ASTM B416-98(2002)

(Specification)Standard Specification for Concentric-Lay-Stranded Aluminum-Clad Steel Conductors

Standard Specification for Concentric-Lay-Stranded Aluminum-Clad Steel Conductors

SCOPE

1.1 This specification covers bare concentric-lay-stranded conductors made from bare, hard-drawn, round, aluminum-clad steel wires of 20.3 % conductivity for general use of electrical purposes. This specification does not apply to stranded conductors for reinforcement in ACSR conductors.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B 416 – 98 (Reapproved 2002)

Standard Specification for

Concentric-Lay-Stranded Aluminum-Clad Steel Conductors

This standard is issued under the fixed designation B 416; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 4.1.1 Quantity of each size,

4.1.2 Conductor size expressed as number andAWG size of

1.1 This specification covers bare concentric-lay-stranded

individual wires (Section 3 and Table 1),

conductors made from bare, hard-drawn, round, aluminum-

4.1.3 Direction of lay of outer layer, if other than left-hand

clad steel wires of 20.3 % conductivity for general use of

(see 6.3),

electrical purposes. This specification does not apply to

4.1.4 Package size (see 15.1),

stranded conductors for reinforcement in ACSR conductors.

4.1.5 Special package markings if required (see 15.3),

1.2 The values stated in inch-pound units are to be regarded

4.1.6 Special lagging if required (see 15.2), and

as the standard. The values given in parentheses are for

4.1.7 Place of inspection if other than place of manufacture

information only.

(Section 13).

2. Referenced Documents

5. Joints

2.1 The following documents of the issue in effect on date

5.1 Joints or splices may be made in the finished individual

of material purchase form a part of this specification to the

aluminum-clad steel wires composing concentric-lay stranded

extent referenced herein:

conductors using more than three wires, provided that such

2.2 ASTM Standards:

joints or splices have a protection and electrical conductance

B 354 Terminology Relating to Uninsulated Metallic Elec-

equivalent to that of the wire itself and that they do not

trical Conductors

decrease the strength of the finished stranded conductor below

B 415 Specification for Hard-Drawn Aluminum-Clad Steel

the minimum breaking strength shown in Table 1. Such joints

Wire

orsplicesshallbenotcloserthan50ft(15m)toanyotherjoint

2.3 Other Documents:

in the same layer in the conductor.

C8.1 Definitions and General Standards for Wires and

Cables

NOTE 1—Joints are made by electrical butt-welding. The ends must be

NBS Handbook 100—Copper Wire Tables of the National cut and the end of each wire must be straightened for a distance of 12 to

15 in. (300 to 380 mm). The proper sleeve is slipped over the end of one

Institute of Standards and Technology

of the wires. The wires are then butt-welded and dressed off to a finished

diameter equal to that of the wire. The weld area is then tempered, the

3. Description of Conductor

sleeve centered over the weld area and compressed to provide a finished

3.1 The designation of the finished conductor shall be

jointthatissmoothandneatinappearance.Thisjointhasatensilestrength

expressed as the number of wires and the diameter of these

of approximately 90 % of rated breaking strength of the wire, but an

individual wires, usually expressed as the AWG size of the

allowance is made for this in the rated strength of the conductor as a

wires. whole. The completed conductor when containing such joints is required

to have the full rated strength.

4. Ordering Information

6. Lay

4.1 Orders for material under this specification shall include

6.1 For 3-wire conductors, the preferred lay is 16 ⁄2 times

the following information:

the outside diameter, but the lay shall not be less than 14 times

nor more than 20 times this diameter.

This specification is under the jurisdiction of ASTM Committee B01 on

6.2 For 7, 19, and 37-wire conductors, the preferred lay is

Electrical Conductors and is the direct responsibility of Subcommittee B01.06 on

13 ⁄2 times the diameter of that layer, but the lay shall not be

Composite Conductors.

less than 10 nor more than 16 times this diameter.

Current edition approved Oct. 10, 2002. Published September 1998. Originally

published as B 416 – 64 T. Last previous edition B 416 – 93.

6.3 The direction of lay of the outer layer shall be left-hand

Annual Book of ASTM Standards, Vol 02.03.

unless the direction of lay is specified otherwise by the

Available from American National Standards Institute (ANSI), 25 W. 43rd St.,

purchaser.

4th Floor, New York, NY 10036.

Available from National Institute of Standards and Technology (NIST), 100

Bureau Dr., Stop 3460, Gaithersburg, MD 20899-3460.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

B 416 – 98 (2002)

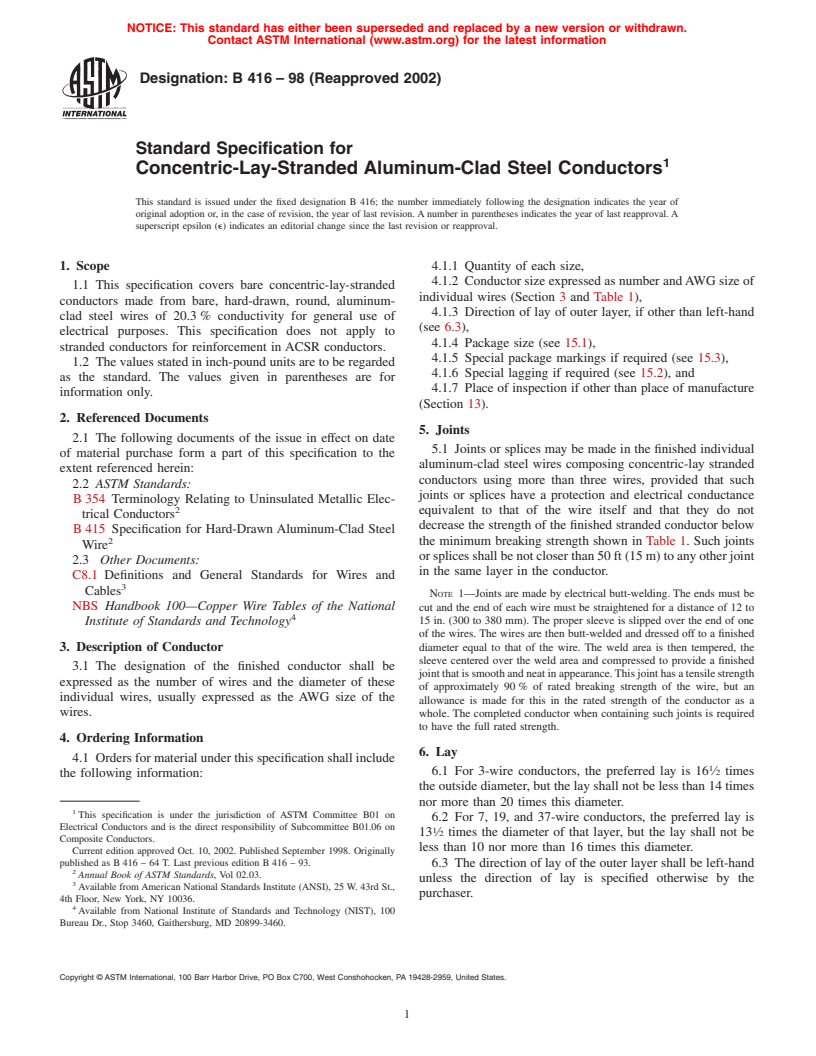

TABLE 1 Construction Requirements and Breaking Strength of NOTE 2—For definitions of terms relating to conductors, reference

A

Concentric-Lay Stranded Aluminum-Clad Steel Conductors

should be made to ANSI C8.1 and Terminology B 354.

Number and Diameter of

Rated 9. Physical and Electrical Tests

Individual Wires

Size Conductor Breaking

B

Nominal 9.1 Tests for physical and electrical properties of wires

Designation Diameter, Strength

Number Diameter, C D

in. min, lb

composing concentric-lay stranded conductors made from

in.

aluminum-clad steel wire shall be made before stranding.

37 No. 5 AWG 37 0.1819 1.27 142 800

9.2 At the option of the purchaser, tension and elongation

37 No. 6 AWG 37 0.1620 1.13 120 200

tests before stranding may be waived and the complete

37 No. 7 AWG 37 0.1443 1.01 100 700

37 No. 8 AWG 37 0.1285 0.899 84 200

conductorsmaybetestedasaunit.Thebreakingstrengthofthe

37 No. 9 AWG 37 0.1144 0.801 66 770

conductorssotestedshallbenotlessthanthatrequiredinTable

37 No. 10 AWG 37 0.1019 0.713 52 950

1.

19 No. 5 AWG 19 0.1819 0.910 73 350

19 No. 6 AWG 19 0.1620 0.810 61 700

9.3 Where breaking strength tests are required on the

19 No. 7 AWG 19 0.1443 0.721 51 730

finished conductor, they shall be made on representative

19 No. 8 AWG 19 0.1285 0.642 43 240

samplesnotlessthan4ft(1.25m)inlength.Forlotsof10 000

19 No. 9 AWG 19 0.1144 0.572 34 290

19 No. 10 AWG 19 0.1019 0.509 27 190

lb (4540 kg) or less, two samples shall be taken from separate

7 No. 5 AWG 7 0.1819 0.546 27 030

reels or coils in the lot except that but one sample shall be

7 No. 6 AWG 7 0.1620 0.486 22 730

required where the total amount of conductor is 5000 ft (1525

7 No. 7 AWG 7 0.1443 0.433 19 060

7 No. 8 AWG 7 0.1285 0.385 15 930

m) or less. For quantities over 10 000 lb, one sample for each

7 No. 9 AWG 7 0.1144 0.343 12 630

10 000 lb or fraction thereof, shall be taken, but the minimum

7 No. 10 AWG 7 0.1019 0.306 10 020

number of samples shall be three.

7 No. 11 AWG 7 0.0907 0.272 7 945

7 No. 12 AWG 7 0.0808 0.242 6 301

9.4 Specimens of the completed conductor shall be tested in

3 No. 5 AWG 3 0.1819 0.392 12 230

a tension testing machine equipped with jaws suitable for

3 No. 6 AWG 3 0.1620 0.349 10 280

3 No. 7 AWG 3 0.1443 0.311 8 621 gripping the conductor or equipped for holding properly

3 No. 8 AWG 3 0.1285 0.277 7 206

socketed specimens. Any test in which the result is below the

3 No. 9 AWG 3 0.1144 0.247 5 715

stated value, and which is obviously caused by improper

3 No. 10 AWG 3 0.1019 0.220 4 532

socketing of the specimen or due to the break occurring in or

A

For metric equivalents: Diameter (mm)—multiply diameter in inches by 25.4

at the gripping jaws of the machine, shall be disregarded and

(round to 4 significant figures).

Breaking Strength (kg)—multiply breaking strength in pounds by 0.45359 (round

another sample from the same coil or reel shall be tested.

to 4 significant figures).

B

The designation is a combination of the number of wires each of the AWG size

10. Density

indicated by“ No.”

C

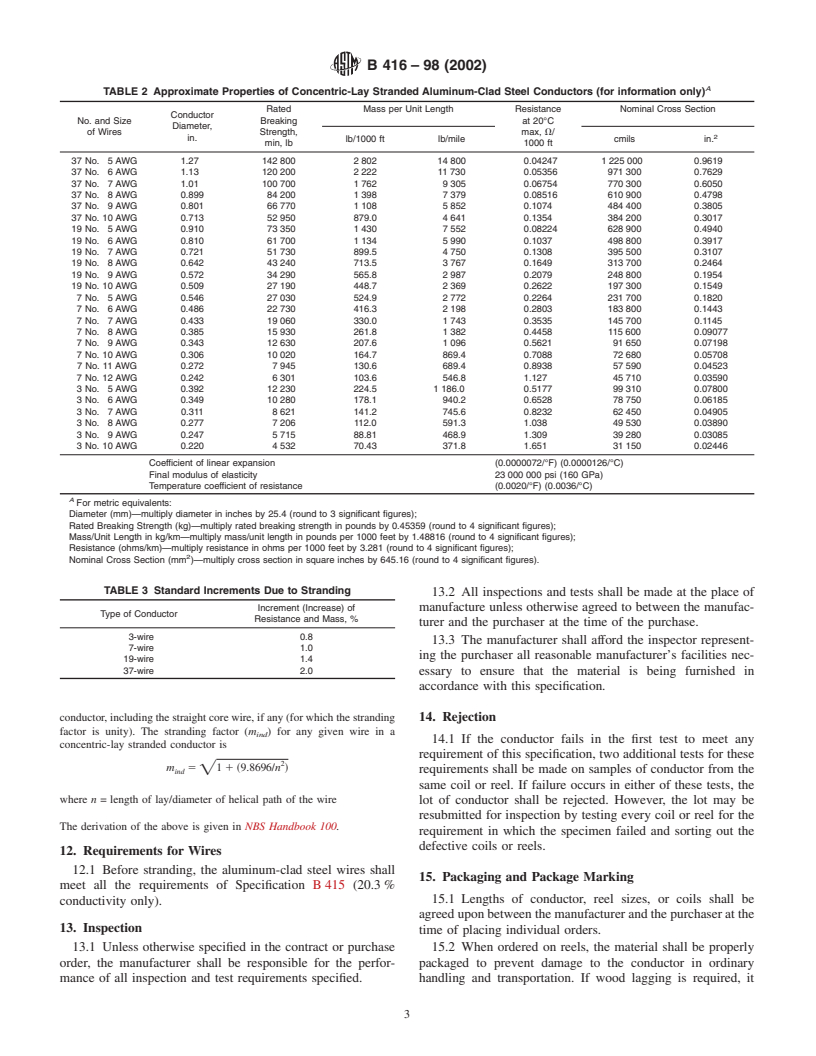

Diameter of circumscribing circle. See Table 3 for complete table of properties. 10.1 Forthepurposeofcalculatingmassperunitlength(see

D

See Section 7.

Note 4), cross-sections, etc., the density of the aluminum-clad

3 3

steel wire shall be taken as 0.2381 lb/in. (6.590 g/cm ) at 20°C

(Note 3). Other constants are given in Table 2.

6.4 The direction of lay shall be reversed in consecutive

NOTE 3—The value of the density of aluminum-clad steel wire is an

layers.

average value which has been found to be in accordance with usual values

6.5 All wires in the conductor shall lie naturally in their true

encountered in practice.

positionsinthecompletedconductor.Theyshalltendtoremain

NOTE 4—The term mass per unit length is used in the specification as

in position when the conductor is cut at any point and shall

being more technically correct. It replaces the terms “weights” and “linear

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.