ASTM A775/A775M-00a

(Specification)Standard Specification for Epoxy-Coated Reinforcing Steel Bars

Standard Specification for Epoxy-Coated Reinforcing Steel Bars

SCOPE

1.1 This specification covers deformed and plain steel reinforcing bars with protective epoxy coating applied by the electrostatic spray method.

Note 1--The coating applicator is identified throughout this specification as the manufacturer.

1.2 Other organic coatings may be used provided they meet the requirements of this specification.

1.3 Requirements for coatings are contained in Annex A1.

1.4 Guidelines for construction practices at the job-site are presented in Appendix X1.

1.5 This specification is applicable for orders in either SI units (as Specification A775M) or inch-pound units [as Specification A775].

1.6 The values stated in either SI or inch-pound units are to be regarded as standard. Within the text, the inch-pound units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other, except as specifically noted in Table 1. Combining values from the two systems may result in nonconformance with this specification.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: A 775/A 775M – 00a

Standard Specification for

Epoxy-Coated Steel Reinforcing Bars

This standard is issued under the fixed designation A 775/A 775M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

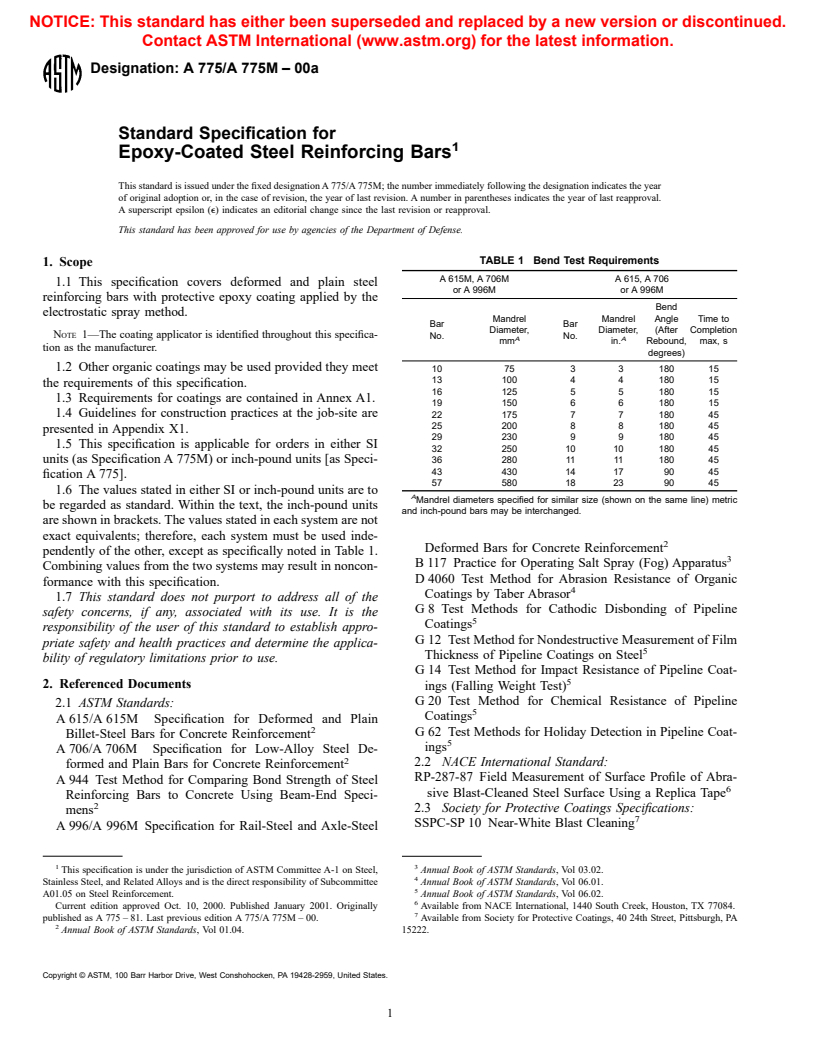

TABLE 1 Bend Test Requirements

1. Scope

A 615M, A 706M A 615, A 706

1.1 This specification covers deformed and plain steel

or A 996M or A 996M

reinforcing bars with protective epoxy coating applied by the

Bend

electrostatic spray method.

Mandrel Mandrel Angle Time to

Bar Bar

Diameter, Diameter, (After Completion

NOTE 1—The coating applicator is identified throughout this specifica- No. No.

A A

mm in. Rebound, max, s

tion as the manufacturer.

degrees)

1.2 Other organic coatings may be used provided they meet

10 75 3 3 180 15

13 100 4 4 180 15

the requirements of this specification.

16 125 5 5 180 15

1.3 Requirements for coatings are contained in Annex A1.

19 150 6 6 180 15

1.4 Guidelines for construction practices at the job-site are

22 175 7 7 180 45

25 200 8 8 180 45

presented in Appendix X1.

29 230 9 9 180 45

1.5 This specification is applicable for orders in either SI

32 250 10 10 180 45

units (as Specification A 775M) or inch-pound units [as Speci- 36 280 11 11 180 45

43 430 14 17 90 45

fication A 775].

57 580 18 23 90 45

1.6 The values stated in either SI or inch-pound units are to

A

Mandrel diameters specified for similar size (shown on the same line) metric

be regarded as standard. Within the text, the inch-pound units

and inch-pound bars may be interchanged.

are shown in brackets. The values stated in each system are not

exact equivalents; therefore, each system must be used inde-

Deformed Bars for Concrete Reinforcement

pendently of the other, except as specifically noted in Table 1.

B 117 Practice for Operating Salt Spray (Fog) Apparatus

Combining values from the two systems may result in noncon-

D 4060 Test Method for Abrasion Resistance of Organic

formance with this specification.

Coatings by Taber Abrasor

1.7 This standard does not purport to address all of the

G 8 Test Methods for Cathodic Disbonding of Pipeline

safety concerns, if any, associated with its use. It is the

Coatings

responsibility of the user of this standard to establish appro-

G 12 Test Method for Nondestructive Measurement of Film

priate safety and health practices and determine the applica-

Thickness of Pipeline Coatings on Steel

bility of regulatory limitations prior to use.

G 14 Test Method for Impact Resistance of Pipeline Coat-

2. Referenced Documents

ings (Falling Weight Test)

G 20 Test Method for Chemical Resistance of Pipeline

2.1 ASTM Standards:

Coatings

A 615/A 615M Specification for Deformed and Plain

G 62 Test Methods for Holiday Detection in Pipeline Coat-

Billet-Steel Bars for Concrete Reinforcement

ings

A 706/A 706M Specification for Low-Alloy Steel De-

2.2 NACE International Standard:

formed and Plain Bars for Concrete Reinforcement

RP-287-87 Field Measurement of Surface Profile of Abra-

A 944 Test Method for Comparing Bond Strength of Steel

sive Blast-Cleaned Steel Surface Using a Replica Tape

Reinforcing Bars to Concrete Using Beam-End Speci-

2.3 Society for Protective Coatings Specifications:

mens

SSPC-SP 10 Near-White Blast Cleaning

A 996/A 996M Specification for Rail-Steel and Axle-Steel

1 3

This specification is under the jurisdiction of ASTM Committee A-1 on Steel, Annual Book of ASTM Standards, Vol 03.02.

Stainless Steel, and Related Alloys and is the direct responsibility of Subcommittee Annual Book of ASTM Standards, Vol 06.01.

A01.05 on Steel Reinforcement. Annual Book of ASTM Standards, Vol 06.02.

Current edition approved Oct. 10, 2000. Published January 2001. Originally Available from NACE International, 1440 South Creek, Houston, TX 77084.

published as A 775 – 81. Last previous edition A 775/A 775M – 00. Available from Society for Protective Coatings, 40 24th Street, Pittsburgh, PA

Annual Book of ASTM Standards, Vol 01.04. 15222.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

A 775/A 775M

SSPC-VIS 1 Pictorial Surface Preparation Standards for 4.1.10 Manufacturer qualification and certification require-

Painting Steel Surfaces ments (if any).

2.4 Naval Facility Guide Specification:

NOTE 2—It is recommended that the coating application procedures and

NFGS 03201, “Manufacture of Prefabricated Epoxy-Coated

processes be audited by an independent certification program such as that

Rebar for Oceans and Other Severe Environments”

provided by the Navy Facility Guide Specifications, the Concrete Rein-

forcing Steel Institute, or equivalent.

2.5 Concrete Reinforcing Steel Institute:

NOTE 3—A typical ordering description is as follows: Deformed Grade

“Voluntary Certification Program for Fusion Bonded Epoxy

420 bars to ASTM A 615M_____; 6000 m, No. 19, 12 m long in secured

Coating Applicator Plants”

lifts with sufficient spacers or padding, or both; epoxy-coated to ASTM

2.6 American Concrete Institute Standard:

A 775M–_____; including written certifications for the powder coating

ACI 301 Specifications for Structural Concrete

and coated bars, and 1 L of patching material.

[Deformed Grade 60 bars to ASTM A 615 –_____; 20 000 ft, No. 6, 40

3. Terminology ft 0 in. long in secured lifts with sufficient spacers or padding, or both;

epoxy-coated to ASTM A 775–_____; including written certifications for

3.1 Definitions of Terms Specific to This Standard:

the powder coating and coated bars, and 1 qt of patching material.]

3.1.1 conversion coating, n—a preparation of the blast-

cleaned steel surface prior to coating application that is

5. Materials

designed to pretreat the metal to promote coating adhesion,

5.1 Steel reinforcing bars to be coated shall meet the

reduce metal-coating reactions, improve corrosion resistance,

requirements of one of the following specifications: A 615M,

and increase blister resistance.

A 706M, or A 996M [A 615, A 706, or A 996], as specified by

3.1.2 disbonding, n—loss of adhesion between the fusion-

the purchaser and shall be free of contaminants such as oil,

bonded epoxy coating and the steel reinforcing bar.

grease, or paint.

3.1.3 fusion-bonded epoxy coating, n—a product containing

NOTE 4—Prior to coating, the steel reinforcing bars should be inspected

pigments, thermosetting epoxy resins, crosslinking agents, and

for their suitability for coating. Bars with sharp edges on the deformations,

other additives, which is applied in the form of a powder onto

rolled-in slivers, or other surface imperfections are difficult to coat

a clean, heated metallic substrate and fuses to form a continu-

properly and should not be coated. The coating will flow away from the

ous barrier coating.

sharp edges and may result in inadequate coating thickness at these points.

3.1.4 holiday, n—a discontinuity in a coating that is not

5.2 The powder coating shall meet the requirements of

discernible to a person with normal or corrected vision.

Annex A1. Upon request, the purchaser shall be provided with

3.1.5 patching material, n—a liquid two-part epoxy coating

the test report for review.

used to repair damaged or uncoated areas.

5.2.1 A written certification shall be furnished to the pur-

3.1.6 wetting agent, n—a material that lowers the surface

chaser that properly identifies the number of each lot of powder

tension of water allowing it to penetrate more effectively into

coating used in the order, material quantity represented, date of

small discontinuities in the coating giving a more accurate

manufacture, name and address of the powder coating manu-

indication of the holiday count.

facturer, and a statement that the supplied powder coating is the

same composition as that qualified according to Annex A1 of

4. Ordering Information

this specification.

4.1 It shall be the responsibility of the purchaser to specify

5.2.2 The powder coating shall be stored in a temperature-

all requirements that are necessary for the coated steel rein-

controlled environment following the written recommenda-

forcing bars under this specification. Such requirements to be

tions of the powder coating manufacturer until ready for use.

considered include, but are not limited to, the following:

At that point, if the storage temperature is below the plant

4.1.1 Reinforcing bar specification and year of issue,

ambient temperature, the powder coating shall be given suffi-

4.1.2 Quantity of bars,

cient time to reach approximate plant ambient temperature.

4.1.3 Size and grade of bars,

The powder coating shall be used within the powder coating

4.1.4 Requirements for the powder coating and provision of

manufacturer’s written recommended shelf life.

test data (5.2 and 5.3),

5.3 If specified in the order, a representative 0.2-kg [8-oz]

4.1.5 Requirements for patching material (5.4),

sample of the powder coating shall be supplied to the purchaser

4.1.6 Quantity of patching material,

from each batch. The sample shall be packaged in an airtight

4.1.7 Specific requirements for test frequency (9.1),

container and identified by batch number.

4.1.8 Whether a report on tests performed on the coated

5.4 If specified in the order, patching material, compatible

steel reinforcing bars being furnished is required (8.4.1 and 14)

with the coating, inert in concrete, and recommended by the

4.1.9 Additional specimens to be provided to the purchaser

powder coating manufacturer, shall be supplied to the pur-

for testing from the coated steel reinforcing bars being fur-

chaser.

nished (12.1), and

6. Surface Preparation

6.1 The surface of the steel reinforcing bars to be coated

Available from NFESC, 560 Center Drive, Port Hueneme, CA 93043.

shall be cleaned by abrasive blast cleaning to near-white metal

Available from Concrete Reinforcing Steel Institute, 933 N. Plum Grove Road,

in accordance with SSPC-SP10. Additional surface treatment

Schaumburg, IL 60173.

steps may be used as indicated in A1.2. The following visual

Available from American Concrete Institute, 38800 International Way, P.O.

Box 9094, Farmington Hills, MI 48333–9094. standard of comparison may be used to define the final surface

A 775/A 775M

condition: SSPC-VIS 1. Average blast profile maximum rough- spaced along each side of the test bar.

ness depth readings of 0.04 to 0.10 mm [1.5 to 4.0 mils], as

8.1.2.1 Measurements shall be made in accordance with

determined by replica tape measurements using NACE RP-

Test Method G 12, following the instructions for calibration

287-87, shall be considered suitable as an anchor pattern.

and use recommended by the thickness gage manufacturer.

Pull-off or fixed probe gages shall be used. “Pencil-type’’

NOTE 5—The use of a “profilometer” type surface measurement instru-

pull-off gages that require the operator to observe the reading

ment that measures the peak count as well as the maximum profile depth

at the instant the magnet is pulled from the surface shall not be

is recommended.

NOTE 6—Abrasive blast cleaning of steel reinforcing bars with a high

used.

degree (> 90 %) of grit in the cleaning media provides the most suitable

8.1.3 The coating thickness shall be measured on the body

anchor profile for coating adhesion. After grit has been recycled, a small

of a straight length of steel reinforcing bar between the

portion will take on the appearance of shot.

deformations.

6.2 Multidirectional, high-pressure dry air knives shall be

8.2 Coating Continuity:

used after blasting to remove dust, grit, and other foreign

8.2.1 Holiday checks to determine the acceptability of the

matter from the blast-cleaned steel surface. The air knives shall

steel reinforcing bars prior to shipment shall be made at the

not deposit oil on the steel reinforcing bars.

manufacturer’s plant with a 67.5–V, 80 000–V, wet-sponge

type direct current holiday detector or equivalent method.

NOTE 7—It is recommended that incoming steel reinforcing bars and

blast media be checked for salt contamination prior to use. Blast media

NOTE 9—In-line holiday detection is recommended. Hand-held holiday

found to be salt contaminated should be rejected. Steel reinforcing bars

detector checks should be performed regularly to verify the accuracy of

found to be salt contaminated from exposure to deicing salts or salt spray

the in-line system.

should be cleaned by acid washing or other suitable methods to remove

salt contaminants from the surface prior to blast cleaning.

8.2.2 On average, there shall not be more than 3 holidays

per meter [one holiday per foot] on a coated steel reinforcing

6.3 It shall be permissible for the manufacturer to use a

bar. The average applies to the full production length of a bar.

chemical wash or conversion of the blast-cleaned steel rein-

forcing bar surface, or both, to enhance coating adhesion. This 8.2.3 A wetting agent shall be used per Test Methods G 62

pretreatment shall be applied after abrasive cleaning and before in the inspection for holidays on the coated steel reinforcing

coating, in accordance with the written application instructions bars.

specified by the pretreatment manufacturer.

8.3 Coating Flexibility:

8.3.1 The coating flexibility shall be evaluated by bending

7. Coating Application

production coated steel reinforcing bars at a uniform rate

7.1 If pretreatment is used in the preparation of the surface,

around a mandrel of specified size within a maximum specified

the powder coating shall be applied to the cleaned and

time period as prescribed in Table 1. The two longitudinal ribs

pretreated steel reinforcing bar surface as soon as possible after

shall be placed in a plane perpendicular to the mandrel radius.

surface treatments have been completed, and before visible

The test specimens shall be between 20 and 30°C [68 and

oxidation of the surface occurs as discernible to a person with

86°F].

normal or corrected vision. In no case shall application of the

8.3.2 No cracking or disbonding of the coating shall be

coating be delayed more than 3 h after cleaning.

visible to the unaided eye on the outside radius of the bent bar.

7.2 The fusion-bonded epoxy powder coating shall be

Except as specified in 10.1, evidence of cracking or disbonding

applied in accordance with the written recommendations of the

of the coating shall be considered cause for rejection of the

manufacturer of the powder coating for initial steel surface

coated steel reinforcing bars represented by the bend test

temperature range and post application

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.