ASTM F1281-24

(Specification)Standard Specification for Crosslinked Polyethylene/Aluminum/Crosslinked Polyethylene (PEX-AL-PEX) Pressure Pipe

Standard Specification for Crosslinked Polyethylene/Aluminum/Crosslinked Polyethylene (PEX-AL-PEX) Pressure Pipe

ABSTRACT

This specification covers coextruded cross linked polyethylene composite pressure pipe with welded aluminum tube reinforcement between the inner and outer layers. The inner and outer cross linked polyethylene layers are bonded to the aluminum tube by a melt adhesive. Included is a system of nomenclature for the cross linked polyethylene-aluminum cross linked polyethylene (PEX-AL-PEX) pipes, the requirements and test methods for materials, the dimensions of the component layers and finished pipe, adhesion tests, and the burst and sustained pressure performance. Also given are the requirements and methods of marking. The pipe covered by this specification is intended for use in potable water distribution systems for residential and commercial applications, water service, underground irrigation systems, and radiant panel heating systems, baseboard, snow- and ice-melt systems, and gases that are compatible with the composite pipe and fittings. It covers only composite pipes incorporating a welded aluminum tube. The PEX-AL-PEX pipes are classified by the outside diameter. The pipe shall be free of visible cracks, holes, foreign inclusions, blisters, and other known injurious defects. The pipe shall be as uniform as practicable in color, opacity, density, and other physical properties.

SCOPE

1.1 This specification covers a coextruded crosslinked polyethylene composite pressure pipe with a welded aluminum tube reinforcement between the inner and outer layers. The inner and outer crosslinked polyethylene layers are bonded to the aluminum tube by a melt adhesive. Included is a system of nomenclature for the crosslinked polyethylene-aluminum-crosslinked polyethylene (PEX-AL-PEX) pipes, the requirements and test methods for materials, the dimensions of the component layers and finished pipe, adhesion tests, and the burst and sustained pressure performance. Also given are the requirements and methods of marking. The pipe covered by this specification is intended for use in potable water distribution systems for residential and commercial applications, water service, building supply lines, underground irrigation systems, and radient panel heating systems, baseboard, snow- and ice-melt systems, and gases that are compatible with the composite pipe and fittings.

Note 1: Piping covered by this specification is not recommended for use in indoor flammable gas applications.

1.2 This specification covers only composite pipes incorporating a welded aluminum tube. Pipes consisting of metallic layers not welded together are outside the scope of this specification.

1.3 Specifications for connectors for use with pipe meeting the requirements of this specification are given in Annex A1.

1.4 This specification excludes polyethylene-aluminum-polyethylene pipes (see Specification F1282).

1.5 The values stated in SI units are to be regarded as standard. The values given in parentheses after SI units are provided for information only and are not considered standard.

1.6 The following precautionary caveat pertains only to the test methods portion, Section 9, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health and environmental practices and determine the applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

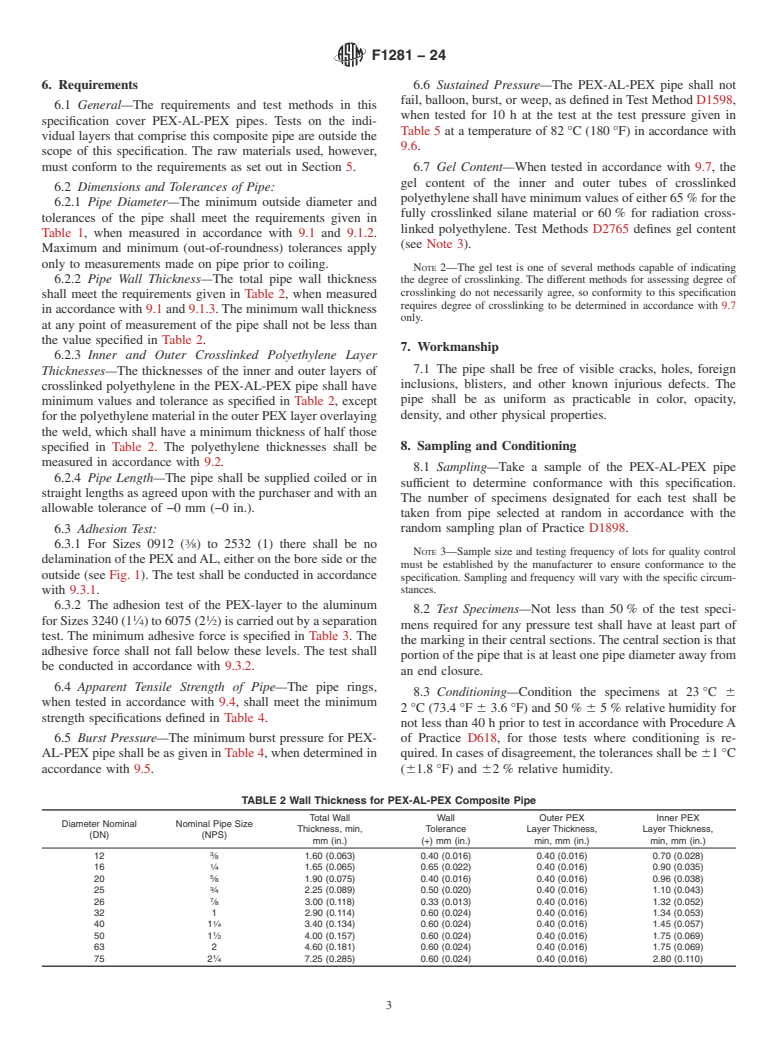

Designation: F1281 − 24 An American National Standard

Standard Specification for

Crosslinked Polyethylene/Aluminum/Crosslinked

1

Polyethylene (PEX-AL-PEX) Pressure Pipe

This standard is issued under the fixed designation F1281; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* if any, associated with its use. It is the responsibility of the user

of this standard to establish appropriate safety, health and

1.1 This specification covers a coextruded crosslinked poly-

environmental practices and determine the applicability of

ethylene composite pressure pipe with a welded aluminum tube

regulatory limitations prior to use.

reinforcement between the inner and outer layers. The inner

1.7 This international standard was developed in accor-

and outer crosslinked polyethylene layers are bonded to the

dance with internationally recognized principles on standard-

aluminum tube by a melt adhesive. Included is a system of

ization established in the Decision on Principles for the

nomenclature for the crosslinked polyethylene-aluminum-

Development of International Standards, Guides and Recom-

crosslinked polyethylene (PEX-AL-PEX) pipes, the require-

mendations issued by the World Trade Organization Technical

ments and test methods for materials, the dimensions of the

Barriers to Trade (TBT) Committee.

component layers and finished pipe, adhesion tests, and the

burst and sustained pressure performance. Also given are the

2. Referenced Documents

requirements and methods of marking. The pipe covered by

2

2.1 ASTM Standards:

this specification is intended for use in potable water distribu-

D618 Practice for Conditioning Plastics for Testing

tion systems for residential and commercial applications, water

D883 Terminology Relating to Plastics

service, building supply lines, underground irrigation systems,

D1598 Test Method for Time-to-Failure of Plastic Pipe

and radient panel heating systems, baseboard, snow- and

Under Constant Internal Pressure

ice-melt systems, and gases that are compatible with the

D1599 Test Method for Resistance to Short-Time Hydraulic

composite pipe and fittings.

Pressure of Plastic Pipe, Tubing, and Fittings

NOTE 1— Piping covered by this specification is not recommended for

D1600 Terminology for Abbreviated Terms Relating to Plas-

use in indoor flammable gas applications. 3

tics (Withdrawn 2024)

3

1.2 This specification covers only composite pipes incorpo-

D1898 Practice for Sampling of Plastics (Withdrawn 1998)

rating a welded aluminum tube. Pipes consisting of metallic

D2122 Test Method for Determining Dimensions of Ther-

layers not welded together are outside the scope of this

moplastic Pipe and Fittings

specification.

D2765 Test Methods for Determination of Gel Content and

Swell Ratio of Crosslinked Ethylene Plastics

1.3 Specifications for connectors for use with pipe meeting

D3350 Specification for Polyethylene Plastics Pipe and Fit-

the requirements of this specification are given in Annex A1.

tings Materials

1.4 This specification excludes polyethylene-aluminum-

E8/E8M Test Methods for Tension Testing of Metallic Ma-

polyethylene pipes (see Specification F1282).

terials

1.5 The values stated in SI units are to be regarded as

F412 Terminology Relating to Plastic Piping Systems

standard. The values given in parentheses after SI units are F1282 Specification for Polyethylene/Aluminum/

provided for information only and are not considered standard.

Polyethylene (PE-AL-PE) Composite Pressure Pipe

F1974 Specification for Metal Insert Fittings for

1.6 The following precautionary caveat pertains only to the

Polyethylene/Aluminum/Polyethylene and Crosslinked

test methods portion, Section 9, of this specification: This

Polyethylene/Aluminum/Crosslinked Polyethylene Com-

standard does not purport to address all of the safety concerns,

posite Pressure Pipe

1 2

This specification is under the jurisdiction of ASTM Committee F17 on Plastic For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Piping Systems and is the direct responsibility of Subcommittee F17.11 on contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Composite. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved Feb. 1, 2024. Published February 2024. Originally the ASTM website.

3

approved in 1990. Last previous edition approved in 2023 as F1281 – 23a. DOI: The last approved version of this historical

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F1281 − 23a F1281 − 24 An American National Standard

Standard Specification for

Crosslinked Polyethylene/Aluminum/Crosslinked

1

Polyethylene (PEX-AL-PEX) Pressure Pipe

This standard is issued under the fixed designation F1281; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This specification covers a coextruded crosslinked polyethylene composite pressure pipe with a welded aluminum tube

reinforcement between the inner and outer layers. The inner and outer crosslinked polyethylene layers are bonded to the aluminum

tube by a melt adhesive. Included is a system of nomenclature for the crosslinked polyethylene-aluminum-crosslinked polyethylene

(PEX-AL-PEX) pipes, the requirements and test methods for materials, the dimensions of the component layers and finished pipe,

adhesion tests, and the burst and sustained pressure performance. Also given are the requirements and methods of marking. The

pipe covered by this specification is intended for use in potable water distribution systems for residential and commercial

applications, water service, building supply lines, underground irrigation systems, and radient panel heating systems, baseboard,

snow- and ice-melt systems, and gases that are compatible with the composite pipe and fittings.

NOTE 1— Piping covered by this specification is not recommended for use in indoor flammable gas applications.

1.2 This specification covers only composite pipes incorporating a welded aluminum tube. Pipes consisting of metallic layers not

welded together are outside the scope of this specification.

1.3 Specifications for connectors for use with pipe meeting the requirements of this specification are given in Annex A1.

1.4 This specification excludes polyethylene-aluminum-polyethylene pipes (see Specification F1282).

1.5 The values stated in SI units are to be regarded as standard. The values given in parentheses after SI units are provided for

information only and are not considered standard.

1.6 The following precautionary caveat pertains only to the test methods portion, Section 9, of this specification: This standard

does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this

standard to establish appropriate safety, health and environmental practices and determine the applicability of regulatory

limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

1

This specification is under the jurisdiction of ASTM Committee F17 on Plastic Piping Systems and is the direct responsibility of Subcommittee F17.11 on Composite.

Current edition approved July 1, 2023Feb. 1, 2024. Published July 2023February 2024. Originally approved in 1990. Last previous edition approved in 2023 as

F1281 – 23.F1281 – 23a. DOI: 10.1520/F1281-23A.10.1520/F1281-24.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F1281 − 24

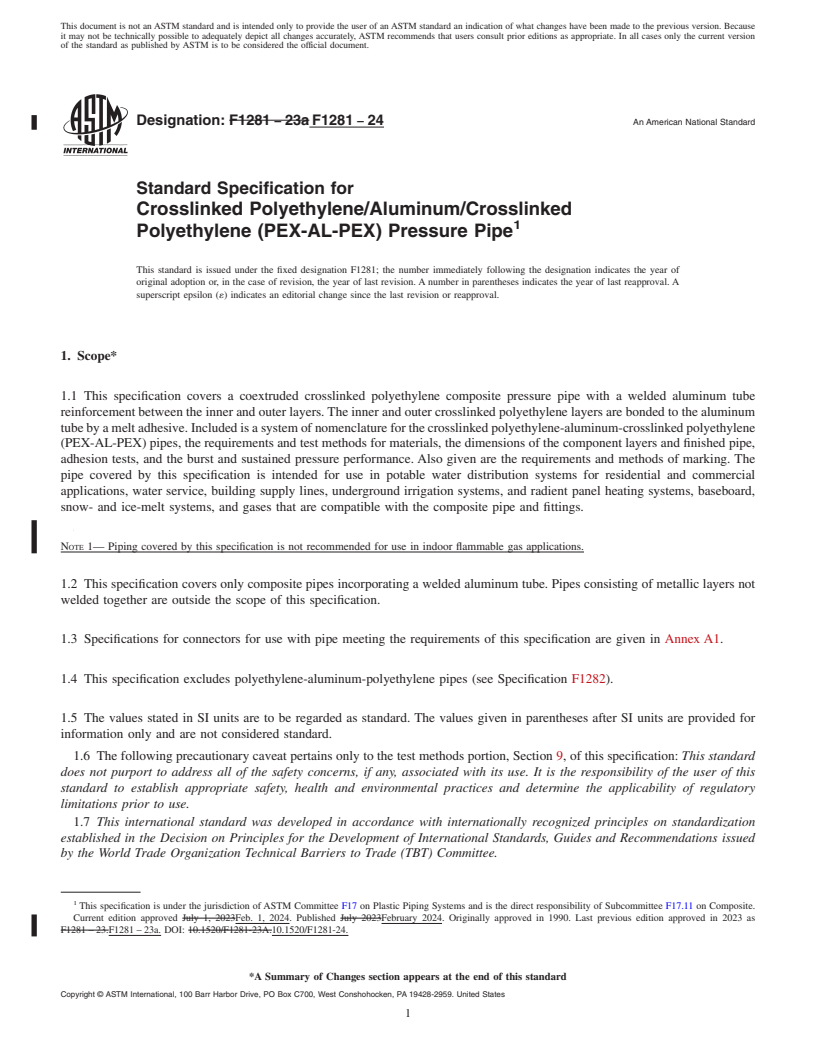

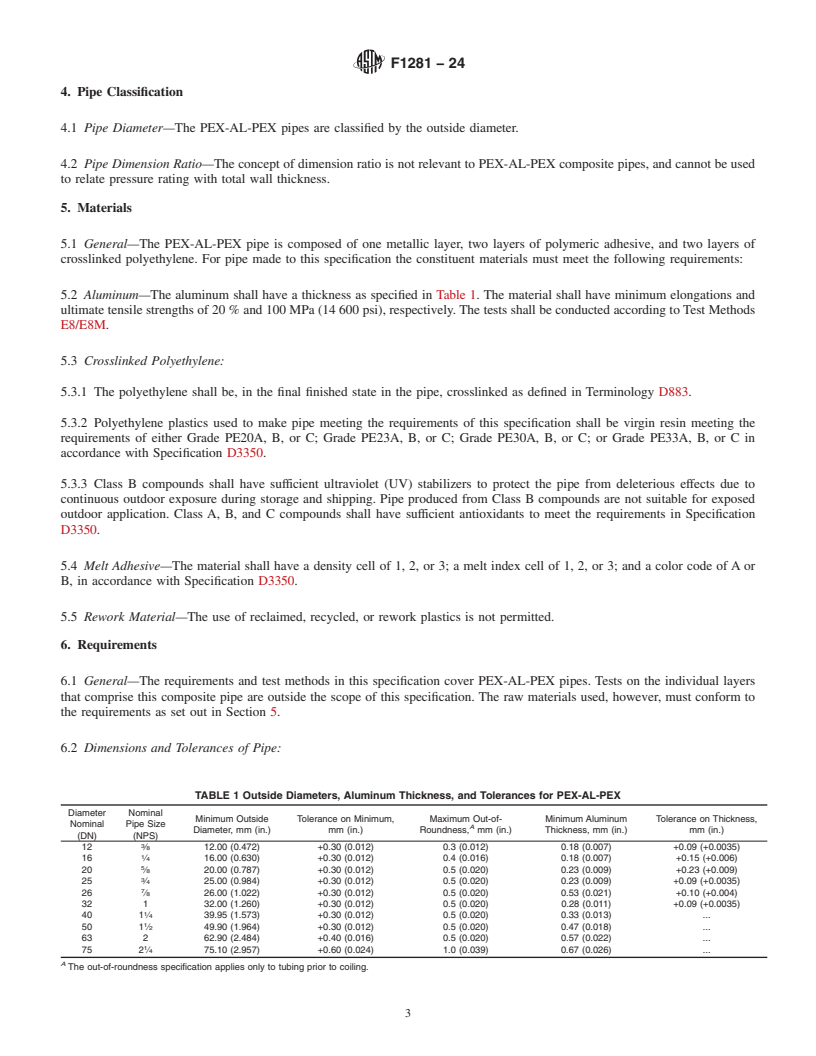

2. Referenced Documents

2

2.1 ASTM Standards:

D618 Practice for Conditioning Plastics for Testing

D883 Terminology Relating to Plastics

D1598 Test Method for Time-to-Failure of Plastic Pipe Under Constant Internal Pressure

D1599 Test Method for Resistance to Short-Time Hydraulic Pressure of Plastic Pipe, Tubing, and Fittings

3

D1600 Terminology for Abbreviated Terms Relating to Plastics (Withdrawn 2024)

3

D1898 Practice for Sampling of Plastics (Withdrawn 1998)

D2122 Test Method for Determining Dimensions of Thermoplastic Pipe and Fittings

D2765 Test Methods for Determination of Gel Content and Swell Ratio of Crosslinked Ethylene Plastics

D3350 Specification for Polyethylene Plastics Pipe and Fittings Materials

E8/E8M Test Methods for Tension Testing of Metallic Materials

F412 Terminology Relating to Plastic Piping Systems

F1282 Specification for Polyethylene/Aluminum/Polyethylene (PE-AL-PE) Composite Pressure Pipe

F1974 Specification for Metal Insert

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.