ASTM D782-82(1993)e1

(Test Method)Test Methods for Shipping Containers in Revolving Hexagonal Drum (Withdrawn 1999)

Test Methods for Shipping Containers in Revolving Hexagonal Drum (Withdrawn 1999)

SCOPE

1.1 This test method covers a procedure for performing tests on loaded shipping containers by means of the revolving drum tester to determine the relative ability of a shipping container to withstand rough handling.

1.2 This test method is used to give an indication of the ability of a shipping container to withstand a variety of shocks and impact stresses, usually for permitting a comparison of different designs of containers of the same size and carrying the same load. This test method permits an observation of the progressive destruction or failure of the package, through which means of improving the design may be determined. The drum test is not intended to simulate any specific environmental hazard.

1.3 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Standards Content (Sample)

ASTM D782 82 - 0759530 053bb05 383 -

AMERICAN SOCIETY FOR TESTING AND MATERIALS

Designation: D 782 - 82 (Reapproved 1993)“’

1916 Race St. Philadelphia, Pa 19103

Reprinted from the Annual Book of ASTM Standards. CopyrIght ASTM

If not listed in the current combined index, will appear in the next edition

Standard Test Method for

Shipping Containers in Revolving Hexagonal Drum’

This standard is issued under the fixed designation D 782; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapprowl. A

superscript epsilon (L) indicates an editorial change since the last revision or reapproval.

‘I NOTE-The title was changed and Section 14 added editorially in May 1993.

1. Scope 3. Terminology

3. I Definitions:

1 .l This test method covers a procedure for performing

3.1.1 Definitions of packaging terms used in this standard

tests on loaded shipping containers by means of the re-

volving drum tester to determine the relative ability of a may be found in Terminology D 996.

shipping container to withstand rough handling. 3.2 Description of Terms Specific to This Standard:

1.2 This test method is used to give an indication of the

3.2.1 crotch of the hazard-the downward facing comer

ability of a shipping container to withstand a variety of

formed by the intersection of two sides of the bafIle on one of

shocks and impact stresses, usually for permitting a compar-

the drum faces.

ison of different designs of containers of the same size and

3.2.2 drum bajles-boards fixed within the drum in a

carrying the same load. This test method permits an obser-

prescribed manner to form baflles designed to cause the

vation of the progressive destruction or failure of the

container to fall on different comers, edges, and faces, and to

package, through which means of improving the design may

present various impact hazards.

be determined. The drum test is not intended to simulate

3.2.3 drum hazards-same as drum baflles.

any specific environmental hazard.

1.3 This standard does not purport to address all of the

safety problems, if any, associated with its use. It is the 4. Summary of Test Method

responsibility of the user of this standard to establish appro-

4.1 A container and its contents are subjected to a series

priate safety and health practices and determine the applica-

of random falls onto the inner faces or against the bafnes

bility of regulatory limitations prior to use.

arranged on the inner periphery of a revolving drum. The

b&es are designed to cause the box to fall on different faces,

2. Referenced Documents

edges, and comers, and they present various impact hazards

2.1 ASTM Standards: to the container.

D 685 Practice for Conditioning Paper and Paper Products

for Testing*

5. Significance and Use

D 775 Test Method for Drop Test for Loaded Boxes*

5.1 The drum test is usually made to compare various

D 880 Test Method for Impact Testing for Shipping Con-

container designs. This test is used primarily when it is

tainers and Systems2

desired to simulate an unpredictable, uncontrolled type of

D996 Terminology of Packaging and Distribution Envi-

rough handling as, for example, in handling and shipment of

ronments*

mixed sizes and masses of packages. This series of falls is

D2956 Practice for Conducting Controlled Shock Input

unpredictable, and probably no two containers tested will

Tests for Shipping Containers3

receive exactly the same cycle of abuse. For this reason,

E 122 Practice for Choice of Sample Size to Estimate a

drum test results may be expected to vary more than results

Measure of Quality for a Lot or Process4

in a test that does not contain this random characteristic (see

2.2 ASTM Adjunct:

Section 13).

Adjunct No. 12-407820-10 (14-B drum)5

Adjunct No. 12-407820-20 (7-ft drum)5

NOTE 1 -As alternatives to the drum test, potential users are asked to

consider using the drop test (Test Method D 775), the incline impact test

(Test Method D 880), or other procedures (Practice D 2956).

1 This test method is under the jurisdiction of ASTM Committee D-IO on

Packaging and is the direct responsibility of Subcommittee D10.22 on Handling

and Transportation.

6. Apparatus

Current edition approved Aug. 27, 1982. Published January 1983. Originally

6.1 The testing machine shall consist of a revolving drum

published as D 782 - 44 T. Last previous edition D 782 - 68(1973).

* Annual Book of ASTM Standards, Vol 15.09.

which shall be in the form of a prism whose bases are regular

3 Discontinued, see 1984 Annual Book of ASTM Standards, Vol 15.09.

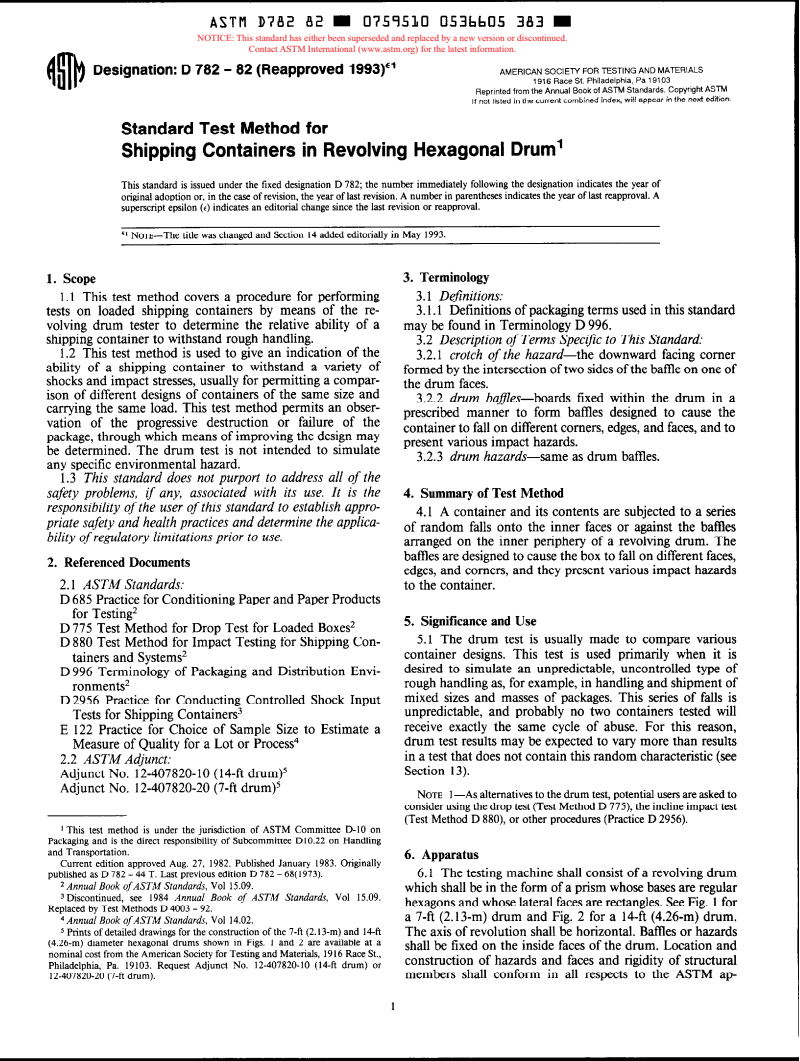

hexagons and whose lateral faces are rectangles. See Fig. 1 for

Replaced by Test Methods D 4003 - 92.

a 7-ft (2.13-m) drum and Fig. 2 for a 14-ft (4.26-m) drum.

4 Annual Book of ASTM Standards, Vol 14.02.

5 Prints of detailed drawings for the construction of the 7-ft (2.13-m) and 14-ft

The axis of revolution shall be horizontal. Baffles or hazards

(4.26-m) diameter hexagonal drums shown in Figs. 1 and 2 are available at a

shall be fixed on the inside faces of the drum. Location and

nominal cost from the American Society for Testing and Materials, 1916 Race St.,

construction of hazards and faces and rigidity of structural

Philadelphia, Pa. 19103. Request Adjunct No. 12-407820-10 (14-ft drum) or

members shall conform in all respects to the ASTM ap-

12-407820-20 (7-ft drum).

ASTM Di’82 82 W 0759510 053bbOb 2LT -

6.2 The 7-ft (2.13-m) drum shall revolve at a speed of 2 f

‘/6 rpm. It may be used for testing containers whose gross

mass does not exceed 250 lb (113 kg), and whose greatest

dimension does not exceed 20 in. (508 mm).

6.3 The 14-ft (4.26-m) drum shall revolve at a speed of 1

+ X2 rpm. It may be used for testing containers whose mass

does not exceed 600 lb (270 kg) and whose greatest dimen-

sion does not exceed 40 in. ( 10 16 mm).

7. Test Specimen

7.1 The container to be tested shall be packed with either

the actual contents for which it was designed, or a dummy

load simulating such contents. In either instance, the con-

tainer shall be closed and sealed in the same manner as will

be used in actual shipment.

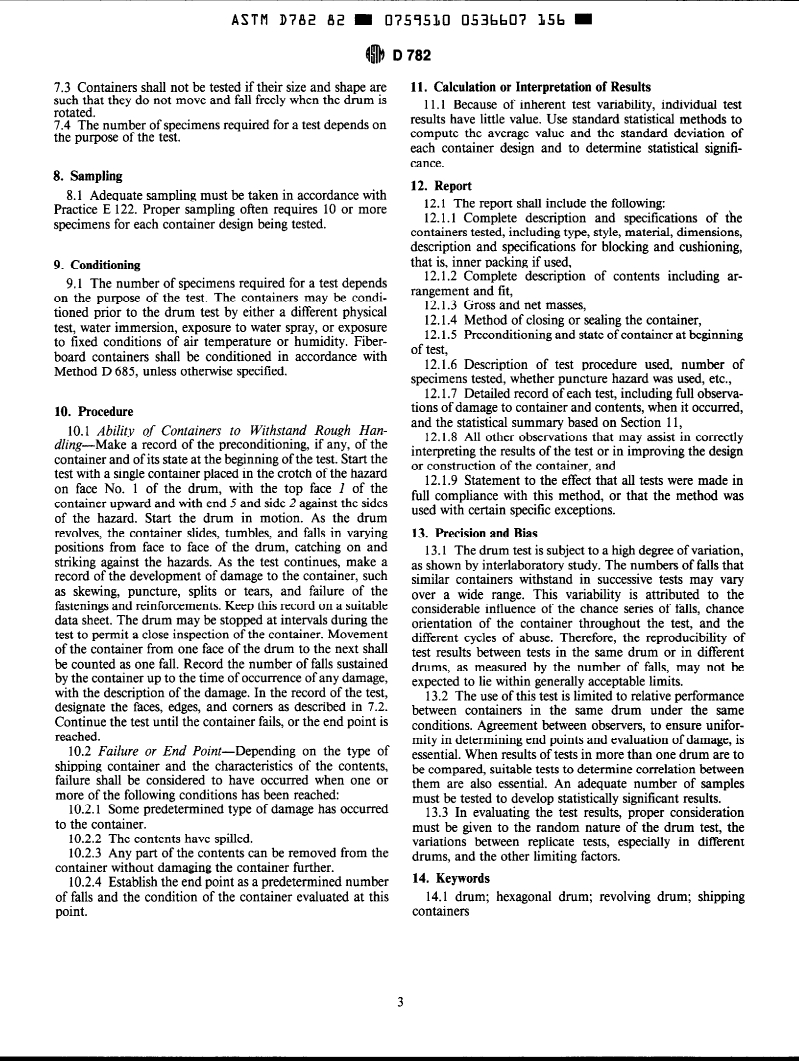

7.2 The procedure for identification of the faces, edges,

and comersof rectangular containers shall be as follows:

7.2.1 Facing one end of the container (for fiberboard

containers, the manufacturer’s joint shall be on the right),

the top of the container shall be designed as I, the right side

as 2, the bottom as 3, the 1eFt side as 4, the near end as 5, and

the far end as 6.

FIG. 1 Box Testing Drum 7 ft (2.13 m) in Diameter

7.2.2 The edges shall be identified by the numbers of the

two faces that form that edge; for example, l-2 identifies the

proved drawings and specifications.5 When prescribed in the

edge where the top and right side meet and 2-5 the edge

specifications for the shipping container being tested, a

formed by the right side and the near end. (In a fiberboard

conical projection shall be positioned on face No. 4 to

container, this edge will have the manufacturer’s joint.)

simulate a puncture hazard. The drum shall be equipped

7.2.3 The comers shall be identified by the numbers of the

with an automatic counting device that will record each

three faces that meet to form that comer; for example, l-2-6

individual fall as the corresponding drum face passes the

identifies the comer where the top, the right side, and the far

counter. The inner faces and hazards of the drum shall be

end meet. This identification is illustrated in Fig. 3.

clean, smooth, polished, and in good repair. Faces shall be of

such condition that an ordinary No. 2% food can (“packers”

40 1 by 4 11) filled with water, or the equivalent to give a gross

mass of 2.1 f 0. I lb (950 f 45 g) resting on its bottom on the

face will just slide when the face of the drum is at an angle of

15 f 2” from the horizontal.

NOTE 2-Wax is recommended to protect against rust when not in

US.5

C0rner

I-2-6

FIG. 3 Identification of the Faces, Edges, and Comers of Test

FIG. 2 Box Testing Drum 14 ft (4.26 m) in Diameter

Specimens

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.