ASTM D3295-06(2011)

(Specification)Standard Specification for PTFE Tubing, Miniature Beading and Spiral Cut Tubing

Standard Specification for PTFE Tubing, Miniature Beading and Spiral Cut Tubing

ABSTRACT

This specification covers PTFE tubing, miniature beading and spiral cut tubing-manufactured from PTFE resin produced from dispersion. Five groups of PTFE tubing, miniature beading and spiral cut tubing, differentiated by size and type are presented. The groups are further subdivided into classes based on wall thickness: group 01 - tubing based upon the AWG sizes, group 02 - tubing based upon fractional inch sizes, group 03 - tubing based upon inner diameter and wall thickness, group 04 - tubing cut to form spiral wrap, and group 05 - miniature beading. The types are further differentiated in accordance with increasing wall thickness as follows: class 1 - light wall, class 2 - thin wall, class 3 - standard wall, class 4 - chemical tubing, and class 5 - heavy wall. The tubing and miniature beading shall be made of PTFE meeting the requirements prescribed. The melting point, specific gravity, weight loss, tensile strength, elongation, dielectric breakdown voltage, heat resistance, and dimensional stability shall be tested to meet the requirements specified.

SCOPE

1.1 This specification covers PTFE tubing, miniature beading and spiral cut tubing-manufactured from PTFE resin produced from dispersion specified in Specification D4895.

Note 1—PTFE tube and rod manufactured from resin specified in Specification D4894 are covered in Specification D1710.

1.2 The values stated in SI units are to be regarded as standard. The inch-pound units given in parentheses are for information only.

1.3 The following hazard caveat pertains only to the test method portion, Section 8, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.4 As PTFE resin produced from dispersion is not a true thermoplastic material, any reuse for the specification referenced above is impossible. However, markets do exist for non-virgin PTFE as additives and fillers.

Note 2—There is no known ISO equivalent to this standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D3295 −06(Reapproved 2011)

Standard Specification for

1

PTFE Tubing, Miniature Beading and Spiral Cut Tubing

This standard is issued under the fixed designation D3295; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope D1708 Test Method forTensile Properties of Plastics by Use

of Microtensile Specimens

1.1 This specification covers PTFE tubing, miniature bead-

D1710 Specification for Extruded Polytetrafluoroethylene

ing and spiral cut tubing-manufactured from PTFE resin

(PTFE) Rod, Heavy Walled Tubing and Basic Shapes

produced from dispersion specified in Specification D4895.

D3892 Practice for Packaging/Packing of Plastics

NOTE 1—PTFE tube and rod manufactured from resin specified in

D4894 Specification for Polytetrafluoroethylene (PTFE)

Specification D4894 are covered in Specification D1710.

Granular Molding and Ram Extrusion Materials

1.2 The values stated in SI units are to be regarded as

D4895 Specification for Polytetrafluoroethylene (PTFE)

standard. The inch-pound units given in parentheses are for

Resin Produced From Dispersion

information only.

3. Terminology

1.3 The following hazard caveat pertains only to the test

method portion, Section 8, of this specification: This standard

3.1 Definitions—The terminology given in Terminologies

does not purport to address all of the safety concerns, if any,

D883 and D1600 is applicable to this specification.

associated with its use. It is the responsibility of the user of this

3.2 Description of Term Specific to This Standard:

standard to establish appropriate safety and health practices

3.2.1 lot—asingleproductionrun,orauniformblendoftwo

and determine the applicability of regulatory limitations prior

or more production runs.

to use.

1.4 As PTFE resin produced from dispersion is not a true

4. Classification

thermoplastic material, any reuse for the specification refer-

enced above is impossible. However, markets do exist for

4.1 This specification provides for five groups of PTFE

non-virgin PTFE as additives and fillers.

tubing, miniature beading and spiral cut tubing, differentiated

NOTE 2—There is no known ISO equivalent to this standard.

bysizeandtype.Thegroupsarefurthersubdividedintoclasses

based on wall thickness.

2. Referenced Documents

4.1.1 Group 01—Tubing based upon the American Wire

2

2.1 ASTM Standards:

Gage (AWG) sizes.

D618 Practice for Conditioning Plastics for Testing

4.1.2 Group 02—Tubing based upon fractional inch sizes.

D638 Test Method for Tensile Properties of Plastics

4.1.3 Group 03—Tubing specified by inner diameter and

D792 Test Methods for Density and Specific Gravity (Rela-

wall thickness in Table 6 referred to as “Custom or Metric.”

tive Density) of Plastics by Displacement

4.1.4 Group 04—Tubing cut to form spiral wrap as in Table

D883 Terminology Relating to Plastics

7.

D1600 Terminology forAbbreviatedTerms Relating to Plas-

4.1.5 Group 05—Miniature beading having diameters as

tics

listed in Table 8.

D1675 Test Methods for Polytetrafluoroethylene Tubing

4.2 The types are further differentiated in accordance with

increasing wall thickness as follows:

1

4.2.1 Class 1—Tubing having walls tabulated in Table 1

This specification is under the jurisdiction of ASTM Committee D20 on

Plastics and is the direct responsibility of Subcommittee D20.15 on Thermoplastic

listed as light wall.

Materials (Section D20.15.12).

4.2.2 Class 2—Tubing having walls of greater thickness

Current edition approved Feb. 1, 2011. Published March 2011. Originally

than Class 1 listed as thin wall.

approved in 1974. Last previous edition approved in 2006 as D3295 - 06. DOI:

10.1520/D3295-06R11.

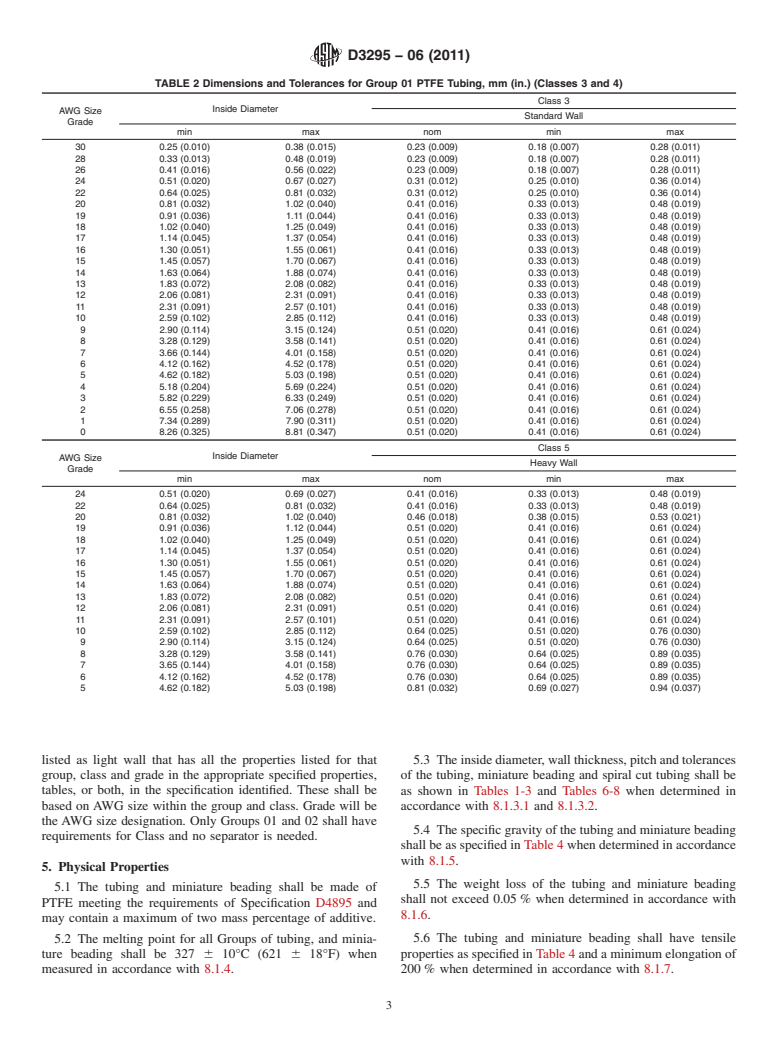

4.2.3 Class 3—Tubing having walls tabulated in Table 2

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

listed as standard wall.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

4.2.4 Class 4—Tubing having walls tabulated in Table 3

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. listed as chemical tubing.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D3295−06 (2011)

TABLE 1 Dimensions and Tolerances for Group 01 PTFE Tubing, mm (in.) (Classes 1 and 2)

Class 1

Inside Diameter

AWG Size

Light Wall

Grade

min max nom min max

30 0.25 (0.010) 0.38 (0.015) 0.15 (0.006) 0.10 (0.004) 0.20 (0.008)

28 0.33 (0.013) 0.46 (0.018) 0.15 (0.006) 0.10 (0.004) 0.20 (0.008)

26 0.41 (0.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.