ASTM A933/A933M-95(2001)

(Specification)Standard Specification for Vinyl (PVC) Coated Steel Wire and Welded Wire Fabric for Reinforcement

Standard Specification for Vinyl (PVC) Coated Steel Wire and Welded Wire Fabric for Reinforcement

SCOPE

1.1 This specification covers plain and deformed steel wire and plain and deformed steel welded wire fabric with protective vinyl (PVC, polyvinyl chloride, or polyvinyl chloride powder compound) coating. Class A is intended for use as reinforcement in concrete and Class B as reinforcement in earth.

1.2 Other thermoplastic organic coatings may be used provided they meet the requirements of this specification.

Note 1--The coating applicator is identified throughout this specification as the manufacturer.

1.3 Requirements for coatings are contained in Annex A1.

1.4 This specification is applicable for orders in either inch-pound units (as Specification A933) or in SI units [as Specification A933M].

1.5 The values stated in either inch-pound or SI units are to be regarded as standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other. Combining values from the two systems may result in nonconformance with this specification.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A 933/A933M – 95 (Reapproved 2001)

Standard Specification for

Vinyl (PVC) Coated Steel Wire and Welded Wire Fabric for

Reinforcement

This standard is issued under the fixed designationA933/A933M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope D4060 Test Method for Abrasion Resistance of Organic

Coatings by the Taber Abraser

1.1 This specification covers plain and deformed steel wire

G8 Test Method for Cathodic Disbonding of Pipeline

and plain and deformed steel welded wire fabric with protec-

Coatings

tive vinyl (PVC, polyvinyl chloride, or polyvinyl chloride

G12 TestMethodforNondestructiveMeasurementofFilm

powder compound) coating. Class A is intended for use as

Thickness of Pipeline Coatings on Steel

reinforcement in concrete and Class B as reinforcement in

G14 Test Method for Impact Resistance of Pipeline Coat-

earth.

ings (Falling Weight Test)

1.2 Other thermoplastic organic coatings may be used

G20 Test Method for Chemical Resistance of Pipeline

provided they meet the requirements of this specification.

Coatings

NOTE 1—The coating applicator is identified throughout this specifica-

2.2 National Association of Corrosion Engineers Stan-

tion as the manufacturer.

dards:

1.3 Requirements for coatings are contained in Annex A1.

RP-287-87 Field Measurement of Surface Profile of Abra-

1.4 This specification is applicable for orders in either

sive Blast Cleaned Steel Surface Using a Replica Tape

inch-pound units (as Specification A933) or in SI units [as

TM-01-70 Visual Standard for Surfaces of New Steel Air

Specification A933M].

Blast Cleaned with Sand Abrasive (NACE No. 2)

1.5 The values stated in either inch-pound or SI units are to

TM-01-75 Visual Standard for Surfaces of New Steel Cen-

beregardedasstandard.Withinthetext,theSIunitsareshown

trifugally Blast Cleaned with Steel Shot or Steel Grit

in brackets. The values stated in each system are not exact

(NACE No. 2)

equivalents; therefore, each system must be used indepen-

2.3 Steel Structures Painting Council Specifications:

dently of the other. Combining values from the two systems

SSPC-SP10-85 Near-White Blast Cleaning

may result in nonconformance with this specification.

SSPC-Vis1-67T PictorialSurfacePreparationStandardsfor

Painting Steel Surfaces

2. Referenced Documents

SSPC-Vis2-82T StandardMethodsofEvaluatingDegreeof

2.1 ASTM Standards:

Rusting on Painted Steel Surfaces

A82 Specification for Steel Wire, Plain, for Concrete Re-

3. Ordering Information

inforcement

A185 SpecificationforSteelWeldedWireFabric,Plain,for

3.1 The purchaser should specify:

Concrete Reinforcement

3.1.1 Wire or welded wire fabric specification,

A496 Specification for SteelWire, Deformed, for Concrete

3.1.2 Wire size,

Reinforcement

3.1.3 Wire spacing and sizes, if welded wire fabric,

A497 Specification for Welded Deformed Steel Wire Fab-

3.1.4 Length and width of sheets or rolls,

ric, for Concrete Reinforcement

3.1.5 Quantity, and

D 2240 Test Method for Rubber Property—Durometer

3.1.6 Class of coating.

Hardness

1 4

This specification is under the jurisdiction ofASTM CommitteeA-1 on Steel, Annual Book of ASTM Standards, Vol 06.01.

Stainless Steel, and Related Alloys and is under the direct responsibility of Annual Book of ASTM Standards, Vol 06.02.

Subcommittee A01.05 on Steel Reinforcement. Available from the National Association of Corrosion Engineers, 1440 South

Current edition approved March 15, 1995. Published May 1995. Creek, Houston, TX 77084.

2 7

Annual Book of ASTM Standards, Vol 01.04. Available from Steel Structures Painting Council, 4400 Fifth Ave., Pittsburgh,

Annual Book of ASTM Standards, Vol 09.01. PA 15213.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

A 933/A933M – 95 (2001)

NOTE 5—A suitable anchor pattern requires the use of grit in the

3.2 The purchaser may specify, if desired:

cleaning media.

3.2.1 Requirements for material samples (4.3),

3.2.2 Requirements for patching material (4.4),

6. Application of Coating

3.2.3 Requirementsforvisualstandardsforsurfacecleaning

comparison (5.1),

6.1 The coating shall be applied to the cleaned surface as

3.2.4 Specific requirements for test frequency (8.1), and

soon as possible after cleaning, and before oxidation of the

3.2.5 Requirements for inspection of manufacturing plant

surface discernible to the unaided eye occurs. However, in no

(11.1).

case shall application of the coating be delayed more than 4 h

after cleaning.

NOTE 2—Atypicalorderingdescriptionisasfollows:150sheets,fabric

style 6 by 12 − D7 by D4 [150 by 300 − MD45 by MD25] vinylcoated

6.2 To achieve a chemical bond of the vinyl coating to

steel welded wire fabric, deformed, with Class A coating for use as

metal,thesteelwireorweldedwirefabricmustbeprimedwith

concrete reinforcement and produced in accordance withA933/A933M.

appropriateprimerasrecommendedbythemanufacturerofthe

primer and vinyl powder compound.

4. Materials

6.3 The coating shall be applied and fully fused in accor-

4.1 Plain or deformed steel wire or welded wire fabric to be

dance with the written recommendations of the manufacturer

coated shall meet the requirements of one of the applicable

of the coating material.

specifications: A82, A185, A496, or A497, as specified by

thepurchaser,andshallbefreeofsurfacecontaminantssuchas

7. Requirements for Coated Wire or Welded Wire Fabric

oil, grease, or paint when received at the manufacturer’s plant

and prior to cleaning and coating.

7.1 Thickness of Coating:

4.2 The coating material shall meet the requirements listed

7.1.1 Class A—The film thickness of the coating after

inAnnexA1. In addition to the requirements ofAnnexA1, the

fusing shall be 7 to 17 mils [175 to 425 µm] for both plain and

coating material shall have demonstrated long-term stability

deformed steel wire and welded wire fabric used for concrete

when embedded in concrete.

reinforcement. Thickness measurements below 5 mils [125

4.2.1 A written certification shall be furnished to the pur-

µm] shall be considered cause for rejection. The upper film

chaser that properly identifies the number of each batch of

thickness limits do not apply to repaired areas of damaged

coating material used in the order, material quantity repre-

coating.

sented, date of manufacture, name and address of manufac-

7.1.2 Class B—The film thickness of the coating after

turer, and a statement that the supplied coating material meets

fusing shall be a minimum of 18 mils [450 µm], for both plain

the requirements of Annex A1.

and deformed steel wire and welded wire fabric used for earth

4.3 If specified in the order, a representative 8-oz [0.20-kg]

reinforcement, such as mechanically stabilized embankments.

sample of the coating material shall be supplied to the

Thickness measurements below 16 mils [400 µm] shall be

purchaserfromeachbatch.Thesampleshallbepackagedinan

considered cause for rejection.

airtight container and identified by batch number.

4.4 If specified in the order, patching material, compatible 7.1.3 Measurements shall be made in accordance with Test

withthecoatingandinertinconcrete,andrecommendedbythe Method G12 following the instructions for calibration and use

coating manufacturer, shall be supplied to the purchaser. recommendedbythethicknessgagemanufacturer.Pull-offand

fixed probe gages may be utilized. Pencil-type pull-off gages

NOTE 3—When subjected to temperatures above 392°F [200°C] for a

that require the operator to observe the reading at the instant

prolonged period of time, PVC is subject to decomposition. One of the

the magnet is pulled from the surface are not to be used.

products of decomposition is hydrochloric acid, HCl, which can damage

concreteandreinforcingsteel.Eveninsmallamounts,HClwillaccelerate

7.1.4 Asingle recorded coated wire and welded wire fabric

corrosion of steel.

thickness measurement is the average of three individual

NOTE 4—PVC coated wire has very low bond strength to concrete, and

readings obtained between consecutive deformations on the

the use of deformed wire provides no advantage over smooth wire. The

body of the wire. A minimum of five recorded measurements

bond strength of PVC coated welded wire fabric is similar to that of

shall be obtained approximately evenly spaced along each side

uncoated plain welded wire fabric since the cross wires provide the

ofthetestspecimen(aminimumoftenrecordedmeasurements

primary bond.

per specimen).

5. Surface Preparation

7.1.5 For acceptance purposes, at least 90% of all recorded

5.1 The surface of the steel wire or welded wire fabric to be

film thickness measurements shall be within the specified

coatedshallbecleanedbyabrasiveblastcleaningtonear-white

limits.

metal in accordance with SSPC-SP10. Additional surface

7.2 Continuity of Coating:

treatment may be used as indicated in A1.3.3.4. Any of the

7.2.1 After fusing, the coating shall be free of holidays

following visual standards of comparison may be used to

(pinholes not discernible to the unaided eye), holes, voids,

define the final surface condition: SSPC-Vis 1, SSPC-Vis 2,

cracks, and damaged areas.

NACETM-01-70,andNACETM-01-75.Averageblastprofile

7.2.1.1 If any of these deficiencies occur during the coating

maximum roughness depth readings of 1.5 to 4.0 mils [0.04 to

0.10 mm] as determined by replica tape measurements using application process, they shall be patched in accordance with

the patching material manufacturer’s written recommenda-

NACE RP-287-87, shall be considered suitable as an anchor

pattern. tions.

A 933/A933M – 95 (2001)

7.2.2 Holiday checks to determine acceptability of the wire bridge. The bundled reinforcement shall be transported with

orweldedwirefabricshallbemadeatthemanufacturer’splant care and stored off the ground on protective cribbing. The

with a 67 ⁄2 -V, 80000 V, wet-sponge-type d-c holiday coated reinforcement shall not be dropped or dragged.

detector. 10.2 The identification of all reinforcing steel shall be

maintained throughout the coating and fabrication process to

NOTE 6—Holiday detection is not intended for use at the job site.

the point of shipment.

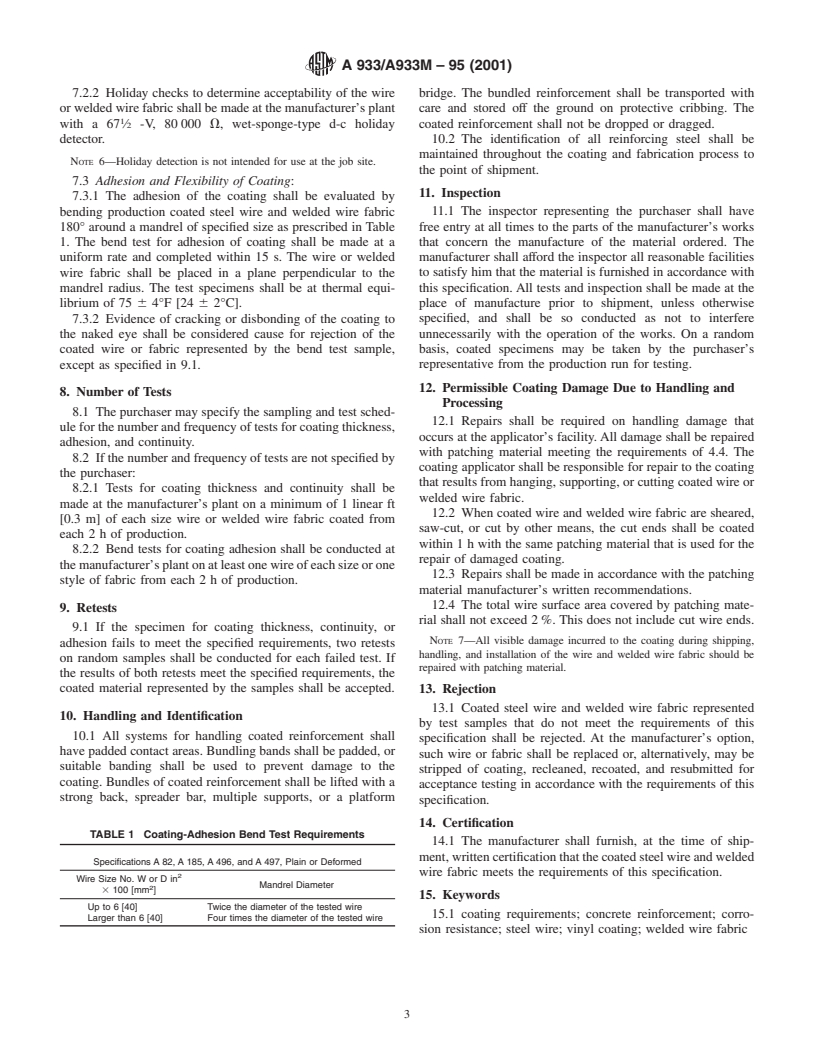

7.3 Adhesion and Flexibility of Coating:

11. Inspection

7.3.1 The adhesion of the coating shall be evaluated by

bending production coated steel wire and welded wire fabric 11.1 The inspector representing the purchaser shall have

free entry at all times to the parts of the manufacturer’s works

180° around a mandrel of specified size as prescribed in Table

1. The bend test for adhesion of coating shall be made at a that concern the manufacture of the material ordered. The

manufacturer shall afford the inspector all reasonable facilities

uniform rate and completed within 15 s. The wire or welded

wire fabric shall be placed in a plane perpendicular to the to satisfy him that the material is furnished in accordance with

this specification.All tests and inspection shall be made at the

mandrel radius. The test specimens shall be at thermal equi-

librium of 75 6 4°F [24 6 2°C]. place of manufacture prior to shipment, unless otherwise

7.3.2 Evidence of cracking or disbonding of the coating to specified, and shall be so conducted as not to interfere

the naked eye shall be considered cause for rejection of the unnecessarily with the operation of the works. On a random

coated wire or fabric represented by the bend test sample, basis, coated specimens may be taken by the purchaser’s

except as specified in 9.1. representative from the production run for testing.

12. Permissible Coating Damage Due to Handling and

8. Number of Tests

Processing

8.1 The purchaser may specify the sampling and test sched-

12.1 Repairs shall be required on handling damage that

uleforthenumberandfrequencyoftestsforcoatingthickness,

occurs at the applicator’s facility.All damage shall be repaired

adhesion, and continuity.

with patching material meeting the requirements of 4.4. The

8.2 Ifthenumberandfrequencyoftestsarenotspecifiedby

coating applicator shall be responsible for repair to the coating

the purchaser:

that results from hanging, supporting, or cutting coated wire or

8.2.1 Tests for coating thickness and continuity shall be

welded wire fabric.

made at the manufacturer’s plant on a minimum of 1 linear ft

12.2 When coated wire and welded wire fabric are sheared,

[0.3 m] of each size wire or welded wire fabric coated from

saw-cut, or cut by other means, the cut ends shall be coated

each2hof production.

within 1 h with the same patching material that is used for the

8.2.2 Bend tests for coating adhesion shall be conducted at

repair of damaged coating.

themanufacturer’splantonatleastonewireofeachsizeorone

12.3 Repairs shall be made in accordance with the patching

style of fabric from each2hof production.

material manufacturer’s written recommendations.

12.4 The total wire surface area covered by patching mate-

9. Retests

rial shall not exceed 2%. This does not include cut wire ends.

9.1 If the specimen for coating thickness, continuity, or

NOTE 7—All visible damage incurred to the coating during shipping,

adhesion fails to meet the specified requirements, two retests

handling, and installation of the wire and welded wire fabric should be

on random samples shall be conducted for each failed test. If

repaired with patching material.

the results of both retests meet the specified requirements, the

coated material represented by the samples shall be accepted.

13. Rejection

13.1 Coated steel wire and welded wire fabric represented

10. Handling and Identification

by test samples that do not meet the requirements of this

10.1 All systems for handling coated reinforcement shall

specification shall be rejected. At the manufacturer’s option,

have padded contact areas. Bundling bands shall be padded, or

such wire or fabric shall be replaced or, alternatively, may be

suitable banding shall be used to prevent damage to the

stripped of coating, recleaned, recoated, and resubmitted for

coating. Bundles of coated reinforcement shall be lifted with a

acceptance testing in accordance with the requirements of this

strong back, spreader bar, multiple supports, or a platform

specification.

14. Certification

TABLE 1 Coating-Adhesion Bend Test Requirements

14.1 The manufacturer shall furnish, at the time of ship-

ment,writtencertificationthatthecoatedsteelwireandwelded

Specifications A 82, A 185, A 496, and A 497, Plain or Deformed

wire fabric meets the requirements of this specification.

Wire Size No. W or D in

Mandrel Diameter

3 100 [mm ]

15. Keywords

U

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.