ASTM D7932-14

(Specification)Standard Specification for Printed, Pressure-Sensitive Adhesive Labels for Use in Extreme Distribution Environments

Standard Specification for Printed, Pressure-Sensitive Adhesive Labels for Use in Extreme Distribution Environments

ABSTRACT

This specification provides a standard means for testing and measuring the performance characteristics of printed, pressure-sensitive adhesive labels for containers, particularly containers to be used in extreme distribution environments (for example, hazardous materials labels, aerospace, military containers). For the purposes of this specification, an extreme distribution environment is one in which it can be reasonably expected to experience direct exposure to deteriorating chemicals, weather, elevated/cold temperatures, and other environmental and physical elements for an extended period of time. This specification includes standard laboratory test methods to simulate exposure to various conditions and measure associated degradation of required performance characteristics. The data from these methods can be used as acceptance criteria between a supplier and customer. This specification covers the physical properties of the labels, as well as workmanship, finish and appearance, acceptance criteria, testing procedures, reporting of all the steps taken, certification, and preparation for delivery.

SCOPE

1.1 This specification provides a standard means to test and measure performance characteristics of printed, pressure-sensitive adhesive labels for containers, particularly containers to be used in extreme distribution environments (for example, hazardous materials labels, aerospace, military containers). For the purposes of this specification, an extreme distribution environment is one in which it can be reasonably expected to experience direct exposure to deteriorating chemicals, weather, elevated/cold temperatures, and other environmental and physical elements for an extended period of time.

1.2 Units—The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D7932 −14

Standard Specification for

Printed, Pressure-Sensitive Adhesive Labels for Use in

Extreme Distribution Environments

This standard is issued under the fixed designation D7932; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D1000 Test Methods for Pressure-Sensitive Adhesive-

Coated Tapes Used for Electrical and Electronic Applica-

1.1 This specification provides a standard means to test and

tions

measure performance characteristics of printed, pressure-

D3611 Practice for Accelerated Aging of Pressure-Sensitive

sensitive adhesive labels for containers, particularly containers

Tapes

to be used in extreme distribution environments (for example,

D3951 Practice for Commercial Packaging

hazardous materials labels, aerospace, military containers). For

D4332 Practice for Conditioning Containers, Packages, or

the purposes of this specification, an extreme distribution

Packaging Components for Testing

environment is one in which it can be reasonably expected to

D4814 Specification for Automotive Spark-Ignition Engine

experience direct exposure to deteriorating chemicals, weather,

Fuel

elevated/cold temperatures, and other environmental and

D6210 Specification for Fully-Formulated Glycol Base En-

physical elements for an extended period of time.

gine Coolant for Heavy-Duty Engines

1.2 Units—The values stated in either SI units or inch-

D6252/D6252M TestMethodforPeelAdhesionofPressure-

pound units are to be regarded separately as standard. The

Sensitive Label Stocks at a 90° Angle

values stated in each system may not be exact equivalents;

G195 Guide for Conducting Wear Tests Using a Rotary

therefore,eachsystemshallbeusedindependentlyoftheother.

Platform Abraser

Combining values from the two systems may result in non-

2.2 Department of Defense Standards:

conformance with the standard.

MIL-STD-810 Environmental Engineering Considerations

1.3 This standard does not purport to address all of the

and Laboratory Tests

safety concerns, if any, associated with its use. It is the

MIL-STD-2073 Standard Practice for Military Packaging

responsibility of the user of this standard to establish appro-

MIL-DTL-83133 Turbine Fuel, Aviation, Kerosene Type,

priate safety and health practices and determine the applica-

JP-8 (NATO F-34), NATO F-35, and JP-8+100 (NATO

bility of regulatory limitations prior to use.

F-37)

2.3 Society of Automotive Engineers Standards:

2. Referenced Documents

SAE J183 Engine Oil Performance and Engine Service

2.1 ASTM Standards:

Classification

A666 Specification forAnnealed or Cold-WorkedAustenitic

SAE J300 Engine Oil Classification

Stainless Steel Sheet, Strip, Plate, and Flat Bar

2.4 Other:

D374 Test Methods for Thickness of Solid Electrical Insu-

3 ISO/IEC 15415 Information Technology – Automatic Iden-

lation (Withdrawn 2013)

tification and Data Capture Techniques – Bar Code Print

D975 Specification for Diesel Fuel Oils

Quality Test Specification – Two Dimensional Symbols

D996 Terminology of Packaging and Distribution Environ-

ISO/IEC 15416 Information Technology – Automatic Iden-

ments

tification and Data Capture Techniques – Bar Code Print

Quality Test Specification – Linear Symbols

This specification is under the jurisdiction of ASTM Committee D10 on

Packaging and is the direct responsibility of Subcommittee D10.14 on Tape and

Labels.

Current edition approved Sept. 1, 2014. Published October 2014. DOI: 10.1520/ Copies of these documents are available online at http://quicksearch.dla.mil or

D7932–14 from the Standardization Document Order Desk, 700 Robbins Avenue, Building

For referenced ASTM standards, visit the ASTM website, www.astm.org, or 4/D, Philadelphia, PA 19111-5094.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM CopiesofthesedocumentsareavailablefromSocietyofAutomotiveEngineers

Standards volume information, refer to the standard’s Document Summary page on (SAE), 400 Commonwealth Dr., Warrendale, PA 15096-0001.

the ASTM website. Copies of these documents are available at www.iso.org or www.ansi.org or

The last approved version of this historical standard is referenced on fromtheAmericanNationalStandardsInstitute,25West43rdStreet,4thFloor,New

www.astm.org. York, NY 10036.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7932−14

ISO/IEC 15426-1 Information Technology – Automatic 10.3). Substitution of panels representative of the proposed

Identification and Data Capture Techniques – Bar Code substratesforthestandardstainlesssteelpanelisacceptablefor

Verifier Conformance Specification – Part 1: Linear Sym- this procedure.

bols

NOTE 1—Test surface panels other than specified stainless steel panels

ISO/IEC 15426-2 Information Technology – Automatic

may not meet the minimum requirements of Tables 2 and 3.

Identification and Data Capture Techniques – Bar Code

4.3 Type I labels are intended for use on container outer

Verifier Conformance Specification – Part 2: Two-

surfaces where direct contact with physical and environmental

Dimensional Symbols

factors is unavoidable. Material strength and resistance to

ANSI MH10.8.1 Linear Bar Code & 2-Dimensional Sym-

abrasion, sunlight, rain, extreme temperatures, chemicals, and

bols

other deteriorating environmental elements are required. Type

ANSI/ASQC Z1.4 Sampling Procedures and Tables for In-

I labels may be used on porous surfaces (Class 1) or non-

spection by Attributes

porous surfaces (Class 2).

4.4 Type II labels are intended for use on inner containers

3. Terminology

where there will be a physical barrier to outside elements, such

3.1 General definitions for packing and distribution envi-

as an overpack. Since not all barriers are hermetically sealed,

ronments are found in Terminology D996.

material strength and resistance to abrasion, extreme

3.2 Definitions:

temperatures, and other deteriorating environmental elements

3.2.1 porous—possessing or full of pores or openings that are required. Type II labels may be used on porous surfaces

permit solids, liquids, or gases to permeate or penetrate an

(Class 1) or non-porous surfaces (Class 2).

outer surface or membrane.

4.5 Type III labels are intended for applications not covered

3.2.2 non-porous—possessing a non-permeable outer sur-

by Type I or II labels. The performance requirements and

face or membrane that does not permit solids, liquids, or gases

testingshallbetailoredbythecustomer.TypeIIIlabelsmaybe

to penetrate an outer surface or membrane.

used on porous surfaces (Class 1) or non-porous surfaces

(Class 2).

3.2.3 printed, pressure-sensitive adhesive label—the combi-

nation of a release liner, pressure-sensitive adhesive, and

5. Classifications

facestock (face material) which has been printed with an

5.1 Type:

image.

5.1.1 Type I—Heavy Duty.

3.2.4 label sample—used to describe a facestock and its

5.1.2 Type II—Medium Duty.

pressure-sensitive adhesive while still adhered to its release

5.1.3 Type III—Custom requirements.

liner only.

5.2 Classes:

3.2.5 test surface panel—used to describe the solid material

5.2.1 Class 1—For use on porous surfaces.

surface onto which the label samples are adhered for the

5.2.2 Class 2—For use on non-porous surfaces.

purpose of testing (see 4.2).

3.2.6 label test specimen—used to describe a test surface

6. Ordering Information

panel with a label sample applied by way of its pressure-

6.1 The inquiry or order shall include the following:

sensitive adhesive.

6.1.1 ASTM designation and date of issue.

6.1.2 Type and Class required (see Section 5).

4. Significance and Use

6.1.3 For Type III Labels—Required tests from Table 1 and

4.1 Degradation of pressure-sensitive adhesive labels due to

minimum performance criteria for each.

environmental and physical factors is a common occurrence

6.1.4 Label form (for example, in sheets, rolls, etc.).

during transportation and storage. This specification provides

6.1.5 Individual label size.

minimum performance requirements for printed, pressure-

sensitive labels for use in extreme distribution environments.

TABLE 1 Minimum Number of Test Samples

In addition, standard laboratory test methods are provided to

simulate exposure to various conditions and measure associ- Minimum Number of Test Samples

Reference Paragraph

Test Method Type I Type II

ated degradation of required performance characteristics. The

Print Quality 5 5 11.2

data from these methods can be used as acceptance criteria

Peel Adhesion 5 5 11.3

Thickness 5 5 11.4

between a supplier and customer.

Abrasion 15 15 11.5

4.2 The test methods described in this specification are High Temperature 5 5 11.6

Low Temperature 5 5 11.7

performed on standard stainless steel test surface panels (see

Rain 5 Not Required 11.8

Salt Fog 5 Not Required 11.9

Blowing Dust 5 Not Required 11.10

Humidity 5 5 11.11

A copy of this document is available at www.mhi.org or from the Material

Freeze and Thaw 5 5 11.12

HandlingIndustry,8720RedOakBoulevard,Suite201,Charlotte,NC28217-3992.

Accelerated Aging 5 5 11.13

AcopyofthisdocumentisavailablefromAmericanSocietyforQuality(ASQ), Contamination by Fluids 40 Not Required 11.14

600 North Plankinton Ave., Milwaukee, WI 53203.

D7932−14

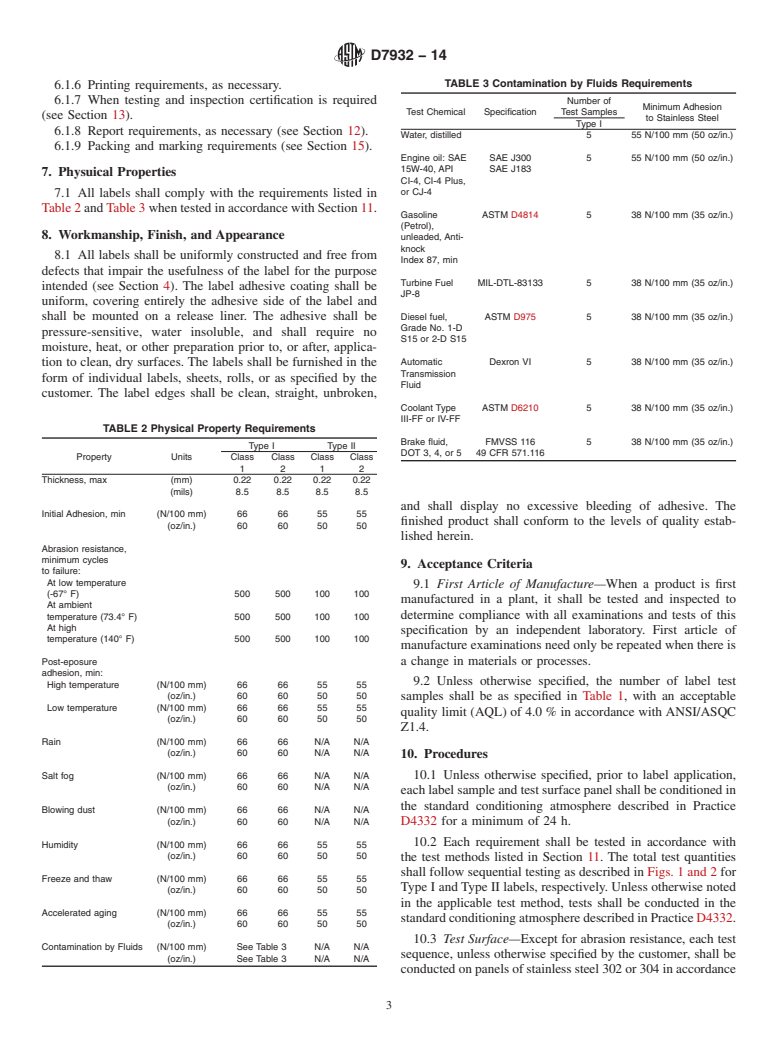

TABLE 3 Contamination by Fluids Requirements

6.1.6 Printing requirements, as necessary.

6.1.7 When testing and inspection certification is required Number of

Minimum Adhesion

Test Chemical Specification Test Samples

(see Section 13).

to Stainless Steel

Type I

6.1.8 Report requirements, as necessary (see Section 12).

Water, distilled 5 55 N/100 mm (50 oz/in.)

6.1.9 Packing and marking requirements (see Section 15).

Engine oil: SAE SAE J300 5 55 N/100 mm (50 oz/in.)

15W-40, API SAE J183

7. Physuical Properties

CI-4, CI-4 Plus,

or CJ-4

7.1 All labels shall comply with the requirements listed in

Table2andTable3whentestedinaccordancewithSection 11.

Gasoline ASTM D4814 5 38 N/100 mm (35 oz/in.)

(Petrol),

8. Workmanship, Finish, and Appearance

unleaded, Anti-

knock

8.1 All labels shall be uniformly constructed and free from

Index 87, min

defects that impair the usefulness of the label for the purpose

Turbine Fuel MIL-DTL-83133 5 38 N/100 mm (35 oz/in.)

intended (see Section 4). The label adhesive coating shall be

JP-8

uniform, covering entirely the adhesive side of the label and

shall be mounted on a release liner. The adhesive shall be Diesel fuel, ASTM D975 5 38 N/100 mm (35 oz/in.)

Grade No. 1-D

pressure-sensitive, water insoluble, and shall require no

S15 or 2-D S15

moisture, heat, or other preparation prior to, or after, applica-

Automatic Dexron VI 5 38 N/100 mm (35 oz/in.)

tion to clean, dry surfaces. The labels shall be furnished in the

Transmission

form of individual labels, sheets, rolls, or as specified by the

Fluid

customer. The label edges shall be clean, straight, unbroken,

Coolant Type ASTM D6210 5 38 N/100 mm (35 oz/in.)

III-FF or IV-FF

TABLE 2 Physical Property Requirements

Brake fluid, FMVSS 116 5 38 N/100 mm (35 oz/in.)

Type I Type II

DOT 3, 4, or 5 49 CFR 571.116

Property Units Class Class Class Class

1 2 1 2

Thickness, max (mm) 0.22 0.22 0.22 0.22

(mils) 8.5 8.5 8.5 8.5

and shall display no excessive bleeding of adhesive. The

Initial Adhesion, min (N/100 mm) 66 66 55 55

finished product shall conform to the levels of quality estab-

(oz/in.) 60 60 50 50

lished herein.

Abrasion resistance,

minimum cycles

9. Acceptance Criteria

to failure:

At low temperature

9.1 First Article of Manufacture—When a product is first

(-67° F) 500 500 100 100

manufactured in a plant, it shall be tested and inspected to

At ambient

determine compliance with all examinations and tests of this

temperature (73.4° F) 500 500 100 100

At high

specification by an independent laboratory. First article of

temperature (140° F) 500 500 100 100

manufacture examinations need only be repeated when there is

Post-eposure a change in materials or processes.

adhesion, min:

9.2 Unless otherwise specified, the number of label test

High temperature (N/100 mm) 66 66 55 55

(oz/in.) 60 60 50 50

samples shall be as specified in Table 1, with an acceptable

Low temperature (N/100 mm) 66 66 55 55

quality limit (AQL) of 4.0 % in accordance with ANSI/ASQC

(oz/in.) 60 60 50 50

Z1.4.

Rain (N/100 mm) 66 66 N/A N/A

(oz/in.) 60 60 N/A N/A

10. Procedures

Salt fog (N/100 mm) 66 66 N/A N/A 10.1 Unless otherwise specified, prior to label application,

(oz/in.) 60 60 N/A N/A

eachlabelsampleandtestsurfacepanelshallbeconditionedin

the standard conditioning atmosphere described in Practice

Blowing dust (N/100 mm) 66 66 N/A N/A

(oz/in.) 60 60 N/A N/A D4332 for a minimum of 24 h.

10.2 Each requirement shall be tested in accordance with

Humidity (N/100 mm) 66 66 55 55

(oz/in.) 60 60 50 50

the test methods listed in Section 11. The total test quantities

shall follow sequential testing as described in Figs. 1 and 2 for

Freeze and thaw (N/100 mm) 66 66 55 55

Type I and Type II labels, respectively. Unless otherwise noted

(oz/in.) 60 60 50 50

in the applicable test method, tests shall be conducted in the

Accelerated aging (N/100 mm) 66 66 55 55

standardconditioningatmospheredescribedinPracticeD4332.

(oz/in.) 60 60 50 50

10.3 Test Surface—Except for abrasion resistance, each test

Contamination by Fluids (N/100 mm) See Table 3 N/A N/A

sequence, unless otherwise specified by the customer, shall be

(oz/in.) See Table 3 N/A N/A

conductedonpanelsofstainlesssteel302or304inaccordance

D7932−14

FIG. 1Type I Test Sequence

with Specification A666 having a bright-annealed finish. The 10.4.1 Stainless steel and other non-porous test surface

stainless steel surface roughness height shall be 2.0 6 0.2-µin.

panels shall be prepared as specified in Test Method D6252/

or 50 6 5-nm arithmetical average deviation from the mean

D6252M.

line. All test surface panels, regardless of material, shall be a

10.4.2 If used for testing, wooden test surface panels shall

minimum 2 by 5-in. and no less than 0.032-in. thick or 50 by

be lightly sanded using at least 220 grit sandpaper to provide a

125-mm and no less than 1.1-mm thick. Any panels showing

smooth test surface. A clean surgical sponge, gauze, or tissue

stains, discoloration, numerous scratches, or other surface

freeoflintshallbeusedtocleanallresiduebeforelabelsample

imperfections are not acceptable.

adhesion.

10.4 Test Surface Panel Preparation—

D7932−14

FIG. 2Type II Test Sequence

10.4.3 All other porous test

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.