ASTM C509-06(2011)

(Specification)Standard Specification for Elastomeric Cellular Preformed Gasket and Sealing Material

Standard Specification for Elastomeric Cellular Preformed Gasket and Sealing Material

ABSTRACT

This specification covers elastomeric cellular preformed gasket and sealing materials. Elastomeric cellular materials shall be manufactured from natural rubber, synthetic rubber, rubber-like materials, or mixture of these, with added compounding ingredients. The material shall conform to the required physical properties such as: compression-deflection, compression set, heat aging, dimensional stability, ozone resistance, low-temperature brittleness, water absorption, flame propagation, and nonstaining. The two classifications of material according to ozone resistance are Type I and Type II. Test for each physical properties shall be made.

SIGNIFICANCE AND USE

Flame Propagation:

This specification has two options:

Option I—Flame propagation test is required.

Option II—Flame propagation test is not required.

In case no option is specified, Option I will apply.

This specification has two classifications as related to ozone resistance. These are Type I and Type II, with the latter having the greater resistance to ozone. The type should be specified when making reference to this specification but in the event that the type is not specified, Type II shall apply.

Note 2—Type II is included in this specification for use where greater ozone resistance is required.

SCOPE

DESIG

1.1 This specification applies to those elastomeric cellular materials of a firm grade that are manufactured in preformed shapes for use as gaskets and for use as sealing materials, in the form of compression seals or gaskets, or both, for glazing other building joint applications.

Note 1—For softer cellular elastomeric materials used in secondary sealing applications, refer to Specification D1056.

1.2 Test Method C1166, as referenced in this specification, should be used to measure and describe the properties of materials, products, or assemblies in response to heat and flame under controlled laboratory conditions and should not be used to describe or appraise the fire hazard or fire risk of materials, products, or assemblies under actual fire conditions. However, results of this test may be used as elements of a fire risk assessment which takes into account all of the factors which are pertinent to an assessment of the fire hazard of a particular end use.

1.3 The following precautionary caveat pertains only to the test method portion, Section 11, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.4 The committee with jurisdiction over this standard is not aware of any comparable standards published by other organizations.

X1.1.1 This test method is intended to determine the ability of compounds made from rubber or rubber-like materials to resist the effect of low temperatures that may cause them to become brittle and fracture or crack when bent. Standard specimens are exposed to specified low temperatures for definite periods after which the specimens are bent in a prescribed manner and any fracture or cracking noted. The procedure is commonly called the “Thiokol” method.

Note X1.1—Results obtained by this test method are influenced by the rate of flexing of the cooled specimens which can not be closely controlled in the prescribed apparatus. They are therefore of a qualitative nature and may not be closely reproducible over a range of several degrees of temperature depending on the speed of flexure. For more accurate determination of brittle temperature, and particularly in new specifications, Test Method D746 is recommended.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C509 −06(Reapproved 2011)

Standard Specification for

Elastomeric Cellular Preformed Gasket and Sealing

Material

This standard is issued under the fixed designation C509; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope C1083Test Method for Water Absorption of Cellular Elas-

tomeric Gaskets and Sealing Materials

1.1 This specification applies to those elastomeric cellular

C1166Test Method for Flame Propagation of Dense and

materials of a firm grade that are manufactured in preformed

Cellular Elastomeric Gaskets and Accessories

shapesforuseasgasketsandforuseassealingmaterials,inthe

D395Test Methods for Rubber Property—Compression Set

formofcompressionsealsorgaskets,orboth,forglazingother

D412TestMethodsforVulcanizedRubberandThermoplas-

building joint applications.

tic Elastomers—Tension

NOTE 1—For softer cellular elastomeric materials used in secondary

D746Test Method for Brittleness Temperature of Plastics

sealing applications, refer to Specification D1056.

and Elastomers by Impact

1.2 Test Method C1166, as referenced in this specification,

D865Test Method for Rubber—Deterioration by Heating in

should be used to measure and describe the properties of

Air (Test Tube Enclosure)

materials, products, or assemblies in response to heat and

D925Test Methods for Rubber Property—Staining of Sur-

flameundercontrolledlaboratoryconditionsandshouldnotbe

faces (Contact, Migration, and Diffusion)

used to describe or appraise the fire hazard or fire risk of

D1056 Specification for Flexible Cellular Materials—

materials, products, or assemblies under actual fire conditions.

Sponge or Expanded Rubber

However, results of this test may be used as elements of a fire

D1149TestMethodsforRubberDeterioration—Crackingin

risk assessment which takes into account all of the factors

an Ozone Controlled Environment

which are pertinent to an assessment of the fire hazard of a

particular end use.

3. Terminology

1.3 The following precautionary caveat pertains only to the

3.1 Definitions—Refer toTerminology C717 for the follow-

test method portion, Section 11, of this specification:This

ing terms used in this specification: cellular material,

standard does not purport to address all of the safety concerns,

elastomeric, gasket glazing, seal, and sealing material.

if any, associated with its use. It is the responsibility of the user

of this standard to establish appropriate safety and health

4. Materials and Manufacture

practices and determine the applicability of regulatory limita-

4.1 Elastomeric cellular materials furnished to this specifi-

tions prior to use.

cation shall be manufactured from natural rubber, synthetic

1.4 Thecommitteewithjurisdictionoverthisstandardisnot

rubber, rubber-like materials, or mixtures of these, with added

aware of any comparable standards published by other orga-

compounding ingredients of such nature and quality that, with

nizations.

proper curing, the finished product will comply with this

2. Referenced Documents

specification.

2.1 ASTM Standards:

4.2 The cured compounds shall be suitable for use where

C717Terminology of Building Seals and Sealants

resistance to sunlight, weathering, oxidation, and permanent

deformation under load are of prime importance.

This specification is under the jurisdiction of ASTM Committee C24 on

4.3 The manufacturing process shall be such to ensure a

BuildingSealsandSealantsandisthedirectresponsibilityofSubcommitteeC24.73

on Compression Seal and Lock Strip Gaskets.

homogeneous cellular material free of defects that may affect

Current edition approved June 1, 2011. Published August 2011. Originally

serviceability.

approved in 1963. Last previous edition approved in 2006 as C509–06. DOI:

10.1520/C0509-06R11.

4.4 Although under this specification the manufacturer is

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

permitted to choose constituent materials, there is no implica-

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

tion that the several compounds are equivalent in all physical

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. properties.Anyspecialcharacteristicsotherthanthoserequired

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C509−06 (2011)

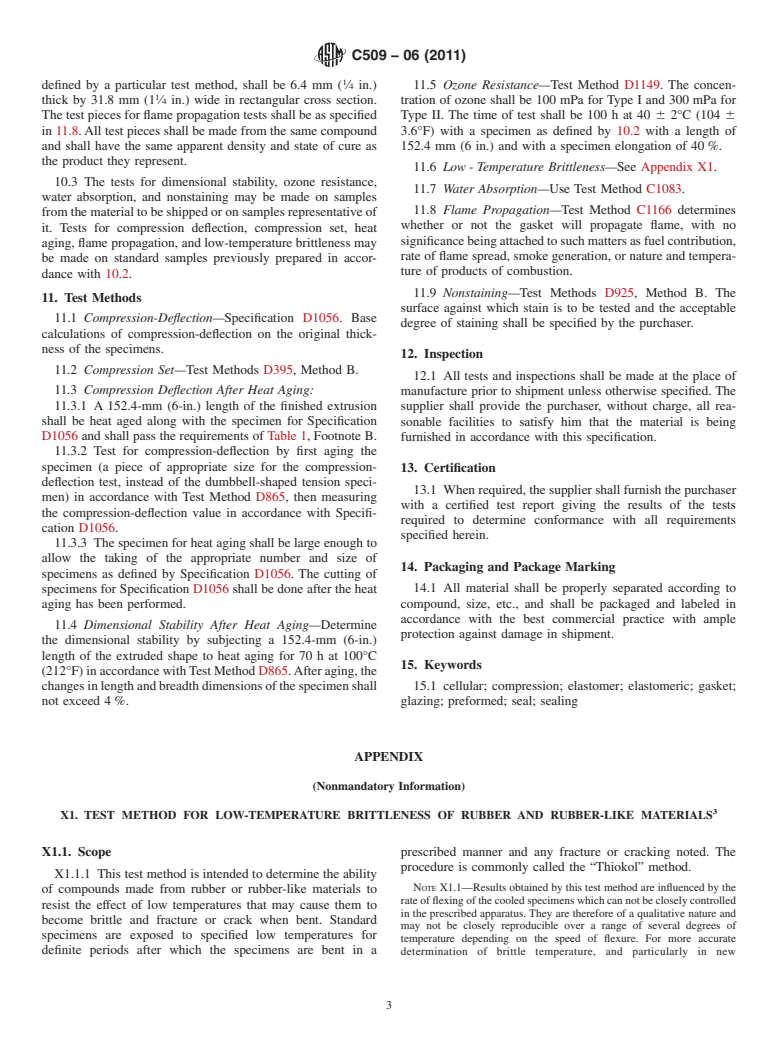

TABLE 2 Standards for Cross-Sectional Tolerance

by this specification, which may be needed for specific

applications, shall be specified by the purchaser, since such

NOTE 1—Dimensional tolerances for outside diameters, inside

characteristics may influence the choice of base materials and

diameters, wall thickness, width, height, and general cross-sectional

dimensions of extrusions

other ingredients.

A

Rubber Manufacturers Association

5. Physical Properties RMA Class 1 RMA Class 1

Drawing Designation BEC 1 Drawing Designation BEC 1

5.1 The material shall conform to the requirements pre-

Dimensions (in inches) Dimensions (in Millimeters)

Above Up To Above Up To

scribed in Table 1.

0 0.25 ±0.016 0 6.4 ±0.4

0.25 0.50 0.025 6.4 12.7 0.63

6. Dimensional Tolerances

0.50 1.00 0.050 12.7 25.4 1.25

1.00 1.60 0.080 25.4 40.6 2.0

6.1 Permissiblevariationincross-sectionaldimensionsshall

1.60 & over multiply by 0.060 40.6 & over multiply by 0.06

be as specified in Table 2 unless otherwise agreed upon

A

Adapted from Rubber ManufacturersAssociation Handbook, Table 36, Fifth Ed.,

between the purchaser and the supplier.

7. Workmanship, Finish, and Appearance

7.1 Theelastomericcellularmaterialsshallbemanufactured

9.1.1.1 Option I—Flame propagation test is required.

and processed in a careful and workmanlike manner in

9.1.1.2 Option II—Flame propagation test is not required.

accordance with the best commercial practices.

9.1.2 In case no option is specified, Option I will apply.

7.2 Thesurfacesofthefinishedmaterialshallbereasonably

9.2 This specification has two classifications as related to

smooth and free of excessive talc or bloom.

ozone resistance. These are Type I and Type II, with the latter

7.3 Unless otherwise specified, the material shall be black. having the greater resistance to ozone. The type should be

specifiedwhenmakingreferencetothisspecificationbutinthe

Whencoloredmaterialisdesired,itisrecommendedthatother

tests, agreed upon between the purchaser and the supplier, be event that the type is not specified, Type II shall apply.

conducted to ensure color stability.

NOTE 2—Type II is included in this specification for use where greater

ozone resistance is required.

8. Number of Tests and Retests

10. Sampling

8.1 Any material that fails in one or more of the test

requirements may be retested by making two additional tests

10.1 When possible, the completed manufactured product

for the requirements in which failure occurs. Failure in one

ofasuitablesectionthereofshallbeusedforthetestsspecified.

such retest shall be cause for final rejection.

Representative samples of the lot being examined shall be

selected at random as required.

8.2 Rejectedmaterialshallbedisposedofasdirectedbythe

supplier.

10.2 When the finished product does not lend itself to

testing or to the taking of test specimens because of compli-

9. Significance and Use

catedshape,smallsize,metalorfabricinserts,orotherreasons,

9.1 Flame Propagation: standard test strips shall be prepared. The standard extruded

9.1.1 This specification has two options: specimens for testing, except where a specific specimen size is

TABLE 1 Physical Requirements of Cellular Elastomeric Materials

A

Property Limit ASTM Test Method

Compression-deflection, 25 % deflection limits:

kPa (psi) 91 to 168 (13 to 24) D1056

Compression set, 22 h @ 70°C (158°F) max, % 30 D395, Method B

B

Heat aging , 70 h @ 100°C (212°F), change in compression-deflection values:

kPa (psi) 0to+70(0to+10) D865 and D1056

Dimensional stability, change, max %, after heat aging, 70 h @ 100°C (212°F) 4 11.4

C

Ozone resistance at 40 % elongation, 100 h @ 40°C (104°F):

Type I 100 mPa ozone no cracks @ 7× magnifica- D1149

tion

Type II 300 mPa ozone no cracks @ 7× magnifica- D1149

tion

Low-temperature brittleness @ − 40°C (−40°F) pass see Appendix X1

Water absorption, max, % weight 5.0 C1083

Flame propagation:

Option I 101.6 mm (4 in.) max C1166

Option II no limit

D

Nonstaining no migratory stain D925

A

See Section 11.

B

After heat aging, surfaces of the specimen shall be neither hard nor brittle.A152.4-mm (6-in.) length of the finished extrusion shall exhibit no surface cracks when bent

on itself 180°.

C

The specimen shall exhibit no surface cracks when in the extended condition.

D

This requirement may be waived, subject to agreement between the purchaser and the supplier.

C509−06 (2011)

defined by a particular test method, shall be 6.4 mm ( ⁄4 in.) 11.5 Ozone Resistance—Test Method D1149. The concen-

thick by 31.8 mm (1 ⁄4 in.) wide in rectangular cross sec

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.