ASTM D6511-00

(Test Method)Standard Test Methods for Solvent Bearing Bituminous Compounds

Standard Test Methods for Solvent Bearing Bituminous Compounds

SCOPE

1.1 These test methods cover procedures for sampling and testing solvent bearing bituminous compounds for use in roofing and waterproofing.

1.2 The test methods appear in the following order: SectionSamplingUniformityWeight per gallonNonvolatile contentSolubilityAsh contentWater contentConsistencyBehavior at 60C (140F)Pliability at -0C (32F)Aluminum contentReflectance of aluminum roof coatingsStrength of laps of rolled roofing adhered with roof adhesiveAdhesion to damp, wet, or underwater surfacesMineral stabilizers and bitumenMineral matterVolatile organic content

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 6511 – 00

Standard Test Methods for

Solvent Bearing Bituminous Compounds

This standard is issued under the fixed designation D 6511; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope D 5 Test Method for Penetration of Bituminous Materials

D 88 Test Method for Saybolt Viscosity

1.1 These test methods cover procedures for sampling and

D 95 Test Method for Water in Petroleum Products and

testing solvent bearing bituminous compounds for use in

Bituminous Materials by Distillation

roofing and waterproofing.

D 140 Practice for Sampling Bituminous Materials

1.2 The test methods appear in the following order:

D 146 Test Methods for Sampling and Test Bitumen-

Section

Saturated Felts and Fabrics Used in Roofing and Water-

Sampling 4

Uniformity 5

proofing

Weight per gallon 6

D 224 Specification for Smooth-Surfaced Asphalt Roll

Nonvolatile content 7

Roofing (Organic Felt)

Solubility 8

Ash content 9

D 249 SpecificationforAsphaltRollRoofing(OrganicFelt)

Water content 10

Surfaced with Mineral Granules

Consistency 11

Behavior at 60°C (140°F) 12 D 402 Test Method for Distillation of Cut-Back Asphalt

Pliability at –0°C (32°F) 13

(Bituminous) Products

Aluminum content 14

D 562 Test Method for Consistency of Paints Using the

Reflectance of aluminum roof coatings 15

Stormer Viscometer

Strength of laps of rolled roofing adhered with roof adhesive 16

Adhesion to damp, wet, or underwater surfaces 17

D 1079 Terminology Relating to Roofing, Waterproofing,

Mineral stabilizers and bitumen 18

and Bituminous Materials

Mineral matter 19

Volatile organic content 20 D 1475 Test Method for Density of Liquid Coatings, Inks,

and Related Products

1.3 The values stated in SI units are to be regarded as the

D 2042 Test Method for Solubility of Asphalt Materials to

standard. The values given in parentheses are for information

Trichloroethylene

only.

D 2369 Test Method for Volatile Content of Coatings

1.4 This standard does not purport to address all of the

D 2824 Specification for Aluminum-Pigmented Asphalt

safety concerns, if any, associated with its use. It is the

Roof Coatings Non-fibered,Asbestos-fibered, and Fibered

responsibility of the user of this standard to establish appro-

Without Asbestos

priate safety and health practices and determine the applica-

D 4017 Test Method forWater in Paints and Paint Materials

bility of regulatory limitations prior to use.

by Karl Fisher Method

E 1 Specification for ASTM Thermometers

2. Referenced Documents

E 145 Specification for Gravity-Convection and Forced

2.1 ASTM Standards:

Ventilation Ovens

C 670 Practice for Preparing Precision and Bias Statements

2 E 200 Practice for Preparation, Standardization, and Stor-

for Test Methods for Construction Materials

age of Standard and Reagent Solutions for Chemical

D 4 Test Method for Bitumen Content

Analysis

These test methods are under the jurisdiction of ASTM Committee D08 on

Roofing, Waterproofing and Bituminous Materials and are the direct responsibility Annual Book of ASTM Standards, Vol 04.03.

of Subcommittee D08.05 on Solvent-Bearing Bituminous Compounds for Roofing Annual Book of ASTM Standards, Vol 05.01.

and Waterproofing. Annual Book of ASTM Standards, Vol 06.01.

Current edition approved Jan. 10, 2000. Published March 2000. Annual Book of ASTM Standards, Vol 14.03.

2 8

Annual Book of ASTM Standards, Vol 04.02. Annual Book of ASTM Standards, Vol 14.04.

3 9

Annual Book of ASTM Standards, Vol 04.04. Annual Book of ASTM Standards, Vol 15.05.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D6511–00

3. Significance and Use

A = tare weight of weight-per-gallon cup, g,

B = weight of sample and tare g, and

3.1 These tests are useful in sampling and testing solvent

D = weight-per-gallonofsample,lb/gal.Toconvertunitsto

bearing bituminous compounds to establish uniformity of

kg/m , multiply D by 119.83.

shipments.

6.3.2 Calculatethespecificgravityofthesampleasfollows:

4. Sampling

SG 5 D/8.33 (2)

4.1 Determine the number of containers sampled to repre-

where:

sent a shipment in accordance with Practice D 140.

SG = specific gravity,

4.2 Open the original containers and examine them for

D = weight-per-gallon of sample calculation from 6.3.1,

uniformity of contents. Record the degree of separation, if any,

and

into portions of appreciably different consistency, such as thick

8.33 = weight-per-gallon of water at 25 6 0.5° C (77 6

or thin layers, sedimentation or coagulation, etc.Also, note any

1°F).

difficulty encountered in stirring to a uniform condition.

6.4 Report:

4.3 Take the samples for laboratory examination from the

6.4.1 Report the weight-per-gallon of the sample in pounds-

original containers immediately after stirring to a uniform

per-gallon to the nearest 0.1 lb at 25°C (77°F).

condition. Restir individual or combined samples immediately

6.4.2 Report the specific gravity of the sample to the nearest

before taking out portions for tests.

hundredth at 25°C (77°F).

5. Uniformity

7. Nonvolatile Content

5.1 Procedure—Examine the contents of a full container of

7.1 Apparatus:

not less than 1 L or 1 qt in volume that has stood undisturbed

7.1.1 Metal Dish, flat-bottom, having a diameter of 65 mm

for 72 h.

(2.5 in.) with walls 10 mm ( ⁄8 in.) high.

5.2 Report—Make a notation of any separation or settle-

7.1.2 Oven,forceddraft,conformingtoSpecificationE 145,

ment of suspended matter that cannot be overcome by moder-

Type III B, for asphalt products, or a standard convection oven

ate agitation.

for coal tar products.

6. Weight-per-Gallon/Specific Gravity

7.1.3 Balance, capable of weighing 50 g to within 60.01 g.

7.2 Procedure—Weigh 10 6 1.00 g in the tared metal dish

6.1 Apparatus:

to the nearest 0.01 g. Dry the dish and its contents in a forced

6.1.1 Weight-per-Gallon Cup, with lid, stainless steel, cali-

draft oven at 163 6 3°C (3256 5°F) for asphalt products or

brated to contain 83.3 g of water at 25 6 0.5°C (77 6 1°F).

(105 to 110°C (221 to 230°F) in standard convection oven for

6.1.2 Balance, accurate to 0.01 g.

coaltarproductsuntiltheresidueshowsalossofnotmorethan

6.1.3 Water Bath, constant temperature, maintained at 25 6

0.05 g on successive hourly weighings (approximately 4 h),

0.5°C (77 6 1°F).

after cooling in a desiccator.

6.2 Procedure:

7.3 Calculation—Calculate the percent nonvolatile content

6.2.1 Stir the sample, and place in the 25°C (77°F) water

R , from the mass of the dry residue and the mass of the

bath until the sample temperature reaches 25 6 0.5°C (776

I

original sample, as follows:

1°F). Time required for temperature equilibration depends on

sample size and configuration.

R 5 ~R/S! 3 100 (3)

I

6.2.2 Condition cup and lid to 25 6 0.5°C (77 6 1°F).

where:

Weigh the weight-per-gallon cup with lid to the nearest 0.01 g

R = mass of dry residue, g, and

and record as tare weight.

S = mass of sample, g.

6.2.3 Remove the sample from the bath, and stir until

7.4 Report—Record the average of two determinations.

homogeneous.Avoid trapping air in the sample during stirring.

6.2.4 Carefully fill the weight-per-gallon cup with the

8. Solubility of Residue in Carbon Disulfide or

sample avoiding the entrapment of air. Jar or vibrate the cup

Trichloroethylene

until no further change in volume occurs.

6.2.5 Immediately place the lid on the weight-per-gallon 8.1 Apparatus—See Test Method D 4.

cup and remove, with a clean rag or paper, the excess sample

8.2 Procedure—Determine the matter soluble in carbon

oozing through the orifice in the lid.

disulfide or trichloroethylene on a representative portion of the

6.2.6 When the lid is placed on tightly, clean the weight-

nonvolatiles (Section 7), in accordance with Test Method D 4.

per-gallon cup carefully, weigh on the balance to the nearest

8.3 Calculation—Calculate the percent solubility in carbon

0.01 g, and record as weight of sample and tare.

disulfide or trichloroethylene S from the mass of the residue

I

6.3 Calculations:

and the mass of the original sample as follows:

6.3.1 Calculate the weight-per-gallon of the sample as

S 5 ~R/S!3 100 (4)

I

follows:

where:

D 5 ~B – A!/10 (1)

R = mass of insoluble residue, g, and

where: S = mass of sample, g.

D6511–00

8.4 Report—Percent by weight of the residue that was 11.1.3.1 Place the stormer viscometer on a table or shelf

soluble in the carbon disulfide or trichloroethylene. high enough to permit the weight to drop about 1 m (40 in.), or

sufficient distance to produce about 125 revolutions of the

9. Ash Content

rotor. Insert the shaft of the propellar-type rotor in the chuck as

9.1 Apparatus: far as it will go and secure it with the set screw.

9.1.1 Porcelain Crucible, 30-cm capacity, or equivalent.

11.1.3.2 Raise the water bath-test cup assembly until the

9.1.2 Balance, capable of weighing 50 g to within 60.01 g.

bottom of the test cup just touches the bottom of the rotor

9.1.3 Muffle Furnace, capable of maintaining a temperature

blade; then, lower the assembly 6 mm ( ⁄4 in.). Tighten the set

of 593 6 2.5°C (1100 6 10°F).

screw on the position collar, if available, while the collar is in

9.2 Procedure—Thoroughly mix the dry residue from the

contact with the bracket and the assembly, and use this setting

determination of residue by evaporation (store the residue in a

to position the cup for all test runs. Using the set screws in the

desiccator at all times prior to this test) (Section 7) and weigh

rim of the bath holder, adjust the water bath-test cup assembly

3 6 0.5 go to the nearest 0.01 g in a previously ignited and

so that the cup and rotor are visually concentric.

taredcrucible.Incineratethecontentsinsideamufflefurnaceat

11.1.3.3 For convenience in weight adjustment, attach a

a temperature of 600°C (1110°F) to constant weight.

slotted metal can cover approximately 50 mm (2 in.) in

diameter to the hanger to support the slotted weights required.

NOTE 1—Caution: This incineration will produce black smoke. This

11.1.4 Calibration:

procedure should be carried out under a fume hood.

11.1.4.1 Use a 94.85 % by weight aqueous glycerin solution

9.3 Calculation—Calculate the ash thus obtained, A,as

r

as a calibration standard. Determine the initial concentration of

percent of the residue by evaporation as follows:

reagent grade glycerin by accurately measuring its specific

A 5 ~A/S! 3 100 (5)

r

gravity (see Appendix X1), and then add additional water to

9.4 Report—Ash as a percentage of the residue by evapo-

make up the desired total of 5.15 % by weight water.

ration.

11.1.4.2 Determine the weight on the viscometer cord

(approximately 100 g) required to produce 100 revolutions of

10. Water Content

the rotor in the glycerin calibration standard at 25 6 0.2°C in

10.1 Apparatus—See Test Method D 95.

18.0 6 0.2 s, this is the standardizing load. Check the

10.2 Procedure—Determine water content in accordance

calibration periodically, particularly after prolonged use of the

with Test Method D 95.

instrument, and recalibrate as necessary.

10.3 Calculation—Calculate the water in the sample, as

11.1.5 Procedure:

mass percent, as follows:

11.1.5.1 Remove the test cup and fill it with the sample to a

V ~0.99707!

level that will extend 6 mm ( ⁄4in.) above the top of the rotor

Water,% 5 (6)

W 3 100

blade.Agitate the sample in the cup thoroughly to remove any

trapped air bubbles. Place the test cup in the water bath, and

where:

then move the assembly up into test position against the preset

V = volume of water in trap (ml), and

collar.

W = mass of sample (gm).

11.1.5.2 Add 450 g to the standardizing load determined in

Volatile water-soluble material, if present, may be measured

11.1.4.2. This will be the test load or driving weight.

as water.

11.1.5.3 Adjust the temperature of the sample and the entire

10.4 Report—Report as mass percent of the sample.

test assembly to 25 6 0.2°C.To expedite reaching equilibrium,

11. Consistency raise the driving weight and release the brake to provide

agitation.When the water bath test cup, sample, and rotor have

11.1 Asphalt Roof Coatings:

all reached 25 6 0.2°C, remove the thermometer.

11.1.1 Summary of Test Method—Consistency is deter-

11.1.5.4 Raise the driving weight on the cord so that it

mined using the stormer viscometer and the rate of shear

nearly touches the pulley. With stop watch in hand, release the

reportedintermsofthetimerequiredfor100revolutionsofthe

brakeandobservethemovingpointer.After8to10revolutions

rotor produced by a specified load (compare with Test Method

have been made, time the next 100 revolutions. Take the

D 562).

average of at least three determinations and record as the

11.1.2 Apparatus:

Stormer consistency in s/100 revolutions. Record the driving

11.1.2.1 Standard Stormer Viscometer.

weight.

11.1.2.2 Water Bath-Test Cup Assembly, without central

11.1.5.5 Consistencies of up to approximately 100 s/100

baffle or thermometer holder.

revolutions shall be determined directly by timing 100 revolu-

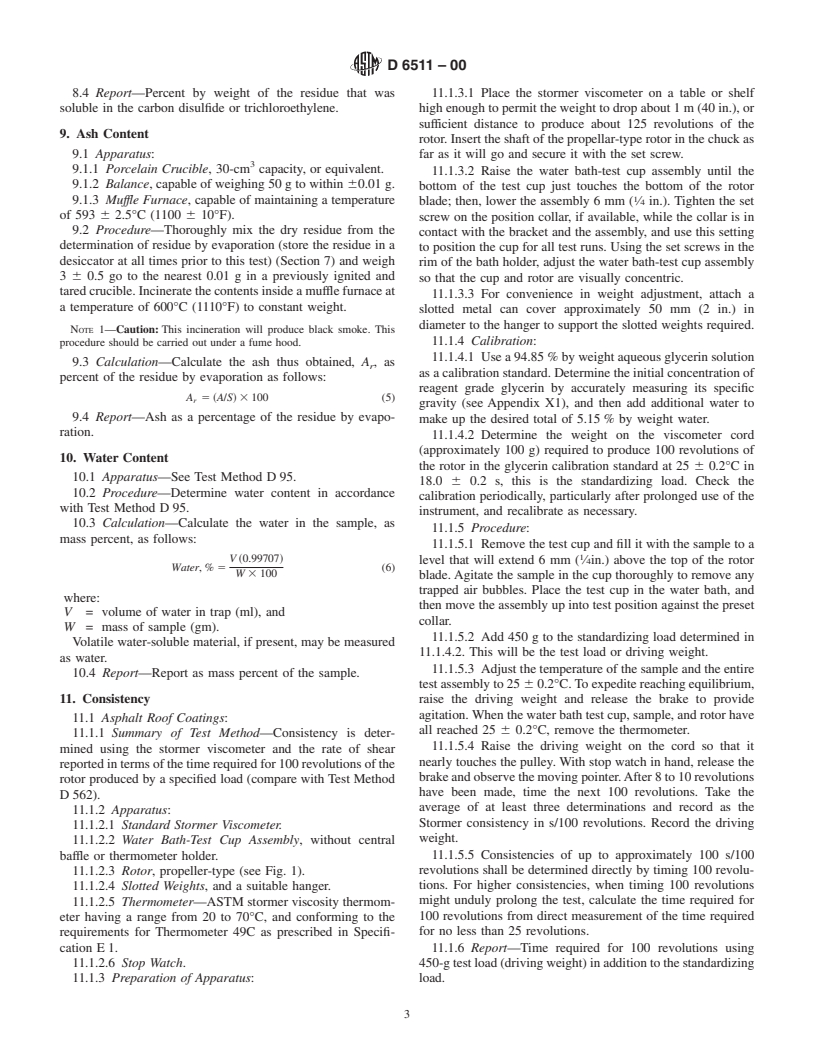

11.1.2.3 Rotor, propeller-type (see Fig. 1).

tions. For higher consistencies, when timing 100 revolutions

11.1.2.4 Slotted Weights, and a suitable hanger.

might unduly prolong the test, calculate the time required for

11.1.2.5 Thermometer—ASTM stormer viscosity thermom-

100 revolutions from direct measurement of the time required

eter having a range from 20 to 70°C, and conforming to the

for no less than 25 revolutions.

requirements for Thermometer 49C as prescribed in Specifi-

cation E 1. 11.1.6 Report—Time required for 100 revolutions using

11.1.2.6 Stop Watch. 450-gtestload(drivingweight)inadditiontothestandardizing

11.1.3 Preparation of Apparatus: load.

D6511–00

NOTE 1—All dimensions are subject to a tolerance of 60.1 mm (60.004 in.). Material: nickel-plated brass or stainless steel.

FIG. 1 Propeller-Type Rotor for Use with Stormer Viscometer

11.2 Aluminum-Pigmented Asphalt Roof Coatings: 11.2.3 Report—Time required for 100 revolutions using

300-gtestload(drivingweight)inadditiontothestandardizing

11.2.1 Apparatus—Use the apparatus and equipment speci-

load.

fied in Test Method D 562, Procedure A.

11.3 Viscosity of Asphalt Primer:

11.2.2 Procedure:

11.3.1 Saybolt Furol Viscosity—Test Method D 88.

11.2.2.1 Testing D 2824 Type I Coating—Thoroughly mix

the sample and fill a 500-ml (1-pt) container to within 20 mm

3 12. Behavior at 60°C (140°F)

( ⁄4 in.) of the top. Stir the coating carefully to remove any

trapped air bubbles. Maintain the temper

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.