ASTM F2137-04(2009)

(Practice)Standard Practice for Measuring the Dynamic Characteristics of Amusement Rides and Devices

Standard Practice for Measuring the Dynamic Characteristics of Amusement Rides and Devices

SIGNIFICANCE AND USE

This practice is intended for use whenever the dynamic characteristics of an amusement ride or device are to be determined. The existence of this practice is not intended to imply that there is a requirement to perform specific testing on amusement rides or devices.

The general provisions of this practice provide instrumentation specifications, data acquisition and testing procedures, and documentation requirements that when applied will improve the repeatability, reliability, and utility of the test results.

Based on the general provisions of this practice, the SARC Test specifications, when followed, will yield standardized test results regarding the patron-related, dynamic motion of amusement rides or devices. The SARC Test will facilitate both the meaningful comparison of the dynamic motion of different amusement rides or devices and the tracking of changes, if any, in the dynamic characteristics of a given ride or device.

SCOPE

1.1 This practice covers acquisition of data related to the dynamic characteristics of amusement rides and devices.

1.2 This practice also defines the specific requirements of a Standardized Amusement Ride Characterization Test (SARC Test) for use in characterizing the dynamic motion of an amusement ride or device.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F2137–04 (Reapproved 2009)

Standard Practice for

Measuring the Dynamic Characteristics of Amusement

Rides and Devices

This standard is issued under the fixed designation F2137; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.3 calibration value—the ratio of the reference calibra-

tion system output, in engineering units relevant to the trans-

1.1 This practice covers acquisition of data related to the

ducer, to the data channel output, in volts, as measured at

dynamic characteristics of amusement rides and devices.

constant excitation frequency and amplitude.

1.2 This practice also defines the specific requirements of a

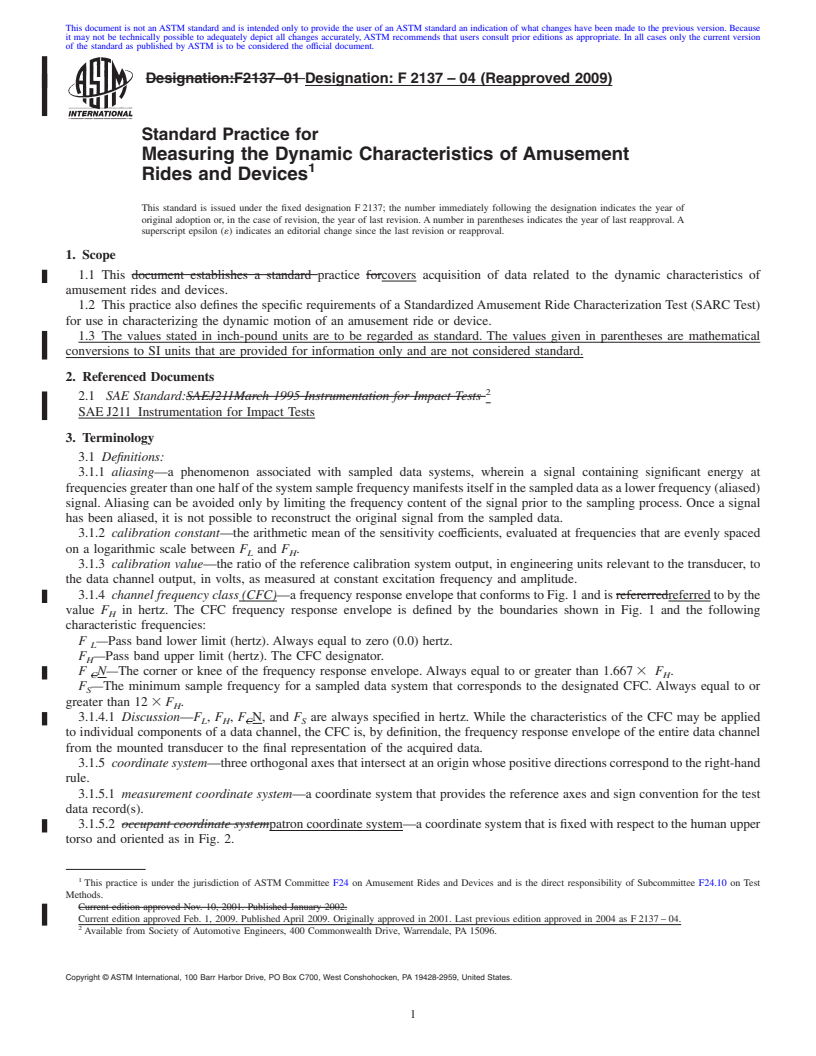

3.1.4 channel frequency class (CFC)—afrequencyresponse

Standardized Amusement Ride Characterization Test (SARC

envelope that conforms to Fig. 1 and is referred to by the value

Test) for use in characterizing the dynamic motion of an

F in hertz. The CFC frequency response envelope is defined

H

amusement ride or device.

by the boundaries shown in Fig. 1 and the following charac-

1.3 The values stated in inch-pound units are to be regarded

teristic frequencies:

as standard. The values given in parentheses are mathematical

F —Pass band lower limit (hertz). Always equal to zero

conversions to SI units that are provided for information only L

(0.0) hertz.

and are not considered standard.

F —Pass band upper limit (hertz). The CFC designator.

H

2. Referenced Documents

F —The corner or knee of the frequency response envelope.

N

Always equal to or greater than 1.667 3 F .

H

2.1 SAE Standard:

F —The minimum sample frequency for a sampled data

SAE J211 Instrumentation for Impact Tests S

system that corresponds to the designated CFC. Always equal

3. Terminology

to or greater than 12 3 F .

H

3.1.4.1 Discussion—F , F , F ,and F arealwaysspecified

3.1 Definitions: L H N S

in hertz. While the characteristics of the CFC may be applied

3.1.1 aliasing—a phenomenon associated with sampled

to individual components of a data channel, the CFC is, by

data systems, wherein a signal containing significant energy at

definition, the frequency response envelope of the entire data

frequencies greater than one half of the system sample fre-

channelfromthemountedtransducertothefinalrepresentation

quency manifests itself in the sampled data as a lower

of the acquired data.

frequency (aliased) signal. Aliasing can be avoided only by

3.1.5 coordinate system—three orthogonal axes that inter-

limiting the frequency content of the signal prior to the

sect at an origin whose positive directions correspond to the

sampling process. Once a signal has been aliased, it is not

right-hand rule.

possible to reconstruct the original signal from the sampled

3.1.5.1 measurement coordinate system—a coordinate sys-

data.

tem that provides the reference axes and sign convention for

3.1.2 calibration constant—the arithmetic mean of the sen-

the test data record(s).

sitivity coefficients, evaluated at frequencies that are evenly

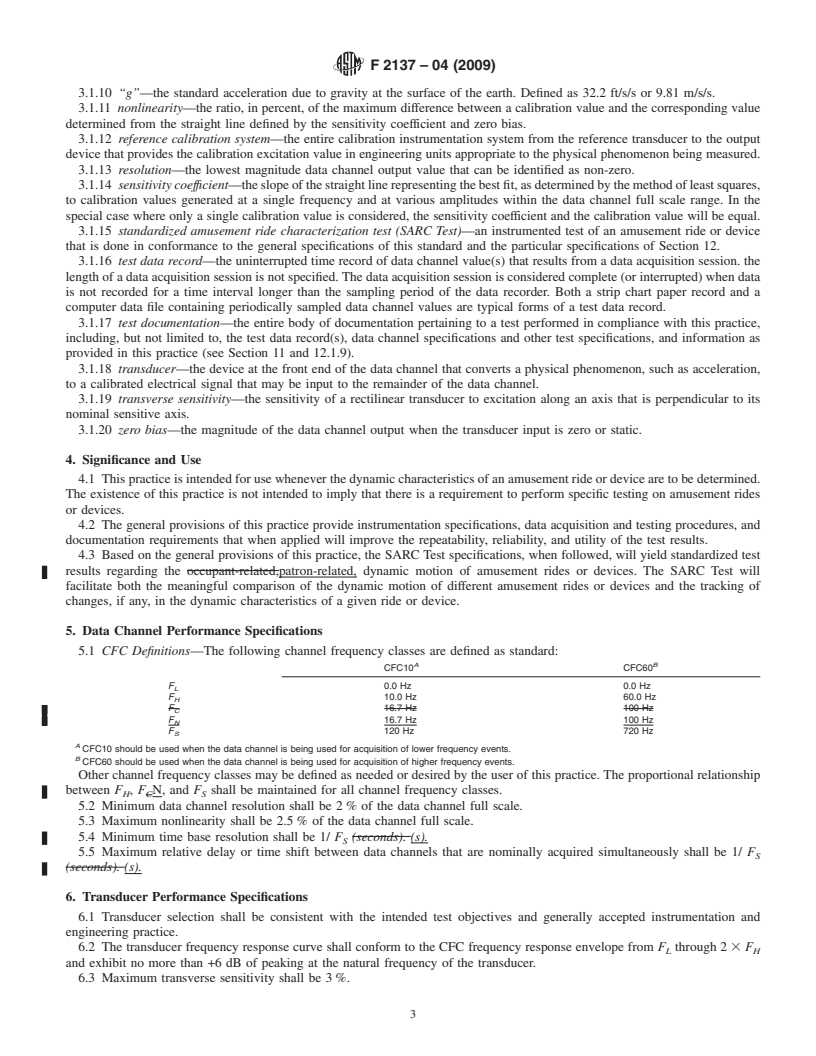

3.1.5.2 patron coordinate system—a coordinate system that

spaced on a logarithmic scale between F and F .

L H

is fixed with respect to the human upper torso and oriented as

in Fig. 2.

3.1.5.3 vehicle coordinate system—a coordinate system that

This practice is under the jurisdiction ofASTM Committee F24 onAmusement

is fixed with respect to the ride or device being tested.

Rides and Devices and is the direct responsibility of Subcommittee F24.10 on Test

3.1.6 data channel—the entire instrumentation system for a

Methods.

Current edition approved Feb. 1, 2009. Published April 2009. Originally

single channel of data acquisition; from the transducer to the

approved in 2001. Last previous edition approved in 2004 as F2137 – 04. DOI:

final representation of the data, including all post-acquisition

10.1520/F2137-04R09.

data processing that may alter the amplitude or frequency

Available from Society of Automotive Engineers, 400 Commonwealth Drive,

Warrendale, PA 15096. content of the data.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F2137–04 (2009)

FIG. 1 Frequency Response Envelope

FIG. 2 Patron Coordinate System

3.1.7 data channel full scale—the maximum usable value, 3.1.9 full-scale—the maximum usable value, in units of the

in units of the physical phenomenon being measured, that may physical phenomenon being measured, which may be repre-

be represented by a data channel. This value is determined by

sented by a data channel or some component thereof.

the data channel component with the lowest full-scale range.

3.1.10 “g”—the standard acceleration due to gravity at the

3.1.8 free-run time—a period of time during the ride cycle

surface of the earth. Defined as 32.2 ft/s/s or 9.81 m/s/s.

when no energy is added to the ride vehicle.

F2137–04 (2009)

3.1.11 nonlinearity—the ratio, in percent, of the maximum 4.3 Based on the general provisions of this practice, the

difference between a calibration value and the corresponding SARC Test specifications, when followed, will yield standard-

value determined from the straight line defined by the sensi- ized test results regarding the patron-related, dynamic motion

tivity coefficient and zero bias. of amusement rides or devices. The SARC Test will facilitate

both the meaningful comparison of the dynamic motion of

3.1.12 reference calibration system—the entire calibration

instrumentation system from the reference transducer to the different amusement rides or devices and the tracking of

changes, if any, in the dynamic characteristics of a given ride

output device that provides the calibration excitation value in

engineering units appropriate to the physical phenomenon or device.

being measured.

5. Data Channel Performance Specifications

3.1.13 resolution—the lowest magnitude data channel out-

put value that can be identified as non-zero.

5.1 CFC Definitions—The following channel frequency

3.1.14 sensitivity coeffıcient—the slope of the straight line

classes are defined as standard:

representing the best fit, as determined by the method of least A B

CFC10 CFC60

squares, to calibration values generated at a single frequency

F 0.0 Hz 0.0 Hz

L

and at various amplitudes within the data channel full scale

F 10.0 Hz 60.0 Hz

H

F 16.7 Hz 100 Hz

range. In the special case where only a single calibration value N

F 120 Hz 720 Hz

S

is considered, the sensitivity coefficient and the calibration

A

CFC10 should be used when the data channel is being used for acquisition of

value will be equal.

lower frequency events.

3.1.15 standardized amusement ride characterization test

B

CFC60 should be used when the data channel is being used for acquisition of

(SARC Test)—an instrumented test of an amusement ride or

higher frequency events.

device that is done in conformance to the general specifications

Otherchannelfrequencyclassesmaybedefinedasneededor

of this standard and the particular specifications of Section 12.

desired by the user of this practice. The proportional relation-

3.1.16 test data record—the uninterrupted time record of shipbetween F , F ,and F shallbemaintainedforallchannel

H N S

data channel value(s) that results from a data acquisition frequency classes.

session. the length of a data acquisition session is not specified. 5.2 Minimum data channel resolution shall be 2 % of the

The data acquisition session is considered complete (or inter- data channel full scale.

rupted) when data is not recorded for a time interval longer 5.3 Maximum nonlinearity shall be 2.5 % of the data

than the sampling period of the data recorder. Both a strip chart channel full scale.

paper record and a computer data file containing periodically 5.4 Minimum time base resolution shall be 1/F (s).

S

sampled data channel values are typical forms of a test data 5.5 Maximum relative delay or time shift between data

record. channels that are nominally acquired simultaneously shall be

3.1.17 test documentation—the entire body of documenta- 1/F (s).

S

tion pertaining to a test performed in compliance with this

practice, including, but not limited to, the test data record(s), 6. Transducer Performance Specifications

data channel specifications and other test specifications, and

6.1 Transducer selection shall be consistent with the in-

information as provided in this practice (see Section 11 and

tended test objectives and generally accepted instrumentation

12.1.9).

and engineering practice.

3.1.18 transducer—the device at the front end of the data

6.2 The transducer frequency response curve shall conform

channel that converts a physical phenomenon, such as accel-

to the CFC frequency response envelope from F through

L

eration, to a calibrated electrical signal that may be input to the

2 3 F and exhibit no more than +6 dB of peaking at the

H

remainder of the data channel.

natural frequency of the transducer.

3.1.19 transverse sensitivity—the sensitivity of a rectilinear

6.3 Maximum transverse sensitivity shall be 3 %.

transducer to excitation along an axis that is perpendicular to

its nominal sensitive axis.

7. Recorder Performance Specifications

3.1.20 zero bias—the magnitude of the data channel output

7.1 Analog Data Recorders:

when the transducer input is zero or static.

7.1.1 The analog data recorder shall provide a method by

which the zero bias, if any, can be reduced to less than the data

4. Significance and Use

channel minimum resolution prior to acquiring any test data.

4.1 This practice is intended for use whenever the dynamic

7.1.2 Minimumamplituderesolutionshallbetwo2 %ofthe

characteristics of an amusement ride or device are to be data channel full scale.

determined. The existence of this practice is not intended to

7.1.3 Paper tape recorders (or their equivalent) shall provide

imply that there is a requirement to perform specific testing on a minimum paper speed, in mm/s, of 1.5 3 F (Hz).

H

amusement rides or devices.

7.2 Digital Data Recorders:

4.2 The general provisions of this practice provide instru- 7.2.1 AlldatashallbeacquiredwithaminimumCFCoften.

mentation specifications, data acquisition and testing proce- 7.2.2 Minimum amplitude resolution shall be 0.10 % of the

dures, and documentation requirements that when applied will data channel full scale.

improve the repeatability, reliability, and utility of the test 7.2.3 Minimum sample rate shall be F (Hz) for the chosen

S

results. CFC.

F2137–04 (2009)

7.2.4 Protection from aliasing errors in the sampled data 9.2.1 Mounting—To avoid distortion in the data channel

shall be accomplished by pre-sample filtering that conforms to values, accelerometers shall be mounted so as to minimize

the specified CFC frequency response envelope for the data relative motion between the transducers and the instrumented

channel. surface.Whendeemedappropriate,ananalyticalorexperimen-

7.2.4.1 Alternate protection from aliasing errors may be tal evaluation of transducer mounting effects on the data

accomplished by providing appropriate pre-sample, anti-alias channel should be provided (see 11.1.6).

filtering in conjunction with a higher-than-F sample rate and 9.2.2 When multi-axis accelerations at a point are to be

S

digital post-acquisition filtering such that the frequency re- measured, the center of seismic mass of each accelerometer

sponse envelope of the data channel conforms to the desired shall be within 60 mm of that point. Each accelerometer axis

CFC frequency response envelope. The anti-alias filter charac- shall be within one degree of orthogonal relative to the other

teristics shall be such that the maximum possible signal axes.

amplitude at one half the sampling frequency is less than the

data channel minimum resolution.

10. Procedure

10.1 The unique characteristics of a particular amusement

8. Calibration Specifications

ride or device or other special circumstances may be such that

8.1 For transducers, data recorders, or any other data chan-

it is not reasonably possible to test in strict conformance with

nel component that is subject to calibration changes over time,

one or more provisions of this practice. Any deviation(s) from

the calibration constant and frequency response shall be

the provisions of this practice shall be recorded so as to clearly

determined and documented annually.

provide a description of the specific deviation(s).

8.2 Reference calibration instrumentation used as a second-

10.2 Field Calibration:

ary standard in the calibration of a data channel or any

10.2.1 Where practical, all data channels should be sub-

subsystem thereof shall have current certificates of calibration

jected to a field calibration procedure to establish the reliability

that are traceable to accepted national standards.

of the data channel calibration.

8.3 The reference calibration system and calibration meth-

10.2.2 For accelerometer-based data channels, the field

ods shall not introduce a calibration error greater than 1.5 % of

calibration procedure, may take the form of a 2g “roll-over”

the data channel full scale.

test. The 2g “roll-over” test requires that the accelerometer be

8.4 To establish a data channel or data channel component

placed with its sensitive axis perpendicular to a plane surface

frequency response and calibration constant, sensitivity coef-

thatisnominallylevelwithrespecttotheearthwhiletheoutput

ficients shall be determined from calibration values measured

of the data channel is recorded. The accelerometer should then

at a minimum of one signal amplitude that represents at least

be oriented with its sensitive axis parallel to this surface to

50 % of the full scale range of the data channel or component

record a zero-g input. Next, the accelerometer should be

being calibrated and throughout a range of frequencies from F

L

inverted with respect to its original orientation and its output

to 10 3 F for a given CFC.Aminimum set of five sensitivity

H

recorded. This procedure will yield a three-point calibration

coefficients establishes the frequency response of a data chan-

(+1g,0g, and -1g) with a nominal 2g range.

nel or component. The minimum set of sensitivity coefficients

10.3 When testing the nominal dynamic characteristics of

shall be generated at frequencies that nominally correspond to

amusement rides and devices that have characteristics that

the following CFC specifications:

change with respect to operating temperature, the rides or

F , F , F ,2 3 F , and 10 3 F

devices shall be operated for a minimum of three full cyc

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:F2137–01 Designation: F 2137 – 04 (Reapproved 2009)

Standard Practice for

Measuring the Dynamic Characteristics of Amusement

Rides and Devices

This standard is issued under the fixed designation F 2137; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This document establishes a standard practice forcovers acquisition of data related to the dynamic characteristics of

amusement rides and devices.

1.2 This practice also defines the specific requirements of a StandardizedAmusement Ride Characterization Test (SARC Test)

for use in characterizing the dynamic motion of an amusement ride or device.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

2. Referenced Documents

2.1 SAE Standard:SAEJ211March 1995 Instrumentation for Impact Tests

SAE J211 Instrumentation for Impact Tests

3. Terminology

3.1 Definitions:

3.1.1 aliasing—a phenomenon associated with sampled data systems, wherein a signal containing significant energy at

frequenciesgreaterthanonehalfofthesystemsamplefrequencymanifestsitselfinthesampleddataasalowerfrequency(aliased)

signal. Aliasing can be avoided only by limiting the frequency content of the signal prior to the sampling process. Once a signal

has been aliased, it is not possible to reconstruct the original signal from the sampled data.

3.1.2 calibration constant—the arithmetic mean of the sensitivity coefficients, evaluated at frequencies that are evenly spaced

on a logarithmic scale between F and F .

L H

3.1.3 calibration value—the ratio of the reference calibration system output, in engineering units relevant to the transducer, to

the data channel output, in volts, as measured at constant excitation frequency and amplitude.

3.1.4 channel frequency class (CFC)—a frequency response envelope that conforms to Fig. 1 and is refererredreferred to by the

value F in hertz. The CFC frequency response envelope is defined by the boundaries shown in Fig. 1 and the following

H

characteristic frequencies:

F —Pass band lower limit (hertz). Always equal to zero (0.0) hertz.

L

F —Pass band upper limit (hertz). The CFC designator.

H

F N—The corner or knee of the frequency response envelope. Always equal to or greater than 1.667 3 F .

C H

F —The minimum sample frequency for a sampled data system that corresponds to the designated CFC. Always equal to or

S

greater than 12 3 F .

H

3.1.4.1 Discussion—F , F , F N, and F are always specified in hertz. While the characteristics of the CFC may be applied

L H C S

to individual components of a data channel, the CFC is, by definition, the frequency response envelope of the entire data channel

from the mounted transducer to the final representation of the acquired data.

3.1.5 coordinate system—threeorthogonalaxesthatintersectatanoriginwhosepositivedirectionscorrespondtotheright-hand

rule.

3.1.5.1 measurement coordinate system—a coordinate system that provides the reference axes and sign convention for the test

data record(s).

3.1.5.2 occupant coordinate systempatron coordinate system—a coordinate system that is fixed with respect to the human upper

torso and oriented as in Fig. 2.

This practice is under the jurisdiction of ASTM Committee F24 on Amusement Rides and Devices and is the direct responsibility of Subcommittee F24.10 on Test

Methods.

Current edition approved Nov. 10, 2001. Published January 2002.

Current edition approved Feb. 1, 2009. Published April 2009. Originally approved in 2001. Last previous edition approved in 2004 as F 2137 – 04.

Available from Society of Automotive Engineers, 400 Commonwealth Drive, Warrendale, PA 15096.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F 2137 – 04 (2009)

FIG. 1 Frequency Response Envelope

FIG. 2 Patron Coordinate System

3.1.5.3 vehicle coordinate system—a coordinate system that is fixed with respect to the ride or device being tested.

3.1.6 data channel—the entire instrumentation system for a single channel of data acquisition; from the transducer to the final

representation of the data, including all post-acquisition data processing that may alter the amplitude or frequency content of the

data.

3.1.7 data channel full scale—the maximum usable value, in units of the physical phenomenon being measured, that may be

represented by a data channel. This value is determined by the data channel component with the lowest full-scale range.

3.1.8 free-run time—a period of time during the ride cycle when no energy is added to the ride vehicle.

3.1.9 full-scale—the maximum usable value, in units of the physical phenomenon being measured, which may be represented

by a data channel or some component thereof.

F 2137 – 04 (2009)

3.1.10 “g”—the standard acceleration due to gravity at the surface of the earth. Defined as 32.2 ft/s/s or 9.81 m/s/s.

3.1.11 nonlinearity—the ratio, in percent, of the maximum difference between a calibration value and the corresponding value

determined from the straight line defined by the sensitivity coefficient and zero bias.

3.1.12 reference calibration system—the entire calibration instrumentation system from the reference transducer to the output

device that provides the calibration excitation value in engineering units appropriate to the physical phenomenon being measured.

3.1.13 resolution—the lowest magnitude data channel output value that can be identified as non-zero.

3.1.14 sensitivity coeffıcient—theslopeofthestraightlinerepresentingthebestfit,asdeterminedbythemethodofleastsquares,

to calibration values generated at a single frequency and at various amplitudes within the data channel full scale range. In the

special case where only a single calibration value is considered, the sensitivity coefficient and the calibration value will be equal.

3.1.15 standardized amusement ride characterization test (SARC Test)—an instrumented test of an amusement ride or device

that is done in conformance to the general specifications of this standard and the particular specifications of Section 12.

3.1.16 test data record—the uninterrupted time record of data channel value(s) that results from a data acquisition session. the

length of a data acquisition session is not specified. The data acquisition session is considered complete (or interrupted) when data

is not recorded for a time interval longer than the sampling period of the data recorder. Both a strip chart paper record and a

computer data file containing periodically sampled data channel values are typical forms of a test data record.

3.1.17 test documentation—the entire body of documentation pertaining to a test performed in compliance with this practice,

including, but not limited to, the test data record(s), data channel specifications and other test specifications, and information as

provided in this practice (see Section 11 and 12.1.9).

3.1.18 transducer—the device at the front end of the data channel that converts a physical phenomenon, such as acceleration,

to a calibrated electrical signal that may be input to the remainder of the data channel.

3.1.19 transverse sensitivity—the sensitivity of a rectilinear transducer to excitation along an axis that is perpendicular to its

nominal sensitive axis.

3.1.20 zero bias—the magnitude of the data channel output when the transducer input is zero or static.

4. Significance and Use

4.1 This practice is intended for use whenever the dynamic characteristics of an amusement ride or device are to be determined.

The existence of this practice is not intended to imply that there is a requirement to perform specific testing on amusement rides

or devices.

4.2 The general provisions of this practice provide instrumentation specifications, data acquisition and testing procedures, and

documentation requirements that when applied will improve the repeatability, reliability, and utility of the test results.

4.3 Based on the general provisions of this practice, the SARC Test specifications, when followed, will yield standardized test

results regarding the occupant-related,patron-related, dynamic motion of amusement rides or devices. The SARC Test will

facilitate both the meaningful comparison of the dynamic motion of different amusement rides or devices and the tracking of

changes, if any, in the dynamic characteristics of a given ride or device.

5. Data Channel Performance Specifications

5.1 CFC Definitions—The following channel frequency classes are defined as standard:

A B

CFC10 CFC60

F 0.0 Hz 0.0 Hz

L

F 10.0 Hz 60.0 Hz

H

F 16.7 Hz 100 Hz

C

F 16.7 Hz 100 Hz

N

F 120 Hz 720 Hz

S

A

CFC10 should be used when the data channel is being used for acquisition of lower frequency events.

B

CFC60 should be used when the data channel is being used for acquisition of higher frequency events.

Other channel frequency classes may be defined as needed or desired by the user of this practice. The proportional relationship

between F , F N, and F shall be maintained for all channel frequency classes.

H C S

5.2 Minimum data channel resolution shall be 2 % of the data channel full scale.

5.3 Maximum nonlinearity shall be 2.5 % of the data channel full scale.

5.4 Minimum time base resolution shall be 1/ F (seconds). (s).

S

5.5 Maximum relative delay or time shift between data channels that are nominally acquired simultaneously shall be 1/ F

S

(seconds). (s).

6. Transducer Performance Specifications

6.1 Transducer selection shall be consistent with the intended test objectives and generally accepted instrumentation and

engineering practice.

6.2 The transducer frequency response curve shall conform to the CFC frequency response envelope from F through 2 3 F

L H

and exhibit no more than +6 dB of peaking at the natural frequency of the transducer.

6.3 Maximum transverse sensitivity shall be 3 %.

F 2137 – 04 (2009)

7. Recorder Performance Specifications

7.1 Analog Data Recorders:

7.1.1 Theanalogdatarecordershallprovideamethodbywhichthezerobias,ifany,canbereducedtolessthanthedatachannel

minimum resolution prior to acquiring any test data.

7.1.2 Minimum amplitude resolution shall be two 2 % of the data channel full scale.

7.1.3 Paper tape recorders (or their equivalent) shall provide a minimum paper speed, in millimetres/second,mm/s, of 1.5 3 F

H

(hertz). (Hz).

7.2 Digital Data Recorders:

7.2.1 All data shall be acquired with a minimum CFC of ten.

7.2.2Any post-acquisition data processing to reduce the data channel CFC shall be performed using the low-pass digital filter

algorithm specified in SAEJ211 March 1995, Appendix C.

7.2.3Minimum amplitude resolution shall be 0.10% of the data channel full scale.

7.2.4Minimum sample rate shall be

7.2.2 Minimum amplitude resolution shall be 0.10 % of the data channel full scale.

7.2.3 Minimum sample rate shall be F (hertz)(Hz) for the chosen CFC.

S

7.2.54 Protection from aliasing errors in the sampled data shall be accomplished by pre-sample filtering that conforms to the

specified CFC frequency response envelope for the data channel.

7.2.54.1 Alternate protection from aliasing errors may be accomplished by providing appropriate pre-sample, anti-alias filtering

in conjunction with a higher-than-F sample rate and digital post-acquisition filtering such that the frequency response envelope

S

of the data channel conforms to the desired CFC frequency response envelope. The anti-alias filter characteristics shall be such

that the maximum possible signal amplitude at one half the sampling frequency is less than the data channel minimum resolution.

8. Calibration Specifications

8.1 For transducers, data recorders, or any other data channel component that is subject to calibration changes over time, the

calibration constant and frequency response shall be determined and documented annually.

8.2 Reference calibration instrumentation used as a secondary standard in the calibration of a data channel or any subsystem

thereof shall have current certificates of calibration that are traceable to accepted national standards.

8.3 The reference calibration system and calibration methods shall not introduce a calibration error greater than 1.5 % of the

data channel full scale.

8.4 To establish a data channel or data channel component frequency response and calibration constant, sensitivity coefficients

shall be determined from calibration values measured at a minimum of one signal amplitude that represents at least 50 % of the

full scale range of the data channel or component being calibrated and throughout a range of frequencies from F to 10 3 F for

L H

a given CFC. A minimum set of five sensitivity coefficients establishes the frequency response of a data channel or component.

The minimum set of sensitivity coefficients shall be generated at frequencies that nominally correspond to the following CFC

specifications:

F , F , F ,2 3 F , and 10 3 F

L H C H C

F , F , F ,2 3 F , and 10 3 F

L H N H C

N

8.5 To establish nonlinearity, a minimum of one sensitivity coefficient shall be determined from calibration values generated at

a minimum of three signal amplitudes that nominally correspond to the following percentages of the minimum full-scale range of

the data channel or data channel component being calibrated: Less than 20 % of full scale, 50 % of full scale, and >80 % of full

scale. For the minimum requirement of a single sensitivity coefficient, the nominal frequency shall be halfway between F and F .

L H

9. Transducer Location and Mounting

9.1 General Instrumentation:

9.1.1 Transducer location, orientation, and mounting method shall be consistent with the intended test objectives and generally

accepted instrumentation and engineering practice.

9.1.2 Transducersshallbemountedsuchthattheanglebetweenthesensitiveaxis(axes)ofthetransducerandthecorresponding

axis (axes) of the selected coordinate system shall be no greater than 5°.

9.2 General Accelerometry:

9.2.1 Mounting—To avoid distortion in the data channel values, accelerometers shall be mounted so as to minimize relative

motion between the transducers and the instrumented surface. When deemed appropr

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.