ASTM D6535/D6535M-05(2010)e1

(Test Method)Standard Test Method for Determining the Dip Tube Length of a Mechanical Pump Dispenser

Standard Test Method for Determining the Dip Tube Length of a Mechanical Pump Dispenser

SIGNIFICANCE AND USE

This test method is to be used to determine the length of a dip tube of a mechanical pump dispenser that extends to the bottom-corner of a container.

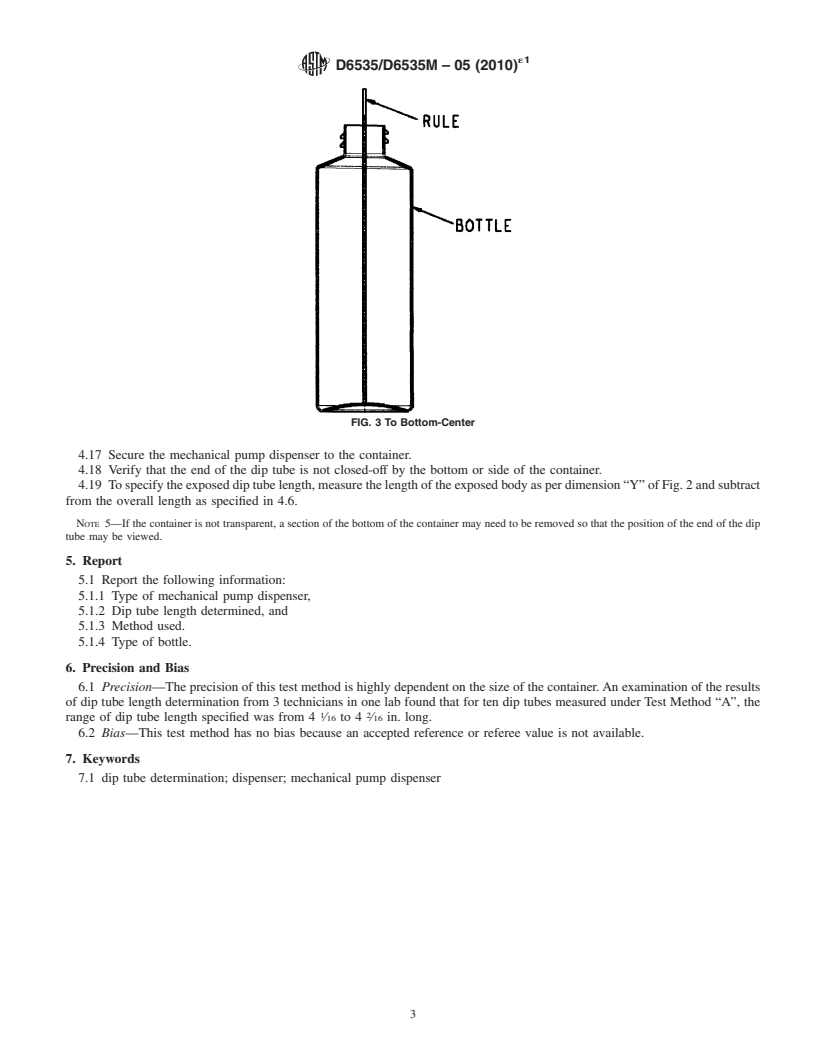

This test method is to be used to determine the length of a dip tube of a mechanical pump dispenser that extends to the bottom-center of a container.

SCOPE

1.1 This test method covers the determination technique for a dip tube of a mechanical pump dispenser.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: D6535/D6535M − 05 (Reapproved 2010)

Standard Test Method for

Determining the Dip Tube Length of a Mechanical Pump

Dispenser

This standard is issued under the fixed designation D6535/D6535M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Units information was editorially revised in December 2010.

1. Scope 4. Procedure

1.1 This test method covers the determination technique for

TEST METHOD “A”—DIP TUBE LENGTH

a dip tube of a mechanical pump dispenser.

DETERMINATION TO THE BOTTOM-CORNER OF

1.2 The values stated in either SI units or inch-pound units THE CONTAINER

NOTE 1—This test method is used when the dip tube of a mechanical

are to be regarded separately as standard. The values stated in

pump dispenser must extend to the bottom-corner of a container.

each system may not be exact equivalents; therefore, each

4.1 Place the zero-index end of the ruler into the container

system shall be used independently of the other. Combining

values from the two systems may result in non-conformance as shown in Fig. 1.

with the standard.

4.2 Turn the ruler so that the side of the ruler reaches as far

1.3 This standard does not purport to address all of the into the bottom-corner of the container as possible.

safety concerns, if any, associated with its use. It is the

NOTE 2—If the cross-sectional area of the container is not round,

responsibility of the user of this standard to establish appro-

position the ruler into the farthest bottom-corner of the container.

priate safety and health practices and determine the applica-

4.3 Adjust the ruler so that it is positioned through the

bility of regulatory limitations prior to use.

center axis of the container opening.

4.4 Measure the dip tube length to within 1 mm or ⁄16 in. If

2. Significance and Use

the measurement value is between the whole millimetre or ⁄16

2.1 This test method is to be used to determine the length of

th

gradient,usethelargervalue(thatis,ifmeasurementis118.5

a dip tube of a mechanical pump dispenser that extends to the

21 11

mm, use 119 mm; or if measurement is 4- ⁄32 in., use 4- ⁄16

bottom-corner of a container.

in).

2.2 This test method is to be used to determine the length of

4.5 If the dip tube measurement is in millimetres, subtract 1

a dip tube of a mechanical pump dispenser that extends to the

mm from the measured value. If the dip tube measurement is in

bottom-center of a container.

inches, subtract ⁄16 in. from the measured value.

3. Apparatus

4.6 Record the net value (original value minus 1 mm or ⁄16

in.).

3.1 Thin Metal Ruler, with minimum gradients of one

millimeter and/or ⁄16 in. along with a zero index at the end of 4.7 To verify the new dip tube specification, prepare a

the ruler.

sample mechanical pump dispenser with the newly-specified

dip tube length.

3.2 Calipers.

4.8 Secure the mechanical pump dispenser to the container.

4.9 Verify that the end of the dip tube is not closed-off by

This test method is under the jurisdiction ofASTM Committee F02 on Flexible

the bottom or side of the container.

Barrier Packaging and is the direct responsibility of Subcommittee F02.30 on

Mechanical Pump Dispensers.

4.10 To specify the exposed dip tube length, measure the

Current edition approved Oct. 1, 2010. Published December 2010. Originally

length of the exposed body as per dimension “Y” of Fig. 2 and

approved in 2000. Last previous edition approved in 2005 as D6535 – 05. DOI:

10.1520/D6535_D6535M-05R10E01. subtract from the overall length as specified in 4.6.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

D6535/D6535M − 05 (2010)

FIG. 3 To Bottom-Center

FIG. 1 To Bottom-Corner

measurement is 118.5 mm, use 118

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation:D6535–05 Designation: D6535/D6535M – 05 (Reapproved 2010)

Standard Test Method for

Determining the Dip Tube Length of a Mechanical Pump

Dispenser

This standard is issued under the fixed designation D6535/D6535M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

´ NOTE—Units information was editorially revised in December 2010.

1. Scope

1.1 This test method covers the determination technique for a dip tube of a mechanical pump dispenser.

1.2The values stated in both inch pound and SI units are to be regarded separately as the standard.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each

system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the

two systems may result in non-conformance with the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Significance and Use

2.1 This test method is to be used to determine the length of a dip tube of a mechanical pump dispenser that extends to the

bottom-corner of a container.

2.2 This test method is to be used to determine the length of a dip tube of a mechanical pump dispenser that extends to the

bottom-center of a container.

3. Apparatus

3.1 Thin Metal Ruler, with minimum gradients of one millimeter and/or ⁄16 in. along with a zero index at the end of the ruler.

3.2 Calipers.

4. Procedure

TEST METHOD “A”—DIP TUBE LENGTH DETERMINATION TO THE BOTTOM-CORNER OF THE

CONTAINER

NOTE 1—This test method is used when the dip tube of a mechanical pump dispenser must extend to the bottom-corner of a container.

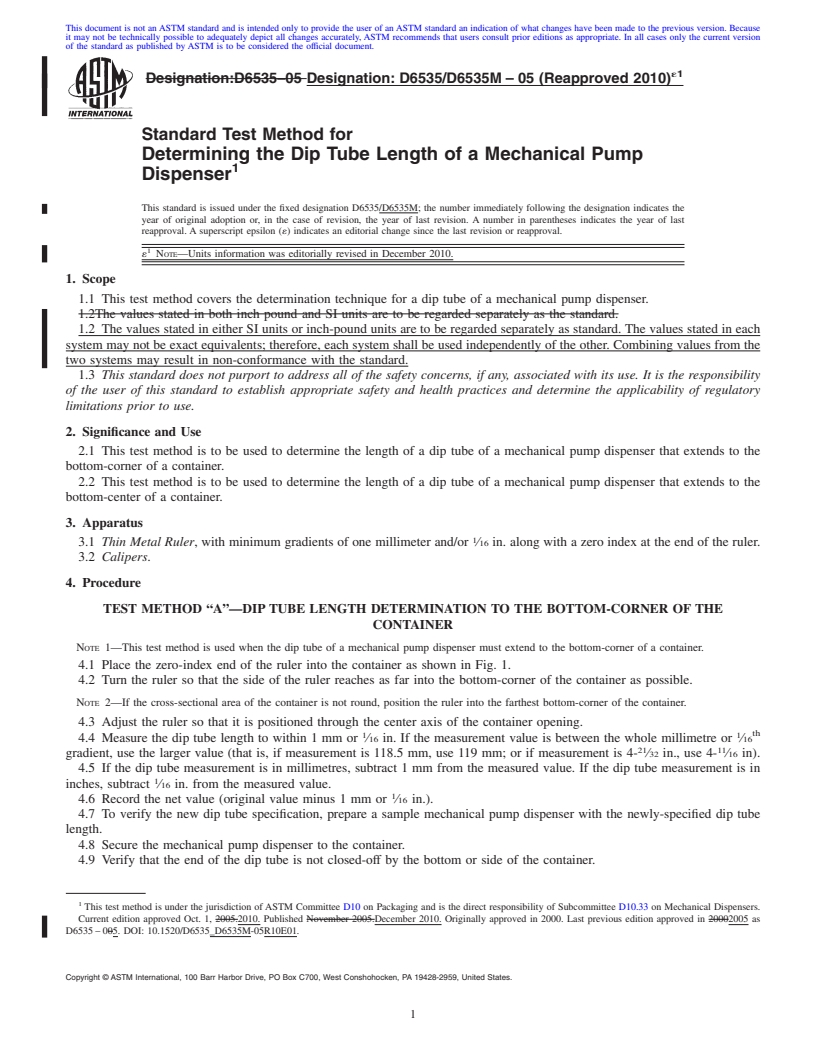

4.1 Place the zero-index end of the ruler into the container as shown in Fig. 1.

4.2 Turn the ruler so that the side of the ruler reaches as far into the bottom-corner of the container as possible.

NOTE 2—If the cross-sectional area of the container is not round, position the ruler into the farthest bottom-corner of the container.

4.3 Adjust the ruler so that it is positioned through the center axis of the container opening.

th

1 1

4.4 Measure the dip tube length to within 1 mm or ⁄16 in. If the measurement value is between the whole millimetre or ⁄16

21 11

gradient, use the larger value (that is, if measurement is 118.5 mm, use 119 mm; or if measurement is 4- ⁄32 in., use 4- ⁄16 in).

4.5 If the dip tube measurement is in millimetres, subtract 1 mm from the measured value. If the dip tube measurement is in

inches, subtract ⁄16 in. from the measured value.

4.6 Record the net value (original value minus 1 mm or ⁄16 in.).

4.7 To verify the new dip tube specification, prepare a sample mechanical pump dispenser with the newly-specified dip tube

length.

4.8 Secure the mechanical pump dispenser to the container.

4.9 Verify that the end of the dip tube is not closed-off by the bottom or side of the container.

This test method is under the jurisdiction of ASTM Committee D10 on Packaging and is the direct responsibility of Subcommittee D10.33 on Mechanical Dispensers.

Current edition approved Oct. 1, 2005.2010. Published November 2005.December 2010. Originally approved in 2000. Last previous edition approved in 20002005 as

D6535 – 005. DOI: 10.1520/D6535_D6535M-05R10E01.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

´1

D6535/D6535M – 05 (2010)

FIG. 1 To Bottom-Corner

4.10 To specify the exposed d

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.