ASTM D6162-00a(2008)

(Specification)Standard Specification for Styrene Butadiene Styrene (SBS) Modified Bituminous Sheet Materials Using a Combination of Polyester and Glass Fiber Reinforcements

Standard Specification for Styrene Butadiene Styrene (SBS) Modified Bituminous Sheet Materials Using a Combination of Polyester and Glass Fiber Reinforcements

ABSTRACT

This specification covers prefabricated bituminous sheet materials reinforced with a combination of polyester fabric and glass fiber, with or without granules, modified by styrene butadiene styrene (SBS) thermoplastic elastomer, and are intended for use in the fabrication of multiple ply roofing and waterproofing membranes. This specification is intended as a material specification only. Hence, issues regarding the suitability of the specific roof constructions or application techniques are beyond this scope. Also not addressed here are in-place roof system design criteria such as fire resistance, field strength, impact/puncture resistance, material compatibility, uplift resistance, and others. Materials shall conform to specified values of the following dimensional and physical properties: total and bottom coating thickness; net mass per unit area; peak load before and after heat conditioning; elongation at peak load; ultimate elongation; tear strength; low temperature flexibility; dimensional stability; compound stability; and granule embedment.

SCOPE

1.1 This specification covers prefabricated modified bituminous sheet materials reinforced with a combination of polyester fabric and glass fiber, with or without granules, which use styrene butadiene styrene (SBS) thermoplastic elastomer as the primary modifier and are intended for use in the fabrication of multiple ply roofing and waterproofing membranes.

1.2 This specification is intended as a material specification only. Issues regarding the suitability of the specific roof constructions or application techniques are beyond this scope.

1.3 The specified tests and property limits used to characterize the sheet materials are intended to establish minimum properties. In-place roof system design criteria such as fire resistance, field strength, impact/puncture resistance, material compatibility, uplift resistance, and others, are factors beyond the scope of this material specification.

1.4 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D6162 −00a(Reapproved 2008)

Standard Specification for

Styrene Butadiene Styrene (SBS) Modified Bituminous

Sheet Materials Using a Combination of Polyester and Glass

Fiber Reinforcements

This standard is issued under the fixed designation D6162; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 4. Classifications

1.1 Thisspecificationcoversprefabricatedmodifiedbitumi- 4.1 Modified bituminous sheet materials reinforced with a

noussheetmaterialsreinforcedwithacombinationofpolyester combination of polyester fabric and glass fiber reinforcement,

fabric and glass fiber, with or without granules, which use Type I, Type II and Type III are covered by this specification.

styrenebutadienestyrene(SBS)thermoplasticelastomerasthe

4.2 The following grades are used to describe the material

primary modifier and are intended for use in the fabrication of

surfacing:

multiple ply roofing and waterproofing membranes.

4.2.1 Grade G—Granule surfaced.

1.2 This specification is intended as a material specification 4.2.2 Grade S—Smooth surfaced.

only. Issues regarding the suitability of the specific roof

5. Material and Manufacture

constructions or application techniques are beyond this scope.

5.1 In the process of manufacture, the reinforcement is

1.3 The specified tests and property limits used to charac-

saturated with asphalt or modified asphalt and is impregnated

terize the sheet materials are intended to establish minimum

and coated on both sides with an SBS modified bituminous

properties. In-place roof system design criteria such as fire

coating. The SBS modified bituminous coating shall be per-

resistance, field strength, impact/puncture resistance, material

mitted to be compounded with a mineral stabilizer.

compatibility, uplift resistance, and others, are factors beyond

5.2 The Grade G sheet is surfaced on the weather side with

the scope of this material specification.

mineralgranules,exceptforanyselvage.Topreventstickingin

1.4 The values stated in SI units are to be regarded as the

the roll, the reverse side and any selvage shall be permitted to

standard. The values given in parentheses are for information

be covered with a mineral or any other surfacing that will not

only.

interfere with adhesion or bonding of the lap during applica-

tion.

2. Referenced Documents

5.3 Sheet material intended for application by heat welding

2.1 ASTM Standards:

(torching)shallmeettheminimumbottomcoatingrequirement

D1079Terminology Relating to Roofing and Waterproofing

found in Table 1.

D5147Test Methods for Sampling and Testing Modified

Bituminous Sheet Material

6. Physical Properties

6.1 The sheet shall conform to the minimum physical

3. Terminology

properties prescribed in Table 2.

3.1 Definitions—For definitions of terms used in this

6.2 The finished product shall not crack nor be so sticky as

specification, refer to Terminology D1079.

to cause tearing or other material damage upon being unrolled

at any product temperature between 4 and 60°C (40 and

140°F).

This specification is under the jurisdiction of ASTM Committee D08 on

7. Dimensions, Mass, and Permissible Variations

RoofingandWaterproofingandisthedirectresponsibilityofSubcommitteeD08.04

on Felts and Fabrics.

7.1 The finished product shall conform to the following

Current edition approved Dec. 1, 2008. Published December 2008. Originally

´1

dimensions and variations:

approved in 1997. Last previous edition approved in 2000 as D6162–00a . DOI:

10.1520/D6162-00AR08.

7.1.1 The width of the roll shall be as agreed between the

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

purchaser and the seller and shall not vary more than 1%.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

7.1.2 The area of the roll shall be no less than as agreed

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. between the purchaser and the seller.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D6162−00a (2008)

TABLE 1 Dimensions and Masses of SBS Modified Bituminous Sheet Materials Using a Combination of Polyester and Glass Fiber

Reinforcements

Description Type I Type II Type III

Thickness, min, mm (mils),

Grade S 1.8 (70) 2.0 (80) 2.0 (80)

Grade G 2.8 (110) 3.3 (130) 3.5 (135)

Net mass per unit area, min.,

2 2

g/m , (lbs/100 ft )

Grade S 2197 (45) 2441 (50) 2685 (55)

Grade G 2929 (60) 3661 (75) 4150 (85)

Bottom coating thickness, heat welding

application products, min, mm (mils)

Grade S 1.0 (40) 1.0 (40) 1.0 (40)

Grade G 1.0 (40) 1.0 (40) 1.0 (40)

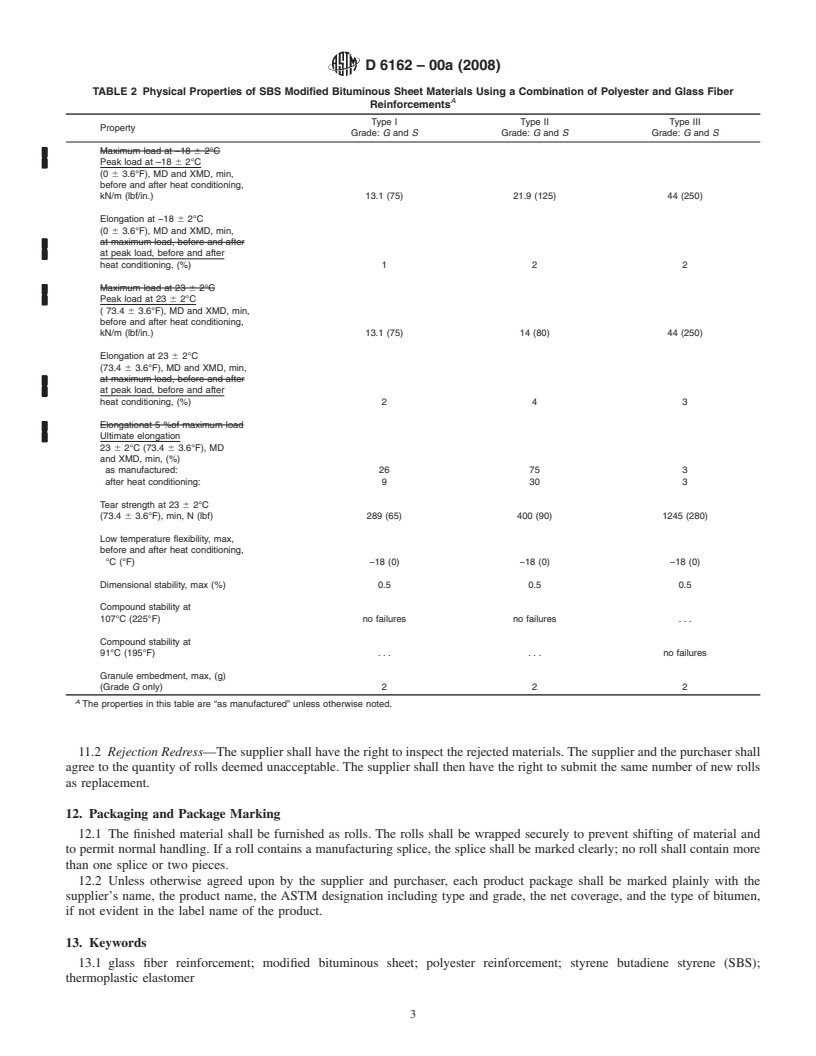

TABLE 2 Physical Properties of SBS Modified Bituminous Sheet Materials Using a Combination of Polyester and Glass Fiber

A

Reinforcements

Type I Type II Type III

Property

Grade: G and S Grade: G and S Grade: G and S

Peak load at –18 ± 2°C

(0 ± 3.6°F), MD and XMD, min,

before and after heat conditioning,

kN/m (lbf/in.) 13.1 (75) 21.9 (125) 44 (250)

Elongation at −18 ± 2°C

(0 ± 3.6°F), MD and XMD, min,

at peak

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation:D6162–00a Designation: D 6162 – 00a (Reapproved 2008)

Standard Specification for

Styrene Butadiene Styrene (SBS) Modified Bituminous

Sheet Materials Using a Combination of Polyester and Glass

Fiber Reinforcements

This standard is issued under the fixed designation D6162; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

´ NOTE—Section 3, subsection 9.2, and Table2 were editorially corrected in March 2008.

1. Scope

1.1 This specification covers prefabricated modified bituminous sheet materials reinforced with a combination of polyester

fabricandglassfiber,withorwithoutgranules,whichusestyrenebutadienestyrene(SBS)thermoplasticelastomerastheprimary

modifier and are intended for use in the fabrication of multiple ply roofing and waterproofing membranes.

1.2 This specification is intended as a material specification only. Issues regarding the suitability of the specific roof

constructions or application techniques are beyond this scope.

1.3 Thespecifiedtestsandpropertylimitsusedtocharacterizethesheetmaterialsareintendedtoestablishminimumproperties.

In-place roof system design criteria such as fire resistance, field strength, impact/puncture resistance, material compatibility, uplift

resistance, and others, are factors beyond the scope of this material specification.

1.4 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

2. Referenced Documents

2.1 ASTM Standards:

D1079 Terminology Relating to Roofing and Waterproofing

D5147 Test Methods for Sampling and Testing Modified Bituminous Sheet Material

3. Terminology

3.1 Definitions— For definitions of terms used in this specification, refer to Terminology D1079.

4. Classifications

4.1 Modified bituminous sheet materials reinforced with a combination of polyester fabric and glass fiber reinforcement, Type

I, Type II and Type III are covered by this specification.

4.2 The following grades are used to describe the material surfacing:

4.2.1 Grade G—Granule surfaced.

4.2.2 Grade S—Smooth surfaced.

5. Material and Manufacture

5.1 Intheprocessofmanufacture,thereinforcementissaturatedwithasphaltormodifiedasphaltandisimpregnatedandcoated

on both sides with an SBS modified bituminous coating. The SBS modified bituminous coating shall be permitted to be

compounded with a mineral stabilizer.

5.2 The Grade G sheet is surfaced on the weather side with mineral granules, except for any selvage.To prevent sticking in the

roll, the reverse side and any selvage shall be permitted to be covered with a mineral or any other surfacing that will not interfere

with adhesion or bonding of the lap during application.

5.3 Sheet material intended for application by heat welding (torching) shall meet the minimum bottom coating requirement

found in Table 1.

This specification is under the jurisdiction of ASTM Committee D08 on Roofing and Waterproofing and is the direct responsibility of Subcommittee D08.04 on Felts

and Fabrics.

Current edition approved June 10, 2000. Published August 2000. Originally published in 1997. Last previous edition D 6162–00.

´1

Current edition approved Dec. 1, 2008. Published December 2008. Originally approved in 1997. Last previous edition approved in 2000 as D6162–00a .

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 6162 – 00a (2008)

TABLE 1 Dimensions and Masses of SBS Modified Bituminous Sheet Materials Using a Combination of Polyester and Glass Fiber

Reinforcements

Description Type I Type II Type III

Thickness, min, mm (mils),

Grade S 1.8 (70) 2.0 (80) 2.0 (80)

Grade G 2.8 (110) 3.3 (130) 3.5 (135)

Net mass per unit area, min.,

2 2

g/m , (lbs/100 ft )

Grade S 2197 (45) 2441 (50) 2685 (55)

Grade G 2929 (60) 3661 (75) 4150 (85)

Bottom coating thickness, heat welding

application products, min, mm (mils)

Grade S 1.0 (40) 1.0 (40) 1.0 (40)

Grade G 1.0 (40) 1.0 (40) 1.0 (40)

6. Physical Properties

6.1 The sheet shall conform to the minimum physical properties prescribed in Table 2.

6.2 The finished product shall not crack nor be so sticky as to cause tearing or other material damage upon being unrolled at

any product temperature between 4 and 60°C (40 and 140°F).

7. Dimensions, Mass, and Permissible Variations

7.1 The finished product shall conform to the following dimensions and variations:

TABLE 2 Physical Properties of SBS Modified Bituminous Sheet Materials Using a Combination of Polyester and Glass Fiber

A

Reinforcements

Type I Type II Type III

Property

Grade: G and S Grade: G and S Grade: G and S

Peak load at –18 6 2°C

(0 6 3.6°F), MD and XMD, min,

before and after heat conditioning,

kN/m (lbf/in.) 13.1 (75)

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D6162–00 Designation: D 6162 – 00a (Reapproved 2008)

Standard Specification for

Styrene Butadiene Styrene (SBS) Modified Bituminous

Sheet Materials Using a Combination of Polyester and Glass

Fiber Reinforcements

This standard is issued under the fixed designation D6162; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification covers prefabricated modified bituminous sheet materials reinforced with a combination of polyester

fabricandglassfiber,withorwithoutgranules,whichusestyrenebutadienestyrene(SBS)thermoplasticelastomerastheprimary

modifier and are intended for use in the fabrication of multiple ply roofing and waterproofing membranes.

1.2 This specification is intended as a material specification only. Issues regarding the suitability of the specific roof

constructions or application techniques are beyond this scope.

1.3 Thespecifiedtestsandpropertylimitsusedtocharacterizethesheetmaterialsareintendedtoestablishminimumproperties.

In-place roof system design criteria such as fire resistance, field strength, impact/puncture resistance, material compatibility, uplift

resistance, and others, are factors beyond the scope of this material specification.

1.4 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

2. Referenced Documents

2.1 ASTM Standards:

D1079 Terminology Relating to Roofing, Waterproofing, and Bituminous Materials Terminology Relating to Roofing and

Waterproofing

D5147 TestMethodsforSamplingandTestingModifiedBituminousSheetMaterialsUsedinRoofingandWaterproofing Test

Methods for Sampling and Testing Modified Bituminous Sheet Material

3. Terminology

3.1 Definitions— For definitions of terms used in this specification, refer to Terminology D1079:

3.1.1elongation at 5% of maximum load, n—the elongation measured on the load-elongation curve at which point the load has

dropped to 5% of its maximum value. .

4. Classifications

4.1 Modified bituminous sheet materials reinforced with a combination of polyester fabric and glass fiber reinforcement, Type

I, Type II and Type III are covered by this specification.

4.2 The following grades are used to describe the material surfacing:

4.2.1 Grade G—Granule surfaced.

4.2.2 Grade S—Smooth surfaced.

5. Material and Manufacture

5.1 Intheprocessofmanufacture,thereinforcementissaturatedwithasphaltormodifiedasphaltandisimpregnatedandcoated

on both sides with an SBS modified bituminous coating. The SBS modified bituminous coating mayshall be permitted to be

compounded with a fine mineral stabilizer.

5.2 The Grade G sheet is surfaced on the weather side with mineral granules, except for any selvage.To prevent sticking in the

This specification is under the jurisdiction of ASTM Committee D-08 on Roofing, Waterproofing, and Bituminous Materials and is the direct responsibility of

Subcommittee D08.04 on Felts and Fabrics.

Current edition approved Feb. 10, 2000. Published April 2000. Originally published as D 6162–97. Last previous edition D 6162–98.

This specification is under the jurisdiction of ASTM Committee D08 on Roofing and Waterproofing and is the direct responsibility of Subcommittee D08.04 on Felts

and Fabrics.

´1

Current edition approved Dec. 1, 2008. Published December 2008. Originally approved in 1997. Last previous edition approved in 2000 as D6162–00a .

Annual Book of ASTM Standards, Vol 04.04.

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 6162 – 00a (2008)

roll, the reverse side and any selvage mayshall be permitted to be covered with finea mineral or any other surfacing that will not

interfere with adhesion or bonding of the lap during application.

5.3 Sheet material intended for application by heat welding (torching) shall meet the minimum bottom coating requirement

found in Table 1.

6. Physical Properties

6.1 The sheet shall conform to the minimum physical properties prescribed in Table 2.

6.2 The finished product shall not crack nor be so sticky as to cause tearing or other material damage upon being unrolled at

any product temperature between 4 and 60°C (40 and 140°F).

7. Dimensions, Mass, and Permissible Variations

7.1 The finished product shall conform to the following dimensions and variations:

7.1.1 The width of the roll shall be as agreed between the purchaser and the seller and shall not vary more than 1%.

7.1.2 The area of the roll shall be no less than as agreed between the purchaser and the seller.

7.1.3 The selvage width shall be within 6.4 mm (¼ in.) of the nominal selvage width and shall be not less than 76.2 mm (3 in.)

in width without a laying line and 63.5 mm (2.5 in.) in width if the sheet has a laying line. If a laying line is provided, the line

must not be less than 76.2 mm (3 in.) from the edge of the sheet.

7.2 The mass and thickness of the finished product shall be as prescribed in Table 1.

8. Workmanship, Finish and Appearance

8.1 The finished product shall be coated completely in a continuous, unbroken film and shall be free of such defects as holes,

tears, cracks, wrinkles or permanent defo

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.