ASTM E1677-95(2000)

(Specification)Standard Specification for an Air Retarder (AR) Material or System for Low-Rise Framed Building Walls

Standard Specification for an Air Retarder (AR) Material or System for Low-Rise Framed Building Walls

SCOPE

1.1 This specification covers minimum performances and specification criteria for an air retarder (AR) material or system for framed walls of low-rise buildings. The intended users are purchasers of the AR, specifiers of the AR and regulatory groups. The provisions contained in this specification are intended to allow the user to design the wall performance criteria and increase AR specifications to accommodate a particular climate location, function, or design of the intended building. Air retarder performance and specification minimums were selected with the service life of the building wall in mind.

1.2 This specification focuses on ARs for opaque walls. Other areas of the exterior envelope, such as roofs, floors, and interfaces between these areas are not included in this specification.

1.3 This specification does not address air leakage into the wall cavity, that is, windwashing. No standardized test has been developed that adequately identifies all of the influencing factors and measures the impact of this effect on the wall's thermal performance.

1.4 The specifications in this standard are not intended to be utilized for energy load calculations and are not based on an expected level of energy consumption.

1.5 The values stated in inch-pound units are to be regarded as the standard. The values in parentheses are for information only and are closely approximated.

1.6 The following safety hazards caveat pertains only to the test method portion, Annex A1, of this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: E 1677 – 95 (Reapproved 2000)

Standard Specification for

an Air Retarder (AR) Material or System for Low-Rise

Framed Building Walls

This standard is issued under the fixed designation E1677; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope C755 PracticeforSelectionofVaporRetardersforThermal

Insulation

1.1 This specification covers minimum performances and

E96 Test Methods for Water Vapor Transmission of Mate-

specificationcriteriaforanairretarder(AR)materialorsystem

rials

for framed walls of low-rise buildings. The intended users are

E241 Practices for Increasing Durability of Building Con-

purchasers of the AR, specifiers of the AR and regulatory

structions Against Water-Induced Damage

groups. The provisions contained in this specification are

E283 TestMethodforDeterminingtheRateofAirLeakage

intended to allow the user to design the wall performance

Through Exterior Windows, Curtain Walls, and Doors

criteria and increase AR specifications to accommodate a

Under Specified Pressure Differences Across Specimen

particular climate location, function, or design of the intended

E330 Test Method for Structural Performance of Exterior

building.Airretarderperformanceandspecificationminimums

Windows, Curtain Walls and Doors by Uniform StaticAir

wereselectedwiththeservicelifeofthebuildingwallinmind.

Pressure Differences

1.2 This specification focuses on ARs for opaque walls.

E331 Test Method for Water Penetration of Exterior Win-

Other areas of the exterior envelope, such as roofs, floors, and

dows, Curtain Walls, and Doors by Uniform Static Air

interfaces between these areas are not included in this specifi-

Pressure Difference

cation.

E1424 Test Method for Determining the Rate ofAir Leak-

1.3 This specification does not address air leakage into the

age Through Exterior Windows, Curtain Walls, and Doors

wall cavity, that is, windwashing. No standardized test has

Under Specified Pressure and Temperature Differences

been developed that adequately identifies all of the influencing

Across the Specimen

factors and measures the impact of this effect on the wall’s

2.2 ASHRAE Standard:

thermal performance.

ASHRAE 62 Acceptable Indoor Air Quality

1.4 Thespecificationsinthisstandardarenotintendedtobe

utilized for energy load calculations and are not based on an

3. Terminology

expected level of energy consumption.

3.1 Definitions:

1.5 The values stated in inch-pound units are to be regarded

3.1.1 air exfiltration—air leakage out of the building driven

as the standard. The values in parentheses are for information

by negative pressure.

only and are closely approximated.

3.1.1.1 negative pressure—air pressure on the outdoor side

1.6 The following safety hazards caveat pertains only to the

of a building envelope lower than on the indoor side.

test method portion, Annex A1, of this specification. This

3.1.2 air infiltration—air leakage into the building driven

standard does not purport to address all of the safety concerns,

by positive pressure.

if any, associated with its use. It is the responsibility of the user

3.1.2.1 positive pressure—air pressure on the outdoor side

of this standard to establish appropriate safety and health

of a building envelope higher than on the indoor side.

practices and determine the applicability of regulatory limita-

3.1.3 air leakage—the movement/flow of air through the

tions prior to use.

building envelope, which is driven by either or both positive

2. Referenced Documents (infiltration) and negative (exfiltration) pressure differences

across the envelope.

2.1 ASTM Standards:

1 2

This specification is under the jurisdiction of ASTM Committee E06 on Annual Book of ASTM Standards, Vol 04.06.

Performance of Buildings and is the direct responsibility of Subcommittee E06.41 Annual Book of ASTM Standards, Vol 04.11.

on Air Leakage and Ventilation. Available from American Society for Heating, Refrigerating, and Air Condi-

Current edition approved Jan. 15, 1995. Published March 1995. tioning Engineers, Inc., 1791 Tullie Crete, N. E., Atlanta, GA 30329.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E 1677 – 95 (2000)

3.1.3.1 Discussion—These pressure differences are caused 5. Performance Requirements

by wind, mechanical systems, and temperature differences

5.1 This specification does not prohibit a user from increas-

(stack effect).

ing a specification performance requirement, however the

3.1.4 air leakage rate—the time rate of air flow across the

specificationshownshallnotbereduced.Theusershallconsult

air retarder. Expressed as cubic feet per minute per square foot

AnnexA1foradditionalmandatoryrequirements,forexample,

of AR surface at a stated pressure differential across the AR

test specimen and procedure. Appendix X1-Appendix X3

expressed in inches of H O. (Cubic meters per second per

contain additional considerations. The performance require-

square meter of AR surface at a pressure differential in

ments are not intended to be used to predict specific levels of

Pascals.)

performance in the field, however they are intended to be used

3.1.5 air retarder (AR)—a material or system in building

in the evaluation of ARs.

constructionthatisdesignedandinstalledtoreduceairleakage

5.1.1 Air Leakage—AR shall be tested in accordance with

either into or through the opaque wall.

Test Method E283. Air leakage rate shall not exceed 0.06

3.1.6 opaque wall—all exposed areas of a wall that enclose 2 −3 3 2

cfm/ft at 0.3 in. H O. (0.3 310 m/(s·m ) at 75 Pa.)

conditioned space, except openings for windows, doors and

NOTE 1—Air leakage rate of 0.06 cfm/ft at 0.3 in. H O corresponds

building service systems.

approximately to a low rise building (floor area=125 m ) with an air

3.1.7 structural integrity—for the purpose of this specifica-

leakage rate of 1.0 to 2.0 air changes/h at 0.2 in. H O (50 Pa) in which

tion, it is the ability of the AR to maintain air leakage

25% of the leakage occurs through the opaque walls.

performance after exposure to elevated positive and negative

pressure (see 5.1.2 for performance). 5.1.2 Structural Integrity—Air retarder shall be tested in

3.1.8 vapor retarder—a material or system that adequately accordance with Test Method E330, ProcedureA—no deflec-

impedes the transmission of water vapor under specified tion information is required. TheAR shall withstand sustained

conditions. minimum pressure of 2 in. H O (500 Pa) (equivalent wind

3.1.8.1 Discussion—For practical purposes it is assumed speed of approximately 65 mph or 29 m/s) for 1 h. The

that the permeance of a vapor retarder will not exceed one specimen shall pass this test by retesting the air leakage

perm in inch-pound units (57.4 ng/(s· m · Pa)), although at performancerequirementandpassingtherequirementin5.1.1.

present this value may only be appropriate for residential

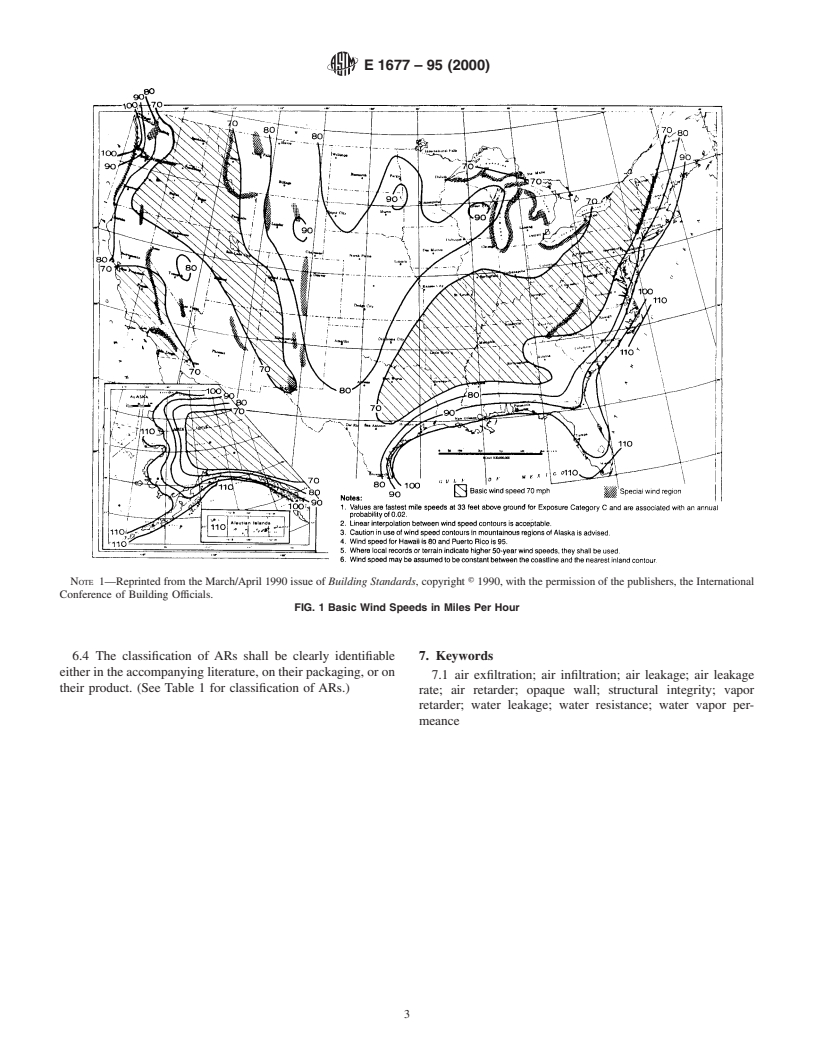

NOTE 2—The user can consult the map in Fig. 1, reference (1) andTest

construction. For certain other types of construction the per-

Method E330 (Significance and Use Section) for guidance on wind

meance must be lower.

speeds for the area where the building will be located. This requirement

3.1.9 water leakage—penetration of water onto the exterior

doesnotaddressgustwindloadswherethewindspeedcanbesignificantly

planeofframingorcavityinsulationunderspecifiedconditions higher but for a very short period of time. If anAR is used in a high gust

area, the user may require testing at a higher pressure for a shorter period

of air pressure difference across the AR during a test period.

to simulate gust conditions.

3.1.10 water resistance—the capability of a material or

system to retard water leakage.

5.1.3 Water Resistance—Type I ARs shall be tested in

3.1.11 water vapor diffusion—the process by which water

accordance with Test Method E331. No water penetration

vaporspreadsormovesthroughpermeablematerialscausedby

shall occur onto the exterior plane of framing or cavity

a difference in water vapor pressure.

insulation, at 0.11 in. H O (27 Pa) pressure difference (equiva-

3.1.12 water vapor permeance—the time rate of water

lent wind speed of approximately 15 mph) during a 15-min.

vapor transmission through unit area of flat material or

test period (see Table 1).

constructioninducedbyunitvaporpressuredifferencebetween

5.1.4 Water Vapor Permeance, or water vapor transmission

two specific surfaces, under specified temperature and humid-

rate of an AR material or materials of a system shall be

ity conditions.

determinedandreportedinaccordancewithTestMethodE96,

3.1.12.1 Discussion—Permeance is a performance evalua-

Procedure A. The test shall utilize standard test conditions of

tion and not a property of a material. An acceptable unit of

73.4°F (23°C) and a relative humidity of 50 62%.

permeance is the perm: expressed in the units grain/h · ft in.

NOTE 3—This test specification is specific to the AR material or

Hg (metric perm=expressed in the units ng/(s · m · Pa)).

materials that make up the system. The user can consult X2.3 for

information on permeance.

4. Classification

4.1 This specification covers two types ofARs. The perfor-

6. Supplemental Requirements

mance requirements are shown in Table 1.

6.1 Air retarder manufacturers shall provide field applica-

tioninstructionsonhowtoinstalltheARtoachievecontinuity.

TABLE 1 AR Classifications

6.2 Air retarder manufacturers shall make available upon

Classifications

Performance Properties

request the test configuration used to achieve the performance

Type I Type II

requirements of Section 5.

Air leakage in accordance with 5.1.1 in accordance with 5.1.1

6.3 If anAR is susceptible to ultraviolet (UV) degradation,

Structural integrity in accordance with 5.1.2 in accordance with 5.1.2

Water resistance in accordance with 5.1.3 not required the AR manufacturers shall provide application/installation

Water vapor permeance in accordance with 5.1.4 in accordance with 5.1.4

instructions that indicate the amount of UV exposure the

Supplemental in accordance with in accordance with

productcanwithstand.TheARmanufacturershallalsoprovide

requirements Section 6 Section 6

upon request test configuration and procedure for UV testing.

E 1677 – 95 (2000)

NOTE 1—Reprinted from the March/April 1990 issue of Building Standards, copyrightr 1990, with the permission of the publishers, the International

Conference of Building Officials.

FIG. 1 Basic Wind Speeds in Miles Per Hour

6.4 The classification of ARs shall be clearly identifiable 7. Keywords

eitherintheaccompanyingliterature,ontheirpackaging,oron

7.1 air exfiltration; air infiltration; air leakage; air leakage

their product. (See Table 1 for classification of ARs.)

rate; air retarder; opaque wall; structural integrity; vapor

retarder; water leakage; water resistance; water vapor per-

meance

E 1677 – 95 (2000)

ANNEX

(Mandatory Information)

A1. TESTING AIR LEAKAGE, STRUCTURAL INTEGRITY, AND WATER RESISTANCE

A1.1 Test Apparatus shallnotbeinstalledintestedassembly.Ifanygasketing/caulk

isrequestedbytheARmanufacturer,itshallbeconsideredpart

A1.1.1 TestapparatusshallconformtoTestMethodsE283,

of the AR.

E330, and E331 except as modified by this specification.

A1.2.4 Fornegativeandpositivepressuredifferencetesting,

A1.2 Test Specimen

use either of the following two test options to simulate the

installation of an exterior finish/cladding. If the exterior finish/

A1.2.1 Wall shall be constructed 8 ft by 8 ft or larger, 2 in.

cladding is the AR the following two test options are not

by 4 in. framing, and stud spacing of 16 in. on center. (Any

required (see reference (2) and (3) for additional guidance).

additional material attached to this frame shall be considered

A1.2.4.1 To simulate a lap siding install 1 in. by 1 in. wood

part of the AR.)

strips placed horizontally 9 in. apart to the face of the exterior

A1.2.2 The AR tested shall not include installation proce-

AR. Install the specimen in the test apparatus so the AR is

dures that are different from those in field application instruc-

observable, particularly during the structural integrity test.

tions. Seams representative of those in the field application

A1.2.4.2 To simulate brick veneer, install brick ties in a 16

shall be included within the test area.

in. by 16 in. grid pattern to the face of the exteriorAR. Install

A1.2.2.1 If a component of an exteriorAR is installed as 4

the specimen in the test apparatus so the AR is observable,

ftby8ftsheathing(withlongdimensionverticallyinstalled)or

particularly during the structural integrity test.

less, at least two vertical seams shall be within the test area.

A1.2.2.2 If an AR is less than 8 ft in the vertical direction,

A1.3 Test Procedure

at least one horizontal seam shall be within the test area. More

seams are required with narrow (less than 4-ft wide) products. A1.3.1 For this specification, conduct both Test Methods

A1.2.2.3 Bothverticaledgesofthewallshallbesealedwith E283 and E330 utilizing both negative and positive pressure

caulk, gasket, or tape. TheAR manufacturer shall specify how differences.

the top and bottom of the wall shall be treated. If the wall has A1.3.2 Structural Integrity—(Test Method E330) Conduct

caulking, gasketing, or tape utilized at the top or bottom, or sustained loading on the specimen at a positive and negative

both, it shall be considered part of the AR, and shall be pressure difference of 2 in. H O, (500 Pa) (approximately 65

prescribed by the manufacturer for field application. mph) for a period of 1 h. The specimen shall have passed this

A1.2.3 Ifinteriorwallboard,orsimilartypematerial,isused test for structural integrity by retesting the air leakage perfor-

aspartoftheAR,thefollowingpracticesshallbeincorporated. mance requirement and passing the requirement in 5.1.1. No

A1.2.3.1 The wallboard shall be installed by sealing seams adjustmentsoralterationsshallbemadetothespecimenorAR

at the top and both vertical edges of the wall.The bottom shall between the completion of the structural integrity test (Test

remain unsealed to simulate normal construction practice. If Method E330) and the completion of the air leakage test (Test

sealingofthebottomedgeiscalledforbytheARmanufacturer Method E283). Users can require more stringent sustained

it is then considered part of their system.Vertical or horizontal load requirements. See Fig. 1 for information on the wind

seams within the field of the test area shall b

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.