ASTM B413-97a

(Specification)Standard Specification for Refined Silver

Standard Specification for Refined Silver

SCOPE

1.1 This specification covers refined silver in cast bar form in three grades as follows:

1.1.1 Grade 99.90 (UNS P07020)-Silver having a minimum fineness of 999.0 commonly referred to as "commercial bar" or "bullion."

1.1.2 Grade 99.95 (UNS P07015)-Silver having a minimum fineness of 999.5.

1.1.3 Grade 99.99 (UNS P07010)-A premium grade having a minimum fineness of 999.9.

1.2 The values stated in inch-pound units are to be regarded as the standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: B 413 – 97a

Standard Specification for

Refined Silver

This standard is issued under the fixed designation B 413; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

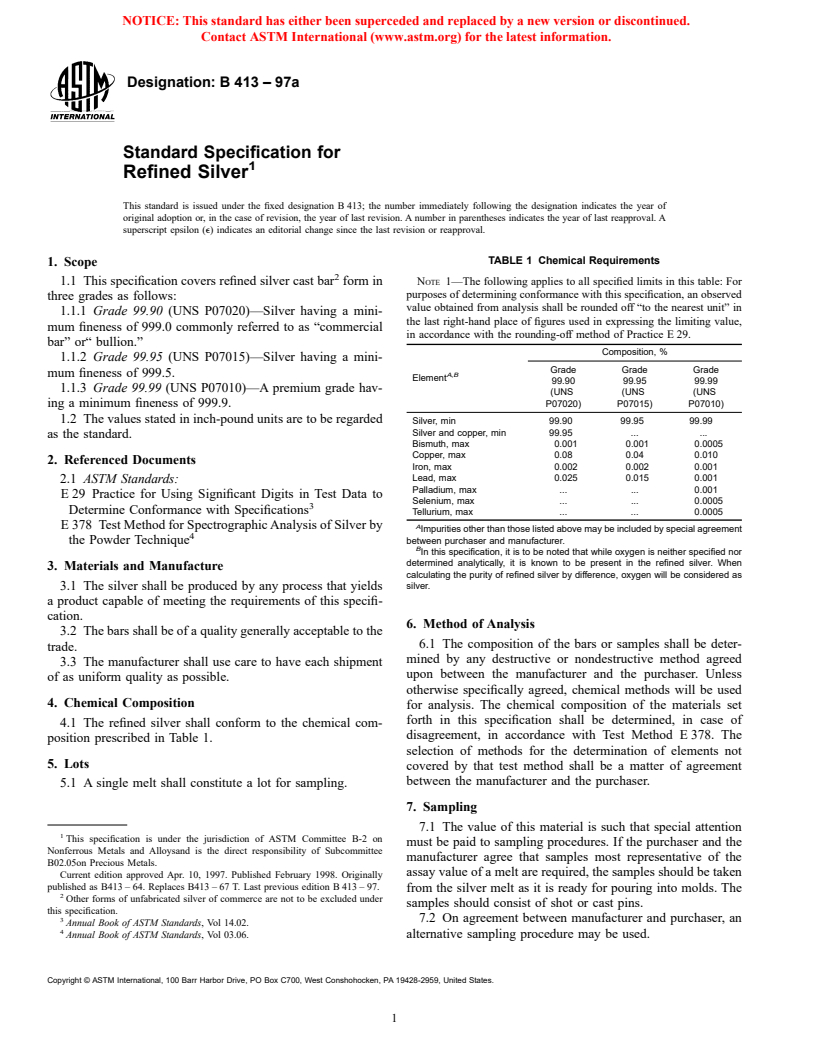

TABLE 1 Chemical Requirements

1. Scope

1.1 This specification covers refined silver cast bar form in NOTE 1—The following applies to all specified limits in this table: For

purposes of determining conformance with this specification, an observed

three grades as follows:

value obtained from analysis shall be rounded off “to the nearest unit” in

1.1.1 Grade 99.90 (UNS P07020)—Silver having a mini-

the last right-hand place of figures used in expressing the limiting value,

mum fineness of 999.0 commonly referred to as “commercial

in accordance with the rounding-off method of Practice E 29.

bar” or“ bullion.”

Composition, %

1.1.2 Grade 99.95 (UNS P07015)—Silver having a mini-

Grade Grade Grade

mum fineness of 999.5.

A,B

Element

99.90 99.95 99.99

1.1.3 Grade 99.99 (UNS P07010)—A premium grade hav-

(UNS (UNS (UNS

ing a minimum fineness of 999.9. P07020) P07015) P07010)

1.2 The values stated in inch-pound units are to be regarded

Silver, min 99.90 99.95 99.99

Silver and copper, min 99.95 . .

as the standard.

Bismuth, max 0.001 0.001 0.0005

Copper, max 0.08 0.04 0.010

2. Referenced Documents

Iron, max 0.002 0.002 0.001

Lead, max 0.025 0.015 0.001

2.1 ASTM Standards:

Palladium, max . . 0.001

E 29 Practice for Using Significant Digits in Test Data to

Selenium, max . . 0.0005

Determine Conformance with Specifications

Tellurium, max . . 0.0005

E 378 Test Method for Spectrographic Analysis of Silver by A

Impurities other than those listed above may be included by special agreement

between purchaser and manufacturer.

the Powder Technique

B

In this specification, it is to be noted that while oxygen is neither specified nor

determined analytically, it is known to be present in the refined silver. When

3. Materials and Manufacture

calculating the purity of refined silver by difference, oxygen will be considered as

silver.

3.1 The silver shall be produced by any process that yields

a product capable of meeting the requirements of this specifi-

cation.

6. Method of Analysis

3.2 The bars shall be of a quality generally acceptable to the

6.1 The composition of the bars or samples shall be deter-

trade.

mined by any destructive or nondestructive method agreed

3.3 The manufacturer shall use care to have each shipment

upon between the manufacturer and the purchaser. Unless

of as uniform quality as possible.

otherwise specifically agreed, chemical methods will be used

4. Chemical Composition

for analysis. The chemical composition of the materials set

forth in this specification shall be determined, in case of

4.1 The refined silver shall conform to the chemical com-

disagreement, in accordance with Test Method E 378. The

position prescribed in Table 1.

selection of methods for the determination of elements not

5. Lots

covered by that test method shall be a matter of agreement

between the manufacturer and the purchaser.

5.1 A single melt shall constitute a lot for sampling.

7. Sampling

7.1 The value of this material is such that special attention

This specification is under the jurisdiction of ASTM Committee B-2 on

must be paid to sampling procedures. If the purchaser and the

Nonferrous Metals and Alloysand is the direct responsibility of Subcommittee

manufacturer agree that samples most representative of the

B02.05on Precious Metals.

assay value of a melt are required, the samples should be taken

Current edition approved Apr. 10, 1997. Published February 1998. Originally

published as B413 – 64. Replaces B413 – 67 T. Last previous edition B 413 – 97.

from the silver melt as it is ready for pouring into molds. The

Other forms of unfabricated silver of commerce are not to be excluded under

samples should consist of shot or cast pins.

this specification.

3 7.2 On agreement between manufacturer and purchaser, an

Annual Book of ASTM Standards, Vol 14.02.

Annual Book of ASTM Standards, Vol 03.06. alternative sampling procedure may be used.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

B 413

7.3 The amount of sample taken shall be sufficient to supply 9.2 Where the silver satisfies the requirements of this

three portions for analysis; the mass of each portion shall be specification, it shall not be condemned for defects in the

sufficient to permit the determination of its composition as set products in which it is used.

forth in Table 1.

10. Investigation of Claims

7.4 Af

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.