ensure conformance to the salt spray corrosion resistant

requirements or to enhance the test results of the lead acetate

4.1 To make the application of this specification complete,

spot test (8.5.2).

the purchaser needs to supply the following information to the

supplier in the purchase order or other governing document:

5.3 Thickness:

4.1.1 Class, including a maximum thickness, if appropriate,

5.3.1 The thickness of the coating everywhere on the

type, and need for supplemental l

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: B635 − 00 (Reapproved 2009) B635 − 00 (Reapproved 2015)

Standard Specification for

1

Coatings of Cadmium-Tin Mechanically Deposited

This standard is issued under the fixed designation B635; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification covers the requirements for a coating that is a mixture of cadmium and tin mechanically deposited on

metal products. The coating is provided in various thicknesses up to and including 12 μm.

1.2 Mechanical deposition greatly reduces the risk of hydrogen embrittlement and is suitable for coating bores and recesses in

many parts that cannot be conveniently plated electrolytically. (See Appendix X1.)

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. For specific hazards statements, see Section 7.

2. Referenced Documents

2

2.1 ASTM Standards:

B117 Practice for Operating Salt Spray (Fog) Apparatus

B183 Practice for Preparation of Low-Carbon Steel for Electroplating

B201 Practice for Testing Chromate Coatings on Zinc and Cadmium Surfaces

B242 Guide for Preparation of High-Carbon Steel for Electroplating

B322 Guide for Cleaning Metals Prior to Electroplating

B487 Test Method for Measurement of Metal and Oxide Coating Thickness by Microscopical Examination of Cross Section

B499 Test Method for Measurement of Coating Thicknesses by the Magnetic Method: Nonmagnetic Coatings on Magnetic Basis

Metals

B567 Test Method for Measurement of Coating Thickness by the Beta Backscatter Method

B571 Practice for Qualitative Adhesion Testing of Metallic Coatings

B602 Test Method for Attribute Sampling of Metallic and Inorganic Coatings

B697 Guide for Selection of Sampling Plans for Inspection of Electrodeposited Metallic and Inorganic Coatings

B762 Test Method of Variables Sampling of Metallic and Inorganic Coatings

3

E87 Methods for Chemical Analysis of Lead, Tin, Antimony, and Their Alloys (Photometric Methods) (Withdrawn 1983)

E396 Test Methods for Chemical Analysis of Cadmium

F1470 Practice for Fastener Sampling for Specified Mechanical Properties and Performance Inspection

2.2 U.S. Federal Standard:

4

FED-STD-141 Paint, Varnish, Lacquer, and Related Materials; Methods of Inspection, Sampling and Testing

2.3 U.S. Military Standard:

4

MIL-L-7808J Lubricating Oil, Aircraft Turbine Engine, Synthetic Base

1

This specification is under the jurisdiction of ASTM Committee B08 on Metallic and Inorganic Coatings and is the direct responsibility of Subcommittee B08.06 on Soft

Metals.

Current edition approved Sept. 1, 2009March 1, 2015. Published November 2009April 2015. Originally approved in 1978. Last previous edition approved in 20042009

ε1

as B635 – 00(2004)(2009). . DOI: 10.1520/B0635-00R09.10.1520/B0635-00R15.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

The last approved version of this historical standard is referenced on www.astm.org.

4

Available from Standardization Documents Order Desk, Bldg. 4 Section D, 700 Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B635 − 00 (2015)

3. Classification

3.1 Classes—Cadmium-tin coatings are classified on the basis of thickness, as follows:

Class Minimum Thickness, μm

12 12

8 8

5 5

3.2 Types—Cadmium-tin coatings are identified by types on the basis of supplementary treatment required, as follows:

3.2.1 Type I—As coated, without supplementary chromate treatment (see X1.1).

3.2.2 Type II—With supplementary chromate treatment (see X1.2).

4. Ordering Information

4.1 To make the application of this specification complete, the purchaser needs to supply the following information to the

supplier in the purchase

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.