ASTM E514-03

(Test Method)Standard Test Method for Water Penetration and Leakage Through Masonry

Standard Test Method for Water Penetration and Leakage Through Masonry

SCOPE

1.1 This laboratory test method provides a procedure for determining the resistance to water penetration and leakage through unit masonry subjected to wind-driven rain.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For a specific hazard statement see Section 5.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E 514 – 03

Standard Test Method for

1

Water Penetration and Leakage Through Masonry

This standard is issued under the fixed designation E 514; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* deterioration by various causes, such as corrosion, vibration,

2 thermal expansion and contraction, curing, and others. It is

1.1 This laboratory test method provides a procedure for

impossible to simulate the complex conditions encountered in

determining the resistance to water penetration and leakage

service, such as variations in wind velocity, negative pressure,

through unit masonry subjected to wind-driven rain.

and lateral or upward moving air and water. Factors such as

1.2 This standard does not purport to address all of the

location, exposure, and wall openings should be considered .

safety concerns, if any, associated with its use. It is the

3.4 Given the complexity of variables noted above, this test

responsibility of the user of this standard to establish appro-

method establishes comparative behavior between various

priate safety and health practices and determine the applica-

masonry wall constructions in a given laboratory.

bility of regulatory limitations prior to use. For a specific

3.5 Even when a single laboratory tests the same wall

hazard statement see Section 5.

design utilizing the same wall materials and the same construc-

2. Referenced Documents tion practices, variables such as the level of skill of the mason

3

building the specimen, the temperature and humidity in the

2.1 American Concrete Institute Standard:

laboratory at the time of construction, curing of the specimen,

ACI 531 Building Code Requirements for Concrete Ma-

the moisture contents of the materials used to build the

sonry Structures

4

specimen, and even the use or lack of use of a lime and water

2.2 Brick Institute of America Standard:

wash on the back of the specimen can affect the results of the

Construction of Brick Masonry, Building Code Require-

test making reliable comparisons dubious. For these reasons

ments for Engineered Brick Masonry

and the multi-variables listed in 3.1, 3.2, and 3.3, a meaningful,

3. Significance and Use

useful, absolute wall leakage rating standard is impractical and

discouraged.

3.1 This test method provides information that aids in

evaluating the effect of four principal variables: materials,

4. Apparatus

coatings, wall design, and workmanship.

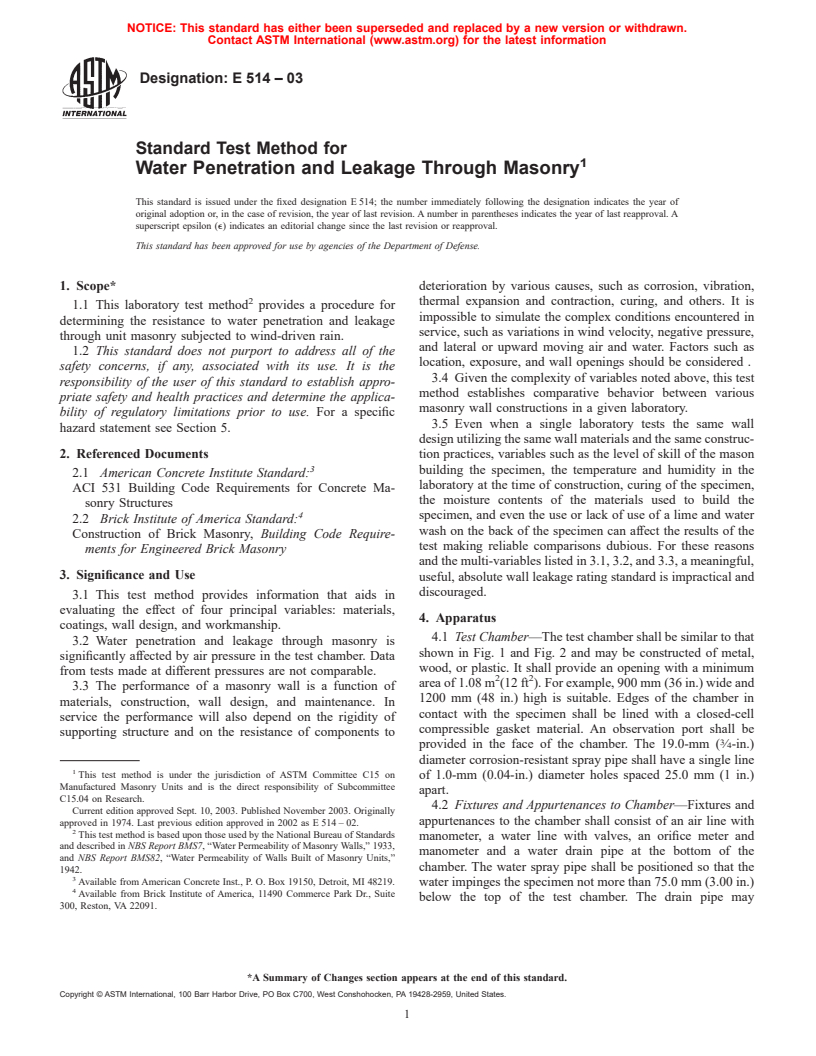

4.1 Test Chamber—The test chamber shall be similar to that

3.2 Water penetration and leakage through masonry is

shown in Fig. 1 and Fig. 2 and may be constructed of metal,

significantly affected by air pressure in the test chamber. Data

wood, or plastic. It shall provide an opening with a minimum

from tests made at different pressures are not comparable.

2 2

area of 1.08 m (12 ft ). For example, 900 mm (36 in.) wide and

3.3 The performance of a masonry wall is a function of

1200 mm (48 in.) high is suitable. Edges of the chamber in

materials, construction, wall design, and maintenance. In

contact with the specimen shall be lined with a closed-cell

service the performance will also depend on the rigidity of

compressible gasket material. An observation port shall be

supporting structure and on the resistance of components to

3

provided in the face of the chamber. The 19.0-mm ( ⁄4-in.)

diameter corrosion-resistant spray pipe shall have a single line

1

This test method is under the jurisdiction of ASTM Committee C15 on

of 1.0-mm (0.04-in.) diameter holes spaced 25.0 mm (1 in.)

Manufactured Masonry Units and is the direct responsibility of Subcommittee

apart.

C15.04 on Research.

4.2 Fixtures and Appurtenances to Chamber—Fixtures and

Current edition approved Sept. 10, 2003. Published November 2003. Originally

appurtenances to the chamber shall consist of an air line with

approved in 1974. Last previous edition approved in 2002 as E 514 – 02.

2

This test method is based upon those used by the National Bureau of Standards

manometer, a water line with valves, an orifice meter and

and described in NBS Report BMS7, “Water Permeability of Masonry Walls,” 1933,

manometer and a water drain pipe at the bottom of the

and NBS Report BMS82, “Water Permeability of Walls Built of Masonry Units,”

chamber. The water spray pipe shall be positioned so that the

1942.

3

Available from American Concrete Inst., P. O. Box 19150, Detroit, MI 48219. water impinges the specimen not more than 75.0 mm (3.00 in.)

4

Available from Brick Institute of America, 11490 Commerce Park Dr., Suit

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.