ASTM D7379-08

(Test Method)Standard Test Methods for Strength of Modified Bitumen Sheet Material Laps Using Cold Process Adhesive

Standard Test Methods for Strength of Modified Bitumen Sheet Material Laps Using Cold Process Adhesive

SIGNIFICANCE AND USE

These tests are useful in sampling and testing combinations of modified bitumen sheet materials used with cold applied adhesives.

SCOPE

1.1 These test methods cover the procedure for sampling and testing the strength of laps formed with adhesive used with polymer-modified bituminous sheet materials.

1.2 The values stated in SI units are to be regarded as standard. The values given in parentheses are mathematical conversions to inch-pound units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D7379 −08

StandardTest Methods for

Strength of Modified Bitumen Sheet Material Laps Using

Cold Process Adhesive

This standard is issued under the fixed designation D7379; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D140. Determine the number of rolls to be selected in

accordance with Section 3, Sampling, of Test Methods D146.

1.1 These test methods cover the procedure for sampling

and testing the strength of laps formed with adhesive used with

5. Conditioning

polymer-modified bituminous sheet materials.

5.1 Condition test materials for a minimum of4hat23 6

1.2 The values stated in SI units are to be regarded as

2°C (73.4 6 3.6°F) and 50 6 5 % relative humidity before

standard. The values given in parentheses are mathematical

preparing specimens for testing.

conversions to inch-pound units that are provided for informa-

6. Lap T-Peel Strength

tion only and are not considered standard.

6.1 This test method covers the determination of the T-peel

1.3 This standard does not purport to address all of the

strength of polymer-modified bituminous sheet material and

safety concerns, if any, associated with its use. It is the

cold applied adhesive combinations.

responsibility of the user of this standard to establish appro-

6.1.1 Modified Bitumen Samples for Testing—Samples for

priate safety and health practices and determine the applica-

testing shall consist of two 140 by 152 mm (5.5 by 6 in.) test

bility of regulatory limitations prior to use.

panels of modified bitumen, bonded with the adhesive to be

2. Referenced Documents

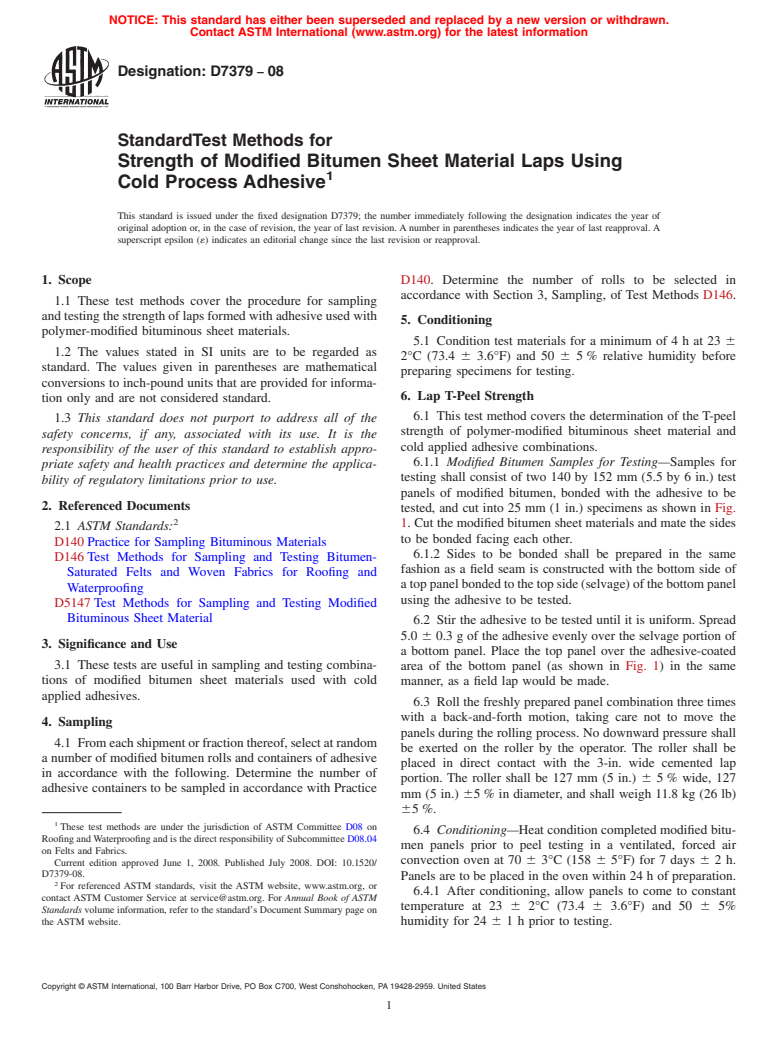

tested, and cut into 25 mm (1 in.) specimens as shown in Fig.

1. Cut the modified bitumen sheet materials and mate the sides

2.1 ASTM Standards:

to be bonded facing each other.

D140 Practice for Sampling Bituminous Materials

6.1.2 Sides to be bonded shall be prepared in the same

D146 Test Methods for Sampling and Testing Bitumen-

fashion as a field seam is constructed with the bottom side of

Saturated Felts and Woven Fabrics for Roofing and

a top panel bonded to the top side (selvage) of the bottom panel

Waterproofing

using the adhesive to be tested.

D5147 Test Methods for Sampling and Testing Modified

Bituminous Sheet Material

6.2 Stir the adhesive to be tested until it is uniform. Spread

5.0 6 0.3 g of the adhesive evenly over the selvage portion of

3. Significance and Use

a bottom panel. Place the top panel over the adhesive-coated

3.1 These tests are useful in sampling and testing combina-

area of the bottom panel (as shown in Fig. 1) in the same

tions of modified bitumen sheet materials used with cold

manner, as a field lap would be made.

applied adhesives.

6.3 Roll the freshly prepared panel combination three times

with a back-and-forth motion, taking care not to move the

4. Sampling

panels during the rolling process. No downward pressure shall

4.1 Fromeachshipmentorfractionthereof,selectatrandom

be exerted on the roller by the operator. The roller shall be

a number of modified bitumen rolls and containers of adhesive

placed in direct contact with the 3-in. wide cemented lap

in accordance with the following. Determine the number of

portion. The roller shall be 127 mm (5 in.) 6 5 % wide, 127

adhesive containers to be sampled in accordance with Practice

mm (5 in.) 65 % in diameter, and shall weigh 11.8 kg (26 lb)

65%.

These test methods are under the jurisdiction of ASTM Committee D08 on

6.4 Conditioning—Heat condition completed modified bitu-

Roofing and Waterproofing and is the direct responsibility of Subcommittee D08.04

men panels prior to peel testing in a ventilated, forced air

on Felts and Fabrics.

convection oven at 70 6 3°C (158 6 5°F) for 7 days 62h.

Current edition approved June 1, 2008. Published July 2008. DOI: 10.1520/

D7379-08.

Panels are to be placed in the oven within 24 h of preparation.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

6.4.1 After conditioning, allow panels to come to constant

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

temperature at 23 6 2°C (73.4 6 3.6°F) and 50 6 5%

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. humidity for 24 6 1 h prior to testing.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7379−08

FIG. 1T-Peel Bonding Configuration for a Modified Bitumen Lap

D7379−08

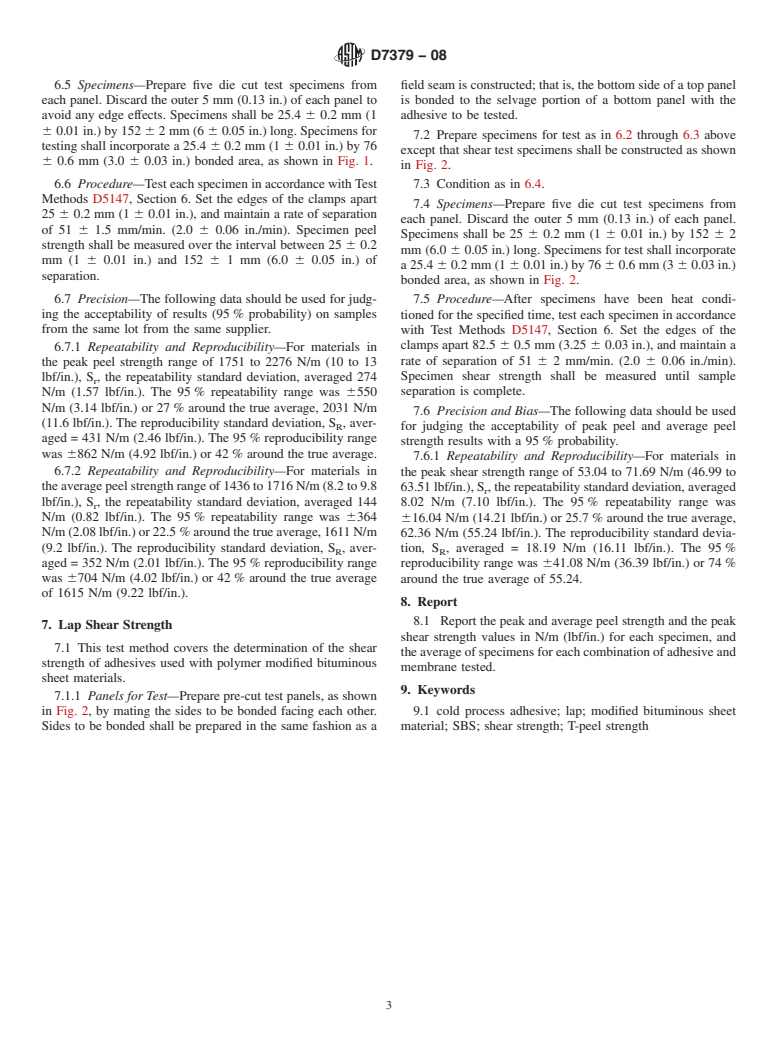

6.5 Specimens—Prepare five die cut test specimens from field seam is constructed; that is, the bottom side of a top panel

each panel. Discard the outer 5 mm (0.13 in.) of each panel to is bonded to the selvage portion of a bottom panel with the

avoid any edge effects. Specimens shall be 25.4 6 0.2 mm (1 adhesive to be tested.

6 0.01 in.) by 152 62mm(6 6 0.05 in.) long. Specimens for

7.2 Prepare specimens for test as in 6.2 through 6.3 above

testing shall incorporate

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.