ASTM B816-00(2004)e1

(Specification)Standard Specification for Coatings of Cadmium-Zinc Mechanically Deposited

Standard Specification for Coatings of Cadmium-Zinc Mechanically Deposited

ABSTRACT

This specification covers the requirements for cadmium-zinc coatings deposited on metallic products by mechanical deposition. The coating shall be classified in four thickness classes namely, Class 7, Class 12, Class 25, and Class 50. The coating shall also be classified according to coating types defined as Type I, Type IIa, Type IIb, Type IIc, and Type IId. The materials shall be subjected to the following test methods: coating composition determination; thickness measurement; adhesion test; corrosion resistance test; appearance test; and hydrogen embrittlement test.

SCOPE

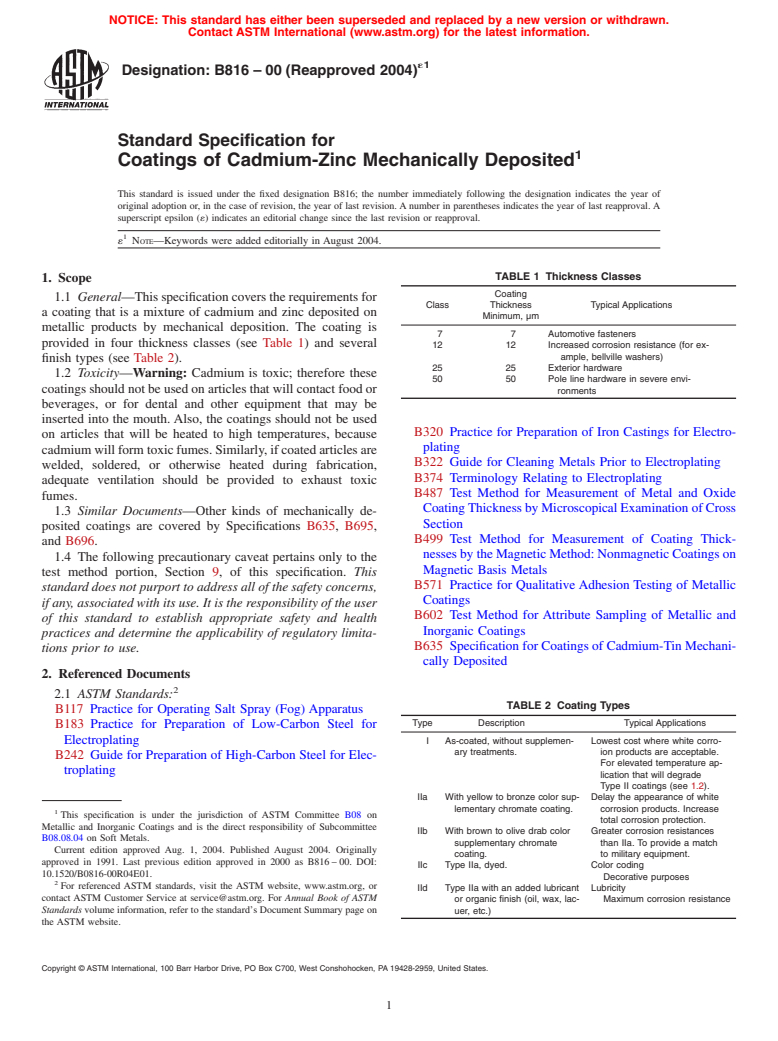

1.1 General—This specification covers the requirements for a coating that is a mixture of cadmium and zinc deposited on metallic products by mechanical deposition. The coating is provided in four thickness classes (see Table 1) and several finish types (see Table 2).

1.2 Toxicity—Warning: Cadmium is toxic; therefore these coatings should not be used on articles that will contact food or beverages, or for dental and other equipment that may be inserted into the mouth. Also, the coatings should not be used on articles that will be heated to high temperatures, because cadmium will form toxic fumes. Similarly, if coated articles are welded, soldered, or otherwise heated during fabrication, adequate ventilation should be provided to exhaust toxic fumes.

1.3 Similar Documents—Other kinds of mechanically deposited coatings are covered by Specifications B635, B695, and B696.

1.4 The following precautionary caveat pertains only to the test method portion, Section 9, of this specification. This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

´1

Designation: B816 – 00 (Reapproved 2004)

Standard Specification for

Coatings of Cadmium-Zinc Mechanically Deposited

This standard is issued under the fixed designation B816; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

´ NOTE—Keywords were added editorially in August 2004.

TABLE 1 Thickness Classes

1. Scope

Coating

1.1 General—Thisspecificationcoverstherequirementsfor

Class Thickness Typical Applications

a coating that is a mixture of cadmium and zinc deposited on

Minimum, µm

metallic products by mechanical deposition. The coating is

7 7 Automotive fasteners

provided in four thickness classes (see Table 1) and several

12 12 Increased corrosion resistance (for ex-

ample, bellville washers)

finish types (see Table 2).

25 25 Exterior hardware

1.2 Toxicity—Warning: Cadmium is toxic; therefore these

50 50 Pole line hardware in severe envi-

coatingsshouldnotbeusedonarticlesthatwillcontactfoodor

ronments

beverages, or for dental and other equipment that may be

inserted into the mouth. Also, the coatings should not be used

B320 Practice for Preparation of Iron Castings for Electro-

on articles that will be heated to high temperatures, because

plating

cadmiumwillformtoxicfumes.Similarly,ifcoatedarticlesare

B322 Guide for Cleaning Metals Prior to Electroplating

welded, soldered, or otherwise heated during fabrication,

B374 Terminology Relating to Electroplating

adequate ventilation should be provided to exhaust toxic

B487 Test Method for Measurement of Metal and Oxide

fumes.

CoatingThicknessbyMicroscopicalExaminationofCross

1.3 Similar Documents—Other kinds of mechanically de-

Section

posited coatings are covered by Specifications B635, B695,

B499 Test Method for Measurement of Coating Thick-

and B696.

nessesbytheMagneticMethod:NonmagneticCoatingson

1.4 The following precautionary caveat pertains only to the

Magnetic Basis Metals

test method portion, Section 9, of this specification. This

B571 Practice for Qualitative Adhesion Testing of Metallic

standard does not purport to address all of the safety concerns,

Coatings

if any, associated with its use. It is the responsibility of the user

B602 Test Method for Attribute Sampling of Metallic and

of this standard to establish appropriate safety and health

Inorganic Coatings

practices and determine the applicability of regulatory limita-

B635 Specification for Coatings of Cadmium-Tin Mechani-

tions prior to use.

cally Deposited

2. Referenced Documents

2.1 ASTM Standards:

TABLE 2 Coating Types

B117 Practice for Operating Salt Spray (Fog) Apparatus

Type Description Typical Applications

B183 Practice for Preparation of Low-Carbon Steel for

Electroplating I As-coated, without supplemen- Lowest cost where white corro-

ary treatments. ion products are acceptable.

B242 Guide for Preparation of High-Carbon Steel for Elec-

For elevated temperature ap-

troplating

lication that will degrade

Type II coatings (see 1.2).

IIa With yellow to bronze color sup- Delay the appearance of white

lementary chromate coating. corrosion products. Increase

This specification is under the jurisdiction of ASTM Committee B08 on

total corrosion protection.

Metallic and Inorganic Coatings and is the direct responsibility of Subcommittee

IIb With brown to olive drab color Greater corrosion resistances

B08.08.04 on Soft Metals.

supplementary chromate than IIa. To provide a match

Current edition approved Aug. 1, 2004. Published August 2004. Originally

coating. to military equipment.

approved in 1991. Last previous edition approved in 2000 as B816 – 00. DOI:

IIc Type IIa, dyed. Color coding

10.1520/B0816-00R04E01.

Decorative purposes

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

IId Type IIa with an added lubricant Lubricity

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

or organic finish (oil, wax, lac- Maximum corrosion resistance

Standards volume information, refer to the standard’s Document Summary page on uer, etc.)

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

´1

B816 – 00 (2004)

B695 Specification for Coatings of Zinc Mechanically De- 5.1.6.6 Corrosion resistance (see 9.7),

posited on Iron and Steel 5.1.6.7 Absence of hydrogen embrittlement, waiting time

B696 Specification for Coatings of Cadmium Mechanically prior to testing and testing loads (see 9.8), and

Deposited 5.1.7 The sampling plan to be used (see 8.1) and responsi-

B697 Guide for Selection of Sampling Plans for Inspection bility for inspection (see section 13.1).

of Electrodeposited Metallic and Inorganic Coatings

6. Significance and Use

B762 Test Method of Variables Sampling of Metallic and

Inorganic Coatings

6.1 Corrosion Resistance, General—This functional coat-

E27 Method for Spectrographic Analysis of Zinc and Zinc

ing is used to provide corrosion resistance.The performance of

Alloys by the Solution-Residue Technique

this coating depends largely on its thickness and the kind of

E396 Test Methods for Chemical Analysis of Cadmium

environment to which it is exposed. Published results of

E536 Test Methods for ChemicalAnalysis of Zinc and Zinc

environmental corrosion studies have demonstrated that the

Alloys

coating provides corrosion resistance greater than equivalent

F1470 Practice for Fastener Sampling for Specified Me-

thicknesses of zinc coatings in industrial environments and

chanical Properties and Performance Inspection

greater corrosion resistance than equivalent thicknesses of

cadmium coatings in marine environments.

3. Terminology

6.2 Galvanic Corrosion Resistance—The galvanic couple

3.1 Definitions—Some of the terms used in this are defined

that results in the corrosion of steel and aluminum parts in

in Terminology B374.

contact with each other in corrosive environments can also be

minimized by plating the steel parts with this mechanically

4. Classification

deposited coating.

4.1 Thickness Classes—The coating is classified in four

6.3 Hydrogen Embrittlement, Absence of—The mechanical

thickness classes, as defined in Table 1.

coating process does not produce any permanent hydrogen

4.2 Coating Types—The coating is classified by type, as

embrittlement in products made from high-strength steels, for

defined in Table 2.

example, fasteners or lock washers.

5. Ordering Information

7. Coating Requirements

5.1 In order to make the application of this specification

7.1 Nature of Coating—Thecoatingshallbeamechanically

complete, the purchaser needs to supply the following infor-

deposited mixture of cadmium and zinc with the composition

mation to the seller on the purchase order or other governing

45 to 75 mass % zinc, remainder cadmium.

documents:

7.2 Coating Process:

5.1.1 The name, designation, and year of issue of this

7.2.1 Coating—The cadmium-zinc coating shall be pro-

specification,

ducedbymechanicaldepositioninaccordancewiththeprocess

5.1.2 Thickness class (see 4.1), including a maximum thick-

description given in Annex A1.

ness if appropriate,

7.2.2 Supplementary Treatments—Type II coatings shall be

5.1.3 Coating type (see 4.2), including required color if

produced by treatment with acidic solutions that contain

Type IIc is used, and required lubricant or organic finish if

hexavalent chromium compounds and anions that act as

Type IId is used,

catalysts or film-forming compounds.

5.1.4 Nature of the substrate, for example: high-carbon

7.3 Appearance:

steel, mild steel, copper, brass:

7.3.1 General—The coating on all readily visible surfaces

5.1.4.1 State if precoating stress relief heat treatment is

shall be uniform in appearance, well compacted, and complete

required and the time and temperature to be used if different

in coverage. Superficial staining from rinsing and drying and

from the standard values (see section 12.1),

mild variations in color and luster are acceptable.

5.1.4.2 State if special pretreatments are required to modify

7.3.2 Surface Defects—Defects and variations in appear-

the surface of the article (see Note 1),

ance in the coating that arise from surface conditions of the

5.1.4.3 If special cleaning precautions are to be followed

substrate(scratches,pores,rollmarks,inclusions,etc.)andthat

(see A1.1), and

persist in the coating despite the observance of good metal

5.1.5 Identification of significant surfaces (see 7.4.2).

finishing practices shall not be cause for rejection.

5.1.6 Requirements and methods of testing one or more of

NOTE 1—Coatings generally perform better in service when the sub-

the following:

strate over which they are applied is smooth and free of torn metal,

5.1.6.1 Need for and type of special test specimens (see

inclusions, pores, and other defects. The specifications covering the

9.1),

unfinished products should provide limits for these defects. A metal

5.1.6.2 Appearance (see 7.3),

finisher can often remove defects through special treatments, such as

5.1.6.3 Deposit composition (see 9.2), grinding, polishing, abrasive blasting, chemical etches, and electropolish-

ing. However, these are not normal in the treatment steps preceding the

5.1.6.4 Thickness (see 9.5),

5.1.6.5 Adhesion (see 9.6),

Holford, Raymond N., Jr., “Five Year Outdoor Exposure Corrosion Compari-

Withdrawn. son,” Mechanical Finishing, July 1988.

´1

B816 – 00 (2004)

application of the coating. When they are desired, they are the subject of

Class 50 300 h

special agreement between the purchaser and the seller.

TheorganiccoatingorlubricantshallberemovedfromType

7.4 Thickness:

IId coatings before the salt spray test or the test can be run on

7.4.1 Conformance to Specified Class—Thethicknessofthe

articles that are withdrawn from processing before the organic

coatingeverywhereonthesignificantsurfacesshallconformto

coating is applied.

the requirements of the specified class as defined in 4.1.

NOTE 4—In many instances, there is no direct relation between the

7.4.2 Significant Surfaces—Significant surfaces are usually

results of an accelerated corrosion test and the resistance to corrosion in

defined as those normally visible (directly or by reflection) that

other tests or actual environments, because several factors that influence

are essential to the appearance and serviceability of the article

the progress of corrosion, such as the formation of protective film, vary

when assembled in normal position; or that can be the source

greatly with the conditions encountered. The results obtained in the test

of corrosion products that deface visible surfaces on the should not, therefore, be regarded as a direct guide to the corrosion

resistanceofthetestedmaterialsinallenvironmentswherethesematerials

assembled article. Significant surfaces are further defined at

may be used. Also, performance of different materials in the test cannot

those surfaces that are identified as such by the purchaser, for

always be taken as a direct guide to the relative corrosion resistance of

example, by indicating them on an engineering drawing of the

these materials in service.

product or by marking a sample item of product.

7.4.3 Minimum Thickness Requirement—The coating re-

8. Sampling

quirement of this specification is a minimum requirement; that

8.1 The purchaser and producer are urged to employ statis-

is, the coating thickness is required to equal or exceed the

tical process control in the coating process. Properly per-

specified thickness everywhere on the significant surfaces.

formed, statistical process control will assure coated products

Variation in the thickness from point to point on an article and

of satisfactory quality and will reduce the amount of accep-

from article to article in a production lot is inherent in

tance inspection. The sampling plan used for the inspection of

mechanically deposited coatings. Therefore, if all of the

the quality coated article shall be agreed upon between the

articles in a production lot are to meet the thickness require-

purchaser and producer.

ment, the average coating thickness for the production lot as a

8.1.1 When a collection of coated articles (inspection lot,

whole will be greater than the specified minimum.

see 8.2) is examined for compliance with the requirements

NOTE 2—The thickness of mechanically deposited coatings varies from placed on the articles, a relatively small number of the articles

point to point on the surface of a product, characteristically tending to be

(sample) is selected at random and is inspected.The inspection

thicker on flat surfaces, and thinner at exposed edges, sharp projections,

lot is then classified as complying with the requirements based

shielded or recessed areas, and interior corners and holes, depending on

on the results of the inspection of the sample. The size of the

the dimensions, with such thinner areas often being exempted from

sample and the criteria for compliance are determined by the

thickness requirements.

application of statistics. The procedure is known as sampling

NOTE 3—Processes used to produce Type II finishes remove some of

inspection. Test Method B602, Guide B697, and Test Method

the coating. Because thickness requirements apply to the finished article,

B762 contain sampling plans that are designed for sampling

additional thicknesses may have to be applied to compensate for the metal

removed in the Type II process. inspection of coatings.

8.1.2 Test Method B602 contains four sampling plans, three

7.5 Adhesion—The coating shall be adherent, as defined or

forusewithteststhatarenondestructiveandonewhentheyare

tested in accordance with 9.6.

destructive.Test Method B602 provides a default plan if one is

7.6 Corrosion Resistance:

not specified.

7.6.1 Type I Coatings on Ferrous Articles—Type I coated

8.1.3 Guide B697 provides a large number of plans and also

ferrous articles shall not develop red corrosion products

gives guidance in the selection of a plan. Guide B697 provides

(“rust”) when submitted to the 5 % salt spray test for the

a default plan if one is not specified.

following times:

8.1.4 Test Method B762 can be used only for coating

Class 7 36 h

requirements that have a numerical limit, such as coating

Class 12 72 h

thickness. The test must yield a numeric value and certain

Class 25 192 h

Class 50 300 h

statistical requirements must be met. Test Method B762

contains several plans and also gives instructions for calculat-

7.6.2 Type II Coatings, White Corrosion—Type II coatings

ing plans to meet special needs. Test Method B762 provides a

shall not develop white corrosion products when submitted to

default plan if one

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.