ASTM A886/A886M-99

(Specification)Standard Specification for Steel Strand, Indented, Seven-Wire Stress-Relieved for Prestressed Concrete

Standard Specification for Steel Strand, Indented, Seven-Wire Stress-Relieved for Prestressed Concrete

SCOPE

1.1 This specification covers seven-wire uncoated, indented, stress-relieved steel strand for use in pretensioned prestressed concrete construction. Grade 250I and Grade 270I have minimum ultimate strengths of 250 ksi [1725 MPa] and 270 ksi [1860 MPa], respectively, based on the nominal area of the strand.

1.2 Supplement I describes low-relaxation strand and relaxation testing for that product. Low-relaxation strand shall be furnished when specifically ordered, and it may be furnished in place of regular strand if mutually agreed to by the purchaser and supplier.

1.3 This specification is applicable for orders in either inch-pound units (as Specification A886) or in SI units (as Specification A886M).

1.4 The values stated in either inch-pound units or SI units are to be regarded separately as standards. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other. Combining values from the two systems may result in nonconformance with the specification.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

Designation: A 886/A 886M – 99

Standard Specification for

Steel Strand, Indented, Seven-Wire Stress-Relieved for

Prestressed Concrete

ThisstandardisissuedunderthefixeddesignationA886/A886M;thenumberimmediatelyfollowingthedesignationindicatestheyear

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 2.3 U.S. Federal Standards:

Fed. Std. No. 123 Marking for Shipments (CivilAgencies)

1.1 Thisspecificationcoversseven-wireuncoated,indented,

stress-relieved steel strand for use in pretensioned prestressed

3. Terminology

concrete construction. Grade 250I and Grade 270I have mini-

3.1 Definitions of Terms Specific to This Standard:

mum ultimate strengths of 250 ksi [1725 MPa] and 270 ksi

3.1.1 strand, n—all strand shall be of the seven-wire type

[1860 MPa], respectively, based on the nominal area of the

having a center wire enclosed tightly by six helically placed

strand.

outerwireswithuniformpitchofnotlessthan12andnotmore

1.2 Supplement I describes low-relaxation strand and relax-

than 16 times the nominal diameter of the strand.

ation testing for that product. Low-relaxation strand shall be

furnished when specifically ordered and furnished in place of

4. Ordering Information

stress-relieved strand if mutually agreed to by the purchaser

4.1 Orders for seven-wire stress-relieved strand under this

and supplier.

specification should include the following information:

1.3 This specification is applicable for orders in either

4.1.1 Quantity (meters [feet]),

inch-pound units (as Specification A886) or in SI units (as

4.1.2 Diameter of strand (millimeters [inches]),

Specification A886M).

4.1.3 Grade of strand,

1.4 The values stated in either inch-pound units or SI units

4.1.4 Packaging,

are to be regarded separately as standards. Within the text, the

4.1.5 ASTM designation and year of issue, and

inch-pound units are shown in parentheses. The values stated

4.1.6 Special requirements, if any.

in each system are not exact equivalents; therefore, each

system must be used independently of the other. Combining

NOTE 1—Atypicalorderingdescriptionisasfollows:25600m(84000

values from the two systems may result in nonconformance ft) 12.70-mm (0.5-in.), Grade 1860I (2701) strand, in 3658-m (12 000-ft)

spoolless packs to ASTM A886/A886M—_______.

with the specification.

5. Materials and Manufacture

2. Referenced Documents

5.1 Base Metal—The base metal shall be carbon steel of

2.1 ASTM Standards:

such quality that when it is drawn to wire, subjected to the

A370 TestMethodsandDefinitionsforMechanicalTesting

indentation process, fabricated into strand, and then stress-

of Steel Products

relieved, it shall have the properties and characteristics pre-

E328 MethodsforStressRelaxationTestsforMaterialsand

scribed in this specification.

Structures

5.2 Wire—The wire from which the strand is to be fabri-

2.2 U.S. Military Standards:

cated shall have a common dry-drawn finish.

MIL-STD-129 Marking for Shipment and Storage

MIL-STD-163 Steel Mill Products Preparation for Ship-

NOTE 2—Thisproductisacompositeofsevenwiresandisproducedto

ment and Storage

mechanical properties only, the chemistry of all wires or any individual

wireisnotpertinenttothisapplication,andheatidentityisnotnecessarily

maintained. It is possible that wire from more than one heat may be used

This specification is under the jurisdiction ofASTM CommitteeA-1 on Steel, inthemanufactureofareelorpack.Traceabilityisbasedonpackidentity

Stainless Steel, and RelatedAlloys and is the direct responsibility of Subcommittee

as maintained and reported by the manufacturer.

A01.05 on Steel Reinforcement.

5.3 Indentations—The outer wires shall have indentations

Current edition approved Sept. 10, 1999. Published December 1999. Originally

published as A886/A886M–88. Last previous edition A886/A886M–98. designed to reduce longitudinal movement of the strand within

Annual Book of ASTM Standards, Vol 01.03.

the concrete, and conform to the provisions in Section7. The

Annual Book of ASTM Standards, Vol 03.01.

AvailablefromStandardizationDocumentsOrderDesk,Bldg.4SectionD,700

Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

A 886/A 886M – 99

TABLE 2 Breaking Strength Requirements

surface of the outer wires shall be suitably deformed mechani-

cally by rolling to produce a series of indentations. Indenta- Diameter of Strand Mass [Weight]

Steel

Breaking Strength of Strand,

tionsshallbeintwoormorelinesspaceduniformlyaroundthe

Area of Strand,

of Strand, kN (lbf) kg/1000 m

2 2

mm in.

mm (in. )

wire. Indentations in adjacent lines shall be staggered through-

(lb/1000 ft)

out the length of the wire.At least 90% of the indentations in

Grade 1725I [250I]

any 0.6 m (2 ft) length of strand shall meet the pitch and shape

6.4 (0.250) 40.0 (9 000) 23.2 (0.036) 182 (122)

requirements ofTable 1.The center wire need not be indented.

7.9 (0.313) 64.5 (14 500) 37.4 (0.058) 294 (197)

9.5 (0.375) 89.0 (20 000) 51.6 (0.080) 405 (272)

5.4 Stress-Relieving—After stranding, all strand shall be

11.1 (0.438) 120.1 (27 000) 69.7 (0.108) 548 (367)

subjected to a stress-relieving continuous heat treatment to

12.7 (0.500) 160.1 (36 000) 92.9 (0.144) 730 (490)

produce the prescribed mechanical properties. Temper colors

15.2 (0.600) 240.2 (54 000) 139.4 (0.216) 1094 (737)

which result from the stress-relieving operation are considered

Grade 1860I (270I)

normal for the finished appearance of this strand.

7.9 (0.313) 74.3 (16 500) 39.4 (0.061) 313 (210)

9.5 (0.375) 102.3 (23 000) 54.8 (0.085) 432 (290)

6. Mechanical Property Requirements

11.1 (0.438) 137.9 (31 000) 74.2 (0.115) 582 (390)

12.7 (0.500) 183.7 (41 300) 98.7 (0.153) 775 (520)

6.1 Methods of testing for mechanical properties are de-

15.2 (0.600) 266.7 (58 600) 140.0 (0.217) 1102 (740)

scribed in Supplement VII of Methods and Definitions A370.

6.2 Breaking Strength—The breaking strength of the fin-

A

ished strand shall conform to the requirements prescribed in

TABLE 3 Yield Strength Requirements

Table 2.

Diameter of Strand Minimum Load at

Initial Load,

6.3 Yield Strength—Yield strength in kN (lb) is measured 1 % Extension, kN

kN (lbf)

mm (in.)

(lbf)

1% extension under load. The load at this extension shall be

Grade 1725I(250I)

recorded as yield strength and shall meet the requirements

prescribed in Table 3. 6.4 (0.250) 4.0 (900) 34.0 (7 650)

7.9 (0.313) 6.5 (1 450) 54.7 (12 300)

6.3.1 The extension under load shall be measured by an

9.5 (0.375) 8.9 (2 000) 75.6 (17 000)

extensometer calibrated with the smallest division not larger

11.1 (0.438) 12.0 (2 700) 102.3 (23 000)

than 0.0001 mm/mm (0.001 in./in.) of gage length.

12.7 (0.500) 16.0 (3 600) 136.2 (30 600)

15.2 (0.600) 24.0 (5 400) 204.2 (45 900)

6.4 Elongation—The total elongation under load shall be

Grade 1860I(270I)

not less than 3.5% and shall be measured in a gage length of

not less than 600 mm (24 in.). In practice the total elongation 7.9 (0.313) 7.3 (1 650) 62.4 (14 030)

9.5 (0.375) 10.2 (2 300) 87.0 (19 550)

value may be determined by adding to the 1% yield extension

11.1 (0.438) 13.8 (3 100) 117.2 (26 350)

the percent extension or movement between the jaws gripping

12.7 (0.500) 18.4 (4 130) 156.1 (35 000)

the strand after yield determination. The percent is calculated

15.2 (0.600) 26.1 (5 860) 221.5 (49 800)

A

on the new base length of jaw-to-jaw distance.

Yield strength minimum is 85 % of specified minimum breaking strength.

7. Dimensions and Permissible Variations

7.3.3 Variationincross-sectionalareaandinstressresulting

7.1 The size of the finished strand shall be expressed as the

therefromshallnotbecauseforrejectionprovidedthediameter

diameter of the strand in decimals of an inch [millimetre].All

differences of the individual wires and the diameters of the

nominal dimensional requirements for wires and strands shall

strand are within the tolerances specified.

refer to the wire and strand before indenting.

7.4 Indentations:

7.2 The diameter of the center wire of any strand must be

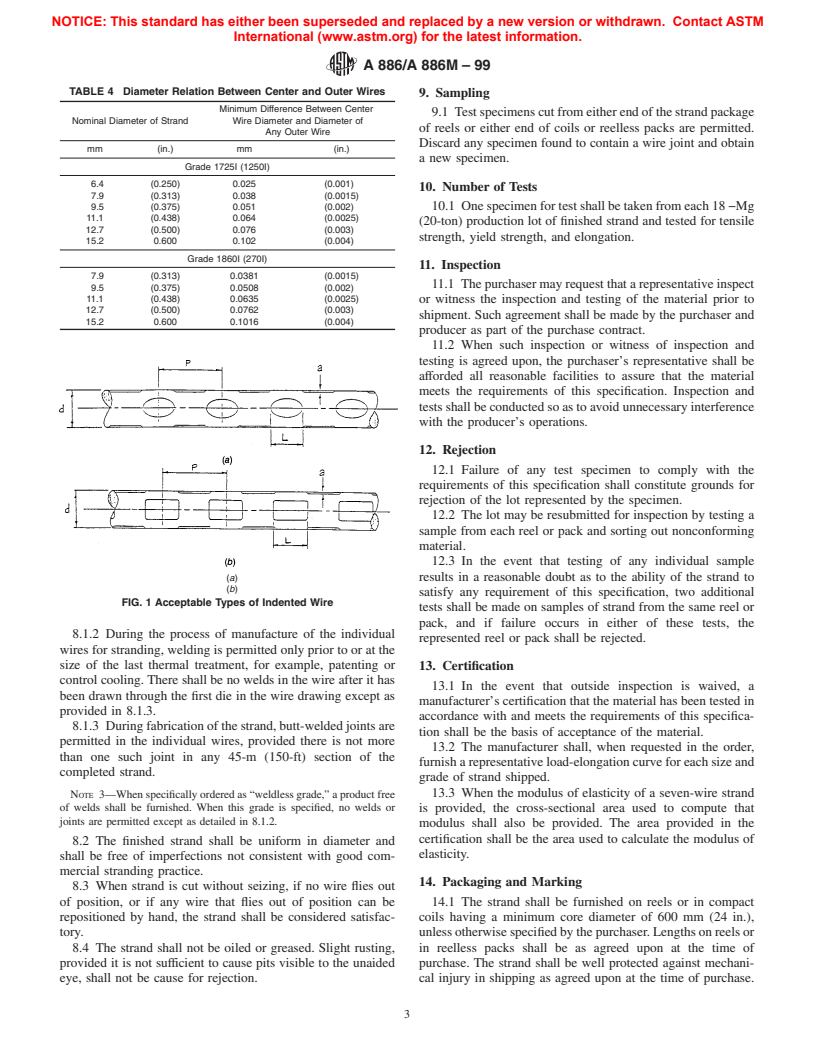

7.4.1 Two acceptable types of indented wire are shown in

larger than the diameter of any outer wire in accordance with

Fig. 1 (a) and ( b) with dimensions given in Table 1.

Table 4.

7.4.2 Other types of indented wire are permitted, by agree-

7.3 Permissible Variations in Diameter:

ment between the purchaser and supplier.

7.3.1 AllGrade250Istrandshallconformtoasizetolerance

8. Workmanship, Finish, and Appearance

of 60.40 mm (60.016 in.) from the nominal diameter mea-

sured across the crowns of the wire. 8.1 Joints:

7.3.2 AllGrade270Istrandshallconformtoasizetolerance 8.1.1 There shall be no strand joints or strand splices in any

of +0.65 mm, −0.15 mm (+0.026 in., −0.006 in.) from the length of the completed strand unless specifically permitted by

nominal diameter measured across the crowns of the wire.

the purchaser.

TABLE 1 Nominal Dimensions of Indentations

Wire Diameter, d Stra

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.