ASTM D647-88A

(Practice)Practice for Design of Molds for Test Specimens of Plastic Molding Materials (Withdrawn 1994)

Practice for Design of Molds for Test Specimens of Plastic Molding Materials (Withdrawn 1994)

General Information

Standards Content (Sample)

ASTM Db47 REV*A 88 0759530 O039340 2

(& Designation: D 647 - 88a

AMERICAN SOCIETY FOR TESTINQ AND MATERIALS

1916 Race St., Philadelphia. Pa. 19103

Reprinted from the Annual Book of ASTM Standards, Copyright ASTM

If not listed in the current combined index, will appear in lhe next edition.

Standard Practice for

Design of Molds for Test Specimens of Plastic Molding

Materials'

Tbis standard is issued under the fied designation D 647; the number immediately following the designation indicates the year of

onghal adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (6) indicates an editorial change since the last revision or reapproval.

This standard has been approved fir use by agencies of the Deparimenr of Definse. Consult the DoD Index of Spec@cations and

aandards fir the specìíìc year of issue which has been adopted by the Depariment of Definse.

D 790 Test Methods for Flexural Properties of Plastics and

1, Scope

Electrical Insulating Materials3

1.1 This practice covers the design of molds for test

D955 Method for Measuring Shrinkage From Mold

specimens of plastic materials. Designs are shown for com-

Dimensions of Molded Plastics3

pression molds (Figs. 1-4), a transfer mold (Fig. 5) for use in

producing bar, disk, and tensile test specimens in thermoset-

3. Significance and Use

ting plastic materiais primarily, and an injection mold (Fig.

3.1 A material is subjected during the molding process to

5) for use in producing bar, disk, and tensile test specimens

a complex interaction of many variables. Standardization of

in either thermoplastic or thermosetting materials. The

the mold design can assist in the control of some of these

plastic and mold temperatures, pressure and cycle timing

variables by controlling the uniformity of the specimen

used for the molding material should conform to the

geometries. A standardized mold design does not necessarily

if available, or to the material

appropriate molding practice,

equate to uniform and equivalent test specimens because of

specification. If such information is not available, the recom-

processing variables and the effect of these variables on

mendations of the material supplier should be followed,

property results.

1.2 Designs shown have been found suitable for a broad

range of plastics but may not be optimum for any given

4. Compression Molds for Bar Test Specimens

materiai. Only the specimen dimensions are actually

4.1 Compression molds for bar test specimens 12.7 mm

standardized?

(112 in.) in width by 127 mm (5 in.) or 64 mm (2112 in.) in

1.3 The values stated in SI units are to be regarded as the

length, and 12.7 (112 in.), 6.4 mm (114 in.), or 3.2 mm ('18 in.)

standard. The values in parentheses are given for informa-

in thickness may be the single-bar, singleavity, positive

tion only.

mold shown in Fig. 1.2

1.4 This standard may involve hazardous materials, oper-

ations, and eqirbment. This standard does not purport to

5. Compression Molds for Disk Test Specimens

address all ofthe safety probletns associated with its use. It is

5.1 Compression molds for the disk test specimens 51

the responsibility of the user of this standard to establish

mm (2 in.) or 102 mm (4 in.) in diameter may be of the

appropriate safty and health practices and determine the

design shown in Fig. 2.

applicability of regulatory limitations prior to use.

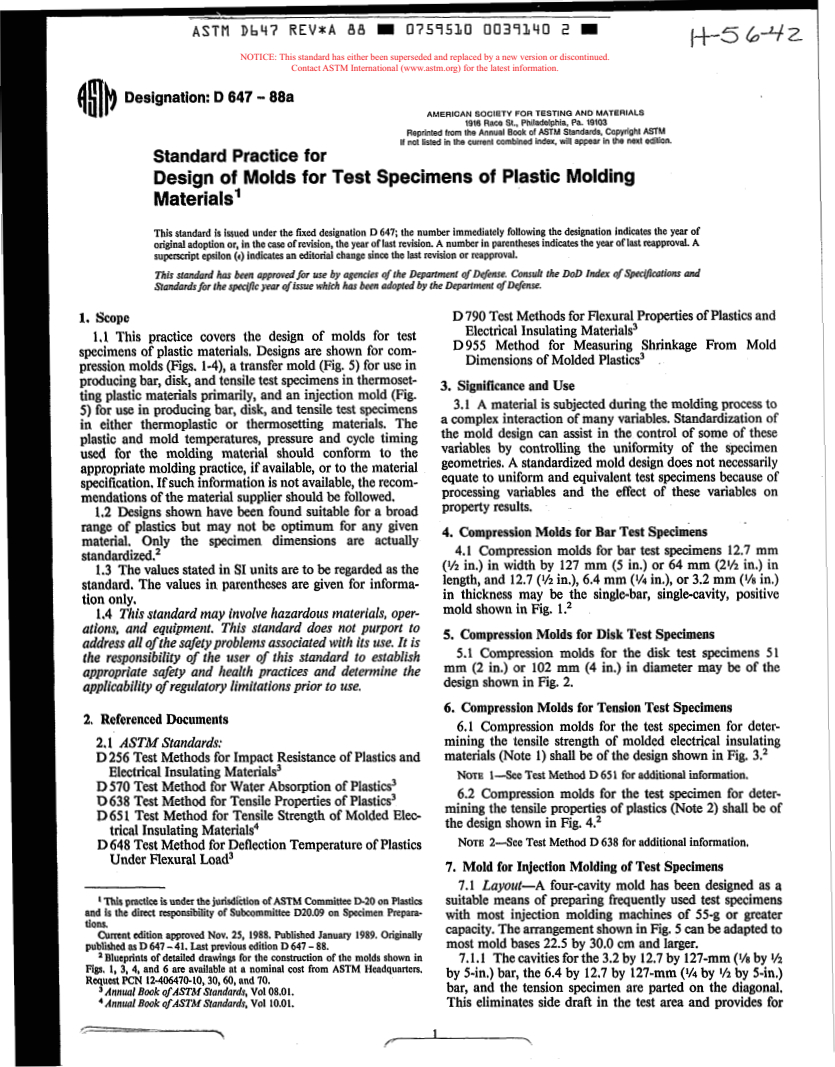

6. Compression Molds for Tension Test Specimens

2, Referenced Dacuments

6.1 Compression molds for the test specimen for deter-

mining the tensile strength of molded electrical insulating

2.1 ASTM Standards:

materiais (Note 1) shall be of the design shown in Fig. 3.2

D 256 Test Methods for Impact Resistance of Plastics and

Elecfricai Insulating Materials3

NOTE 1-See Test Method D 651 fer additional information.

D 570 Test Method for Water Absorption of Plastics3

6.2 Compression molds for the test specimen for deter-

D 638 Test Method for Tensile Properties of Plastics3

mining the tensile properties of plastics (Note 2) shali be of

D651 Test Method for Tensile Strength of Molded Elec-

the design shown in Fig. 4.2

trical Insulating Materials4

NOTE 2See Test Method D 638 for additional information.

D 648 Test Method for Deflection Temperature of Plastics

Under Flexural had3

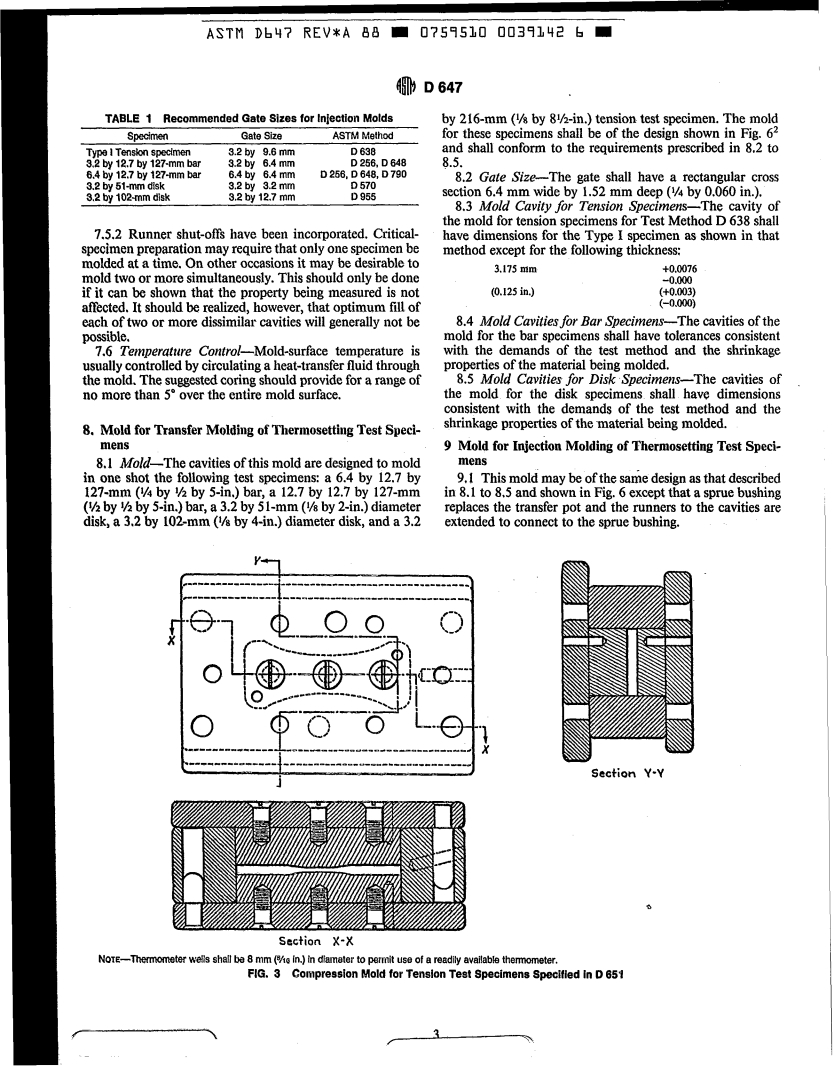

7. Mold for Injection Molding of Test Specimens

7.1 Layout-A four-cavity mold has been designed as a

I This pradœ is under the jurisdi.hion of ASTM Committee D-20 on Plastics suitable means of preparing frequently used test specimens

and is the direct rwponsibility of Subcommittee D20.09 on Specimen ¶-

with most injection molding machines of 55-g or greater

tiom

capacity. The arrangement shown in Fig. 5 can be adapted to

Cumnt edition approved Nov. 25, 1988. Published January 1989. Onginally

most mold bases 22.5 by 30.0 cm and larger.

published BS D 647 -41. Last previous edition

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.