ASTM A409/A409M-01(2005)

(Specification)Standard Specification for Welded Large Diameter Austenitic Steel Pipe for Corrosive or High-Temperature Service

Standard Specification for Welded Large Diameter Austenitic Steel Pipe for Corrosive or High-Temperature Service

SCOPE

1.1 This specification covers straight seam or spiral seam electric-fusion-welded, light-wall, austenitic chromium-nickel alloy steel pipe for corrosive or high-temperature service. The sizes covered are NPS 14 to 30 with extra light (Schedule 5S) and light (Schedule 10S) wall thicknesses. Table X1.1 shows the wall thickness of Schedule 5S and 10S pipe. Pipe having other dimensions may be furnished provided such pipe complies with all other requirements of this specification.

1.2 Several grades of alloy steel are covered as indicated in Table 1.

1.3 Optional supplementary requirements are provided. These call for additional tests to be made, and when desired shall be stated in the order, together with the number of such tests required.

1.4 The values stated in either inch-pound units or SI units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other. Combining values from the two systems may result in nonconformance with the specification. The inch-pound units shall apply unless the "M" designation of this specification is specified in the order.

Note 1--The dimensionless designator NPS (nominal pipe size) has been substituted in this standard for such traditional terms as "nominal diameter," "size," and "nominal size."

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A 409/A 409M – 01 (Reapproved 2005)

Standard Specification for

Welded Large Diameter Austenitic Steel Pipe for Corrosive

or High-Temperature Service

This standard is issued under the fixed designationA 409/A 409M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope A 480/A 480M Specification for General Requirements for

2 Flat-Rolled Stainless and Heat-Resisting Steel Plate,

1.1 This specification covers straight seam or spiral seam

Sheet, and Strip

electric-fusion-welded, light-wall, austenitic chromium-nickel

A 999/A 999M Specification for General Requirements for

alloy steel pipe for corrosive or high-temperature service. The

Alloy and Stainless Steel Pipe

sizes covered are NPS 14 to 30 with extra light (Schedule 5S)

E 527 Practice for Numbering Metals and Alloys (UNS)

and light (Schedule 10S) wall thicknesses. Table X1.1 shows

2.2 ASME Boiler and Pressure Vessel Code:

the wall thickness of Schedule 5S and 10S pipe. Pipe having

Section IX Welding Qualifications.

other dimensions may be furnished provided such pipe com-

2.3 AWS Standards:

plies with all other requirements of this specification.

A 5.22 Flux Cored Arc Welding

1.2 Several grades of alloy steel are covered as indicated in

A 5.30 Consumable Weld Inserts for Gas Tungsten Arc

Table 1.

Welding

1.3 Optional supplementary requirements are provided.

A 5.4 Corrosion-Resisting Chromium and Chromium-

These call for additional tests to be made, and when desired

Nickel Steel Covered Welding Electrodes

shall be stated in the order, together with the number of such

A 5.9 Corrosion-Resisting Chromium and Chromium-

tests required.

Nickel Steel Welding Rods and Bare Electrodes

1.4 The values stated in either inch-pound units or SI units

A 5.11 Nickel and Nickel-Alloy Covered Welding Elec-

are to be regarded separately as standard. Within the text, the

trodes

SI units are shown in brackets. The values stated in each

A 5.14 Nickel and Nickel-Alloy Bare Welding Rods and

system are not exact equivalents; therefore, each system must

Electrodes

be used independently of the other. Combining values from the

2.4 Other Standard:

two systems may result in nonconformance with the specifi-

SAE J1086 Practice for Numbering Metals and Alloys

cation. The inch-pound units shall apply unless the “M”

(UNS)

designation of this specification is specified in the order.

NOTE 1—The dimensionless designator NPS (nominal pipe size) has 3. Ordering Information

been substituted in this standard for such traditional terms as nominal

3.1 Orders for material to this specification should include

diameter, size, and nominal size.

the following, as required, to describe the desired material

adequately:

2. Referenced Documents

3.1.1 Quantity (feet, centimetres, or number of lengths),

2.1 ASTM Standards:

3.1.2 Name of material (straight seam or spiral seam

A 262 Practices for Detecting Susceptibility to Intergranu-

electric-fusion-welded austenitic steel pipe),

lar Attack in Austenitic Stainless Steels

3.1.3 Grade (Table 1),

3.1.4 Size (outside diameter and schedule number, or wall

thickness).

This specification is under the jurisdiction of ASTM Committee A01 on Steel,

Stainless Steel, and RelatedAlloys and is the direct responsibility of Subcommittee

3.1.5 Length (specific or random) (Section 11),

A01.10 on Stainless and Alloy Steel Tubular Products.

Current edition approved Sept. 1, 2005. Published October 2005. Originally

approved in 1957 . Last previous edition approved in 2001 as A 409/A 409M – 01.

2 4

For ASME Boiler and Pressure Vessel Code applications see related Specifi- .Available from American Society of Mechanical Engineers (ASME), ASME

cation SA-409 in Section II of that Code. International Headquarters, Three Park Ave., New York, NY 10016-5990.

3 5

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available from American Welding Society (AWS), 550 NW LeJeune Rd.,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Miami, FL 33126.

Standards volume information, refer to the standard’s Document Summary page on Available from Society of Automotive Engineers (SAE), 400 Commonwealth

the ASTM website. Dr., Warrendale, PA 15096-0001.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

A 409/A 409M – 01 (2005)

TABLE 1 Chemical Requirements

UNS Composition, %

Designa-

Car- Man- Phos- Sulfur, Sili- Nickel Chromium Molyb- Tita- Colum- Cerium Other Elements

A

tions

bon, ganese, phorus, max con denum nium bium

max max max

TP304 S30400 0.08 2.00 0.045 0.030 1.00 max 8.0–11.0 18.0–20.0 . . . . . . . . . . . . . . .

TP304L S30403 0.035 2.00 0.045 0.030 1.00 max 8.0–12.0 18.0–20.0 . . . . . . . . . . . . . . .

TP309Cb S30940 0.08 2.00 0.045 0.030 1.00 max 12.0–16.0 22.0–24.0 . . . . . . . . . Cb 10 3 C min,

1.10 max

TP309S S30908 0.08 2.00 0.045 0.030 1.00 max 12.0–15.0 22.0–24.0 . . . . . . . . .

TP310Cb S31040 0.08 2.00 0.045 0.030 1.00 max 19.0–22.0 24.0–26.0 . . . . . . . . . Cb 10 3 C min,

1.10 max

TP310S S31008 0.08 2.00 0.045 0.030 1.00 max 19.0–22.0 24.0–26.0 . . . . . . . . .

TP316 S31600 0.08 2.00 0.045 0.030 1.00 max 10.0–14.0 16.0–18.0 2.00–3.00 . . . . . . . . .

TP316L S31603 0.035 2.00 0.045 0.030 1.00 max 10.0–14.0 16.0–18.0 2.00–3.00 . . . . . . . . . . . .

TP317 S31700 0.08 2.00 0.045 0.030 1.00 max 11.0–15.0 18.0–20.0 3.0–4.0 . . . . . . . . . .

B

TP321 S32100 0.08 2.00 0.045 0.030 1.00 max 9.00–12.0 17.0–20.0 . . . . . .

C

TP347 S34700 0.08 2.00 0.045 0.030 1.00 max 9.00–12.0 17.0–19.0 . . . . . . . .

D

TP348 S34800 0.08 2.00 0.045 0.030 1.00 max 9.00–12.0 17.0–19.0 . . . . . . . .

. . . S31254 0.020 1.00 0.030 0.010 0.80 max 17.5–18.5 19.5–19.5 6.0–6.5 . . . . . . . . . Cu 0.50–1.00

N 0.18–0.22

. . . S30815 0.05–0.10 0.80 0.040 0.030 1.40–2.00 10.0–12.0 20.0–22.0 . . . . . . . . . 0.03–0.08 N 0.14–0.20

. . . S31725 0.030 2.00 0.045 0.030 1.00 max 13.5–17.5 18.0–20.0 4.0–5.0 . . . . . . . . . N 0.020 max

. . . S31726 0.030 2.00 0.045 0.030 1.00 max 14.5–17.5 17.0–20.0 4.0–5.0 . . . . . . . . . N 0.10–0.20

. . . S34565 0.030 5.0–7.0 0.030 0.010 1.00 max 16.0–18.0 23.0–25.0 4.0–5.0 . . . 0.10 . . . N 0.40–0.60

max

. . . N08367 0.030 2.00 0.040 0.030 1.00 max 23.5–25.5 20.0–22.0 6.0–7.0 . . . . . . . . . Cu 0.75 max

Ni 0.18–0.25

. . . S20400 0.030 7.0–9.0 0.45 0.030 1.00 max 1.50–3.00 15.0–17.0 . . . . . . . . . . . . N 0.15–0.30

A

New designation established in accordance with ASTM E 527 and SAE J1086.

B

The titanium content shall be not less than 5 times the carbon content and not more than 0.70 %.

C

The columbium plus tantalum content shall be not less than 10 times the carbon content and not more than 1.10 %.

D

The columbium plus tantalum content shall be not less than 10 times the carbon content and not more than 1.10 %. The tantalum content shall be 0.10 % maximum,

CO 0.20 % maximum.

3.1.6 End finish (Section on Ends of Specification A 999/ 5.2.2 The weld surface on either side of the weld may be

A 999M), flush with the base plate or may have a reasonably uniform

3.1.7 Optional requirements (5.2.1-5.2.3 removal of weld crown, not to exceed ⁄16 in. [2 mm]. Any weld reinforcement

bead; 5.3.2, special heat treatment; 15.2, nondestructive test; may be removed at the manufacturer’s option or by agreement

10.1.1, outside diameter tolerance; 11.2, length circumferen- between the manufacturer and purchaser. The contour of the

tially welded; 12.3, repair by welding and heat treatment reinforcement should be reasonably smooth and free from

subsequent to repair welding; 12.4, sand blasted or pickled; irregularities. The weld metal shall be fused uniformly into the

17.1 Certification; Supplementary Requirements S1 to S6). plate surface. No concavity of contour is permitted unless the

3.1.8 Specification designation, and resulting thickness of weld metal is equal to or greater than the

3.1.9 Special requirements. minimum thickness of the adjacent base metal.

5.2.3 Weld defects, as determined by specified inspection

4. General Requirements

requirements, shall be repaired by removal to sound metal and

rewelding.

4.1 Material furnished to this specification shall conform to

the applicable requirements of the current edition of Specifi- 5.3 Heat Treatment:

cation A 999/A 999M, unless otherwise provided herein.

5.3.1 Except as provided in 5.3.2, all pipe shall be furnished

in the heat-treated condition. The heat-treatment procedure

5. Materials and Manufacture

shall consist of heating the material to a minimum temperature

of 1900°F [1040°C], except for S31254 and S30815 which

5.1 If a specific type of melting is required by the purchaser

it shall be stated on the order. shall be heat treated to 2100°F [1150°C] and 1920°F [1050°C]

respectively, S24565 which shall be heat treated in the range

5.2 Welding:

2050°F [1120°C] to 2140°F [1170°C], and N08367, which

5.2.1 The welds shall be made by the manual or automatic

shallbeheatedtoaminimumtemperatureof2025°F[1107°C],

electric-weldingprocess.Formanualwelding,theoperatorand

all materials to be followed by quenching in water or rapidly

procedure shall be qualified in accordance with the ASME

cooling by other means.

Boiler and Pressure Vessel Code, Section IX. Unless otherwise

specified on the purchase order, the pipe may be welded with 5.3.2 The purchase order shall specify one of the following

or without filler metal when the automatic electric-welding conditions if the heat-treated condition specified in 5.3.1 is not

process is used. desired by the purchaser:

A 409/A 409M – 01 (2005)

5.3.2.1 A final heat-treatment temperature under 1900°F to the requirements of the applicableAWS specification for the

[1040°C]. Each pipe supplied under this requirement shall be corresponding grade shown in Table 2. Grades with no filler

stenciled with the final heat-treatment temperature in degrees metal classification indicated shall be welded with filler metals

Fahrenheit or degrees Celsius after the suffix “HT”. Controlled producing deposited weld metal having a composition in

structural or special service characteristics may be specified as accordancewiththechemicalcompositionspecifiedinTable1.

a guide for the most suitable heat treatment. The method of analysis for nitrogen and cerium shall be a

5.3.2.2 No final heat treatment of pipe fabricated of plate, matter of agreement between the purchaser and manufacturer.

that has been solution heat treated at temperatures required by The purchaser may choose a higher-alloy filler metal when

this specification. Each pipe supplied under this requirement needed for corrosion resistance.

shall be stenciled with the suffix “HT-O”.

5.3.2.3 No final heat treatment of pipe fabricated of plate, 7. Tensile Requirements

that has not been solution heat treated. Each pipe supplied

7.1 The tensile properties of the plate or sheet used in

under this requirement shall be stenciled with the suffix

making the pipe shall conform to the requirements prescribed

“HT-SO”.

in Table 3. Certified mill test reports shall be submitted to the

5.4 A solution annealing temperature above 1950°F

pipe manufacturer.

[1065°C] may impair the resistance to intergranular corrosion

7.2 Atransversetensiontesttakenacrosstheweldedjointof

after subsequent exposure to sensitizing conditions in TP321,

the finished pipe shall meet the same minimum tensile strength

TP347, and TP348. When specified by the purchaser, a lower

requirements as the sheet or plate. The weld section on the

temperature stabilization or re-solution anneal shall be used

tension specimen shall be in the same condition as the finished

subsequent to the initial high temperature solution anneal (see

pipe (with or without bead as specified).

Supplementary Requirement S5).

8. Mechanical Tests Required

6. Chemical Composition

8.1 Tension Test—One transverse tension test of the weld

6.1 The steel shall conform to the chemical composition in

shall be made on each lot (Note 2) of finished pipe.

Table 1.

NOTE 2—The term “lot” applies to each 200 ft [60 m] or less of pipe of

6.2 When specified on the purchase order, a product analy-

the same NPS and wall thickness (or schedule number) which is produced

sisshallbesuppliedfromonetubeorcoilofsteelperheat.The

from the same heat of steel and subjected to the same finishing treatment

product analysis tolerance of Specification A 480/A 480M

in a continuous furnace. When final heat treatment is in a batch-type

shall apply.

furnace, the lot shall include only that pipe which is heat treated in the

6.3 Unless otherwise specified in the purchase order, the

same furnace charge.When no heat treatment is performed following final

chemical composition of the welding filler metal shall conform forming operations, the lot shall include each 200 ft [60 m] or less of pipe

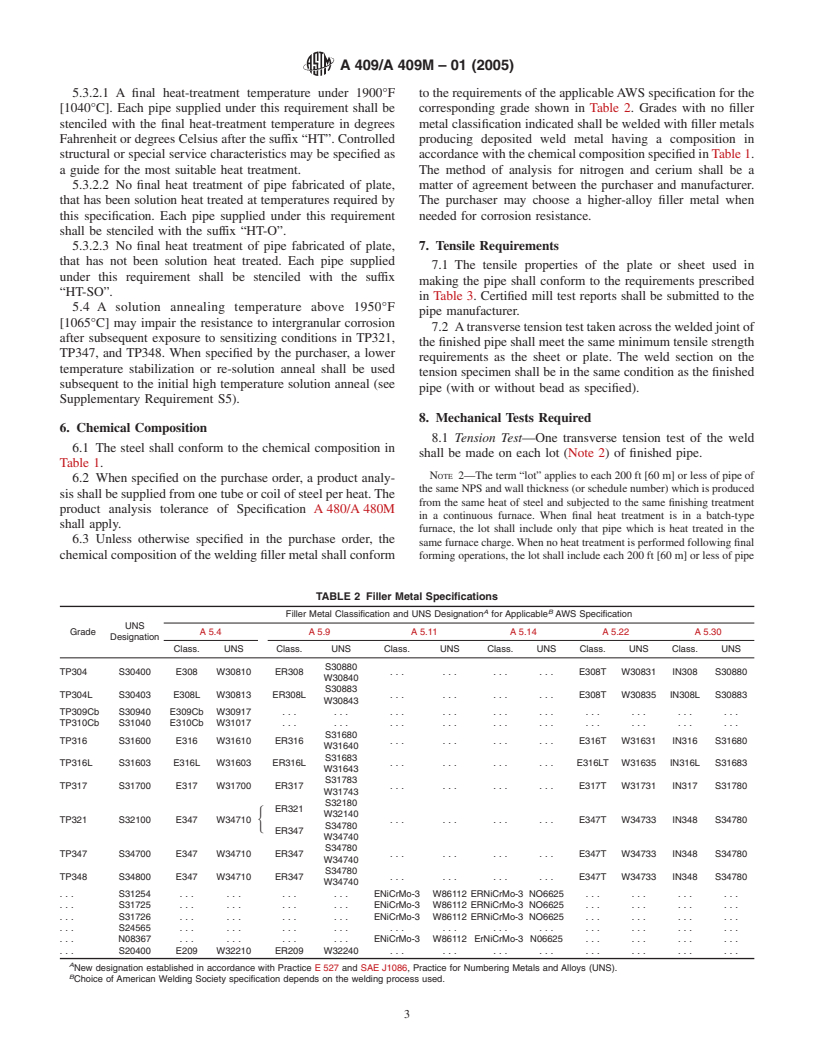

TABLE 2 Filler Metal Specifications

A B

Filler Metal Classification and UNS Designation for Applicable AWS Specification

UNS

Grade A5.4 A5.9 A5.11 A 5.14 A5.22 A 5.30

Designation

Class. UNS Class. UNS Class. UNS Class. UNS Class. UNS Class. UNS

S30880

TP304 S30400 E308 W30810 ER308 . . . . . . . . . . . . E308T W30831 IN308 S30880

W30840

S30883

TP304L S30403 E308L W30813 ER308L . . . . . . . . . . . . E308T W30835 IN308L S30883

W30843

TP309Cb S30940 E309Cb W30917 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TP310Cb S31040 E310Cb W31017 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

S31680

TP316 S31600 E316 W31610 ER316 . . . . . . . . . . . . E316T W31631 IN316 S31680

W31640

S31683

TP316L S31603 E316L W31603 ER316L . . . . . . . . . . . . E316LT W31635 IN316L S31683

W31643

S31783

TP317 S31700 E317 W31700 ER317 . . . . . . . . . . . . E317T W31731 IN317 S31780

W31743

S32180

ER321

W32140

TP321 S32100 E347 W34710 . . . . . . . . . . . . E347T W34733 IN348 S34780

H

S34780

ER347

W34740

S34780

TP347 S34700 E347 W34710 ER347 . . . . . . . . . . . . E347T W34733 IN348 S34780

W34740

S34780

TP348 S34800 E347 W34710 ER347 . . . . . . . . . . . . E347T W34733 IN348 S34780

W34740

. . . S31254 . . . . . . . . . . . . ENiCrMo-3 W86112 ERNiCrMo-3 NO6625 . . . . . . . . . . . .

. . . S31725 . . . . . . . . . . . . ENiCrMo-3 W86112 ERNiCrMo-3 NO6625 . . . . . . . . . . . .

. . . S31726 . . . . . . . . . . . . ENiCrMo-3 W86112 ERNiCrMo-3 NO6625 . . . . . . . . . . . .

. . . S24565 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . N08367 . . . . . . . . . . . . ENiCrMo-3 W86112 ErNiCrMo-3 N06625 . . . . . . . . . . . .

. . . S20400 E209 W3221

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:A409/A409M–01 Designation: A 409/A 409M – 01 (Reapproved 2005)

Standard Specification for

Welded Large Diameter Austenitic Steel Pipe for Corrosive

or High-Temperature Service

This standard is issued under the fixed designationA 409/A 409M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification covers straight seam or spiral seam electric-fusion-welded, light-wall, austenitic chromium-nickel alloy

steel pipe for corrosive or high-temperature service. The sizes covered are NPS 14 to 30 with extra light (Schedule 5S) and light

(Schedule 10S) wall thicknesses.Table X1.1 shows the wall thickness of Schedule 5S and 10S pipe. Pipe having other dimensions

may be furnished provided such pipe complies with all other requirements of this specification.

1.2 Several grades of alloy steel are covered as indicated in Table 1.

1.3 Optional supplementary requirements are provided. These call for additional tests to be made, and when desired shall be

stated in the order, together with the number of such tests required.

1.4 Thevaluesstatedineitherinch-poundunitsorSIunitsaretoberegardedseparatelyasstandard.Withinthetext,theSIunits

are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used

independently of the other. Combining values from the two systems may result in nonconformance with the specification. The

inch-pound units shall apply unless the “M” designation of this specification is specified in the order.

NOTE 1—The dimensionless designator NPS (nominal pipe size) has been substituted in this standard for such traditional terms as “nominal diameter,”

“ size,”nominal diameter, size, and “nominal size.” nominal size.

2. Referenced Documents

2.1 ASTM Standards:

A 262 Practices for Detecting Susceptibility to Intergranular Attack in Austenitic Stainless Steels

A 480/A 480M Specification for General Requirements for Flat-Rolled Stainless and Heat-Resisting Steel Plate, Sheet, and

Strip

A 999/A 999M Specification for General Requirements for Alloy and Stainless Steel Pipe

E 527 Practice for Numbering Metals and Alloys (UNS)

2.2 ASME Boiler and Pressure Vessel Code:

Section IX Welding Qualifications.

2.3 AWS Standards:

A 5.22 Flux Cored Arc Welding

A 5.30 Consumable Weld Inserts for Gas Tungsten Arc Welding

A 5.4 Corrosion-Resisting Chromium and Chromium-Nickel Steel Covered Welding Electrodes

A 5.9 Corrosion-Resisting Chromium and Chromium-Nickel Steel Welding Rods and Bare Electrodes

A 5.11 Nickel and Nickel-Alloy Covered Welding Electrodes

A 5.14 Nickel and Nickel-Alloy Bare Welding Rods and Electrodes

2.4 Other Standard:

SAE J1086 Practice for Numbering Metals and Alloys (UNS)

This specification is under the jurisdiction ofASTM CommitteeA01 on Steel, Stainless Steel, and RelatedAlloys and is the direct responsibility of SubcommitteeA01.10

on Stainless and Alloy Steel Tubular Products.

Current edition approved Mar. 10, 2001. Published May 2001. Originally published as A409–57T. Last previous edition A409–95a.

Current edition approved Sept. 1, 2005. Published October 2005. Originally approved in 1957 . Last previous edition approved in 2001 as A 409/A 409M – 01.

For ASME Boiler and Pressure Vessel Code applications see related Specification SA-409 in Section II of that Code.

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

, Vol 01.03.volume information, refer to the standard’s Document Summary page on the ASTM website.

Annual Book of ASTM Standards, Vol 01.01.

.Available from American Society of Mechanical Engineers (ASME), ASME International Headquarters, Three Park Ave., New York, NY 10016-5990.

Available from American Society of Mechanical Engineers, 345 E. 47th St., New York, NY 10017.

Available from American Welding Society (AWS), 550 NW LeJeune Rd., Miami, FL 33126.

Available from American Welding Society, 550 Le Jeune Road, P.O. Box 351040, Miami, FL 33135.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

A 409/A 409M – 01 (2005)

TABLE 1 Chemical Requirements

UNS Composition, %

Designa-

Car- Man- Phos- Sulfur, Sili- Nickel Chromium Molyb- Tita- Colum- Cerium Other Elements

A

tions

bon, ganese, phorus, max con denum nium bium

max max max

TP304 S30400 0.08 2.00 0.045 0.030 1.00 max 8.0–11.0 18.0–20.0 . . . . . . . . . . . . . . .

TP304L S30403 0.035 2.00 0.045 0.030 1.00 max 8.0–12.0 18.0–20.0 . . . . . . . . . . . . . . .

TP309Cb S30940 0.08 2.00 0.045 0.030 1.00 max 12.0–16.0 22.0–24.0 . . . . . . . . . Cb 10 3 C min,

1.10 max

TP309S S30908 0.08 2.00 0.045 0.030 1.00 max 12.0–15.0 22.0–24.0 . . . . . . . . .

TP310Cb S31040 0.08 2.00 0.045 0.030 1.00 max 19.0–22.0 24.0–26.0 . . . . . . . . . Cb 10 3 C min,

1.10 max

TP310S S31008 0.08 2.00 0.045 0.030 1.00 max 19.0–22.0 24.0–26.0 . . . . . . . . .

TP316 S31600 0.08 2.00 0.045 0.030 1.00 max 10.0–14.0 16.0–18.0 2.00–3.00 . . . . . . . . .

TP316L S31603 0.035 2.00 0.045 0.030 1.00 max 10.0–14.0 16.0–18.0 2.00–3.00 . . . . . . . . . . . .

TP317 S31700 0.08 2.00 0.045 0.030 1.00 max 11.0–15.0 18.0–20.0 3.0–4.0 . . . . . . . . . .

B

TP321 S32100 0.08 2.00 0.045 0.030 1.00 max 9.00–12.0 17.0–20.0 . . . . . .

C

TP347 S34700 0.08 2.00 0.045 0.030 1.00 max 9.00–12.0 17.0–19.0 . . . . . . . .

D

TP348 S34800 0.08 2.00 0.045 0.030 1.00 max 9.00–12.0 17.0–19.0 . . . . . . . .

. . . S31254 0.020 1.00 0.030 0.010 0.80 max 17.5–18.5 19.5–19.5 6.0–6.5 . . . . . . . . . Cu 0.50–1.00

N 0.18–0.22

. . . S30815 0.05–0.10 0.80 0.040 0.030 1.40–2.00 10.0–12.0 20.0–22.0 . . . . . . . . . 0.03–0.08 N 0.14–0.20

. . . S31725 0.030 2.00 0.045 0.030 1.00 max 13.5–17.5 18.0–20.0 4.0–5.0 . . . . . . . . . N 0.020 max

. . . S31726 0.030 2.00 0.045 0.030 1.00 max 14.5–17.5 17.0–20.0 4.0–5.0 . . . . . . . . . N 0.10–0.20

. . . S34565 0.030 5.0–7.0 0.030 0.010 1.00 max 16.0–18.0 23.0–25.0 4.0–5.0 . . . 0.10 . . . N 0.40–0.60

max

. . . N08367 0.030 2.00 0.040 0.030 1.00 max 23.5–25.5 20.0–22.0 6.0–7.0 . . . . . . . . . Cu 0.75 max

Ni 0.18–0.25

. . . S20400 0.030 7.0–9.0 0.45 0.030 1.00 max 1.50–3.00 15.0–17.0 . . . . . . . . . . . . N 0.15–0.30

A

New designation established in accordance with ASTM E 527 and SAE J1086.

B

The titanium content shall be not less than 5 times the carbon content and not more than 0.70 %.

C

The columbium plus tantalum content shall be not less than 10 times the carbon content and not more than 1.10 %.

D

The columbium plus tantalum content shall be not less than 10 times the carbon content and not more than 1.10 %. The tantalum content shall be 0.10 % maximum,

CO 0.20 % maximum.

3. Ordering Information

3.1 Orders for material to this specification should include the following, as required, to describe the desired material

adequately:

3.1.1 Quantity (feet, centimetres, or number of lengths),

3.1.2 Name of material (straight seam or spiral seam electric-fusion-welded austenitic steel pipe),

3.1.3 Grade (Table 1),

3.1.4 Size (outside diameter and schedule number, or wall thickness).

3.1.5 Length (specific or random) (Section 11),

3.1.6 End finish (Section on Ends of Specification A 999/A 999M),

3.1.7 Optional requirements (5.2.1-5.2.3 removal of weld bead; 5.3.2, special heat treatment; 15.2, nondestructive test; 10.1.1,

outside diameter tolerance; 11.2, length circumferentially welded; 12.3, repair by welding and heat treatment subsequent to repair

welding; 12.4, sand blasted or pickled; 17.1 Certification; Supplementary Requirements S1 to S6).

3.1.8 Specification designation, and

3.1.9 Special requirements.

4. General Requirements

4.1 Material furnished to this specification shall conform to the applicable requirements of the current edition of Specification

A 999/A 999M, unless otherwise provided herein.

5. Materials and Manufacture

5.1 If a specific type of melting is required by the purchaser it shall be stated on the order.

5.2 Welding:

5.2.1 The welds shall be made by the manual or automatic electric-welding process. For manual welding, the operator and

procedure shall be qualified in accordance with theASME Boiler and Pressure Vessel Code, Section IXr00001. Unless otherwise

specified on the purchase order, the pipe may be welded with or without filler metal when the automatic electric-welding process

is used.

Available from Society of Automotive Engineers (SAE), 400 Commonwealth Dr., Warrendale, PA 15096-0001.

A 409/A 409M – 01 (2005)

5.2.2 The weld surface on either side of the weld may be flush with the base plate or may have a reasonably uniform crown,

not to exceed ⁄16 in. [2 mm].Any weld reinforcement may be removed at the manufacturer’s option or by agreement between the

manufacturer and purchaser. The contour of the reinforcement should be reasonably smooth and free from irregularities. The weld

metal shall be fused uniformly into the plate surface. No concavity of contour is permitted unless the resulting thickness of weld

metal is equal to or greater than the minimum thickness of the adjacent base metal.

5.2.3 Weld defects, as determined by specified inspection requirements, shall be repaired by removal to sound metal and

rewelding.

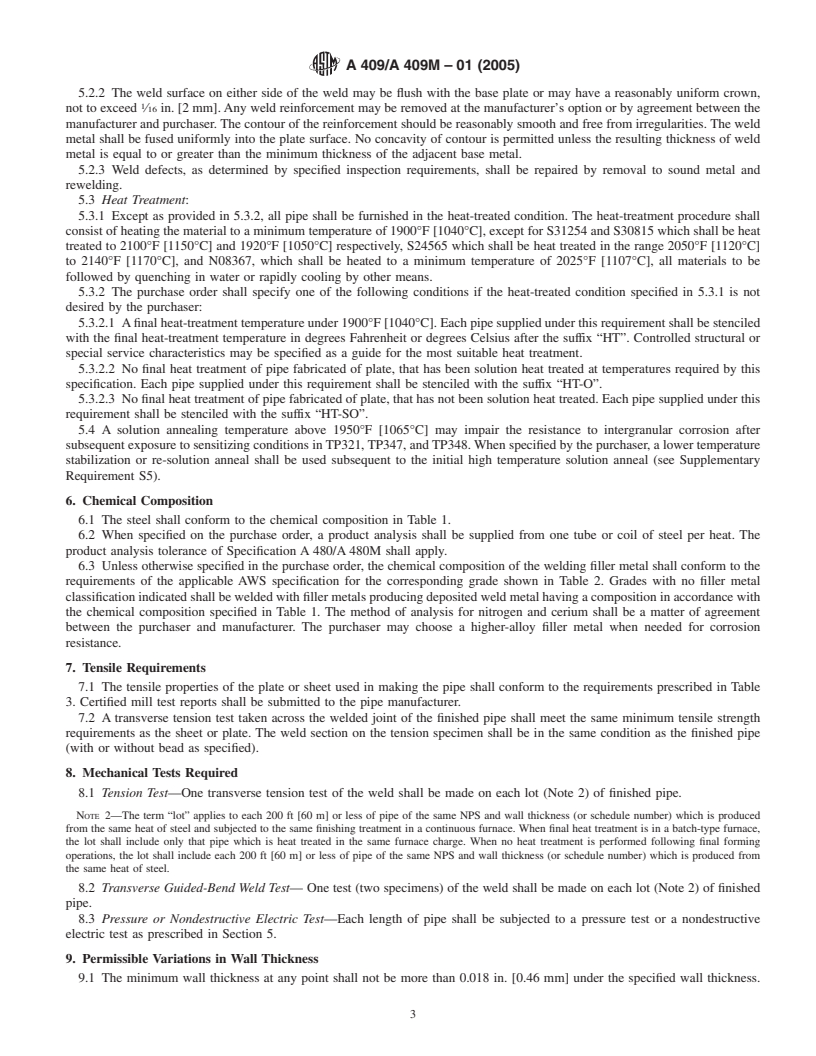

5.3 Heat Treatment:

5.3.1 Except as provided in 5.3.2, all pipe shall be furnished in the heat-treated condition. The heat-treatment procedure shall

consist of heating the material to a minimum temperature of 1900°F [1040°C], except for S31254 and S30815 which shall be heat

treated to 2100°F [1150°C] and 1920°F [1050°C] respectively, S24565 which shall be heat treated in the range 2050°F [1120°C]

to 2140°F [1170°C], and N08367, which shall be heated to a minimum temperature of 2025°F [1107°C], all materials to be

followed by quenching in water or rapidly cooling by other means.

5.3.2 The purchase order shall specify one of the following conditions if the heat-treated condition specified in 5.3.1 is not

desired by the purchaser:

5.3.2.1 Afinal heat-treatment temperature under 1900°F [1040°C]. Each pipe supplied under this requirement shall be stenciled

with the final heat-treatment temperature in degrees Fahrenheit or degrees Celsius after the suffix “HT”. Controlled structural or

special service characteristics may be specified as a guide for the most suitable heat treatment.

5.3.2.2 No final heat treatment of pipe fabricated of plate, that has been solution heat treated at temperatures required by this

specification. Each pipe supplied under this requirement shall be stenciled with the suffix “HT-O”.

5.3.2.3 No final heat treatment of pipe fabricated of plate, that has not been solution heat treated. Each pipe supplied under this

requirement shall be stenciled with the suffix “HT-SO”.

5.4 A solution annealing temperature above 1950°F [1065°C] may impair the resistance to intergranular corrosion after

subsequent exposure to sensitizing conditions inTP321,TP347, andTP348.When specified by the purchaser, a lower temperature

stabilization or re-solution anneal shall be used subsequent to the initial high temperature solution anneal (see Supplementary

Requirement S5).

6. Chemical Composition

6.1 The steel shall conform to the chemical composition in Table 1.

6.2 When specified on the purchase order, a product analysis shall be supplied from one tube or coil of steel per heat. The

product analysis tolerance of Specification A 480/A 480M shall apply.

6.3 Unless otherwise specified in the purchase order, the chemical composition of the welding filler metal shall conform to the

requirements of the applicable AWS specification for the corresponding grade shown in Table 2. Grades with no filler metal

classification indicated shall be welded with filler metals producing deposited weld metal having a composition in accordance with

the chemical composition specified in Table 1. The method of analysis for nitrogen and cerium shall be a matter of agreement

between the purchaser and manufacturer. The purchaser may choose a higher-alloy filler metal when needed for corrosion

resistance.

7. Tensile Requirements

7.1 The tensile properties of the plate or sheet used in making the pipe shall conform to the requirements prescribed in Table

3. Certified mill test reports shall be submitted to the pipe manufacturer.

7.2 A transverse tension test taken across the welded joint of the finished pipe shall meet the same minimum tensile strength

requirements as the sheet or plate. The weld section on the tension specimen shall be in the same condition as the finished pipe

(with or without bead as specified).

8. Mechanical Tests Required

8.1 Tension Test—One transverse tension test of the weld shall be made on each lot (Note 2) of finished pipe.

NOTE 2—The term “lot” applies to each 200 ft [60 m] or less of pipe of the same NPS and wall thickness (or schedule number) which is produced

from the same heat of steel and subjected to the same finishing treatment in a continuous furnace. When final heat treatment is in a batch-type furnace,

the lot shall include only that pipe which is heat treated in the same furnace charge. When no heat treatment is performed following final forming

operations, the lot shall include each 200 ft [60 m] or less of pipe of the same NPS and wall thickness (or schedule number) which is produced from

the same heat of steel.

8.2 Transverse Guided-Bend Weld Test— One test (two specimens) of the weld shall be made on each lot (Note 2) of finished

pipe.

8.3 Pressure or Nondestructive Electric Test—Each length of pipe shall be subjected to a pressure test or a nondestructive

electric test as prescribed in Section 5.

9. Permissible Variations in Wall Thickness

9.1 The minimum wall thickness at any point shall not be more than 0.018 in. [0.46 mm] under the specified wall thickness.

A 409/A 409M – 01 (2005)

TABLE 2 Filler Metal Specifications

A B

Filler Metal Classification and UNS Designation for Applicable AWS Specification

UNS

Grade A5.4 A5.9 A5.11 A5.14 A5.22 A5.30

Designation

Class. UNS Class. UNS Class. UNS Class. UNS Class. UNS Class. UNS

S30880

TP304 S30400 E308 W30810 ER308 . . . . . . . . . . . . E308T W30831 IN308 S30880

W30840

S

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.