ASTM D5948-96(2002)e1

(Specification)Standard Specification for Molding Compounds, Thermosetting

Standard Specification for Molding Compounds, Thermosetting

SCOPE

1.1 This specification covers the basic properties of thermoset molding compounds and the test methods used to establish the properties.

1.2 ClassificationMolding thermosetting plastic compounds shall be of the following resins and are covered by the individual specification sheets (see 5.1and Annex A1-Annex A8).ResinPhenolic, cellulose filledPhenolic, mineral/glass filledMelaminePolyesterDiallyl iso-phthalateDiallyl ortho-phthalateSiliconeEpoxy

Note 1—There is no equivalent ISO standard.

1.3 Order of Precedence—In the event of a conflict between the text of this specification and the references cited in Section (except for related specification sheets), the text of this specification takes precedence. Nothing in this specification, however, supersedes applicable laws and regulations unless a specific exemption has been obtained.

1.4 The values stated in SI units are to be considered standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

e1

Designation: D 5948 – 96 (Reapproved 2002)

Standard Specification for

Molding Compounds, Thermosetting

This standard is issued under the fixed designation D 5948; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—Editorially added three ASTM practices to the Referenced Documents section, as well as in paragraph 7.1.3 in

November 2002.

1. Scope* Used for Electrical Insulation

D 256 Test Methods for Determining the Izod Pendulum

1.1 This specification covers the basic properties of thermo-

Impact Resistance of Plastics

set molding compounds and the test methods used to establish

D 495 Test Method for High-Voltage, Low-Current, Dry

the properties.

Arc Resistance of Solid Electrical Insulation

1.2 Classification—Molding thermosetting plastic com-

D 570 Test Method for Water Absorption of Plastics

pounds shall be of the following resins and are covered by the

D 618 Practice for Conditioning Plastics for Testing

individual specification sheets (see 5.1 and Annex A1-Annex

D 638 Test Method for Tensile Properties of Plastics

A8).

D 648 Test Method for Deflection Temperature of Plastics

Resin

Under Flexural Load in the Edgewise Position

Phenolic, cellulose filled

Phenolic, mineral/glass filled

D 695 Test Method for Compressive Properties of Rigid

Melamine

Plastics

Polyester

D 790 TestMethodsforFlexuralPropertiesofUnreinforced

Diallyl iso-phthalate

Diallyl ortho-phthalate

and Reinforced Plastics and Electrical Insulating Materi-

Silicone

als

Epoxy

D 796 PracticeforCompressionMoldingTestSpecimensof

NOTE 1—There is no equivalent ISO standard.

Phenolic Molding Compounds

1.3 Order of Precedence—Intheeventofaconflictbetween

D 883 Terminology Relating to Plastics

the text of this specification and the references cited in Section

D 1896 Practice for Transfer Molding Test Specimens of

2 (except for related specification sheets), the text of this

Thermosetting Compounds

specification takes precedence. Nothing in this specification,

D 3419 Practice for In-Line Screw-Injection Molding Test

however, supersedes applicable laws and regulations unless a

Specimens from Thermosetting Compounds

specific exemption has been obtained.

D 3636 Practice for Sampling and Judging Quality of Solid

1.4 The values stated in SI units are to be considered

Electrical Insulating Materials

standard.

D 3638 Test Method for Comparative Tracking Index of

Electrical Insulating Materials

2. Referenced Documents

D 4350 Test Method for Corrosivity Index of Plastics and

2.1 ASTM Standards:

Fillers

D 149 Test Methods for Dielectric Breakdown Voltage and

D 4697 Guide for Maintaining Test Methods in the User’s

Dielectric Strength of Electrical Insulating Materials at

Laboratory

Commercial Power Frequencies

E 994 Guide for Calibration and Testing Laboratory Ac-

D 150 Test Methods for A-C Loss Characteristics and

creditation Systems General Requirements for Operation

Permittivity (Dielectric Constant) of Solid Electrical Insu-

and Recognition

lation

E 1224 Guide for Categorizing Fields of Capability for

D 229 Test Methods for Rigid Sheet and Plate Materials

Discontinued; see 1992 Annual Book of ASTM Standards, Vol 08.01. Replaced

This specification is under the jurisdiction of ASTM Committee D20 on by Practice D 5224.

Plastics and is the direct responsibility of Subcommittee D20.16 on Thermosetting Annual Book of ASTM Standards, Vol 08.02.

Materials. Annual Book of ASTM Standards, Vol 10.02.

Current edition approved November 10, 2002. Published January 2003. Origi- Annual Book of ASTM Standards, Vol 08.03.

nally approved in 1996. Last previous edition approved in 1996 as D 5948 - 96. Annual Book of ASTM Standards, Vol 07.02.

2 8

Annual Book of ASTM Standards, Vol 08.01. Annual Book of ASTM Standards, Vol 14.02.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

e1

D 5948 – 96 (2002)

Laboratory Accreditation Purposes 5.3 Material Safety Data Sheet (MSDS)— The user shall be

2.2 Underwriters Laboratory Standard: provided with a material safety data sheet.

UL 94 Tests for Flammability of Plastic Materials for Parts 5.4 Uniformity—All molding compound of the same brand

in Devices and Appliances from one manufacturer shall be uniform in texture, in color,

2.3 Other Standard: and in the specified properties as determined by the batch-

DDC AD 297457 Procedure for Determining Toxicity of acceptance inspection specified in 8.3.

Synthetic Compounds 5.5 Property Values—Standard specimens of the com-

pounds shall conform to the property values shown in the

3. Terminology

individual specification sheets for qualification (see 8.2) and

3.1 For definitions of technical terms pertaining to plastics batch acceptance (see 8.3).

used in this specification, refer to Terminology D 883.

6. Conditioning

3.2 Definitions of Terms Specific to This Standard:

3.2.1 batch—a homogeneous unit of finished molding com-

6.1 Standard test specimens shall be conditioned before

pound manufactured at one time.

testing, as specified in Tables 1-4.

6.1.1 Nomenclature—The following letters shall be used to

4. Significance and Use

indicate the respective general conditioning procedures:

4.1 This specification is a revision of STD MIL-M-14H,

6.1.1.1 Condition A—As received; no special conditioning.

Specification for Molding Compound, Thermosetting, retain-

6.1.1.2 Condition C—Humidity conditioning in accordance

ing the MIL-M-14H material designations and property re-

with Practice D 618.

quirements while conforming to ASTM form and style. It is

6.1.1.3 Condition D—Immersion conditioning in distilled

intended for qualification and batch acceptance for materials

water in accordance with Practice D 618.

used by government and industry, and is intended as a direct

6.1.1.4 Condition E—Temperature conditioning in accor-

replacement for MIL-M-14H.

dance with Practice D 618; Condition Desiccation–cooling

over silica gel or calcium chloride in a desiccator at 23°C for

5. Requirements

16 to 20 h after temperature conditioning in accordance with

5.1 Specification Sheets—The individual item requirements

Practice D 618.

shall be as specified herein and in accordance with the

6.2 Designation—Conditioning procedures shall be desig-

applicablespecificationsheet(seeAnnexA1-AnnexA8).Inthe

nated as follows:

event of any conflict between the requirements of this specifi-

6.2.1 A capital letter indicating the general condition of the

cation and the material specification, the latter shall govern.

specimen; that is, as-received, humidity, immersion, or tem-

5.2 Qualification—Molding compounds furnished under

perature conditioning.

this specification shall be products which conform to the

6.2.2 A number indicating the duration of the conditioning

applicable material specification and quality assurance provi-

in hours.

sions in this specification.

6.2.3 A number indicating the conditioning temperature in

degrees Celsius.

6.2.4 Anumber indicating relative humidity, whenever rela-

Available from Underwriters Laboratory Inc., 333 Pfingsten Road, Northbrook,

tive humidity is controlled.

IL 60062.

6.3 The numbers shall be separated from each other by slant

Available from the Department of Commerce, National Technical Information

marks and from the capital letter by a dash. A sequence of

Service, 5285 Port Royal Rd., Springfield, VA 22151.

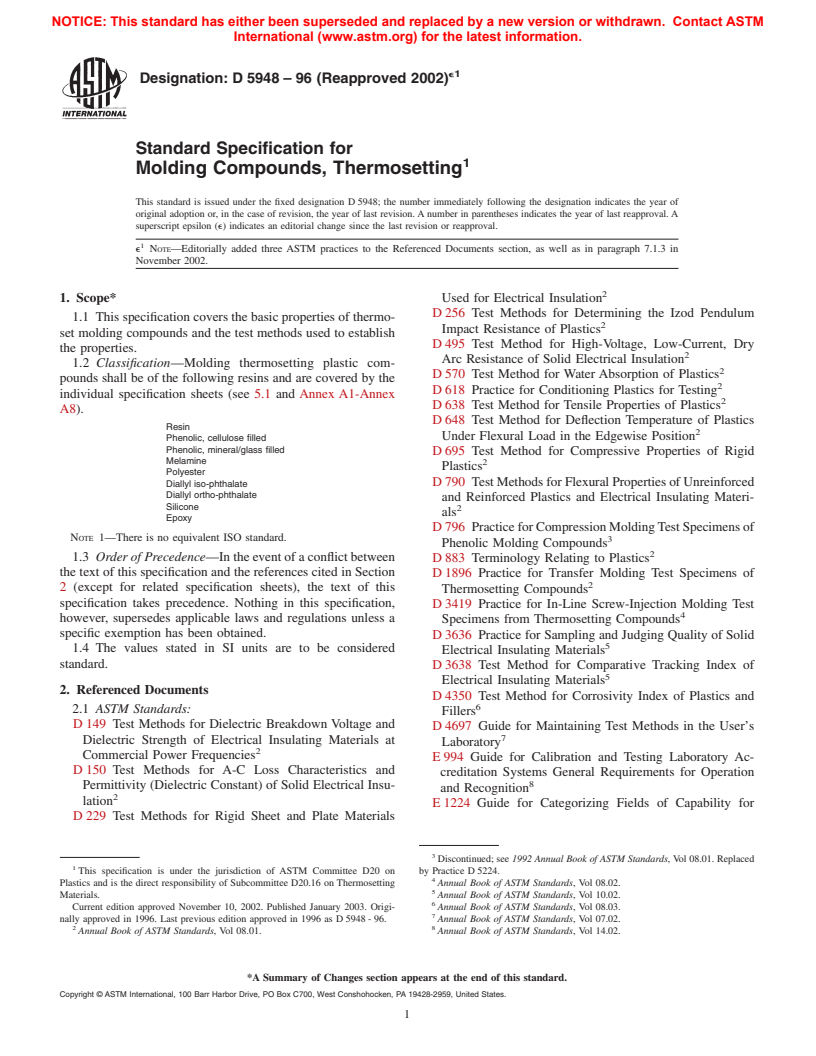

TABLE 1 Sampling and Conditioning for Mechanical/Physical Qualification Tests

NOTE 1—A 50 % retention of initial flexural strength is required.

NOTE 2—The side of a test specimen is that area formed by the chase of the mold.

NOTE 3—The face of the test specimen is that area formed by the top or bottom force plug.

NOTE 4—When specified.

Property to Be Tested- ASTM Test Modified Specimens, Form, and Number Conditioning Procedure

Unit of Value

Mechanical/Physical Method by Dimension Tested (see Section 6)

Compressive strength, end- D 695 . 25.4 by 12.7 by 12.7 mm 5 E-48/50 + C-96/23/50 MPa (minimum average)

wise

Dimensional stability . 7.2.1 127 bar, 12.7 by 12.7 mm 5 C-96/23/50 Percent (maximum average)

Flexural strength D 790 7.2.2 127 bar, 6.4 by 12.7 mm 5 E-48/50 + C-96/23/50 MPa (minimum average)

Heat deflection temperature D 648 7.2.3 127 bar, 12.7 by 12.7 mm 3 A Degrees Celsius (minimum

average)

Heat resistance (1) D 790 7.2.4 127 bar, 6.4 by 12.7 mm 5 E-1/at designated tempera- Degrees Celsius (minimum

ture test. Test at tempera- average) at temperature

ture

Impact strength

Side (2) D 256 . As per Test Method D 256 5 E-48/50 + C96/23/50 J/m notch (minimum average)

Face (3), (4) D 256 . As per Test Method D 256 5 E-48/50 + C96/23/50 J/m notch (minimum average)

Tensile strength D 638 . As per Test Method D 638 5 E-48/50 + C-96/23/50 MPa (minimum average)

Water absorption D 570 7.2.5 51-mm disk, 3.2 mm thick 3 E-24/100 + des + D-48/50 Percent (maximum average)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

e1

D 5948 – 96 (2002)

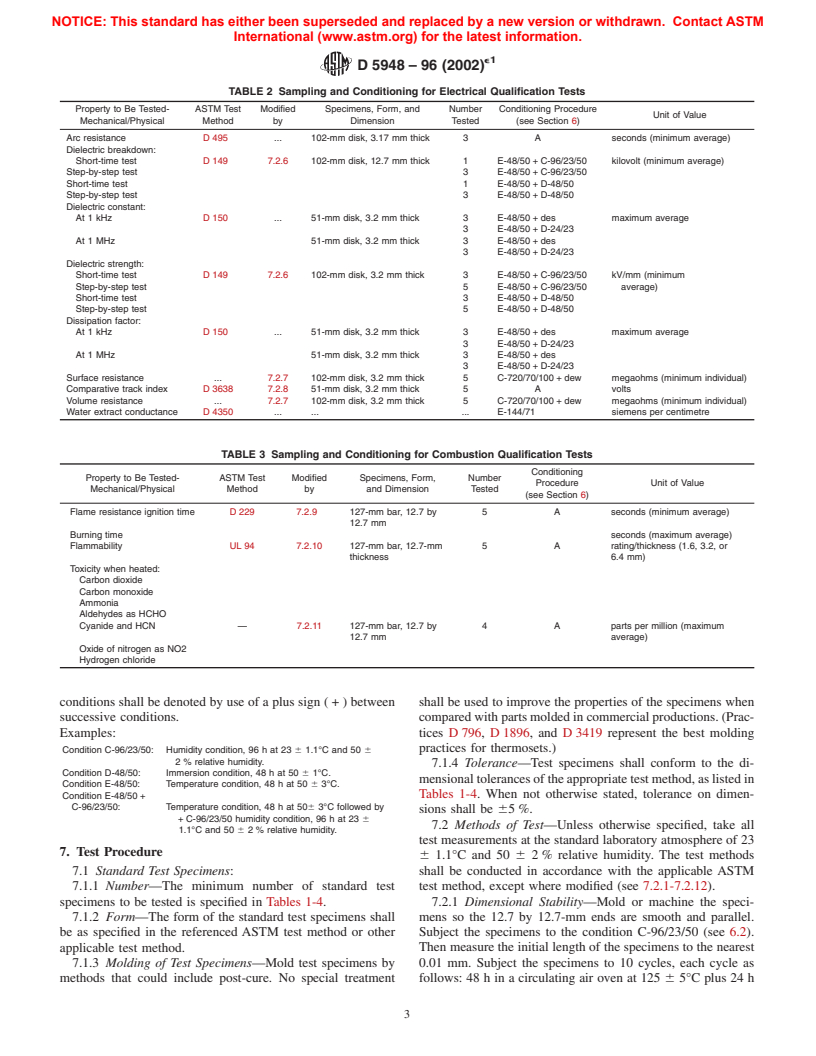

TABLE 2 Sampling and Conditioning for Electrical Qualification Tests

Property to Be Tested- ASTM Test Modified Specimens, Form, and Number Conditioning Procedure

Unit of Value

Mechanical/Physical Method by Dimension Tested (see Section 6)

Arc resistance D 495 . 102-mm disk, 3.17 mm thick 3 A seconds (minimum average)

Dielectric breakdown:

Short-time test D 149 7.2.6 102-mm disk, 12.7 mm thick 1 E-48/50 + C-96/23/50 kilovolt (minimum average)

Step-by-step test 3 E-48/50 + C-96/23/50

Short-time test 1 E-48/50 + D-48/50

Step-by-step test 3 E-48/50 + D-48/50

Dielectric constant:

At 1 kHz D 150 . 51-mm disk, 3.2 mm thick 3 E-48/50 + des maximum average

3 E-48/50 + D-24/23

At 1 MHz 51-mm disk, 3.2 mm thick 3 E-48/50 + des

3 E-48/50 + D-24/23

Dielectric strength:

Short-time test D 149 7.2.6 102-mm disk, 3.2 mm thick 3 E-48/50 + C-96/23/50 kV/mm (minimum

Step-by-step test 5 E-48/50 + C-96/23/50 average)

Short-time test 3 E-48/50 + D-48/50

Step-by-step test 5 E-48/50 + D-48/50

Dissipation factor:

At 1 kHz D 150 . 51-mm disk, 3.2 mm thick 3 E-48/50 + des maximum average

3 E-48/50 + D-24/23

At 1 MHz 51-mm disk, 3.2 mm thick 3 E-48/50 + des

3 E-48/50 + D-24/23

Surface resistance . 7.2.7 102-mm disk, 3.2 mm thick 5 C-720/70/100 + dew megaohms (minimum individual)

Comparative track index D 3638 7.2.8 51-mm disk, 3.2 mm thick 5 A volts

Volume resistance . 7.2.7 102-mm disk, 3.2 mm thick 5 C-720/70/100 + dew megaohms (minimum individual)

Water extract conductance D 4350 . . . E-144/71 siemens per centimetre

TABLE 3 Sampling and Conditioning for Combustion Qualification Tests

Conditioning

Property to Be Tested- ASTM Test Modified Specimens, Form, Number

Procedure Unit of Value

Mechanical/Physical Method by and Dimension Tested

(see Section 6)

Flame resistance ignition time D 229 7.2.9 127-mm bar, 12.7 by 5 A seconds (minimum average)

12.7 mm

Burning time seconds (maximum average)

Flammability UL 94 7.2.10 127-mm bar, 12.7-mm 5 A rating/thickness (1.6, 3.2, or

thickness 6.4 mm)

Toxicity when heated:

Carbon dioxide

Carbon monoxide

Ammonia

Aldehydes as HCHO

Cyanide and HCN — 7.2.11 127-mm bar, 12.7 by 4 A parts per million (maximum

12.7 mm average)

Oxide of nitrogen as NO2

Hydrogen chloride

conditions shall be denoted by use of a plus sign ( + ) between shall be used to improve the properties of the specimens when

successive conditions. comparedwithpartsmoldedincommercialproductions.(Prac-

Examples: tices D 796, D 1896, and D 3419 represent the best molding

practices for thermosets.)

Condition C-96/23/50: Humidity condition, 96 h at 23 6 1.1°C and 50 6

2 % relative humidity.

7.1.4 Tolerance—Test specimens shall conform to the di-

Condition D-48/50: Immersion condition, 48 h at 50 6 1°C.

mensionaltolerancesoftheappropriatetestmethod,aslistedin

Condition E-48/50: Temperature condition, 48 h at 50 6 3°C.

Tables 1-4. When not otherwise stated, tolerance on dimen-

Condition E-48/50 +

C-96/23/50: Temperature condition, 48 h at 506 3°C followed by

sions shall be 65%.

+ C-96/23/50 humidity condition, 96 h at 23 6

7.2 Methods of Test—Unless otherwise specified, take all

1.1°C and 50 6 2 % relative humidity.

test measurements at the standard laboratory atmosphere of 23

7. Test Procedure

6 1.1°C and 50 6 2 % relative humidity. The test methods

7.1 Standard Test Specimens: shall be conducted in accordance with the applicable ASTM

7.1.1 Number—The minimum number of standard test test method, except where modified (see 7.2.1-7.2.12).

specimens to be tested is specified in Tables 1-4. 7.2.1 Dimensional Stability—Mold or machine the speci-

7.1.2 Form—The form of the standard test specimens shall mens so the 12.7 by 12.7-mm ends are smooth and parallel.

be as specified in the referenced ASTM test method or other Subject the specimens to the condition C-96/23/50 (see 6.2).

applicable test method. Then measure the initial length of the specimens to the nearest

7.1.3 Molding of Test Specimens—Mold test specimens by 0.01 mm. Subject the specimens to 10 cycles, each cycle as

methods that could include post-cure. No special treatment follows: 48 h in a circulating air oven at 125 6 5°C plus 24 h

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

e1

D 5948 – 96 (2002)

TABLE 4 Sampling and Conditioning for Batch Acceptance Tests

NOTE 1—The side of a test specimen is that area formed by the chase of the mold.

Property to Be Tested- ASTM Test Modified Specimens, Form, Number Conditioning Procedure

Unit of Value

Mechanical/Physical Method by and Dimension Tested (see Section 6)

Arc resistance D 495 . 102-mm disk, 3.2 mm 3 A seconds (minimum aver-

thick age)

Comparative track index D 3638 7.2.8 51-mm disk, 3.17 mm 5 A volts

thick

Dielectric constant at 1 MHz D 150 . 51-mm disk, 3.2 mm thick 3 E-48/50 + D-24/23 maximum average

Dissipation factor at 1 MHz D 150 . 51-mm disk, 3.2 mm thick 3 E-48/50 + D-24/23 maximum average

maximum average

Dielectric strength, step-by-step D 149 7.2.6 102-mm disk, 3.2 mm 5 E-48/50 + D-48/50 kV/mm (minimum average)

thick

Flexural strength D

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.