ASTM B456-17

(Specification)Standard Specification for Electrodeposited Coatings of Copper Plus Nickel Plus Chromium and Nickel Plus Chromium

Standard Specification for Electrodeposited Coatings of Copper Plus Nickel Plus<brk/> Chromium and Nickel Plus Chromium

ABSTRACT

This specification establishes the requirements for several types and grades of electrodeposited copper plus nickel plus chromium and nickel plus chromium coatings on steel, copper, copper alloys, Type 300 and 400 series stainless steels, aluminum, aluminum alloys, and zinc alloys for application where both appearance and protection of the basis metal against corrosion are important. This specification does not cover plating on plastics. Each coating shall be designated a classification code, which comprises of the following numbers and symbols: service condition number, which indicates the severity of exposure for which the coating is intended; coating classification number, which contains the chemical symbol of each metallic element that comprises the basis metal, or the designated AISI number in the case of stainless steels, and their corresponding thickness; and symbols for expressing the type of coating. Products shall be sampled and inspected accordingly for visual defects, thickness, adhesion, elongation, ductility, corrosion, sulfur content, density, and discontinuities.

SCOPE

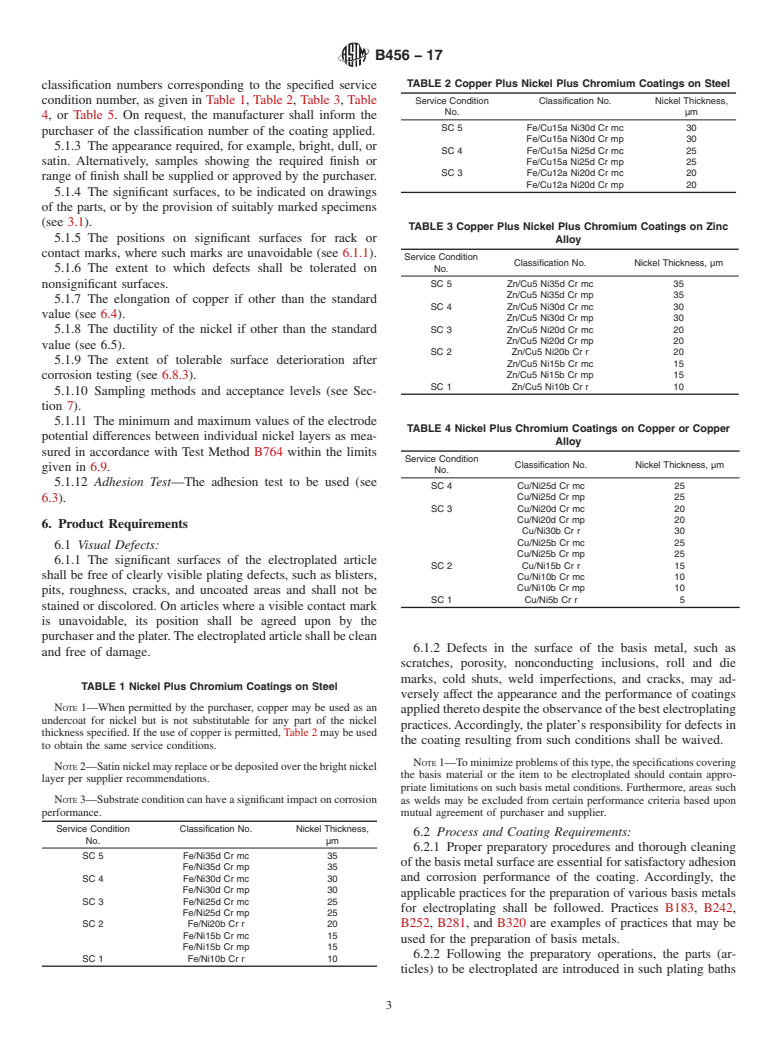

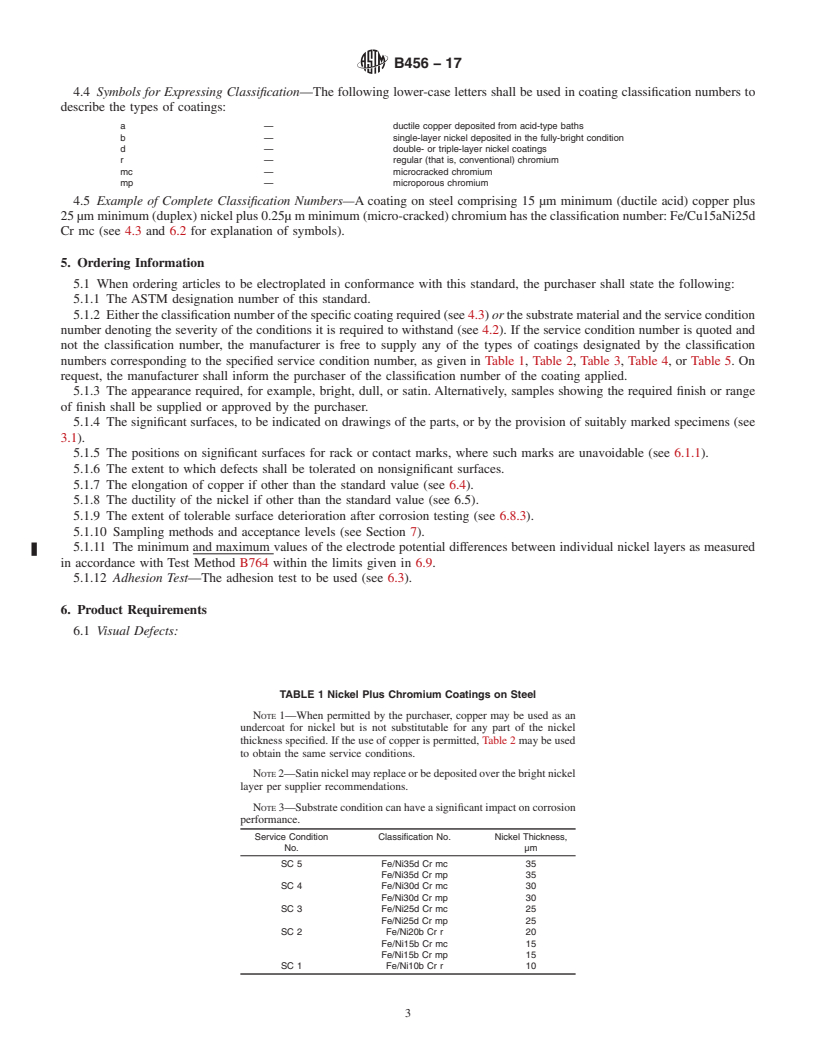

1.1 This specification covers requirements for several types and grades of electrodeposited copper plus nickel plus chromium or nickel plus chromium coatings on steel, nickel plus chromium coatings on copper and copper alloys, nickel plus chromium coatings on Type 300 and 400 series stainless steel and copper plus nickel plus chromium coatings on aluminum and its alloys and zinc alloys for applications where both appearance and protection of the basis metal against corrosion are important. Five grades of coatings are provided to correspond with the service conditions under which each is expected to provide satisfactory performance: namely, extended very severe, very severe, severe, moderate, and mild. Definitions and typical examples of these service conditions are provided in Appendix X1.

1.2 This specification does not cover the requirements for the plating on plastics, see Specification B604.

1.3 The following hazards caveat pertains only to the test methods portions, Appendix X2, Appendix X3, Appendix X4, and Appendix X5 of this specification: This standard does not purport to address all of safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:B456 −17

Standard Specification for

Electrodeposited Coatings of Copper Plus Nickel Plus

1

Chromium and Nickel Plus Chromium

This standard is issued under the fixed designation B456; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope 2. Referenced Documents

2

2.1 ASTM Standards:

1.1 This specification covers requirements for several types

B183Practice for Preparation of Low-Carbon Steel for

and grades of electrodeposited copper plus nickel plus chro-

Electroplating

mium or nickel plus chromium coatings on steel, nickel plus

B242Guide for Preparation of High-Carbon Steel for Elec-

chromium coatings on copper and copper alloys, nickel plus

troplating

chromium coatings on Type 300 and 400 series stainless steel

B252Guide for Preparation of Zinc Alloy Die Castings for

and copper plus nickel plus chromium coatings on aluminum

Electroplating and Conversion Coatings

and its alloys and zinc alloys for applications where both

B253Guide for Preparation of Aluminum Alloys for Elec-

appearance and protection of the basis metal against corrosion

troplating

are important. Five grades of coatings are provided to corre-

B254Practice for Preparation of and Electroplating on

spondwiththeserviceconditionsunderwhicheachisexpected

Stainless Steel

to provide satisfactory performance: namely, extended very

B281Practice for Preparation of Copper and Copper-Base

severe, very severe, severe, moderate, and mild. Definitions

Alloys for Electroplating and Conversion Coatings

and typical examples of these service conditions are provided

B320Practice for Preparation of Iron Castings for Electro-

in Appendix X1.

plating

B368Test Method for Copper-AcceleratedAceticAcid-Salt

1.2 This specification does not cover the requirements for

Spray (Fog) Testing (CASS Test)

the plating on plastics, see Specification B604.

B380Test Method for Corrosion Testing of Decorative

1.3 The following hazards caveat pertains only to the test Electrodeposited Coatings by the Corrodkote Procedure

B487Test Method for Measurement of Metal and Oxide

methods portions, Appendix X2, Appendix X3, Appendix X4,

Coating Thickness by Microscopical Examination of

and Appendix X5 of this specification: This standard does not

Cross Section

purport to address all of safety concerns, if any, associated

B489Practice for Bend Test for Ductility of Electrodepos-

with its use. It is the responsibility of the user of this standard

ited and Autocatalytically Deposited Metal Coatings on

to establish appropriate safety and health practices and

Metals

determine the applicability of regulatory limitations prior to

B490Practice for Micrometer Bend Test for Ductility of

use.

Electrodeposits

1.4 This international standard was developed in accor-

B499Test Method for Measurement of CoatingThicknesses

dance with internationally recognized principles on standard-

by the Magnetic Method: Nonmagnetic Coatings on

ization established in the Decision on Principles for the

Magnetic Basis Metals

Development of International Standards, Guides and Recom-

B504Test Method for Measurement of Thickness of Metal-

mendations issued by the World Trade Organization Technical

lic Coatings by the Coulometric Method

Barriers to Trade (TBT) Committee.

B530Test Method for Measurement of CoatingThicknesses

by the Magnetic Method: Electrodeposited Nickel Coat-

ings on Magnetic and Nonmagnetic Substrates

1

This specification is under the jurisdiction of ASTM Committee B08 on

Metallic and Inorganic Coatings and is the direct responsibility of Subcommittee

2

B08.05 on Decorative Coatings. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved May 1, 2017. Published June 2017. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1967. Last previous edition approved in 2011 as B456–11. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/B0456-17. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B456−17

B537Practice for Rating of Electroplated Panels Subjected 4.2.1 Theserviceconditionnumberindicatestheseverityof

to Atmospheric Exposure exposure for which the grade of coating is intended:

B568Test Method for Measurement of Coating Thickness SC 5 extended severe service

by X-Ray Spectrometry SC 4 very severe service,

B571Practice for Qualitative Adhesion T

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: B456 − 11 B456 − 17

Standard Specification for

Electrodeposited Coatings of Copper Plus Nickel Plus

1

Chromium and Nickel Plus Chromium

This standard is issued under the fixed designation B456; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1

ε NOTE—This standard was corrected editorially in 2011.

1. Scope

1.1 This specification covers requirements for several types and grades of electrodeposited copper plus nickel plus chromium

or nickel plus chromium coatings on steel, nickel plus chromium coatings on copper and copper alloys, nickel plus chromium

coatings on Type 300 and 400 series stainless steel and copper plus nickel plus chromium coatings on aluminum and its alloys and

zinc alloys for applications where both appearance and protection of the basis metal against corrosion are important. Five grades

of coatings are provided to correspond with the service conditions under which each is expected to provide satisfactory

performance: namely, extended very severe, very severe, severe, moderate, and mild. Definitions and typical examples of these

service conditions are provided in Appendix X1.

1.2 This specification does not cover the requirements for the plating on plastics, see Specification B604.

1.3 The following hazards caveat pertains only to the test methods portions, Appendix X2, Appendix X3, Appendix X4, and

Appendix X5 of this specification: This standard does not purport to address all of safety concerns, if any, associated with its use.

It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the

applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

B183 Practice for Preparation of Low-Carbon Steel for Electroplating

B242 Guide for Preparation of High-Carbon Steel for Electroplating

B252 Guide for Preparation of Zinc Alloy Die Castings for Electroplating and Conversion Coatings

B253 Guide for Preparation of Aluminum Alloys for Electroplating

B254 Practice for Preparation of and Electroplating on Stainless Steel

B281 Practice for Preparation of Copper and Copper-Base Alloys for Electroplating and Conversion Coatings

B320 Practice for Preparation of Iron Castings for Electroplating

B368 Test Method for Copper-Accelerated Acetic Acid-Salt Spray (Fog) Testing (CASS Test)

B380 Test Method for Corrosion Testing of Decorative Electrodeposited Coatings by the Corrodkote Procedure

B487 Test Method for Measurement of Metal and Oxide Coating Thickness by Microscopical Examination of Cross Section

B489 Practice for Bend Test for Ductility of Electrodeposited and Autocatalytically Deposited Metal Coatings on Metals

B490 Practice for Micrometer Bend Test for Ductility of Electrodeposits

B499 Test Method for Measurement of Coating Thicknesses by the Magnetic Method: Nonmagnetic Coatings on Magnetic Basis

Metals

1

This specification is under the jurisdiction of ASTM Committee B08 on Metallic and Inorganic Coatings and is the direct responsibility of Subcommittee B08.05 on

Decorative Coatings.

Current edition approved June 1, 2011May 1, 2017. Published July 2011June 2017. Originally approved in 1967. Last previous edition approved in 2011 as B456 – 11.

DOI: 10.1520/B0456-11E01.10.1520/B0456-17.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B456 − 17

B504 Test Method for Measurement of Thickness of Metallic Coatings by the Coulometric Method

B530 Test Method for Measurement of Coating Thicknesses by the Magnetic Method: Electrodeposited Nickel

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.