ASTM D3907-03(2008)

(Test Method)Standard Test Method for Testing Fluid Catalytic Cracking (FCC) Catalysts by Microactivity Test

Standard Test Method for Testing Fluid Catalytic Cracking (FCC) Catalysts by Microactivity Test

SIGNIFICANCE AND USE

The microactivity test provides data to assess the relative performance of FCC catalyst. Because results are affected by catalyst pretreatment, feedstock characteristics, test equipment, and operating parameters, adherence to this test method is a prerequisite for correct interpretation of results. Apparatus, test conditions, and analytical procedures actually used should closely resemble those described in this test method.

Caution should be used in interpreting results above 80 weight % conversion due to the significance of overcracking.

SCOPE

1.1 This test method covers determining the activity of equilibrium or laboratory-deactivated fluid catalytic cracking (FCC) catalysts, or both. This is evaluated on the basis of weight percent conversion of gas oil in a microactivity unit. The selectivity of FCC catalysts can be determined using Test Method D 5154.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D3907 − 03(Reapproved 2008)

Standard Test Method for

Testing Fluid Catalytic Cracking (FCC) Catalysts by

Microactivity Test

This standard is issued under the fixed designation D3907; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.1 ASTM consensus mean conversion—each reference

catalyst has a consensus mean conversion value assigned to it

1.1 This test method covers determining the activity of

by Committee D32 (see 11.2).

equilibrium or laboratory-deactivated fluid catalytic cracking

3.1.2 ASTM reference catalysts—a set of equilibrium fluid

(FCC) catalysts, or both. This is evaluated on the basis of

cracking catalysts with conversions within the useful range of

weight percent conversion of gas oil in a microactivity unit.

this test method is used to improve the reproducibility of test

The selectivity of FCC catalysts can be determined using Test

results between different laboratories. Samples of the ASTM

Method D5154.

reference catalysts can be obtained from NIST.

1.2 The values stated in SI units are to be regarded as the

3.1.3 ASTM standard feed—aspecificbatchofgasoilthatis

standard. The values given in parentheses are for information

used as feedstock in the described test method. This standard

only.

feed can be obtained from the National Institute of Standards

1.3 This standard does not purport to address all of the

and Technology (NIST).

safety concerns, if any, associated with its use. It is the

3.1.4 conversion calibration curve—a calibration curve can

responsibility of the user of this standard to establish appro-

be obtained by plotting the consensus mean conversion values

priate safety and health practices and determine the applica-

for the ASTM reference catalysts (see 11.2) versus the indi-

bility of regulatory limitations prior to use.

vidual laboratory-measured conversion for the same catalysts.

2. Referenced Documents

3.1.5 measured conversion—is calculated as the difference

betweentheweightoffeedusedandtheweightofunconverted

2.1 ASTM Standards:

D2887 Test Method for Boiling Range Distribution of Pe- material, divided by the weight of feed used, times 100 %.The

unconverted material is defined as all liquid product with a

troleum Fractions by Gas Chromatography

boiling point above 216°C (421°F).

D5154 TestMethodforDeterminingActivityandSelectivity

of Fluid Catalytic Cracking (FCC) Catalysts by Microac-

4. Summary of Test Method

tivity Test

4.1 A sample of cracking catalyst in a fixed-bed reactor is

E105 Practice for Probability Sampling of Materials

contacted with gas oil (ASTM standard feed). Cracked liquid

E177 Practice for Use of the Terms Precision and Bias in

products are analyzed for unconverted material and the con-

ASTM Test Methods

version is calculated.

E456 Terminology Relating to Quality and Statistics

E691 Practice for Conducting an Interlaboratory Study to

4.2 A corrected conversion value can be obtained from the

Determine the Precision of a Test Method

measured conversion and the conversion calibration curve.

5. Significance and Use

3. Terminology

5.1 The microactivity test provides data to assess the rela-

3.1 Definitions of Terms Specific to This Standard:

tive performance of FCC catalyst. Because results are affected

by catalyst pretreatment, feedstock characteristics, test

This test method is under the jurisdiction of ASTM Committee D32 on

equipment, and operating parameters, adherence to this test

Catalysts and is the direct responsibility of Subcommittee D32.04 on Catalytic

method is a prerequisite for correct interpretation of results.

Properties.

Apparatus, test conditions, and analytical procedures actually

Current edition approved April 1, 2008. Published April 2008. Originally

approved in 1992. Last previous edition approved in 2003 as D3907–03. DOI:

used should closely resemble those described in this test

10.1520/D3907-03R08.

method.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Available from National Institute of Standards and Technology (NIST), 100

the ASTM website. Bureau Dr., Stop 3460, Gaithersburg, MD 20899-3460.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D3907 − 03 (2008)

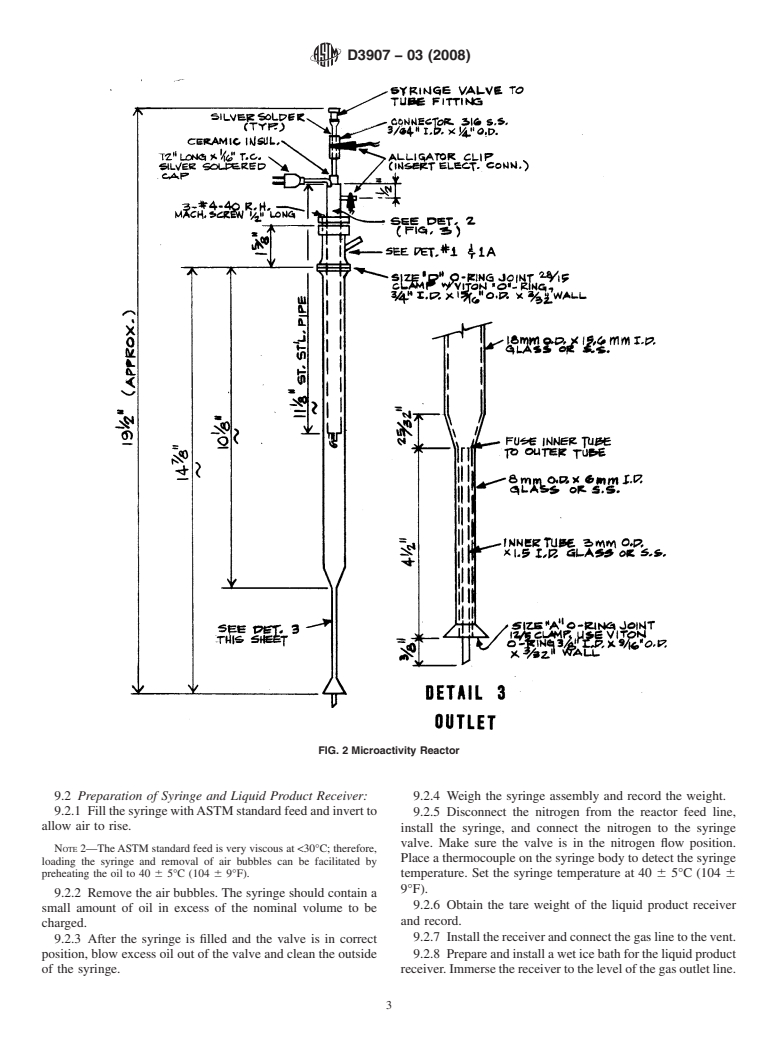

NOTE 1—General dimensions are given in SI units. Dimensions given

5.2 Caution should be used in interpreting results above 80

in SAE, U.S. Standard gage sizes for sheet, tubing, and wire are

weight % conversion due to the significance of overcracking.

considered standard. In general, the closest metric equivalent should be

adequate for proper functioning.

6. Apparatus

6.7 Liquid Product Collection System—Liquid product is

6.1 Flow Chart—The flow chart is given in Fig. 1. During

collected in the receiver shown in Fig. 4.

75 s, gas oil from a syringe is forced over4gof catalyst in a

fixed-bed reactor. Liquid products are collected in a receiver

6.8 Analytical Balance and Weights—The balance used to

and kept at a wet ice temperature.

weigh the sample, the receiver, and the syringe shall have a

precision of 1 mg. Analytical weights shall be precision grade

6.2 Syringe—Asyringe with 2.5 mL capacity is used for oil

or calibrated against a set of certified standard weights.

addition. It should be equipped with a multiport, high-pressure

valve to allow nitrogen and oil entry to the reactor through a

6.9 Chromatographic Equipment—The gas chromato-

common feed line.

graphic equipment specified in Test Method D2887 is sug-

gested for the analysis of liquid product. A flame ionization

6.3 Syringe Heater—Heat syringe to 40 6 5°C (104 6 9°F)

detector is recommended.

using a heat lamp or resistance heater or any other suitable

means.

7. Sampling

6.4 Syringe Pump—A syringe pump that can deliver uni-

7.1 If a sampling procedure is desired, Practice E105 is

form flow of 1.33 6 0.03 g of gas oil in 75 61s.

recommended.

6.5 Furnace—A three-zone furnace is used: middle zone,

8. Sample Preparation

150-mm (6-in.) length, and top and bottom zones, 75-mm

8.1 Dry samples or decoke, or both, by heating a shallow

(3-in.) length. The catalyst bed is positioned in the middle

(less than 10 mm thick) bed of catalyst in a porcelain crucible

zone. The temperature controllers of the three zones are

as follows:

calibratedtoachieveaconstanttemperature482 61°C(900 6

2°F) over the whole length of the catalyst bed (actual bed 120 ± 20°C (248 ± 36°F) for 1 h

120°C (248°F) to 590°C (1094°F) for approximately 1 h

temperature).

590 ± 20°C (1094 ± 36°F) for 3 h

6.6 Reactor and Insert—Aglass or stainless steel reactor of

8.2 Sufficient air should be available in the furnace to burn

15.6 mm internal diameter is used. Dimensions are shown in

the sample free of coke. Insufficient decoking is indicated by a

Fig. 2. Details of the reactor insert are shown in Figs. 2 and 3.

difference in color of the top and bottom layers. The hot

crucible is cooled in a desiccator to prevent moisture pickup.

9. Procedure

9.1 Reactor Preparation:

9.1.1 Rinse the feed line with acetone or other suitable

solvent and dry with air. Periodic cleaning of the insert is

recommended by an air purge at 482°C (900°F) for 1 h, at least

once every 12 tests.

9.1.2 Wash the reactor and product receiver thoroughly with

acetone or other suitable solvent and dry. If necessary, burn out

any coke deposited in the reactor by heating in air at 482°C

(900°F) prior to washing.

9.1.3 Insert a plug of quartz or borosilicate glass wool

(about 20-mm length) into the reactor. Add 4.00 6 0.05 g of

catalyst in a free-flowing manner. Tap the reactor lightly to

ensure good radial distribution (do not pack). Position another

plug of quartz or glass wool (about 6-mm length) above the

catalyst bed. Do not tamp wool plugs excessively.

9.1.4 Inspect the reactor feed tube insert to be sure it is free

of deposits and the tip of the thermocouple (see Fig. 3, Detail

2) is bent under the tip of the syringe needle. (This is necessary

to control the oil preheat temperature accurately.) Place the

insert in

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D3907–92

Standard Method for Designation: D 3907 – 03 (Reapproved

2008)

Standard Test Method for

Testing Fluid Catalytic Cracking (FCC) Catalysts by

Microactivity Test

This standard is issued under the fixed designation D 3907; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers determining the activity of equilibrium or laboratory-deactivated fluid catalytic cracking (FCC)

catalysts, or both. This is evaluated on the basis of weight percent conversion of gas oil in a microactivity unit. The selectivity of

FCC catalysts can be determined using Test Method D 5154.

1.2 ThevaluesstatedinSIunitsaretoberegardedasthestandard.Thevaluesgiveninparenthesesareprovidedforinformation

only.

1.3 This standard does not purport to address all of the safety problems,concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of

regulatory limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

D 2887 Test Method for Boiling Range Distribution of Petroleum Fractions by Gas Chromatography

D 5154 Test Method for Determining theActivity and Selectivity of Fluid Catalytic Cracking (FCC) Catalysts by Microactivity

Test

E 105 Practice for Probability Sampling ofOf Materials

E 177 Practice for Use of the Terms Precision and Bias in ASTM Test Methods

E 456 Terminology Relating to Quality and Statistics

E 691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 ASTM standard feed—a specific batch of gas oil that is used as feedstock in the described method. This standard feed can

be obtained from the National Institute of Standards and Technology (NIST).

3.1.2ASTM reference catalysts—a set of equilibrium fluid cracking catalysts with conversions within the useful range of this

method is used to improve the reproducibility of test results between different laboratories. Samples of the ASTM reference

catalysts can be obtained from NIST.

3.1.3measured conversion—is calculated as the difference between the weight of feed used and the weight of unconverted

material, divided by the weight of feed used, times 100%. The unconverted material is defined as all liquid product with a boiling

point above 216°C (421°F).

3.1.4ASTM consensus mean conversion—each reference catalyst has a consensus mean conversion value assigned to it by

Committee D-32D32 (see 11.2).

3.1.5

This test method is under the jurisdiction of ASTM Committee D-32D32 on Catalysts and is the direct responsibility of Subcommittee D32.04 on Catalytic Properties

.

Current edition approved Jan. 15, 1992.April 1, 2008. Published March 1992.April 2008. Originally published as D3907–80.approved in 1992. Last previous edition

D3907–87.approved in 2003 as D 3907–03.

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

, Vol 05.02.volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 3907 – 03 (2008)

3.1.2 ASTM reference catalysts—a set of equilibrium fluid cracking catalysts with conversions within the useful range of this

test method is used to improve the reproducibility of test results between different laboratories. Samples of the ASTM reference

catalysts can be obtained from NIST.

3.1.3 ASTM standard feed—a specific batch of gas oil that is used as feedstock in the described test method. This standard feed

can be obtained from the National Institute of Standards and Technology (NIST).

3.1.4 conversion calibration curve—a calibration curve can be obtained by plotting the consensus mean conversion values for

the ASTM reference catalysts (see 11.2) versus the individual laboratory-measured conversion for the same catalysts.

3.1.5 measured conversion—is calculated as the difference between the weight of feed used and the weight of unconverted

material, divided by the weight of feed used, times 100 %. The unconverted material is defined as all liquid product with a boiling

point above 216°C (421°F).

4. Summary of Test Method

4.1 Asampleofcrackingcatalystinafixed-bedreactoriscontactedwithgasoil(ASTMstandardfeed).Crackedliquidproducts

are analyzed for unconverted material and the conversion is calculated.

4.2 A corrected conversion value can be obtained from the measured conversion and the conversion calibration curve.

5. Significance and Use

5.1 The microactivity test provides data to assess the relative performance of FCC catalyst. Because results are affected by

catalyst pretreatment, feedstock characteristics, test equipment, and operating parameters, adherence to this test method is a

prerequisite for correct interpretation of results.Apparatus, test conditions, and analytical procedures actually used should closely

resemble those described in this test method.

5.2 Caution should be used in interpreting results above 80 weight % conversion due to the significance of overcracking.

6. Apparatus

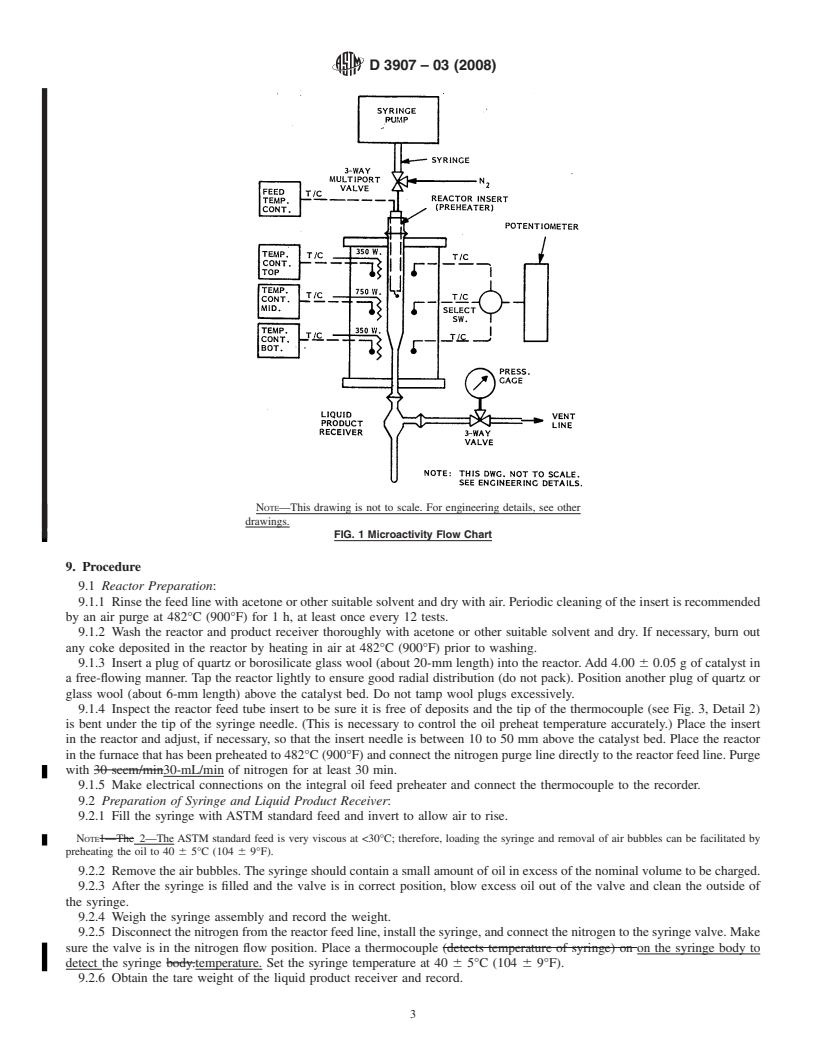

6.1 Flow Chart— The—The flow chart is given in Fig. 1. During 75 s, gas oil from a syringe is forced over4gof catalyst in

a fixed-bed reactor. Liquid products are collected in a receiver and kept at a wet ice temperature.

6.2 Syringe, —A syringe with 2.5 mL capacity is used for oil addition. It should be equipped with a multiport, high-pressure

valve to allow nitrogen and oil entry to the reactor through a common feed line.

6.3 Syringe Heater—Heat syringe to 40 6 5°C (104 6 9°F) using a heat lamp or resistance heater or any other suitable means.

6.4 Syringe Pump—A syringe pump that can deliver uniform flow of 1.33 6 0.03 g of gas oil in 75 61s.

6.5 Furnace—A three-zone furnace is used: middle zone, 150-mm (6-in.) length, and top and bottom zones, 75-mm (3-in.)

length. The catalyst bed is positioned in the middle zone. The temperature controllers of the three zones are calibrated to achieve

a constant temperature 482 6 1°C (900 6 2°F) over the whole length of the catalyst bed (actual bed temperature).

6.6 Reactor and Insert—Aglass or stainless steel reactor of 15.6 mm internal diameter is used. Dimensions are shown in Fig.

2. Details of the reactor insert are shown in Fig. 2 and Fig. 3Figs. 2 and 3.

NOTE 1—General dimensions are given in SI units. Dimensions given in SAE, U.S. Standard gage sizes for sheet, tubing, and wire are considered

standard. In general, the closest metric equivalent should be adequate for proper functioning.

6.7 Liquid Product Collection System—Liquid— Liquid product is collected in the receiver shown in Fig. 4.

6.8 Analytical Balance and Weights—Thebalanceusedtoweighthesample,thereceiver,andthesyringeshallhaveaprecision

of 1 mg. Analytical weights shall be precision grade or calibrated against a set of certified standard weights.

6.9 Chromatographic Equipment—The gas chromatographic equipment specified in Test Method D 2887 is suggested for the

analysis of liquid product. A flame ionization detector is recommended.

7. Sampling

7.1 If a sampling procedure is desired, Practice E 105 is recommended.

8. Sample Preparation

8.1 Dry samples or decoke, or both, by heating a shallow (less than 10 mm thick) bed of catalyst in a porcelain crucible as

follows: 1206

120 6 20°C (248 6 36°F) for 1 h 120°C

120 6 20°C (248 6 36°F) for 1 h

120°C (248°F) to 590°C (1094°F) approximately 1 h 5906

120°C (248°F) to 590°C (1094°F) for approximately 1 h

590 6 20°C (1094 6 36°F) for 3 h

8.2 Sufficient air should be available in the furnace to burn the sample free of coke. Insufficient decoking is indicated by a

difference in color of the top and bottom layers. The hot crucible is cooled in a desiccator to prevent moisture pickup.

Annual Book of ASTM Standards, Vol 05.03.

Available from National Institute of Standards and Technology (NIST), 100 Bureau Dr., Stop 3460, Gaithersburg, MD 20899-3460.

D 3907 – 03 (2008)

NOTE—This drawing is not to scale. For engineering details, see other

drawings.

FIG. 1 Microactivity Flow Chart

9. Procedure

9.1 Reactor Preparation:

9.1.1 Rinse the feed line with acetone or other suitable solvent and dry with air. Periodic cleaning of the insert is recommended

by an air purge at 482°C (900°F) for 1 h, at least once every 12 tests.

9.1.2 Wash the reactor and product receiver thoroughly with acetone or other suitable solvent and dry. If necessary, burn out

any coke deposited in the reactor by heating in air at 482°C (900°F) prior to washing.

9.1.3 Insert a plug of quartz or borosilicate glass wool (about 20-mm length) into the reactor.Add 4.00 6 0.05 g of catalyst in

a free-flowing

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.