ASTM D4365-13

(Test Method)Standard Test Method for Determining Micropore Volume and Zeolite Area of a Catalyst

Standard Test Method for Determining Micropore Volume and Zeolite Area of a Catalyst

SIGNIFICANCE AND USE

5.1 This gas adsorption method complements the X-ray procedure of Test Method D3906. This test method will be useful to laboratories that do not have X-ray diffractometers. Each test method can be calibrated by use of an appropriate series of mechanical mixtures to provide what may be termed percent zeolite. If there is disorder in the zeolite, the adsorption method will yield higher values than the X-ray method. The reverse will be true if some zeolite pores (micropores) are blocked or filled.

SCOPE

1.1 This test method covers the determination of total surface area and mesopore area. From these results are calculated the zeolite area and micropore volume of a zeolite containing catalyst. The micropore volume is related to the percent zeolite in the catalyst. The zeolite area, a number related to the surface area within the zeolite pores, may also be calculated. Zeolite area, however, is difficult to intepret in physical terms because of the manner in which nitrogen molecules pack within the zeolite.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For a specific precautionary statement, see Note 3.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D4365 − 13

Standard Test Method for

Determining Micropore Volume and Zeolite Area of a

1

Catalyst

This standard is issued under the fixed designation D4365; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

1.1 This test method covers the determination of total 3.1 Definitions of Terms Specific to This Standard:

surface area and mesopore area. From these results are calcu- 3.1.1 mesopore (matrix) area of a catalyst—the area deter-

lated the zeolite area and micropore volume of a zeolite mined from the slope of the t-plot.

containing catalyst. The micropore volume is related to the

3.1.2 micropore volume of the catalyst—the pore volume in

percent zeolite in the catalyst. The zeolite area, a number

pores having radii less than 1 nm, usually associated with the

relatedtothesurfaceareawithinthezeolitepores,mayalsobe

zeolite portion of the catalyst, and determined from the

calculated. Zeolite area, however, is difficult to intepret in

intercept of the t-plot.

physical terms because of the manner in which nitrogen

3.1.3 surface area of a catalyst—the total surface of the

molecules pack within the zeolite.

catalyst pores. It is expressed in square metres per gram.

1.2 The values stated in SI units are to be regarded as

3.1.4 zeoliteareaofacatalyst—thedifferencebetweentotal

standard. No other units of measurement are included in this

surface area and mesopore area.

standard.

3.2 Symbols:

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

P = initial helium pressure, torr

H

1

priate safety and health practices and determine the applica-

P = helium pressure after equilibration, torr

H

2

bility of regulatory limitations prior to use. For a specific

S = slope of BET plot, 11.7

B

precautionary statement, see Note 3. I = intercept of BET plot, 11.7

B

S = slope of t-plot, 11.13

t

2. Referenced Documents

I = intercept of t-plot, 11.13

t

2 T = temperatureofmanifoldatinitialheliumpressure,

H1

2.1 ASTM Standards:

°C

D3663Test Method for Surface Area of Catalysts and

T = temperature of manifold after equilibration, °C

H2

Catalyst Carriers

T '(i) = extra volume bulb temperature, °C

x

D3906Test Method for Determination of Relative X-ray

T (i) = extra volume bulb temperature, K

x

Diffraction Intensities of Faujasite-Type Zeolite-

P (i) = initial N pressure, torr

1 2

Containing Materials

T (i) = manifold temperature at initial N pressure, K

1 2

E177Practice for Use of the Terms Precision and Bias in

T '(i) = manifold temperature at initial N pressure, °C

1 2

ASTM Test Methods

P (i) = pressure after equilibration, torr

2

E456Terminology Relating to Quality and Statistics

T (i) = manifold temperature after equilibration, K

2

E691Practice for Conducting an Interlaboratory Study to

T '(i) = manifold temperature after equilibration, °C

2

Determine the Precision of a Test Method P (i) = liquid nitrogen vapor pressure, torr

0

T (i) = liquid nitrogen temperature, K

s

X = relative pressure, P /P

2 0

3

1

This test method is under the jurisdiction of ASTM Committee D32 on

V = volume of manifold, cm

d

3

Catalysts and is the direct responsibility of Subcommittee D32.01 on Physical-

V = extra volume bulb, cm

x

Chemical Properties. 3

V = effective void volume, cm

s

Current edition approved April 1, 2013. Published August 2013. Originally

W = weight of sample, g

approved in 1984. Last previous edition approved in 2008 as D4365–95(2008). s

W = tare weight of sample tube, g

DOI: 10.1520/D4365-13.

1

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

W = weight of sample+tare weight of tube, g

2

3

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

V = volume of nitrogen in the dead-space, cm

ds

Standards volume information, refer to the standard’s Document Summary page on

V = see 11.4.3

1

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D4365 − 13

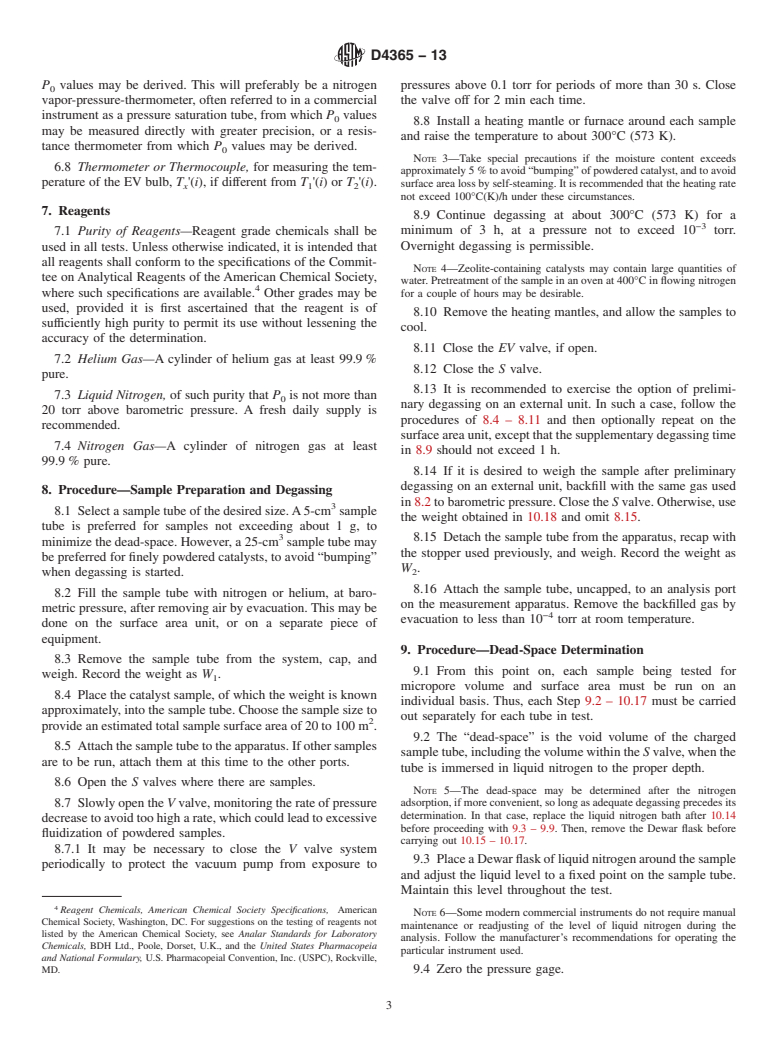

FIG. 1 Schematic Diagram of Surface Area Apparatus

6.1.3 Pressure Sensing Devices or Pressure Transducer,

V = see 11.4.4

2

capable of measurements to the nearest 0.1-torr sensitivity in

V = see 11.4.5

t

V = see 11.4.7 the range from 0 to 1000 torr (1 torr=133.3 Pa).

a

V = see 11.8

m

NOTE 1—See, for example, the article by Joy for a description of a

BET(i) = see 11.4.8 3

constant-volume manometer.

t(i) = see 11.10

6.1.4 Valve (H), from the helium supply t

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D4365 − 95 (Reapproved 2008) D4365 − 13

Standard Test Method for

Determining Micropore Volume and Zeolite Area of a

1

Catalyst

This standard is issued under the fixed designation D4365; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the determination of total surface area and mesopore area. From these results are calculated the

zeolite area and micropore volume of a zeolite containing catalyst. The micropore volume is related to the percent zeolite in the

catalyst. The zeolite area, a number related to the surface area within the zeolite pores, may also be calculated. Zeolite area,

however, is difficult to intepret in physical terms because of the manner in which nitrogen molecules pack within the zeolite.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. For a specific precautionary statement, see Note 3.

2. Referenced Documents

2

2.1 ASTM Standards:

D3663 Test Method for Surface Area of Catalysts and Catalyst Carriers

D3906 Test Method for Determination of Relative X-ray Diffraction Intensities of Faujasite-Type Zeolite-Containing Materials

E177 Practice for Use of the Terms Precision and Bias in ASTM Test Methods

E456 Terminology Relating to Quality and Statistics

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 mesopore (matrix) area of a catalyst—the area determined from the slope of the t-plot.

3.1.2 micropore volume of the catalyst—the pore volume in pores having radii less than 1 nm, usually associated with the zeolite

portion of the catalyst, and determined from the intercept of the t-plot.

3.1.3 surface area of a catalyst—the total surface of the catalyst pores. It is expressed in square metres per gram.

3.1.4 zeolite area of a catalyst—the difference between total surface area and mesopore area.

3.2 Symbols:

P = initial helium pressure, torr

H

1

P = helium pressure after equilibration, torr

H

2

S = slope of BET plot, 11.7

B

I = intercept of BET plot, 11.7

B

S = slope of t-plot, 11.13

t

I = intercept of t-plot, 11.13

t

T = temperature of manifold at initial helium pressure, °C

H1

1

This test method is under the jurisdiction of ASTM Committee D32 on Catalysts and is the direct responsibility of Subcommittee D32.01 on Physical-Chemical

Properties.

Current edition approved April 1, 2008April 1, 2013. Published May 2008August 2013. Originally approved in 1984. Last previous edition approved in 20072008 as

ε1

D4365–95(2007)D4365 – 95 .(2008). DOI: 10.1520/D4365-95R08.10.1520/D4365-13.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D4365 − 13

FIG. 1 Schematic Diagram of Surface Area Apparatus

T = temperature of manifold after equilibration, °C

H2

T '(i) = extra volume bulb temperature, °C

x

T (i) = extra volume bulb temperature, K

x

P (i) = initial N pressure, torr

1 2

T (i) = manifold temperature at initial N pressure, K

1 2

T '(i) = manifold temperature at initial N pressure, °C

1 2

P (i) = pressure after equilibration, torr

2

T (i) = manifold temperature after equilibration, K

2

T '(i) = manifold temperature after equilibration, °C

2

P (i) = liquid nitrogen vapor pressure, torr

0

T (i) = liquid nitrogen temperature, K

s

X = relative pressure, P /P

2 0

3

V = volume of manifold, cm

d

3

V = extra volume bulb, cm

x

3

V = effective void volume, cm

s

W = weight of sample, g

s

W = tare weight of sample tube, g

1

W = weight of sample + tare weight of tube, g

2

3

V = volume of nitrogen in the dead-space, cm

ds

V = see 11.4.3

1

V = see 1

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.