ASTM A688/A688M-00

(Specification)Standard Specification for Welded Austenitic Stainless Steel Feedwater Heater Tubes

Standard Specification for Welded Austenitic Stainless Steel Feedwater Heater Tubes

SCOPE

1.1 This specification covers welded austenitic stainless steel feedwater heater tubes including those bent, if specified, into the form of U-tubes for application in tubular feed-water heaters.

1.2 The tubing sizes covered shall be 5/8 to 1 in. [15.9 to 25.4 mm] inclusive outside diameter, and average or minimum wall thicknesses of 0.028 in. [0.7 mm] and heavier.

1.3 The values stated in either inch-pound units or SI units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the specification.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: A 688/A 688M – 00 An American National Standard

Standard Specification for

Welded Austenitic Stainless Steel Feedwater Heater Tubes

This standard is issued under the fixed designation A 688/A 688M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope the following as required to adequately describe the desired

material:

1.1 This specification covers welded austenitic stainless

4.1.1 Quantity (length or number of pieces),

steel feedwater heater tubes including those bent, if specified,

4.1.2 Material description,

into the form of U-tubes for application in tubular feed-water

4.1.3 Dimensions—Outside diameter, wall thickness (mini-

heaters.

5 mum or average wall), and length,

1.2 The tubing sizes covered shall be ⁄8 to 1 in. [15.9 to

4.1.4 Grade (chemical composition) (Table 1),

25.4 mm] inclusive outside diameter, and average or minimum

4.1.5 U-bend requirements, if order specifies bending,

wall thicknesses of 0.028 in. [0.7 mm] and heavier.

U-bend schedules or drawings shall accompany the order,

1.3 The values stated in either inch-pound units or SI units

4.1.6 Optional requirements—Purchaser shall specify if an-

are to be regarded separately as standard. Within the text, the

nealing of the U-bends is required or whether tubes are to be

SI units are shown in brackets. The values stated in each

hydrotested or air tested (see 11.6)

system are not exact equivalents; therefore, each system shall

4.1.7 Supplementary requirements—Purchaser shall

be used independently of the other. Combining values from the

specify on the purchase order if material is to be eddy current

two systems may result in nonconformance with the specifi-

tested in accordance with Supplementary Requirements S1 or

cation.

S2, and if special test reports are required under Supplementary

2. Referenced Documents

Requirement S3.

2.1 ASTM Standards:

5. General Requirements

A 262 Practices for Detecting Susceptibility to Intergranu-

5.1 Material furnished to this specification shall conform to

lar Attack in Austenitic Stainless Steels

the applicable requirements of the latest published edition of

A 370 Test Methods and Definitions for Mechanical Testing

Specification A 450/A 450M unless otherwise provided herein.

of Steel Products

A 450/A 450M Specification for General Requirements for

6. Materials and Manufacture

Carbon, Ferritic Alloy, and Austenitic Alloy Steel Tubes

6.1 The tube shall be made from flat-rolled steel by an

A 480/A 480M Specification for General Requirements for

automatic welding process with no addition of filler metal.

Flat-Rolled Stainless and Heat-Resisting Steel Plate,

6.2 Subsequent to welding and prior to final heat treatment,

Sheet, and Strip

the tubes shall be cold worked either in both the weld and base

A 941 Terminology Relating to Steel, Stainless Steel, Re-

metal, or in the weld metal only. The method of cold work may

lated Alloys, and Ferroalloys

4 be specified by the purchaser. When cold drawn, the purchaser

E 527 Practice for Numbering Metals and Alloys (UNS)

may specify the minimum amount of reduction in cross-

3. Terminology sectional area or wall thickness, or both.

6.3 Many surface contaminants may have detrimental ef-

3.1 Definitions Of Terms—For definitions of terms used in

fects on high temperature properties or corrosion resistance of

this specification, refer to terminology A 941.

tubing. Contamination by copper, lead, mercury, zinc, chlo-

4. Ordering Information

rides, or sulfur may be detrimental to stainless steels. The

manufacturer shall employ techniques that minimize surface

4.1 Orders for material to this specification should include

contamination by these elements.

7. Cleaning Before Annealing

This specification is under the jurisdiction of ASTM Committee A01 on Steel,

Stainless Steel, and Related Alloys and is the direct responsibility of Subcommittee

7.1 All lubricants of coatings used in the manufacture of

A01.10 on Steel Tubing.

straight-length tube or in the bending shall be removed from all

Current edition approved March 10, 2000. Published June 2000. Originally

published as A 688 – 73. Last previous edition A 688M – 98.

surfaces prior to any annealing treatments. U-bends on which

For ASME Boiler and Pressure Vessel Code applications see related Specifi-

a lubricant had been applied to the inside surface during

cation SA-688 in Section II of that Code.

bending shall have the cleanness of their inside surface

Annual Book of ASTM Standards, Vol 01.03.

Annual Book of ASTM Standards, Vol 01.01. confirmed by blowing close fitting acetone-soaked felt plugs

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

A 688/A 688M

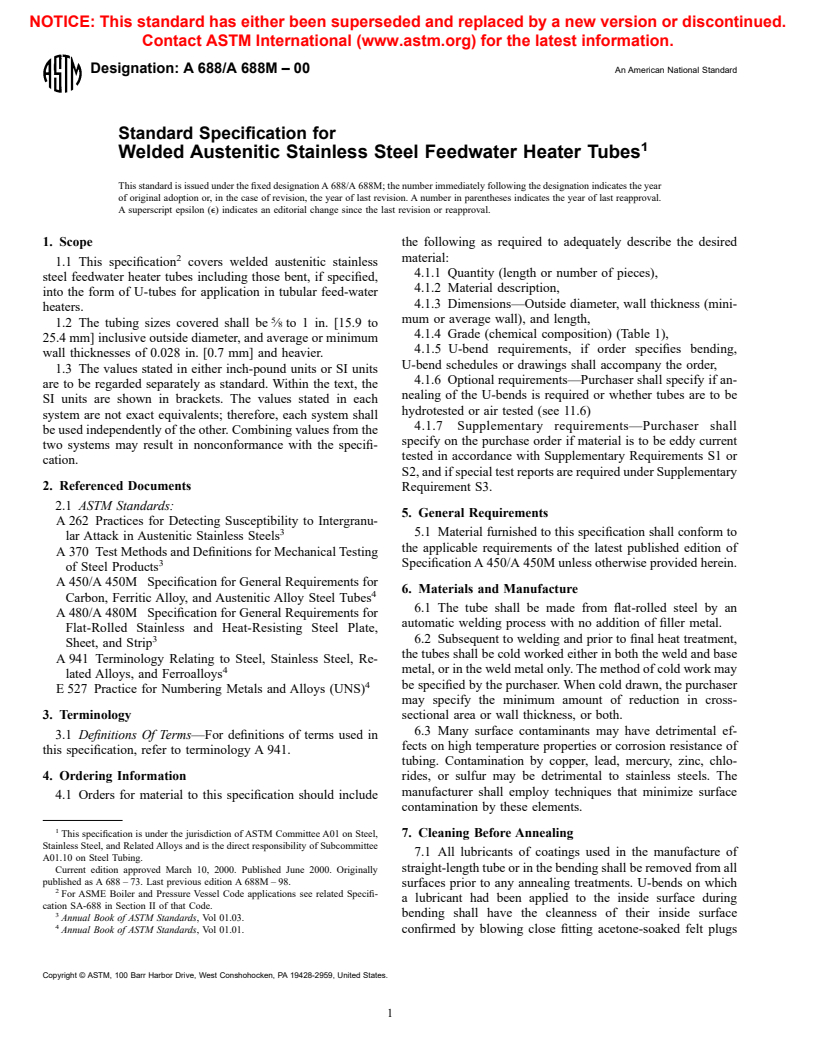

TABLE 1 Chemical Requirements

Grade. TP 304 TP 304L TP 304LN TP 316 TP 316L TP 316LN TP XM-29 TP 304N TP 316N . . . . . . . . . . . .

UNS S30400 S30403 S30453 S31600 S31603 S31653 S24000 S30451 S31651 N08367 N08926 S31254 S32654

Element

A

Designation .

Composition, %

Carbon, max 0.08 0.035 0.035 0.08 0.035 0.035 0.060 0.08 0.08 0.030 0.020 0.020 0.020

B

Manganese, max 2.00 2.00 2.00 2.00 2.00 2.00 11.50– 2.00 2.00 2.00 2.00 1.00 2.0–4.0

14.50

Phosphorus, max 0.040 0.040 0.040 0.040 0.040 0.040 0.060 0.040 0.040 0.040 0.03 0.030 0.030

Sulfur, max 0.030 0.030 0.030 0.030 0.030 0.030 0.030 0.030 0.030 0.030 0.01 0.010 0.005

Silicon, max 0.75 0.75 0.75 0.75 0.75 0.75 1.00 0.75 0.75 1.00 0.5 0.80 0.50

Nickel 8.00– 8.00– 8.00– 10.00– 10.00– 10.00– 2.25– 8.00– 10.00– 23.50– 24.00– 17.5– 21.0–

11.00 13.00 13.00 14.00 15.00 15.00 3.75 11.0 14.00 25.50 26.00 18.5 23.0

Chromium 18.00– 18.00– 18.00– 16.00– 16.00– 16.00– 17.00– 18.0– 16.0– 20.00– 19.00– 19.5– 24.0–

20.00 20.00 20.00 18.00 18.00 18.00 19.00 20.0 18.0 22.00 21.00 20.5 25.0

Molybdenum . . . 2.00– 2.00– 2.00– . . 2.00– 6.00– 6.0– 6.0– 7.0–

3.00 3.00 3.00 3.00 7.00 7.0 6.5 8.0

C

Nitrogen . . 0.10– . . 0.10– 0.20– 0.10– 0.10– 0.18– 0.15– 0.18– 0.45–

0.16 0.16 0.40 0.16 0.16 0.25 0.25 0.22 0.55

Copper . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.75 max 0.5–1.5 0.50–1.00 0.30–0.60

A

New designation established in accordance with Practice E 527 and SAE J1086, Practice for Numbering Metals and Alloys (UNS).

B

Maximum, unless otherwise noted.

C

The method of analysis for nitrogen shall be a matter of agreement between the purchaser and manufacturer.

through 10 % of the tubes of each bend radius. Dry, oil-free, air 8.3.4 The inside of the tube shall be purged with a protective

or inert gas shall be used to blow the plugs through the tubes. or an inert gas atmosphere during heating and cooling to below

If the plugs blown through any tube shows more than a light 700°F [370°C] to prevent scaling of the inside surface. The

gray discoloration, all tubes that have had a lubricant applied to atmosphere should be noncarburizing.

the inside surface during bending shall be recleaned. After

9. Surface Condition

recleaning 10 % of the tubes of each bend radius whose inside

surface had been subjected to bending lubricants shall be

9.1 The straight tubes, after final annealing, shall be pickled

retested.

using a solution of nitric and hydrofluoric acids followed by

flushing and rinsing in water. If bright annealing is performed,

8. Heat Treatment

this requirement does not apply.

8.1 All finished straight tubing or straight tubing ready for

9.2 A light oxide scale on the outside surface of U-bend area

U-bending shall be furnished in the solution-annealed condi-

shall be permitted for tubes which have been electric-resistance

tion. The annealing procedure, except for N08367 and N08926,

heat treated after bending.

shall consist of heating the material to a minimum temperature

of 1900°F [1040°C] followed by a rapid cooling to below

10. Chemical Composition

700°F [370°C]. The cooling rate shall be sufficiently rapid to

10.1 Product Analysis:

prevent harmful carbide precipitation as determined in Section

10.1.1 When requested in the purchase order, a product

13. UNS N08367 should be solution annealed from 2025°F

analysis shall be made by the supplier from one tube or coil of

[1107°C] minimum followed by rapid quenching.

steel per heat. The chemical composition shall conform to the

8.2 N08926 shall be heat-treated to a minimum temperature

requirements shown in Table 1.

of 2010°F [1100°C] followed by quenching in water or rapidly

10.1.2 A product analysis tolerance of Specification A 480/

cooling by other means.

A 480M shall apply. The product analysis tolerance is not

8.3 If heat treatment of U-bends is specified, it shall satisfy

applicable to the carbon content for material with a specified

the annealing procedure described in 8.1 and 8.2, and shall be

maximum carbon of 0.04 % or less.

done as follows:

10.1.3 If the original test for product analysis fails, retests of

8.3.1 The heat treatment shall be applied to the U-bend area

two additional lengths of flat-rolled stock or tubes shall be

plus approximately 6 in. [150 mm] of each leg beyond the

made. Both retests, for the elements in question, shall meet the

tangent point of the U-bend.

requirements of this specification; otherwise all remaining

8.3.2 If the heat treatment specified in 8.3 is accomplished

material in the heat or lot (Note 1) shall be rejected, or at the

by resistance-heating methods wherein electrodes are clamped

option of the producer, each length of flat-rolled stock or tube

to the tubes, the clamped areas shall be visually examined for

may be individually tested for acceptance. Lengths of flat-

arc burns. Burn indications shall be cause for rejection unless

rolled stock or tubes that do not meet the requirements of this

they can be removed by local polishing without encroaching

specification shall be rejected.

upon minimum wall thickness.

8.3.3 Temperature control shall be accomplished through

NOTE 1—For flattening and flange requirements, the term “lot” applies

the use of optical or emission pyrometers, or both. No

to 125 tube groupings, prior to cutting to length, of the same nominal size

temperature-indicating crayons, lacquers, or pellets shall be

and wall thickness, produced from the same heat of steel and annealed in

used. a continuous furnace.

A 688/A 688M

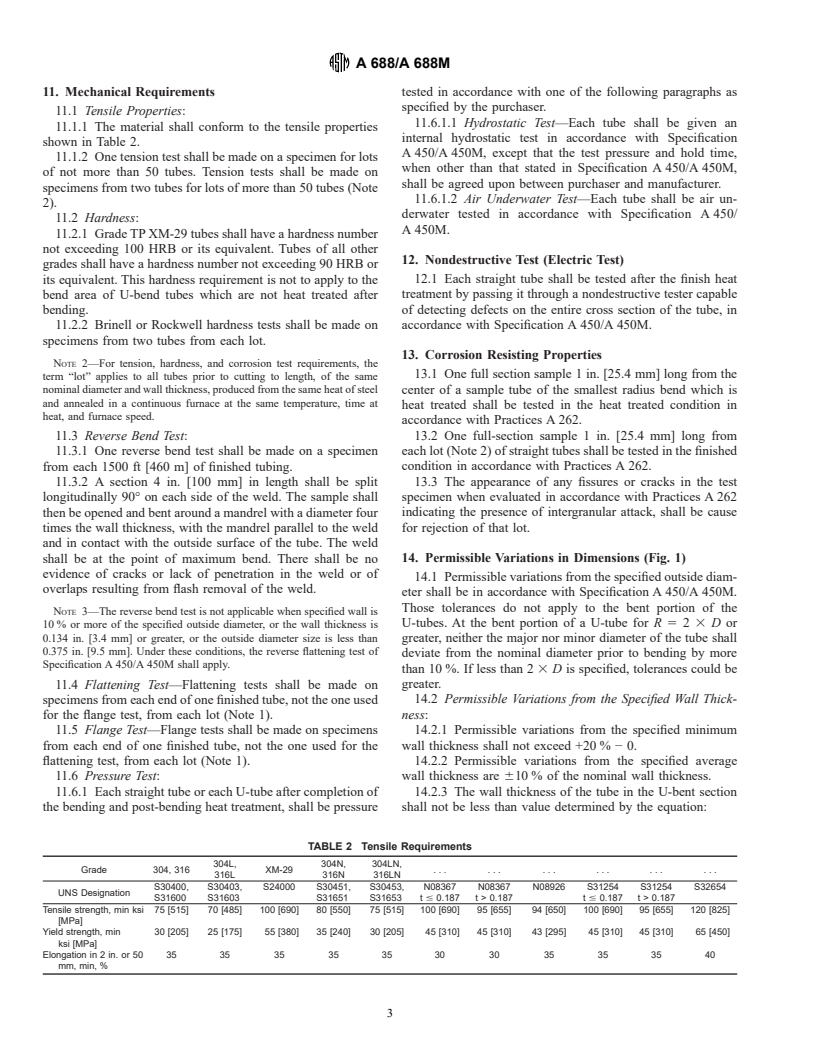

11. Mechanical Requirements tested in accordance with one of the following paragraphs as

specified by the purchaser.

11.1 Tensile Properties:

11.6.1.1 Hydrostatic Test—Each tube shall be given an

11.1.1 The material shall conform to the tensile properties

internal hydrostatic test in accordance with Specification

shown in Table 2.

A 450/A 450M, except that the test pressure and hold time,

11.1.2 One tension test shall be made on a specimen for lots

when other than that stated in Specification A 450/A 450M,

of not more than 50 tubes. Tension tests shall be made on

shall be agreed upon between purchaser and manufacturer.

specimens from two tubes for lots of more than 50 tubes (Note

11.6.1.2 Air Underwater Test—Each tube shall be air un-

2).

derwater tested in accordance with Specification A 450/

11.2 Hardness:

A 450M.

11.2.1 Grade TP XM-29 tubes shall have a hardness number

not exceeding 100 HRB or its equivalent. Tubes of all other

12. Nondestructive Test (Electric Test)

grades shall have a hardness number not exceeding 90 HRB or

its equivalent. This hardness requirement is not to apply to the 12.1 Each straight tube shall be tested after the finish heat

treatment by passing it through a nondestructive tester capable

bend area of U-bend tubes which are not heat treated after

bending. of detecting defects on the entire cross section of the tube, in

accordance with Specification A 450/A 450M.

11.2.2 Brinell or Rockwell hardness tests shall be made on

specimens from two tubes from each lot.

13. Corrosion Resisting Properties

NOTE 2—For tension, hardness, and corrosion test requirements, the

13.1 One full section sample 1 in. [25.4 mm] long from the

term “lot” applies to all tubes prior to cutting to length, of the same

nominal diameter and wall thickness, produced from the same heat of steel

center of a sample tube of the smallest radius bend which is

and annealed in a continuous furnace at the same temperature, time at

heat treated shall be tested in the heat treated condition in

heat, and furnace speed.

accordance with Practices A 262.

13.2 One full-section sample 1 in. [25.4 mm] long from

11.3 Reverse Bend Test:

11.3.1 One reverse bend test shall be made on a specimen each lot (Note 2) of straight tubes shall be tested in the finished

condition in accordance with Practices A 262.

from each 1500 ft [460 m] of finished tubing.

11.3.2 A section 4 in. [100 mm] in length shall be split 13.3 The appearance of any fissures or cracks in the test

specimen when evaluated in accordance with Practices A 262

longitudinally 90° on each side of the weld. The sample shall

then be opened and bent around a mandrel with a diameter four indicating the presence of intergranular attack, shall be cause

times the wall thickness, with the mandrel parallel to the weld for rejection of that lot.

and in contact with the outside surface of the tube. The weld

shall be at the point of maximum bend. There shall be no 14. Permissible Variations in Dimensions (Fig. 1)

evidence of cracks or lack of penetration in the weld or of

14.1 Permissible variations from the specified outside diam-

overlaps resulting from flash removal of the weld.

eter shall be in accordance with Specification A 450/A 450M.

Those tolerances do not apply to the bent portion of the

NOTE 3—The reverse bend test is not applicable when specified wall is

U-tubes. At the bent portion of a U-tube for R 5 2 3 D or

10 % or more of the specified outside diameter, or the wall thickness is

0.134 in. [3.4 mm] or greater, or the outside diameter size is less than greater, neither the major nor minor diameter of the tube shall

0.375 in. [9.5 mm]. Under these conditions, the reverse flattening test of

deviate from the nominal diameter prior to bending by more

Specification A 450/A 450M shall apply.

than 10 %. If less than 2 3 D is specified, tolerances could be

11.4 Flattening Test—Flattening tests shall be made on greater.

specimens from each end of one finished tube, not the one used 14.2 Permissible Variations from the Specified Wall Thick-

for the flange test, from each lot (Note 1). ness:

11.5 Flange Test—Flange tests shall be made on specimens 14.2.1 Permissible variations from the specified minimum

from each end of one finished tube, not the one used for the wall thickness shall not exceed +20 % − 0.

flattening te

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.