ASTM A970/A970M-98

(Specification)Standard Specification for Welded or Forged Headed Bars for Concrete Reinforcement

Standard Specification for Welded or Forged Headed Bars for Concrete Reinforcement

SCOPE

1.1 This specification covers deformed low-alloy steel reinforcing bars in cut length, with head(s) welded or forged to one or both ends, for concrete reinforcement. Heads shall be forge formed or cut from plate.

NOTE 1 - This specification is applicable for headed bars produced with welded or forged heads only. The requirements of this specification are not applicable to headed bars where the attachment of the head is accomplished by alternate means, such as by tapered or straight threads.

1.2 Grade-Headed bars are of a single minimum yield strength level of 420 MPA (60 000 psi), designated a Grade 420 (60).

1.3 Controlled Mechanical Properties and Performance Requirements-This specification by use of tensile and bend tests and the specified minimum performance levels in Sections 7 and 8 provides the required performance properties for these assemblies.

1.4 Welding and Forging:

1.4.1 Welding of heads to the reinforcing steel shall be approached with care. A welding procedure conforming to ANSI/AWS D1.4 shall be used for all required production welding of the head to the bar, except for friction welding that shall conform to ANSI/AWS C6.1.

1.4.2 Forging-Integrally forged headed bars where the heads are produced by deforming the bar ends in a hot forging process also are acceptable.

1.4.3 Low-Alloy Steel Bars-Low-alloy steel reinforcing bars conforming to Specification A706/A706M shall be used to manufacture welded headed bars. Specification A706/A706M limits chemical composition and carbon equivalence to enhance weldability of the material.

1.4.4 reinforcing bar material conforming to A615/A615M or A706/A706M is acceptable for the production of forged headed bars.

1.4.5 Other types of steel reinforcing bars shall be permitted: (1) providing they conform to the dimensional and weight requirements of the reinforcement as specified in 1.4.3 or 1.4.4 as applicable, and (2) when specified and agreed upon by the purchaser and the manufacturer and only when the suitability of the head and bar materials for the welding or forging process specified is demonstrated through successful application of the requirements for testing and frequency of testing in Sections 7 and 8 of this specification.

1.4.6 All reinforcing bars shall conform to the mechanical performance requirements of this specification.

1.5 This specification is applicable for orders in either SI or inch-pound units.

1.6 The values stated in either inch-pound units or SI units are to be regarded separately as the standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the specification. The inch-pound units shall apply unless the "M" designation of this specification is specified in the order.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: A 970/A 970M – 98

Standard Specification for

Welded or Forged Headed Bars for Concrete

Reinforcement

This standard is issued under the fixed designation A 970/A 970M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope as applicable, and (2) when specified and agreed upon by the

purchaser and the manufacturer and only when the suitability

1.1 This specification covers deformed low-alloy steel rein-

of the head and bar materials for the welding or forging process

forcing bars in cut lengths, with head(s) welded or forged to

specified is demonstrated through successful application of the

one or both ends, for concrete reinforcement. Heads shall be

requirements for testing and frequency of testing in Sections 7

forge formed or cut from plate.

and 8 of this specification.

NOTE 1—This specification is applicable for headed bars produced with

1.4.6 All reinforcing bars shall conform to the mechanical

welded or forged heads only. The requirements of this specification are not

performance requirements of this specification.

applicable to headed bars where the attachment of the head is accom-

1.5 This specification is applicable for orders in either SI or

plished by alternate means, such as by tapered or straight threads.

inch-pound units.

1.2 Grade—Headed bars are of a single minimum yield

1.6 The values stated in either inch-pound units or SI units

strength level of 420 MPa [60 000 psi], designated as Grade

are to be regarded separately as the standard. Within the text,

420 [60].

the SI units are shown in brackets. The values stated in each

1.3 Controlled Mechanical Properties and Performance

system are not exact equivalents; therefore, each system shall

Requirements—This specification by use of tensile and bend

be used independently of the other. Combining values from the

tests and the specified minimum performance levels in Sections

two systems may result in nonconformance with the specifi-

7 and 8 provides the required performance properties for these

cation. The inch-pound units shall apply unless the “M”

assemblies.

designation of this specification is specified in the order.

1.4 Welding and Forging:

1.7 This standard does not purport to address all of the

1.4.1 Welding of heads to the reinforcing steel shall be

safety concerns, if any, associated with its use. It is the

approached with care. A welding procedure conforming to

responsibility of the user of this standard to establish appro-

ANSI/AWS D1.4 shall be used for all required production

priate safety and health practices and determine the applica-

welding of the head to the bar, except for friction welding that

bility of regulatory limitations prior to use.

shall conform to ANSI/AWS C6.1.

1.4.2 Forging—Integrally forged headed bars where the

2. Referenced Documents

heads are produced by deforming the bar ends in a hot forging

2.1 ASTM Standards:

process also are acceptable.

A 29/A 29M Specification for Steel Bars, Carbon and Alloy,

1.4.3 Low-Alloy Steel Bars—Low-alloy steel reinforcing

Hot-Wrought and Cold-Finished, General Requirements

bars conforming to Specification A 706/A 706M shall be used 2

for

to manufacture welded headed bars. Specification A 706/

A 36/A 36M Specification for Carbon Structural Steel

A 706M limits chemical composition and carbon equivalence

A 108 Specification for Steel Bars, Carbon, Cold Finished,

to enhance weldablity of the material.

Standard Quality

1.4.4 Reinforcing bar material conforming to A 615/A

A 304 Specification for Carbon and Alloy Steel Bars Sub-

615M or A 706/A 706M is acceptable for the production of 2

ject to End-Quench Hardenability Requirements

forged headed bars.

A 370 Test Methods and Definitions for Mechanical Testing

1.4.5 Other types of steel reinforcing bars shall be permit- 4

of Steel Products

ted: (1) providing they conform to the dimensional and weight

A 572/A 572M Specification for High-Strength Low-Alloy

requirements of the reinforcement as specified in 1.4.3 or 1.4.4, 3

Columbium-Vanadium Steels of Structural Steels

A 615/A 615M Specification for Deformed and Plain

This specification is under the jurisdiction of ASTM Committee A-1 on Steel,

Stainless Steel, and Related Alloys and is the direct responsibility of Subcommittee

A01.05 on Steel Reinforcement. Annual Book of ASTM Standards, Vol 01.05.

Current edition approved March 10, 1998. Published December 1998. Originally Annual Book of ASTM Standards, Vol 01.04.

published as A 970–97. Last previous edition A 970–97a. Annual Book of ASTM Standards, Vol 01.03.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

A 970/A 970M

Manufacturer shall provide certified copies of manufacturing test report as

Billet-Steel Bars for Concrete Reinforcement

required in 14.2 of this specification.

A 700 Practices for Packaging, Marking and Loading Meth-

ods for Steel Products for Domestic Shipment

5. Material and Manufacture

A 706/A 706M Specification for Low-Alloy Steel De-

3 5.1 The reinforcing bars shall be rolled from properly

formed and Plain Bars for Concrete Reinforcement

identified heats of mold cast or strand cast steel using the

E 29 Practice for Using Significant Digits in Test Data to

open-hearth, basic-oxygen, or electric-furnace process.

Determine Conformance with Specifications

5.2 Heads shall be formed or cut from properly identified

2.2 ANSI/AWS Standards:

heats of mold cast or strand cast steel using the open-hearth,

ANSI/AWS C6.1 Recommended Practices for Friction

6 basic oxygen, or electric-furnace process.

Welding

5.3 The head shall be dimensioned to be capable of resisting

ANSI/AWS D1.4 Structural Welding Code - Reinforcing

6 the nominal tensile strength of the reinforcing bar when the

Steel

welded or forged headed reinforcing bar is embedded in

2.3 U.S. Military Standards:

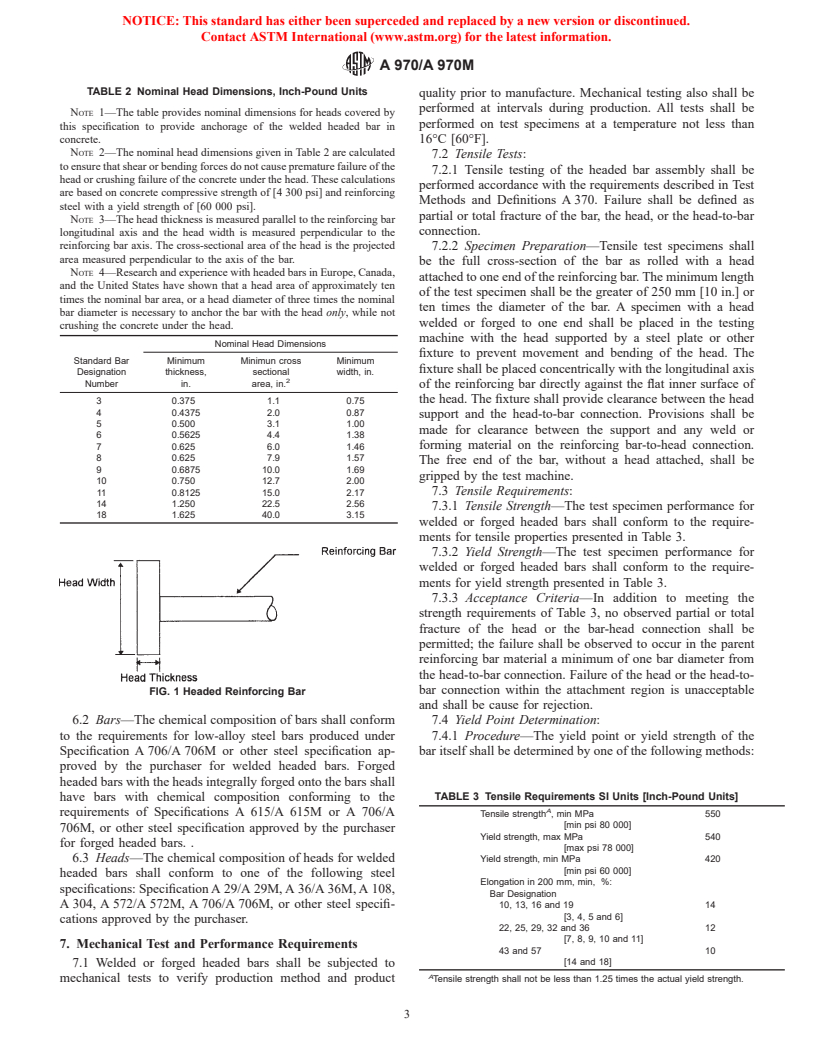

7 concrete. Nominal head dimensions to be used for standard bar

MIL-STD-129 Marking for Shipment and Storage

sizes shall be those listed in Table 1 and Table 2 and defined in

MIL-STD-163 Steel Mill Products Preparation for Ship-

7 Fig. 1. It shall be permissible to use head dimensions other than

ment and Storage

those in Table 1 and Table 2 providing the manufacturer

2.4 U.S. Federal Standard:

7 furnishes documentation to the purchaser in the form of

Fed. Std. No. 123 Marking for Shipment (Civil Agencies)

calculations or test reports, or both, that confirms the suitability

of the head dimensions for the intended application.

3. Terminology

3.1 Definitions:

6. Chemical Composition

3.1.1 forged headed bar—a steel bar used in the reinforce-

6.1 An analysis of each heat of steel for bar and heads shall

ment of concrete that has the head(s) integrally forged to one or

be made by the manufacturer from test samples taken during

both ends.

the pouring of heats. The percentage of carbon, manganese,

3.1.2 head—a round, elliptical, or rectangular shape em-

phosphorus, sulfur, silicon, copper, nickel, chromium, molyb-

ployed to anchor a steel bar in concrete.

denum, and vanadium shall be determined. Carbon equivalent

3.1.3 welded headed bar—a steel bar used in the reinforce-

(CE) shall be determined using the CE formula in Specification

ment of concrete that has the head(s) welded to one or both

A 706/A 706M.

ends.

4. Ordering Information TABLE 1 Nominal Head Dimensions, SI Units

4.1 It shall be the responsibility of the purchaser to specify

NOTE 1—The table provides nominal dimensions for heads covered by

all requirements that are necessary for material ordered to this this specification to provide anchorage of the welded headed bar in

concrete.

specification. Such requirements shall include but are not

NOTE 2—The nominal head dimensions given in Table 1 are calculated

limited to the following:

to ensure that shear or bending forces do not cause premature failure of the

4.1.1 Quantity,

head or crushing failure of the concrete under the head. These calculations

4.1.2 Name of product: welded or forged headed bars for the

are based on concrete compressive strength of 30 MPa and reinforcing

reinforcement of concrete,

steel with a yield strength of 420 MPa.

4.1.3 Bar material specification,

NOTE 3—The head thickness is measured parallel to the reinforcing bar

longitudinal axis and the head width is measured perpendicular to the

4.1.4 Bar size,

reinforcing bar axis. The cross-sectional area of the head is the projected

4.1.5 Head material specification,

area measured perpendicular to the axis of the bar.

4.1.6 Type of head attachment.

NOTE 4—Research and experience with headed bars in Europe, Canada,

4.1.7 Number of heads per bar length,

and the United States have shown that a head area of approximately ten

4.1.8 Length of bar assembly,

times the nominal bar area, or a head diameter of three times the nominal

4.1.9 Packaging, and

bar diameter, is necessary to anchor the bar with the head only, while not

4.1.10 ASTM designation and year of issue. crushing the concrete under the head.

Nominal Head Dimensions

NOTE 2—A typical example of an ordering description is as follows:

200 Mg [220 tons] welded headed reinforcing bars for concrete reinforce- Standard Bar Minimum Minimun cross Minimum

Designation thickness, sectional width, mm

ment, Size No. 25 [No. 8] in 18 m [60 ft] lengths in secured lifts,

Number mm area, mm

conforming to Specification A 970/A 970M. Two heads per bar assembly

shall be provided and shall be attached by welding. Heads shall be cut

10 10 710 19

13 11 1 290 22

from plate material conforming to Specification A 36/A 36M plate and

16 12 2 000 25

shall be 75 mm [3 in.] square. Certified mill test reports are required.

19 14 2 840 35

22 16 3 870 37

25 16 5 100 40

29 18 6 450 43

Annual Book of ASTM Standards, Vol 14.02.

6 32 20 8 200 51

Available from American Welding Society, P.O. Box 351040, 550 N.W.

36 22 9 700 55

LeJeune Rd., Miami, FL 33135.

7 43 32 14 500 65

Available from Standardization Documents Order Desk, Bldg. 4 Section D, 700

57 40 25 800 80

Robbins Ave., Philadelphia, PA 19111–5094, Attn: NPODS.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

A 970/A 970M

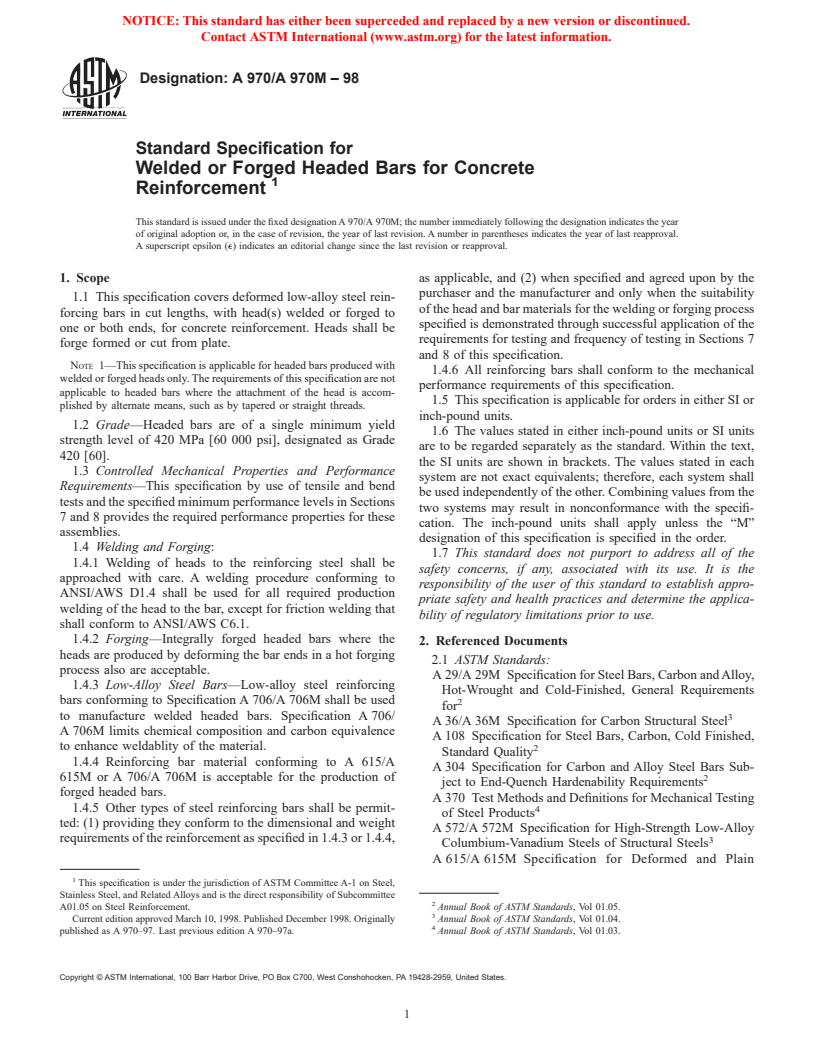

TABLE 2 Nominal Head Dimensions, Inch-Pound Units

quality prior to manufacture. Mechanical testing also shall be

performed at intervals during production. All tests shall be

NOTE 1—The table provides nominal dimensions for heads covered by

performed on test specimens at a temperature not less than

this specification to provide anchorage of the welded headed bar in

concrete. 16°C [60°F].

NOTE 2—The nominal head dimensions given in Table 2 are calculated

7.2 Tensile Tests:

to ensure that shear or bending forces do not cause premature failure of the

7.2.1 Tensile testing of the headed bar assembly shall be

head or crushing failure of the concrete under the head. These calculations

performed accordance with the requirements described in Test

are based on concrete compressive strength of [4 300 psi] and reinforcing

Methods and Definitions A 370. Failure shall be defined as

steel with a yield strength of [60 000 psi].

partial or total fracture of the bar, the head, or the head-to-bar

NOTE 3—The head thickness is measured parallel to the reinforcing bar

connection.

longitudinal axis and the head width is measured perpendicular to the

reinforcing bar axis. The cross-sectional area of the head is the projected 7.2.2 Specimen Preparation—Tensile test specimens shall

area measured perpendicular to the axis of the bar.

be the full cross-section of the bar as rolled with a head

NOTE 4—Research and experience with headed bars in Europe, Canada,

attached to one end of the reinforcing bar. The minimum length

and the United States have shown that a head area of approximately ten

of the test specimen shall be the greater of 250 mm [10 in.] or

times the nominal bar area, or a head diameter of three times the nominal

ten times the diameter of the bar. A specimen with a head

bar diameter is necessary to anchor the bar with the head only, while not

welded or forged to one end shall be placed in the testing

crushing the concrete under the head.

machine with the head supported by a steel plate or other

Nominal Head Dimensions

fixture to prevent movement and bending of the head. The

Standard Bar Minimum Minimun cross Minimum

fixture shall be placed concentrically with the longitudinal axis

Designation thickness, sectional width, in.

Number in. area, in. of the reinforcing bar directly against the flat inner surface of

the head. The fixture shall provide clearance between the head

3 0.375 1.1 0.75

4 0.4375 2.0 0.87

support and the head-to-bar connection. Provisions shall be

5 0.500 3.1 1.00

made for clearance between the support and any weld or

6 0.5625 4.4 1.38

forming material on the reinforcing bar-to-head connection.

7 0.625 6.0 1.46

8 0.625 7.9 1.57

The free end of the bar, without a head attached, shall be

9 0.6875 10.0 1.69

gripped by the test machine.

10 0.750 12.7 2.00

11 0.8125 15.0 2.17 7.3 Tensile Requirements:

14 1.250 22.5 2.56

7.3.1 Tensile Strength—The test specimen performance for

18 1.625 40.0 3.15

welded or forged headed bars shall conform to the require-

ments for tensile properties presented in Table 3.

7.3.2 Yield Strength—The test specimen performance for

welded or forged headed bars shall conform to the require-

ments for yield strength presented in Table 3.

7.3.3 Acceptance Criteria—In addition to meeting the

strength requirements of Table 3, no observed partial or total

fracture of the head or the bar-head connection shall be

permitted; the failure shall be observed to occur in the parent

reinforcing bar material a minimum of one bar diameter from

the head-to-bar connection. Failure of the head or the head-to-

bar connection within the attachment region is unacceptable

FIG. 1 Headed Reinforcing Bar

and shall be cause for rejection.

6.2 Bars—The chemical composition of bars shall conform 7.4 Yield Point Determination:

to the requirements for low-alloy steel bars produced under 7.4.1 Procedure—The yield point or yield strength of the

Specification A 706/A 706M or other steel specification ap- bar itself shall be determined by one of the following methods:

proved by the purchaser for welded headed bars. Forged

headed bars with the heads integrally f

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.