ASTM D3093-72(1992)

(Test Method)Test Method for Pickup Efficiency of Residual Aerosol Insecticides (Withdrawn 1999)

Test Method for Pickup Efficiency of Residual Aerosol Insecticides (Withdrawn 1999)

SCOPE

1.1 This test method covers the determination of the pickup efficiency of residual aerosol insecticides.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Standards Content (Sample)

ASTM DI093 72 9 0759530 0533344 Tb2

41) Designation: D 3093 - 72 (Reapproved 1992)

Standard Test Method for

Pickup Efficiency of Residual Aerosol Insecticides'

This standard is issued under the fixed designation D 3093: the number immediately following the designation indicates the year of

original adoption or. in the case of revision. the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscnpt epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the determination of the

pickup efficiency of residual aerosol insecticides.

1.2 The values stated in inch-pound units are to be

regarded as the standard. The values given in parentheses are

for information only.

1.3 This standard does not purport to address all of the

safety problems, if an!', associated with its use. It is the

responsibilily of the user of this srandard IO establish appro-

priate safeti' and health pradices and determine the applica-

bilit)? of regulatory limitarions prior to use.

2. Summary of Test Method

2.1 In this test method a smooth, nonabsorbent target is

used to represent an ordinary household application or

residual insecticides to baseboard. cabinets. etc. Any very

coarse particles that do not reach the target are also collected

and weighed with the target deposit.

2.2 The aerosol is directed from the test specimen con-

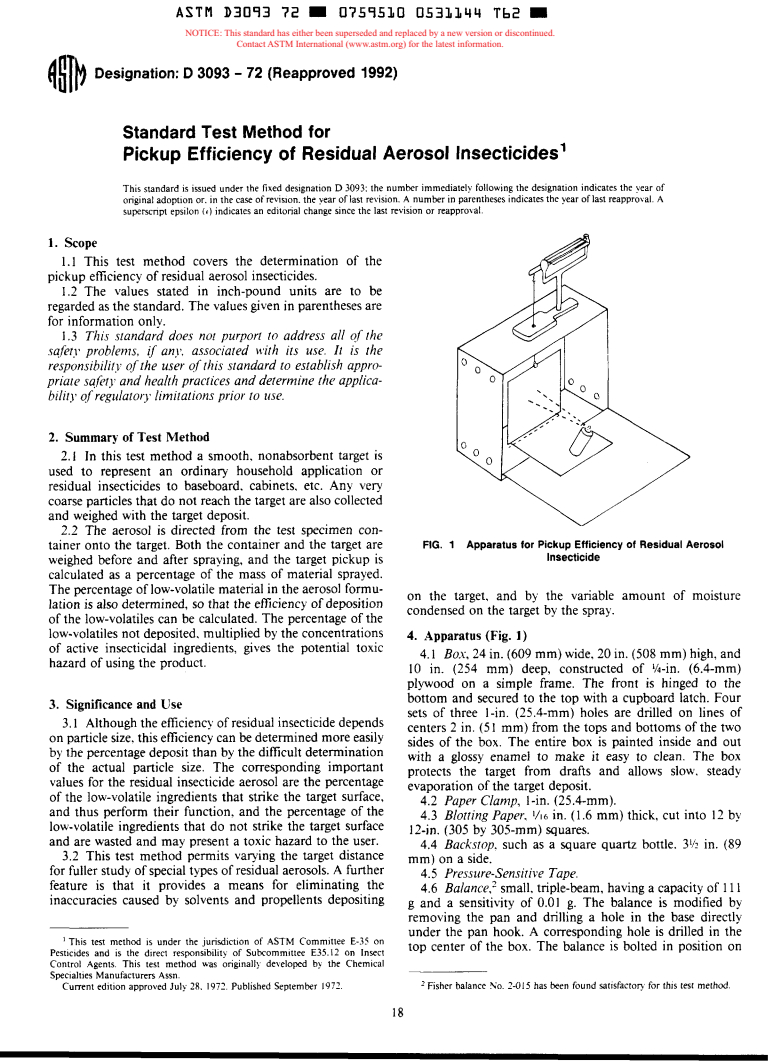

FIG. 1 Apparatus for Pickup Efficiency of Residual Aerosol

tainer onto the target. Both the container and the target are

Insecticide

weighed before and after spraying. and the target pickup is

calculated as a percentage of the mass of matenal sprayed.

The percentage of low-volatile material in the aerosol formu-

on the target, and by the variable amount of moisture

lation is also determined, so that the efficiency of deposition

condensed on the target by the spray.

of the low-volatiles can be calculated. The percentage of the

low-volatiles not deposited, multiplied by the concentrations

4. Apparatus (Fig. i)

of active insecticidal ingredients, gives the potential toxic

4.1 Box-, 24 in. (609 mm) wide, 20 in. (508 mm) high, and

hazard of using the product.

10 in. (254 mm) deep, constructed of Y4-in. (6.4-mm)

plywood on a simple frame. The front is hinged to the

bottom and secured to the top with a cupboard latch. Four

3. Significance and Use

sets of three 1%. (25.4-mm) holes are drilled on lines of

3, i Although the efficiency of residual insecticide depends

centers 2 in. (5 1 mm) from the tops and bottoms of the two

on particle size. this efficiency can be determined more easily

sides of the box. The entire box is painted inside and out

by the percentage deposit than by the difficult determination

with a glossy enamel to make it easy to clean. The box

of the actual particle size. The corresponding important

protects the target from drafts and allows slow. steady

values for the residual insecticide aerosol are the percentage

evaporation of the target deposit.

of the low-volatile ingredients that strike the target surface,

4.2 Paper Clamp, I-in. (25.4-mm).

and thus perform their function, and the percentage of the

Blotting Paper, '/I6 in. (1.6 mm) thick, cut into 12 by

4.3

low-volatile ingredients that do not strike the target surface

12%. (305 by 305-mm) squares.

and are wasted and may present a toxic hazard to the user.

4.4 Backstop. such as a square quartz bottle. 3% in. (89

3.2 This test method permits varying the target distance

mm) on a side.

for fuller study of special types of residual aerosols. A further

4.5 Presstire-Sensitive Tape.

feature is that it provides a means for eliminating the

4.6 Balance,' small, tnple-beam, having a capacity of 11 1

inaccuracies caused by solvents and propellents depositing

g and a sensitivity of 0.01 g. The balance is modified by

removing the pan and drilling a hole in the base directly

under the pan hook. A corresponding hole is drilled in the

' This test method is under the jurisdiction of ASTM Committee E-35 on

top center of the box. The balance is bolted in position on

Pesticides and is the direct responsibility of Subcommittee E35.12 on Insect

Control Agents. This test method was originally developed by the Chemical

Specialties Manufacturers Assn.

Fisher balance No. 2-015 has been found satisfactop for this test method.

Current edition approved July 28. 1972. Published September 1972.

18

---------------------- Page: 1 ----------------------

ASTM D3093 72 0759530 0533345 9T9

fim D3093

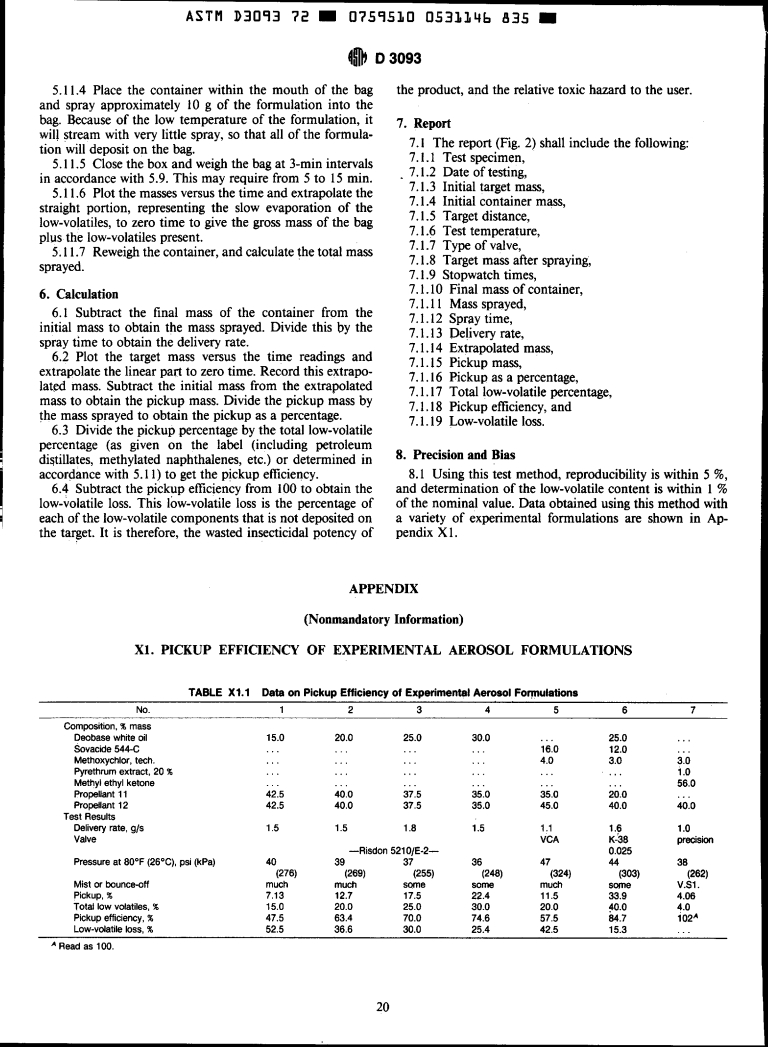

Notebook 52-67-4-Date 8-27-56

top of the box. An extra mass, approximately equal to the

Test Specimen

mass of the pan, may be required. If so, it is attached to the

Target Mass Data

pan hook, and a wire passing through the holes in the base of

Extrapolated Mass

81.33 g

Initial Mass 78.31 g

the balance and top of the box is attached to the extra mass.

Pickup Mass 3.02 g

A 1-in. (25.4-mm) paper cla

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.